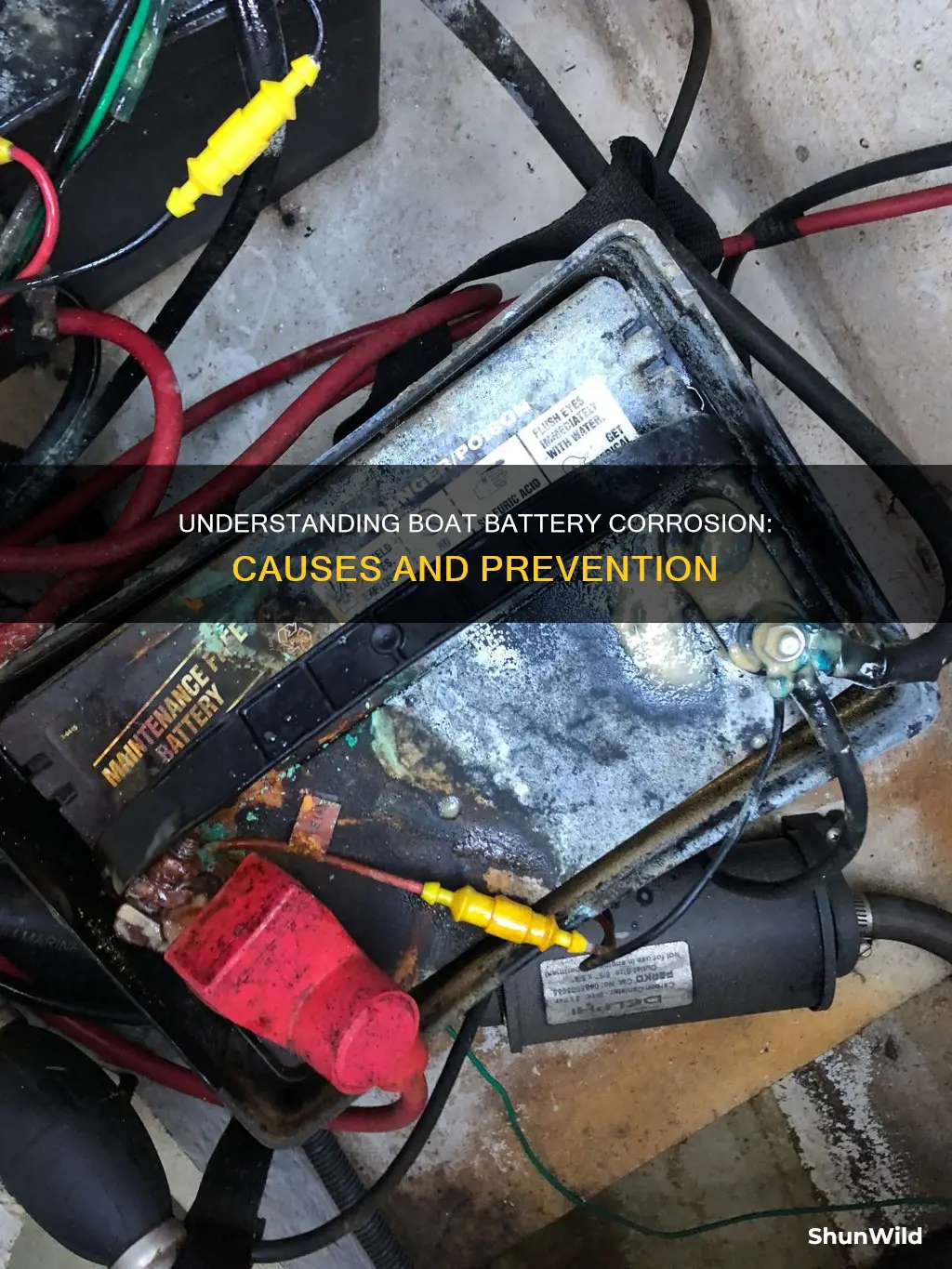

Corrosion on boat batteries is a common issue that can significantly impact performance and battery life. Marine batteries are designed to withstand harsh water environments, but they are still susceptible to corrosion due to several factors, including the release of hydrogen gas during battery operation, exposure to saltwater and high humidity, and improper maintenance and charging practices. Understanding the causes of corrosion and implementing effective prevention and cleaning techniques are crucial to maintaining optimal battery performance and longevity.

| Characteristics | Values |

|---|---|

| Cause of corrosion | Chemical reactions between metal terminals and battery acid |

| Release of hydrogen gas from sulfuric acid | |

| Exposure to air, moisture and salt | |

| Overfilled batteries | |

| Damaged or leaking batteries | |

| Overcharging | |

| High temperatures | |

| Age | |

| High humidity and saltwater exposure |

What You'll Learn

High humidity and saltwater exposure

Marine batteries are designed to withstand the harsh conditions of the marine environment, but they are not immune to corrosion. Marine conditions such as high humidity and saltwater exposure can increase the likelihood of corrosion.

The powdery buildup of corrosion can interfere with the battery's performance, making it difficult to start the engine and reducing the overall lifespan of the battery. Therefore, it is essential to take preventative measures and perform regular maintenance to mitigate the effects of high humidity and saltwater exposure.

To prevent corrosion in high humidity and saltwater environments, it is crucial to maintain proper battery care and maintenance. This includes regular cleaning and inspection of the battery terminals, as well as the application of protective coatings, such as dielectric grease or terminal protectors. Keeping the battery stored in a cool, dry, and well-ventilated place, away from saltwater and excess humidity, is also essential.

