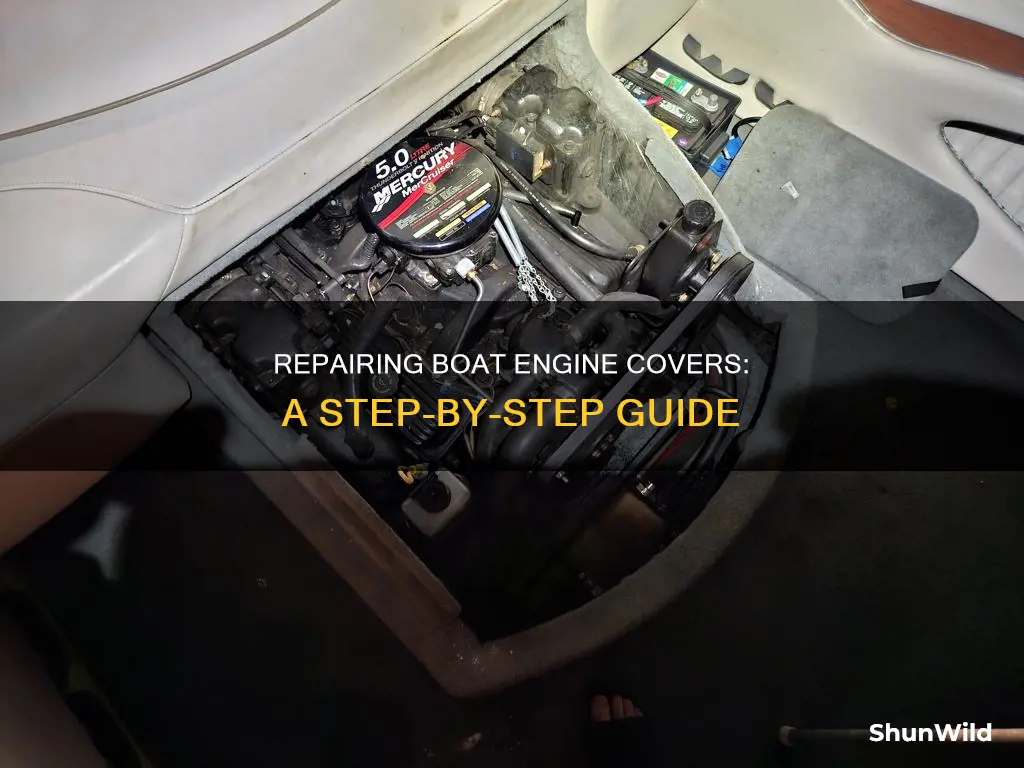

Repairing a boat engine cover can be a simple task, depending on the type of cover and the extent of the damage. For example, if your engine cover is made of plastic and has a broken tab, you can glue it back together with G/flex or G/5. If your engine cover is made of fiberglass and has cracks, you can repair it by cleaning the area, grinding down around the crack, using epoxy resin, and sanding the area once it's cured. You can also use a repair kit with vinyl or leather repair tape to fix tears or holes in your boat engine cover. These kits are available for purchase online and can provide a quick and easy solution. Additionally, if your engine cover is fabric, you can patch it with marine fabric or use a sewing machine to sew on a patch.

| Characteristics | Values |

|---|---|

| Materials | Epoxy resin, vinylester, polyester resin, fiberglass, G/flex, G/5, glue, fabric, vinyl, leather, canvas, snaps, tape, adhesive, epoxy |

| Tools | Sewing machine, pliers, snap pliers, snap fastener tool, snap fastener pliers, sewing awl, needles |

| Techniques | Grinding, taping, sewing, gluing, flame treating, waterproofing |

What You'll Learn

Identify the type of cover material

When identifying the type of cover material for your boat engine, it's important to consider factors such as breathability, water repellency, UV resistance, and mildew resistance. The ideal cover fabric should keep rainwater out while allowing trapped water vapour to escape. Additionally, it should be able to withstand temperature and humidity changes, protecting your boat engine from damage caused by expansion and contraction.

There are various materials available for boat engine covers, each offering unique advantages. One popular option is Marinex WindStorm boat cover fabric, a high-quality 600 denier polyester fabric. This fabric is designed for extreme outdoor environments and is solution-dyed, which prevents colour bleeding and fading. It also undergoes a coating process that enhances UV protection, water repellency, and mildew resistance. With its breathability, Marinex fabric ensures that heat and moisture don't get trapped beneath the cover.

Another option is the Carver Universal Fit Flex-Fit™ PRO Boat Covers, made from Poly-Flex II, a 5.3-ounce material with a 3/4-ounce urethane coating. These covers offer a durable, water-repellent, and mildew-resistant finish, making them suitable for mooring, trailering, or storage.

