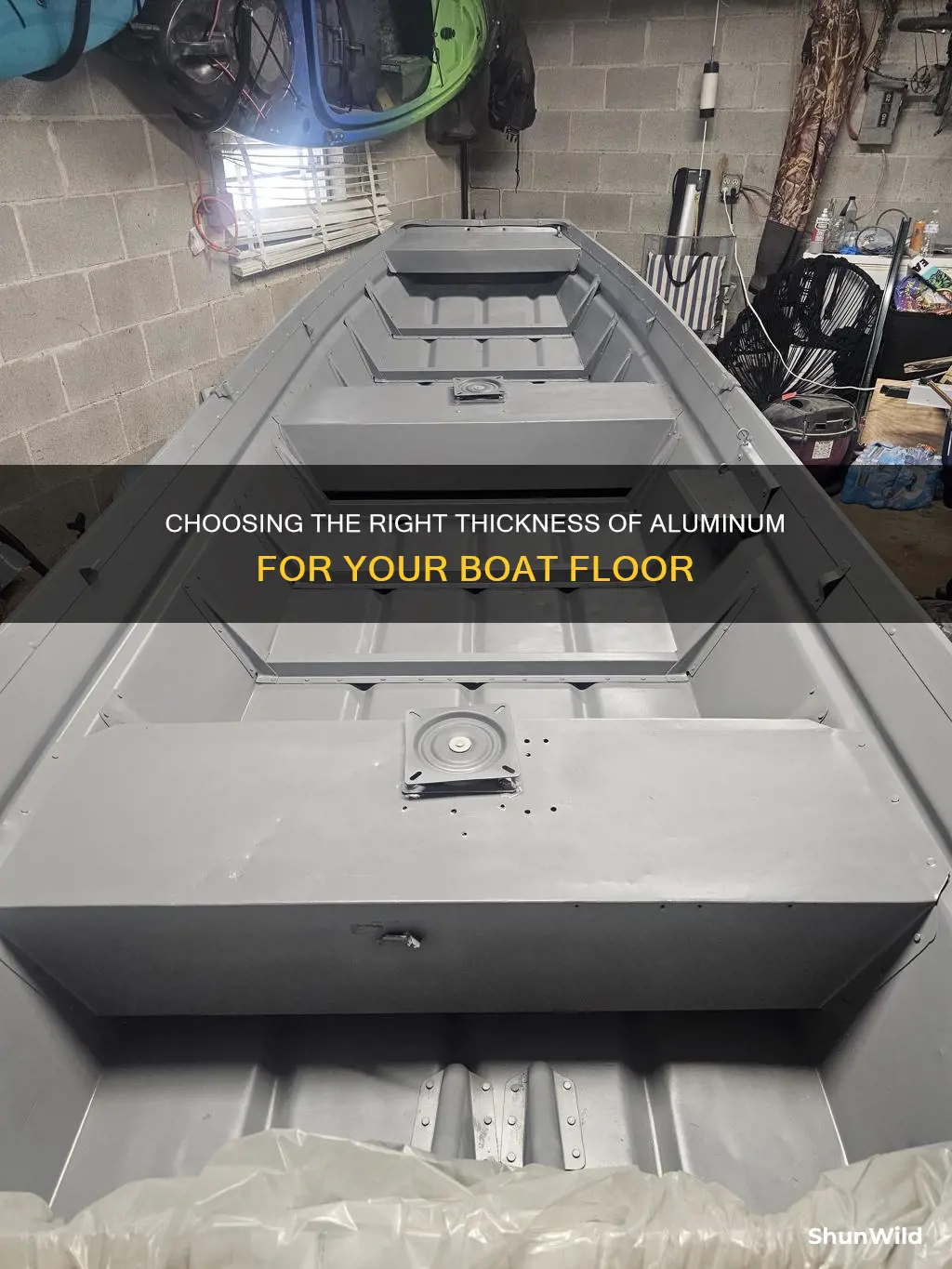

Boat flooring is an important consideration for any boat owner, and choosing the right thickness of aluminum can be crucial. While some opt for materials like plywood or planks, aluminum is a popular choice for its durability and ease of cleaning. The thickness of the aluminum sheet for a boat floor typically ranges from 1/16 to 3/16, with some standard jon boats using 1/8 aluminum sheeting. Thickness is an important factor as it determines the weight and strength of the floor, with thicker aluminum providing more support but also adding more weight to the boat. Boat owners must consider factors such as the spacing of the boat's ribs, the expected weight and pressure, and the desired level of flexibility when selecting the appropriate thickness of aluminum for their boat floor.