Additionally, proper charging practices are critical. Overcharging should be avoided as it can lead to increased hydrogen gas production, contributing to corrosion. Therefore, it is important to maintain the battery's state of charge using a suitable charger that meets the manufacturer's specifications.

The Mystery of Wansa Boat's Ownership

You may want to see also

Overcharging

To prevent overcharging, it is important to properly maintain the battery's state of charge using a charger that meets the manufacturer's specifications. This will help to ensure that the battery does not exceed its capacity and reduce the risk of corrosion. Additionally, adhering to proper charging practices, such as avoiding full charge cycles, overnight charging, and the use of fast charging, can help to prevent overcharging and exposure to high temperatures, both of which contribute to corrosion.

It is also important to regularly inspect and maintain boat batteries to prevent corrosion. This includes cleaning the battery terminals and connections with a wire brush or a solution of baking soda and water, and applying protective coatings or dielectric grease to the terminals to inhibit corrosion. Checking the battery's water levels and replenishing distilled water when necessary is another important aspect of maintaining proper battery care.

By understanding the causes of corrosion and implementing proper charging and maintenance practices, boat owners can help extend the life of their batteries and ensure reliable performance.

Sun Dolphin Paddle Boat Weight and Capacity Insights

You may want to see also

High temperatures

To prevent corrosion caused by high temperatures, it is important to adhere to correct charging practices and avoid extreme heat exposure for your battery. Keeping your battery properly stored and secured while operating can also help to regulate its temperature and prevent corrosion.

Additionally, maintaining the correct electrolyte levels in your battery is crucial. Overfilled batteries can lead to corrosion during the chemical reaction that takes place inside the battery. Distilled water should be used to replenish the water levels, and it is important not to fill the battery beyond the manufacturer's recommended level.

Proper maintenance and regular inspection of your battery are crucial in preventing corrosion. By regularly checking the battery terminals for corrosion and cleaning them as necessary, you can ensure the proper functioning and longevity of your battery. Protective coatings, such as dielectric grease or battery terminal protectors, can also be applied to the terminals to prevent corrosion.

Best Grease for Boat Trailer Wheel Bearings

You may want to see also

Leaking fluids

Leaking battery acid is a major cause of corrosion on boat batteries. Corrosion occurs when there is a chemical reaction between the battery acid and the battery's metal terminals. This reaction is accelerated when hydrogen gas, moisture, and salt in the air come into contact with the battery terminals.

Damaged or leaking batteries can cause electrolyte buildup on the terminals, leading to corrosion. Physical damage, such as dropping the battery, or age and wear, could be potential causes of a damaged or leaking battery. It is important to carefully handle and promptly replace leaking or damaged batteries to prevent corrosion and potential damage to the battery cables.

Corrosion can also be caused by overfilled batteries, where excess water comes into contact with the battery's surfaces and terminals, leading to corrosion during the chemical reaction inside the battery. Overfilled batteries may also result in heightened risks of leakage or spillage, damage to the battery casing or seals, decreased battery lifespan and capacity, and an increased risk of corrosion on battery terminals and connections.

To prevent corrosion caused by leaking or damaged batteries, it is necessary to replace them promptly. Regular maintenance, such as protective coatings, proper charging practices, and inspections, is crucial for preventing corrosion and extending the life of the battery. Additionally, using lithium batteries can provide a safe and maintenance-free option, as they have a sealed design that eliminates the potential for acid leaks or fumes.

Checking Boat Engine History: What You Need to Know

You may want to see also

Loose connectors

To prevent this, it is important to ensure that all connections are tight. First, attach the red cable to the positive terminal and tighten the nut securely. Then, attach the black cable to the negative terminal and tighten it in the same way.

It is also important to keep the battery secured while operating. If the battery slides around or is hit by moving objects, the casing could puncture, leading to increased corrosion. Spray from water can also add to the problem. Therefore, keeping the battery in a specialized box, strapped down, and clear of loose items and electrical components is essential.

In addition to tight connections, using anti-corrosion pads made of fibre between the terminals and cables can provide an extra barrier to corrosion.

By ensuring tight connections and taking other preventative measures, you can help reduce the potential for corrosion on your boat battery.

The First Steam-Powered Boat: A Historical Overview

You may want to see also

Frequently asked questions

Corrosion refers to the oxidation of metal terminals on the surface of a battery, resulting in a greenish or white powdery substance. It is caused by a chemical reaction between hydrogen gas, air, moisture, and salt. This powdery buildup can be easily spotted and typically surrounds one of the battery terminals, posts, or cables.

Corrosion on boat batteries can be attributed to several factors, including age, overheating, leaking fluid, and overcharging. Boat batteries have an average lifespan of three to five years, and the likelihood of corrosion increases as they approach the end of their lifespan. Overheating and overcharging can also accelerate corrosion.

Marine conditions, such as high humidity and saltwater exposure, can make corrosion more likely. Saltwater exposure, in particular, exacerbates the corrosive effects of moisture. Therefore, it is crucial to properly maintain and store boat batteries to prevent corrosion.

Overcharging a boat battery can lead to increased hydrogen gas production, which contributes to corrosion. It is essential to maintain the correct charge using a suitable charger to prevent overcharging and ensure optimal battery performance.

To prevent corrosion, regularly clean your boat battery and apply protective coatings, such as dielectric grease or terminal protectors. Additionally, practice proper charging habits, keep the battery secure and stored in a safe location when not in use, and ensure tight connections.