For those seeking a more economical option, Hot Shot™ fabric is a good choice. It is an acrylic-coated polyester that offers breathability, strength, and resistance to water, mildew, and UV radiation. This fabric is ideal for hot or humid climates and is commonly used in semi-custom covers.

When selecting a cover material, it's essential to consider the specific needs of your boat engine and the environment in which it will be used. By choosing a cover with the right combination of breathability, water repellency, and resistance to UV and mildew, you can effectively protect your boat engine and ensure its longevity.

Measuring Engine Height: Perfecting Boat Engine Installation

You may want to see also

Assess the damage

Before you start repairing your boat engine cover, it's important to assess the damage to understand the extent of the problem and what you'll need to fix it. Here's a step-by-step guide to help you through the process:

Inspect the Cover for Damage

Start by carefully examining the engine cover for any signs of damage. Look for cracks, chips, nicks, scratches, or other imperfections. Pay close attention to the areas around these defects to determine if the damage is superficial or if it goes deeper into the material. Take note of the size, location, and severity of each issue you find.

Determine the Type of Cover

Identifying the type of engine cover you have is crucial for assessing the damage and choosing the appropriate repair method. Engine covers can be made from different materials, such as fiberglass, plastic, or fabric. Each material has its own unique characteristics and repair requirements. For example, a fiberglass cover may require grinding and the use of epoxy resin, while a fabric cover can often be patched or repaired with marine fabric.

Consider Structural Integrity

Evaluate whether the damage has compromised the structural integrity of the engine cover. Look for signs of warping, deformation, or deep cracks that could weaken the cover. If the damage is extensive and affects the overall structure, it may be more cost-effective to replace the cover entirely rather than attempting repairs.

Check for Water Damage

Water damage can be a serious issue, especially if it has penetrated the engine cover. Look for signs of water intrusion, such as discolouration, soft spots, or corrosion. Water can cause electrical issues, promote the growth of mould or mildew, and weaken the cover's structure over time. If you suspect water damage, it's important to address it promptly to prevent further complications.

Assess Repair Complexity

Based on your observations, assess the complexity of the required repairs. Minor cracks or chips may only need to be filled and sanded, while larger defects might require more extensive work. Consider whether you have the necessary skills, tools, and materials to perform the repairs effectively. If the damage is extensive or you're unsure about the repair process, it may be best to consult a professional or seek advice from experienced boat owners or mechanics.

Remember, safety should always come first. If the engine cover is severely damaged or structurally compromised, it's important to address the issue promptly to ensure the safe operation of your boat.

Intentionally Sinking Your Boat for Insurance Claims: A Step-by-Step Guide

You may want to see also

Gather materials and tools

To repair a boat engine cover, you will need to gather the necessary materials and tools. The specific items you will need will depend on the type of cover you have and the extent of the damage. Here is a detailed list of materials and tools you may need to repair your boat engine cover:

Materials:

- Replacement fabric: Look for fabric that matches the colour and type of your existing cover. Common boat cover fabrics include Sunbrella or similar marine-grade fabrics.

- Fabric patches: Self-adhesive fabric patches or repair tape can be used to cover small tears or holes. Look for patches or tape that are waterproof and UV-resistant.

- Adhesives: If your cover is made of plastic, you may need an adhesive such as epoxy resin or G/flex to glue broken pieces back together. For fabric covers, you can use fabric glue or double-sided tape.

- Thread: If you are sewing patches onto your cover, you will need strong marine thread. Polyester 92 is a common option for home sewing machines, but the stronger the better.

- Snaps and fasteners: If your cover uses snaps or fasteners, you may need to replace them. Look for marine-grade stainless steel snaps and fasteners.

Tools:

- Sewing machine: A sewing machine will be needed if you are sewing patches onto your cover.

- Fabric scissors: For cutting fabric patches to the correct size.

- Measuring tape: To measure the size of the patch you need and to ensure it is cut to the correct size.

- Pliers: In some cases, you may need pliers to remove broken pieces or to twist and break test blocks if you are gluing plastic pieces.

- Sandpaper: If you are gluing plastic pieces, you may need to sand the area before applying the adhesive.

- Flame treating tool: Flame treating the area can also help prepare the surface for gluing, especially if the plastic is difficult to sand.

Finding the Best Boat Upholstery Repair in Portland

You may want to see also

Prepare the cover surface

To repair your boat engine cover, you'll first need to prepare the cover surface. This process will depend on the material of your cover and the type of damage it has sustained.

If your engine cover is made of fiberglass and has cracks or nicks, you'll need to clean the repair area and grind down around the cracks, extending out at least an inch and tapering deeper over the crack. This will allow for the 'glass mat'l to be applied. You can use epoxy resin or vinylester for this repair.

