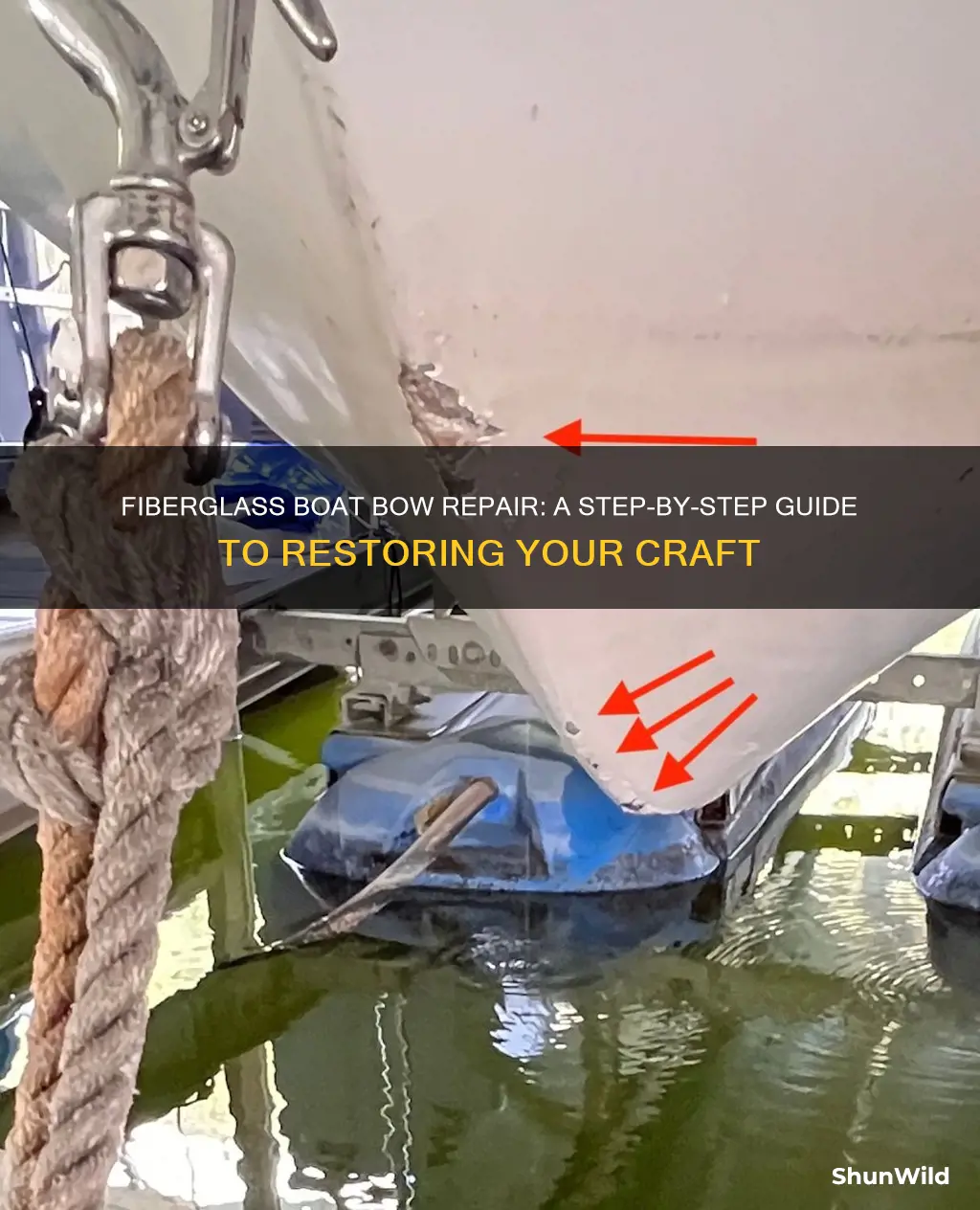

Repairing the bow of a fiberglass boat can be a challenging but rewarding task. The process involves identifying the specific damage, whether it's a small crack, a large hole, or a delamination, and then choosing the appropriate repair method. Common techniques include filling the damage with a suitable epoxy resin, sanding the area smooth, and applying a gelcoat to restore the original finish. It's crucial to follow a step-by-step guide to ensure a successful repair, which may include preparing the surface, applying primer, and finishing with a new gelcoat layer. Proper preparation and attention to detail are key to achieving a seamless and long-lasting repair.