What You'll Learn

Plywood with carpet

If you're looking for a non-aluminum floor for your boat, one option is to use plywood with carpet. This option is relatively inexpensive and can provide a warm surface for your feet when out on the cold water.

When selecting plywood for your boat, it is important to avoid using pressure-treated plywood as the chemicals used in the treatment process can react with the aluminum and cause corrosion. Instead, opt for marine-grade or exterior-grade plywood that has been sealed with epoxy resin or another waterproof sealant.

The thickness of the plywood you choose will depend on the weight you want to achieve and the amount of support your boat floor will need. Some boat owners have suggested using 1/2" or 3/4" plywood for their boat floors, while others have recommended going as thin as 1/4" or 3/8" to reduce weight. If you are set on using a thinner plywood, you can add support by placing dense foam between the ribs of your boat.

When installing your plywood floor, it is important to seal all holes with silicone and to consider coating the plywood with a waterproof paint or resin to help protect it from water damage. You can then add marine-grade carpet or vinyl flooring to the plywood for added traction and comfort.

By following these suggestions and tips, you can create a plywood and carpet boat floor that is both functional and durable.

Fixing Trim Tabs: A Step-by-Step Guide for Boat Owners

You may want to see also

1/8 aluminum sheeting

1/8" Aluminum Sheeting for Boat Floors

When it comes to choosing the right thickness of aluminum sheeting for a boat floor, one option that is often considered is 1/8" aluminum. This material has its advantages and disadvantages, and there are several factors to take into account when making a decision.

Firstly, it is important to understand the benefits of using aluminum for a boat floor. Aluminum is a strong and durable material that can provide a sturdy and long-lasting surface for walking on. It is also relatively lightweight, which can be advantageous for boat construction. In addition, aluminum is resistant to corrosion and water damage, making it a suitable choice for use in marine environments.

One of the key considerations when choosing the thickness of aluminum sheeting for a boat floor is the weight it is expected to support. 1/8" aluminum sheeting is a relatively thick option and can provide good strength and rigidity. It is often used in jon boats and other similar vessels, and it can be an appropriate choice if you require a sturdy and durable floor. However, it is important to note that thicker aluminum sheeting will also add more weight to the boat, which may be a factor to consider depending on the specific application.

Another factor to consider is the spacing of the ribs or supports underneath the floor. 1/8" aluminum sheeting can be a good choice if the ribs are spaced further apart, as it provides more support and rigidity than thinner options. However, if the ribs are spaced closely together, a thinner sheet of aluminum may also be sufficient. In some cases, additional support can be added using closed-cell foam or other materials to help reduce the thickness of aluminum sheeting required.

It is also worth considering the finish of the aluminum sheeting. Aluminum diamond plate is a popular option for boat floors, as it provides good traction and is not slippery, even when wet. However, it can be more expensive and may require additional treatment or painting to prevent slipping. Some boaters also prefer to use marine-grade plywood or other materials for the floor and use aluminum only in high-traffic areas, such as where people walk or stand frequently. This can help reduce weight and cost while still providing a durable and functional surface.

In terms of pricing, the cost of 1/8" aluminum sheeting can vary depending on the specific type of aluminum alloy, the size of the sheet, and the supplier. It is generally more expensive than thinner options, and special orders or alloys may further increase the price. It is important to compare prices and shop around to find the best deal.

Overall, 1/8" aluminum sheeting can be a good choice for boat floors, particularly in jon boats or similar vessels. It provides good strength and durability, and it can be suitable for applications where weight is not a significant concern. However, it is important to consider the specific requirements of your boat, including weight expectations, rib spacing, and finish preferences, before making a final decision.

Exploring RumRries Boat Yard's Ownership in Biddeford, Maine

You may want to see also

1/2 marine-grade plywood

Marine-grade plywood is an ideal material for boat building. It has no voids between the layers and is made with an exterior resin glue.

Marine-grade plywood with a thickness of 1/2 inch is available in various materials, including FIR, Okoume, Baltic Birch, and Aquatek. It is glued with a water-resistant structural adhesive for durability and can be painted or stained to complement the boat's decor.

When considering the thickness of aluminum for a boat floor, factors such as weight, support, and flexibility come into play. While some suggest that the floor should be thicker than the hull to support more pressure per square inch, others recommend thinner aluminum with dense foam underneath for support and floatation.

For a 16' semi-modified Alweld jon boat, one boat owner installed 1/8" thick aluminum with closed-cell foam underneath and covered it with wood grain hydroturf. Another boat owner suggested using marine-grade plywood instead, as 1/2" plywood would be roughly the same weight per square foot as 1/8" aluminum.

Ultimately, the decision on the thickness of the boat floor material depends on various factors, including the boat's size, weight distribution, and intended use.

