Proper engine height is crucial for optimal performance on your boat. The outboard motor height affects the stern lift, drag, porpoising, and the quality of water fed to the prop. To achieve higher efficiency, better fuel economy, and extra miles per hour at top speed, it is important to set the outboard motor height on the transom correctly. The rule of thumb is to keep the cavitation plate level with the keel right in front of it, with the prop shaft trimmed parallel to the keel.

What You'll Learn

- The cavitation plate should be level with the keel

- The prop shaft should be parallel to the keel

- Without a cavitation plate, the top of the propeller should be 100-150mm under water

- Higher engine mounts can improve performance

- Signs of an engine mounted too high include propeller ventilation and overheating

The cavitation plate should be level with the keel

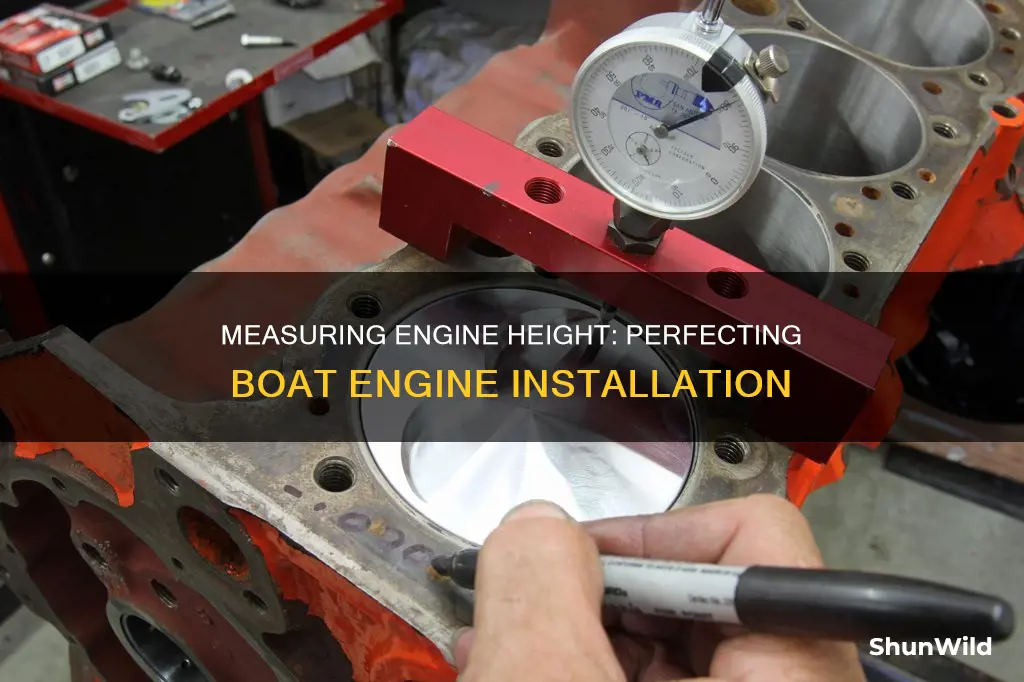

How to Measure Proper Engine Height on a Boat

The correct height of an outboard motor is crucial as it affects the stern lift, drag, porpoising, quality of water fed to the prop, and, ultimately, the performance of your boat. Ensuring that the cavitation plate is level with the keel is an important step in this process.

The cavitation plate, also known as the anti-ventilation plate, is an integral part of the gear housing, or gearcase, of an outboard motor. Its purpose is to reduce the possibility of air being drawn from the surface into the negative pressure side of the propeller blades. By minimising air intake, the plate helps to optimise the performance of the propeller.

To ensure the cavitation plate is level with the keel, you will need to adjust the height of the outboard motor. This can be done by switching the mounting holes. Outboard motors typically feature a clamp bracket with a series of four to six holes spaced 0.75" apart. By moving the motor up or down the mounting holes, you can adjust the height to achieve the desired level with the keel.

It is recommended to start by setting the cavitation plate slightly above or at the water level. This can be fine-tuned by loading the boat for a typical day, running it, and trimming it up to your usual conditions. During operation, the cavitation plate should be visible and splashed with water, not buried. If the plate is too high, you may observe symptoms such as the propeller blowing out while turning or the motor overheating. On the other hand, if the plate is too low, you may experience poor maneuverability or water pushing up into the cowling.

In addition to adjusting the mounting holes, a Jack plate can also be used to fine-tune the outboard motor height. This accessory allows for more precise adjustments to ensure the cavitation plate is level with the keel.

Cheeky Monkey: A Boat Like No Other

You may want to see also

The prop shaft should be parallel to the keel

To ensure optimal performance on your boat, it is crucial to set the correct outboard motor height. This is important as it affects the stern lift, drag, porpoising, and the quality of water fed to the propeller. One of the key rules to remember when setting the outboard motor height is that the prop shaft should be parallel to the keel. This is a standard that can be used as a starting point for setting the correct height.

The prop shaft being parallel to the keel is important because it ensures that the propeller is at the right height relative to the keel. If the prop shaft is not parallel, the propeller could be too high or too low in the water, which would affect the performance of the boat. A propeller that is too high might cause the boat to have poor maneuverability or experience water pushing up into the cowling. On the other hand, if the propeller is too low, it can cause issues such as the propeller blowing out while turning or ventilating, as well as increased motor heat and the potential for internal damage.

To achieve the proper height, adjustments can be made by switching the mounting holes or using a Jack plate for fine-tuning. It is recommended to refer to diagrams and height adjustment guides to get a better understanding of the proper height. Additionally, the outboard motor shaft length is also a factor in setting the correct height.