What You'll Learn

- Assess Damage: Inspect the boat's bow for extent of damage, including holes, cracks, or delamination

- Prepare Materials: Gather necessary tools and materials: epoxy, fiberglass cloth, resin, and primer

- Clean and Prepare Surface: Ensure a clean, dry, and smooth surface for repair by removing old material and debris

- Apply Epoxy: Mix and apply epoxy resin to create a strong base for fiberglass repair

- Fiberglass Repair: Lay fiberglass cloth over the repair area, apply resin, and smooth for a seamless finish

Assess Damage: Inspect the boat's bow for extent of damage, including holes, cracks, or delamination

When assessing the damage to a fiberglass boat's bow, a thorough inspection is crucial to determine the extent of the issue and guide the repair process. Start by carefully examining the entire forward section of the boat, paying close attention to the hull and any attached components. Look for visible signs of damage, such as holes, which could be caused by impacts or marine life. These holes may vary in size and depth, and it's important to note their location and any surrounding areas that might be affected. Additionally, check for cracks in the fiberglass, as these can occur due to structural stress, impact, or age. Inspect the surface for any signs of delamination, where the fiberglass layers separate from the underlying structure. Delamination can weaken the boat's integrity and may be indicated by a soft, spongy feel when pressed.

Use a flashlight to illuminate the interior of the boat's hull and any hidden areas that might be affected. This is especially important if you suspect damage to the core or internal structure. Look for any signs of water intrusion, as this could have led to corrosion or further damage. Inspect the gelcoat, the outer layer of the fiberglass, for any discoloration or texture changes, as these can indicate underlying issues.

If you find any damage, it's essential to measure and document the affected areas. Take precise notes on the dimensions of holes or cracks and their locations. This information will be vital when deciding on the appropriate repair method. Consider the severity of the damage; minor issues might be repairable with simple filling and sanding, while more extensive damage may require a more complex process, such as replacing sections of the hull.

In cases of significant damage, it is recommended to seek professional assistance. Experienced marine technicians can provide expert advice and ensure the repair is done correctly, maintaining the boat's structural integrity. They can also advise on the best materials and techniques to use, ensuring a long-lasting repair.

Remember, proper assessment is the first step towards a successful repair, ensuring the boat's longevity and safety on the water.

Louisville Boat Race: Timing and Event Details

You may want to see also

Prepare Materials: Gather necessary tools and materials: epoxy, fiberglass cloth, resin, and primer

Before you begin the repair process, it's crucial to gather all the necessary tools and materials to ensure a successful and efficient fix. Here's a detailed guide on what you need to prepare:

Epoxy Resin: Choose a high-quality epoxy resin specifically designed for marine applications. This resin will act as the bonding agent, creating a strong and durable bond between the fiberglass and the repair area. Select a two-part epoxy system, typically consisting of a resin and a hardener, and follow the manufacturer's instructions for mixing and application.

Fiberglass Cloth: Select a suitable fiberglass cloth or mat that is slightly wider than the damaged area. This cloth will be used to reinforce and strengthen the repair. Opt for a cloth with a fine weave to ensure a smooth finish. You can find various weights of fiberglass cloth, so choose one appropriate for your project, considering the thickness of the boat's hull.

Resin: In addition to the epoxy resin, you'll need a clear or tinted resin, depending on your preference and the desired finish. The resin will help fill the void and provide a smooth surface. Ensure you have enough resin to cover the entire repair area, considering any additional layers you might want to apply.