Foam and Bass Boats: Added Buoyancy, Better Performance?

You may want to see also

1/16 or 3/32 aluminum with closed-cell foam underneath

When it comes to choosing the right thickness of aluminium for a boat floor, there are a few key factors to consider. These include weight, strength, and the need for additional support or flotation devices. Aluminium thicknesses commonly used for boat floors include 1/8", 3/16", and 1/16" or 3/32" with closed-cell foam underneath.

If you're considering 1/16" or 3/32" aluminium with closed-cell foam underneath for your boat floor, here are some things to keep in mind:

Weight: Aluminium is a lightweight material, which is one of the reasons it's commonly used for boat construction. The weight of 1/16" or 3/32" aluminium sheeting will depend on the specific alloy chosen, but it is generally a lightweight option. Using closed-cell foam underneath can add some weight, but it is still a relatively lightweight combination compared to other flooring options.

Strength: The strength of your boat floor will depend on the thickness of the aluminium, the type of alloy used, and the spacing of the ribs or supports underneath. 1/16" or 3/32" aluminium with closed-cell foam can provide a strong and rigid floor, especially when supported by closely spaced ribs. However, if you anticipate very heavy loads or passengers with high heels, you may need to consider thicker aluminium or additional support.

Closed-Cell Foam: Closed-cell foam is an excellent choice for boat flooring as it provides buoyancy, sound deadening, and insulation. It also helps to distribute weight and can make the floor feel more rigid. Closed-cell foam is resistant to water absorption, but it is important to ensure proper drainage in your boat to prevent any potential issues over time.

Cost: The cost of 1/16" or 3/32" aluminium sheeting will depend on the specific alloy and the quantity purchased. Closed-cell foam can also vary in price, but it is generally a cost-effective option. This combination can provide a durable and affordable boat flooring solution.

Installation: Installing an aluminium floor with closed-cell foam is a straightforward process. The aluminium sheets can be cut to fit the contours of your boat and riveted to the ribs. The closed-cell foam can be added between the ribs for additional support and flotation. It is important to ensure a secure fit to prevent any slipping or movement.

In summary, 1/16" or 3/32" aluminium with closed-cell foam underneath can be an excellent choice for a boat floor. It provides a strong, lightweight, and affordable option. Proper installation and consideration of weight distribution and drainage will ensure a safe and durable flooring solution for your boat.

The Owner of Titan Explorer: Captain Sig Hansen

You may want to see also

3/16 aluminum with 2ft spacing

When it comes to choosing the right thickness of aluminum for your boat floor, there are a few key factors to consider, including the spacing of the ribs or supports in your boat, the weight and use of your boat, and your personal preferences for weight, cost, and ease of installation.

If you're working with 2-foot rib spacing and are considering 3/16" aluminum, this is generally considered a good option for providing a sturdy floor that can handle significant weight. While 1/8" aluminum is also an option, it may not provide sufficient support without additional bracing.

For example, if you have a 27-year-old boat with 2-foot rib spacing and a factory-installed floor made of very thin aluminum (similar to aluminum roof flashing) and 1/4" plywood on top, you may not need to replace the aluminum. However, if you're looking for a more robust solution or are concerned about dropping something heavy on the floor, opting for 3/16" aluminum with 2-foot spacing is a good choice.

Additionally, consider the weight of the aluminum and how it will impact the overall weight of your boat. Standard 1/8" 6061 aluminum plate weighs approximately 1.76 pounds per square foot, while thicker options will be heavier. If weight is a significant concern, you may want to consider other flooring options, such as marine-grade plywood or sealed MDO plywood, which can provide a durable and cost-effective solution.

Finally, keep in mind that aluminum floors can be slippery, especially when wet, so you may need to add an anti-slip material or coating to your aluminum floor to improve traction and safety.

Boat Trip: Hilton Head to Tybee Island

You may want to see also

Frequently asked questions

The thickness of aluminum for a boat floor depends on the spacing of the supports. If the supports are 2ft on center, you will need 3/16" aluminum. If the supports are closer, 1/8" aluminum should be sufficient.

Aluminum is a good material for a boat floor because it is durable, easy to clean, and resistant to rot. It is also a good choice for a duck boat, as it can be washed out with a hose after each use.

Some alternatives to using aluminum for a boat floor include plywood, carpet, and foam. Plywood is a good option if you want to keep costs down, while carpet can add warmth and improve traction. Foam can be used to support the aluminum and add floatation.

The cost of aluminum flooring is approximately $15 per square foot, while plywood costs around $2 per square foot.

The grade of aluminum that you use for a boat floor is important. 5052 aluminum is a good option, as it is strong and resistant to corrosion.