If your engine cover is made of plastic and has broken tabs or other damage, you may be able to glue it back together with a product like G/flex or G/5. It's important to determine the type of plastic your engine cover is made of to choose the right adhesive and surface preparation. You can perform a simple test by gluing blocks of plywood to different areas prepared with different adhesives and surface preparations. This will help you determine which combination provides the strongest bond.

If your engine cover is made of fabric and has a small tear, you can use a fabric patching product, such as sail tape, Tear-Aid, or marine fabric, to repair the damage. Cut a patch that is slightly larger than the torn area, hem the edges with double-sided tape or fabric glue, and then stick it over the damaged area. You can also use a sewing machine to secure the patch.

If your engine cover has holes, it's important to inspect your entire cover to identify any other areas that may need repair. Chafing may be the cause of the holes, so you'll need to reinforce your repair and cover any sharp corners or edges with a cap, abrasion tape, or another buffer to prevent further damage. You can use a fabric patching product or a canvas snap kit to repair the holes and secure any loose fabric.

Foam Options for Boat Flotation Tanks: Choose Wisely

You may want to see also

Apply adhesive or patching techniques

When repairing a boat engine cover, there are several adhesive and patching techniques you can use. The specific method you choose will depend on the type of cover you have and the extent of the damage. Here is a step-by-step guide to help you through the process:

Prepare the Work Area and Materials:

Before beginning the repair, ensure you have a clean, flat work area and gather all the necessary tools and materials. These may include items such as:

- Commercial-grade spray adhesive (e.g., 3M Hi-Strength Spray Adhesive)

- Ripstop nylon patch or matching tarp material

- Painter's tape

- Tape measure

- Marker

- Scissors

- Cardboard

- Newspaper or paper

- Utility knife

- Gloves and safety equipment

Assess the Damage:

Inspect the engine cover to determine the extent of the damage. Look for cracks, holes, or tears that need to be repaired. Clean the area around the damage and ensure it is free of any debris or residue. If there is any loose material or fragments, remove them carefully.

Measure and Cut the Patch:

Using the tape measure, measure the size of the damage. For holes, add one to two inches to the measurements to ensure adequate coverage. Cut two patches from your chosen material to match these adjusted measurements. It is recommended to use a material that matches your tarp, such as ripstop nylon or marine fabric.

Create a Template:

Create a paper template by tracing the outline of your patch onto a piece of newspaper or regular printer paper. This template will help you position the patch accurately. Place the patch on top of the paper and use a marker to trace around its outside edge. Cut out the centre of the template by placing it on a piece of cardboard and using a utility knife to cut along the outline.

Secure the Template and Apply Adhesive:

Use painter's tape to secure the template to the area of the engine cover that needs repair. Overlap the tape just enough for it to stick. Place cardboard underneath the area to protect the surrounding surface from adhesive. Shake the can of adhesive for about a minute to mix it thoroughly. Spray the adhesive onto the area around the hole in short bursts, slightly overlapping each time. Change the direction of spraying and repeat the application process to ensure full coverage.

Apply the Patch:

Wait for 5-10 minutes until the adhesive becomes tacky. Remove the template and place one of the patches directly onto the engine cover, matching it up with the adhesive around the hole. Apply pressure over the entire patch to ensure a secure bond. Flip the cover over and repeat the process on the backside of the hole, using the second patch. This creates a "sandwich" effect, reinforcing the repair and preventing future tears.

Finishing Touches:

Once both patches are in place and secure, your boat engine cover is ready to be used again. However, you may want to consider applying a coat of paint or varnish to blend the repair with the surrounding area, especially if you have used a different coloured patch.

Remember to follow all safety instructions when working with adhesives and other materials, and always work in a well-ventilated area. With these steps, you can effectively repair your boat engine cover and extend its lifespan.

Sailing Basics: A Comprehensive Guide to Boating

You may want to see also

Frequently asked questions

Clean the repair area, grind down around the crack and use epoxy resin to repair it. Sand the area once cured, then prime and paint.

First, inspect your cover for more holes or tears. If you only have one, use sail tape, Tear-Aid or a similar fabric patching product to cover the hole. Then, follow the steps outlined in the answer to the next question to create a more permanent fix.

Measure the size of the patch you need by adding 2 inches to all sides of the torn area. Cut two patches to size, hem them, and add double-sided tape or fabric glue around the hem. Stick the patches to the inside and outside of the cover, then sew the corners.

Yes, there are several boat cover repair kits available on Amazon. These typically include canvas repair patches, fabric repair tape, and/or snap fastener tools.