Primer: A marine-grade primer is essential to prepare the surface before applying the epoxy. It helps create a smooth base and ensures better adhesion. Choose a primer that is compatible with your epoxy system. Proper priming will also help prevent any discoloration or imperfections in the final repair.

Tools: Gather the necessary tools to facilitate the repair process. This includes gloves to protect your hands, safety goggles for eye protection, a respirator or mask for working with epoxy, a heat gun or hairdryer for warming the resin, a putty knife or spatula for applying materials, and a sharp knife or utility knife for cutting the fiberglass cloth. Additionally, have some masking tape and a small brush or paintbrush for any necessary detailing.

Having all these materials ready will ensure you can proceed with the repair efficiently, following a well-prepared plan. It's always a good idea to have some extra supplies on hand, especially for larger projects, to avoid any delays during the repair process.

Lifting a Boat Engine: A Step-by-Step Guide

You may want to see also

Clean and Prepare Surface: Ensure a clean, dry, and smooth surface for repair by removing old material and debris

Before you begin the repair process, it's crucial to thoroughly clean and prepare the damaged area of your fiberglass boat's bow. This step is essential to ensure a strong and durable fix. Start by thoroughly rinsing the entire section with water to remove any loose dirt, grime, or salt. Use a stiff-bristled brush or a scraper to carefully scrape away any flaking or damaged fiberglass. Be gentle but firm to avoid further damage. It's important to be thorough here; you want to remove all the compromised material to create a clean slate for the repair.

Once the old and damaged fiberglass is removed, inspect the surface. If there are any remaining small holes or imperfections, fill them with a suitable fiberglass repair compound or putty. Smooth it out with a putty knife, ensuring the surface is level and even. Allow the filler to cure according to the manufacturer's instructions. This step is key to creating a seamless transition between the old and new material.

After the filler has cured, sand the entire area gently with fine-grit sandpaper (600-grit or higher) to create a smooth, uniform surface. Remove any dust or debris with a damp cloth, ensuring the area is completely clean and dry before proceeding. This preparation process might take some time, but it's crucial for the long-term success of the repair.

If the damage is extensive and the fiberglass has delaminated or cracked significantly, you may need to consider a more comprehensive repair method, such as using a fiberglass repair kit or seeking professional help. However, for minor to moderate damage, following these steps will provide a solid foundation for your repair. Remember, a well-prepared surface is the key to a successful and long-lasting fix.

Boat Exhaust Manifolds: Powering Performance with Efficient Exhaust Systems

You may want to see also

Apply Epoxy: Mix and apply epoxy resin to create a strong base for fiberglass repair

Before you begin the epoxy application process, ensure you have all the necessary materials and equipment. You'll need epoxy resin, a hardener, mixing containers, brushes or rollers, and possibly a heat gun for faster curing. It's crucial to follow the manufacturer's instructions for mixing ratios and timing. Proper mixing is essential to achieve a strong and durable bond.

Start by cleaning the damaged area thoroughly. Remove any loose fibers, dirt, or old epoxy residue. This step ensures that the new epoxy adheres properly. You can use a sharp blade or a scraper for this process, being careful not to damage the surrounding fiberglass. Once the area is clean and dry, you're ready to mix the epoxy.

Mix the epoxy resin and hardener according to the product's instructions. Typically, you'll need to measure the correct amounts of each and mix them thoroughly. Use a clean, dry container and a stirring tool suitable for the epoxy type. Over-mixing can lead to a stringy consistency, so be careful not to overdo it. Aim for a smooth, pourable consistency.

Now, it's time to apply the epoxy. Use a brush or roller to carefully spread the mixed epoxy over the prepared fiberglass surface. Ensure complete coverage of the damaged area, including any holes or cracks. Take your time and be precise; a smooth, even layer is crucial for a strong repair. If the epoxy starts to set, you can re-heat it slightly with a heat gun to make it more manageable, but be cautious not to overheat it.