Once the adjustments have been made, it is important to test the setup to ensure that the outboard motor is performing optimally. This can be done by listening to how the motor runs through the water, observing the engine's RPM versus boat speed, and paying attention to the water or wake behind the boat and outboard. By following these guidelines and making the necessary adjustments, you can ensure that your outboard motor is set at the correct height, with the prop shaft parallel to the keel, for optimal performance.

Nebraska Boat Trailer Title Requirements: What You Need to Know

You may want to see also

Without a cavitation plate, the top of the propeller should be 100-150mm under water

The height of an outboard motor is crucial as it affects the stern lift, drag, porpoising, quality of water fed to the prop, and optimal performance on your boat. The rule of thumb is that the cavitation plate should be about even with the keel right in front of it, and the prop shaft should be trimmed to parallel the keel.

However, if you are running an outboard motor without a cavitation plate, as is the case with most electric outboards, the height is adjusted differently. Without a cavitation plate, the top of the propeller should be 100-150mm under the water. This measurement is an industry standard that can be used as a starting point for setting the outboard motor height correctly.

Cavitation occurs when the pressure on one side of the propeller becomes too low, causing water to vaporize and form small air bubbles. This can lead to a loss of efficiency, reduced propulsion, and increased propeller noise. The cavitation plate helps mitigate cavitation by redirecting water flow and creating a barrier between the propeller and the water surface. It can increase water pressure on the propeller blades, enhancing traction and reducing the risk of cavitation.

The best way to find the ideal outboard motor height is through trial and error. Load the boat for a typical day, run it, and trim it up to your usual settings for your conditions. Operate it, including turns, and observe the anti-ventilation plate while running. With the proper height, the AV plate should be slightly above or at the water level, visible and being splashed with water, not buried.

Best Fabric for Pedal Boat Canopy: Waterproof and Durable

You may want to see also

Higher engine mounts can improve performance

While engine mounts are often overlooked, they can have a significant impact on a boat's performance. These mounts act as small cushions that absorb movement between the engine and the boat's frame, and the correct height of the engine mount is crucial for optimal performance.

The height of an engine mount can affect the stern lift, drag, porpoising, and the quality of water fed to the propeller. By adjusting the height of the engine mount, you can improve efficiency, fuel economy, and top speed. In some cases, mounting the engine higher can produce better total performance.

Engine mounts are typically made of rubber or polyurethane to dampen vibrations and noise. However, softer engine mounts can cause a loss of torque as the engine moves around. Upgrading to stiffer, high-performance engine mounts can improve engine response and power delivery. These mounts are made of harder materials like urethane, which absorb less vibration and, as a result, less power.

It's important to note that stiffer engine mounts may also increase vibration and noise in the cabin, so it's a trade-off between performance and comfort. The ideal configuration depends on your specific needs and comfort levels.

To measure the proper engine height on a boat, you need to consider the overall dimensions of the boat, including its length, beam, draft, and height. The engine height should be adjusted to ensure optimal performance and efficiency.

Exploring the Seas: Jacques Cousteau's Boats and Their Legacy

You may want to see also

Signs of an engine mounted too high include propeller ventilation and overheating

An outboard motor mounted too high can cause a host of issues, including propeller ventilation and overheating. Here are some signs that indicate your outboard motor is mounted too high:

Propeller Ventilation

A propeller that ventilates or "blows out" while turning is a common symptom of an outboard motor mounted too high. This means that the propeller is not receiving enough water, which can lead to a lack of thrust and reduced manoeuvrability.

Overheating and Internal Damage

An outboard motor mounted too high can cause the engine to overheat and sustain internal damage. This is because the higher mounting position prevents the propeller from receiving enough water for proper cooling. As a result, the engine may stall or fail, and the gears and bearings inside the motor may experience increased friction, reducing the engine's lifespan.

Poor Performance and Fuel Economy

An outboard motor that is too high can result in decreased engine performance and poor fuel economy. This is due to the motor's inability to produce sufficient backward thrust, which leads to higher RPMs and reduced torque. Additionally, the higher mounting position can cause increased fuel consumption as the motor requires more power to thrust the boat.

Increased Noise and Vibration

Excessive noise and vibration from the motor are also signs that it is mounted too high. This is often caused by the motor working harder to overcome the resistance of the propeller being buried too deeply in the water.

Difficult Manoeuvrability

A higher-mounted outboard motor can make the boat more difficult to control, especially in strong currents or windy conditions. The boat becomes more susceptible to wind and waves, increasing instability and making it challenging to turn and control the boat's movement.

It is important to note that these symptoms may vary depending on specific applications and that the optimal outboard motor height can be determined through trial and error. Adjusting the height of an outboard motor can usually be done by switching the mounting holes or using a Jack plate for fine-tuning.

Fresh Off the Boat: A Satisfying Conclusion?

You may want to see also

Frequently asked questions

If your outboard motor is mounted too low, you may experience poor maneuverability and water may push up into the cowling. If it's mounted too high, you may notice issues such as the propeller blowing out while turning, ventilation of the propeller, reduced drag and low water pressure, engine overheating, and excessive engine noise.

The cavitation plate should be about even with the keel right in front of it, and the prop shaft should be trimmed to be parallel to the keel.

The height of an outboard motor can be adjusted by switching the mounting holes. Outboard motors typically feature a clamp bracket with a series of four to six holes spaced 0.75" apart, allowing for height adjustment. Alternatively, you can use a Jack plate for fine-tuning the mounting height.