After applying the epoxy, allow it to cure according to the manufacturer's guidelines. This process may take several hours or even days, depending on the epoxy type. Once cured, sand the repaired area gently to ensure a smooth finish. Finally, you can apply additional layers of epoxy or other finishes to restore the boat's appearance and functionality. Remember, proper preparation and attention to detail are key to a successful fiberglass repair.

Putting a Boat on a Roof Rack: Step-by-Step Guide

You may want to see also

Fiberglass Repair: Lay fiberglass cloth over the repair area, apply resin, and smooth for a seamless finish

When it comes to repairing a fiberglass boat bow, a common and effective method is to use a process known as "laying up" or "glassing." This technique involves applying a layer of fiberglass cloth over the repair area and then carefully applying a resin (often a two-part epoxy) to create a strong, durable bond. Here's a step-by-step guide to help you through the process:

Step 1: Prepare the Repair Area

Start by thoroughly cleaning the damaged area of the boat's bow. Ensure that the surface is free from dirt, grease, and any loose fibers. If there are any protruding fragments or sharp edges, carefully remove them to prevent further damage during the repair. It's crucial to work in a well-ventilated area or outdoors to avoid inhaling resin fumes.

Step 2: Lay the Fiberglass Cloth

Cut a piece of fiberglass cloth slightly larger than the repair area. The cloth should be a suitable weight, typically 4 or 6 ounces, depending on the size of the damage. Carefully lay the cloth over the prepared area, ensuring it is centered and aligned properly. You can use a small amount of resin mixed with a catalyst to act as an initial bond, but be cautious not to use too much, as it can make the repair difficult to handle.

Step 3: Apply the Resin

Now, it's time to apply the resin. Carefully mix the epoxy resin and hardener according to the manufacturer's instructions. Typically, you'll need to mix the two components in the right ratio to ensure proper curing. Use a small brush or a spreader to apply the resin evenly over the fiberglass cloth. Make sure to cover the entire surface, including the edges, for a strong bond.

Step 4: Smooth and Shape

As you apply the resin, use a straight edge or a smooth, rigid tool to ensure the cloth is flat and smooth. Work quickly but carefully to avoid air bubbles. If any bubbles appear, gently press them out with a pin or a thin tool. Once the resin is applied, you can use a wet cloth or a damp sponge to smooth the surface further, creating a seamless finish.

Step 5: Allow to Cure

After the resin has been applied and the surface is smooth, let the repair sit undisturbed for the recommended curing time, which is usually several hours or even overnight. During this time, the resin will harden, forming a strong bond with the fiberglass cloth. Once cured, you can sand the area gently to create a smooth finish that matches the surrounding surface.

Remember, fiberglass repair requires patience and attention to detail. Take your time with each step, and don't rush the process. With proper preparation and careful application, you can effectively repair a fiberglass boat bow, ensuring its structural integrity and a seamless appearance.

Boat Shoes, Rechristened: Exploring Synonymous Styles for Your Feet

You may want to see also

Frequently asked questions

For minor cracks, you can use a fiberglass repair kit. Clean the area, apply a filler or putty, and then sand it smooth once it's cured. Follow up with a fiberglass repair resin and cloth to strengthen the area.

Cracks can be caused by various factors, including impact damage from waves, collisions, or improper handling. Age and sun exposure can also lead to structural degradation over time. Regular maintenance and proper storage can help prevent such issues.

Yes, temporary solutions like marine-grade epoxy or specialized boat repair compounds can provide a quick fix. However, it's essential to understand that these are temporary measures and should be followed by a proper repair to ensure the structural integrity of the boat.

Regular inspections are crucial, especially after exposure to rough waters or after any impact. It's recommended to check the bow at least once a month and after any significant boating activities. Promptly addressing any issues will prevent further damage.

Yes, you can use a process called 'fiberglass repair and reinforcement'. This involves removing the damaged section, applying a new layer of fiberglass cloth and resin, and then bonding it to the existing structure. Proper preparation and adherence to the process are key to a successful repair.