A jet boat is propelled by a jet of water ejected from the back of the craft. Unlike a powerboat or motorboat that uses an external propeller, a jet boat draws water from under the boat through an intake and into a pump-jet inside the boat, before expelling it through a nozzle at the stern. This makes jet boats safer for swimmers and marine life.

| Characteristics | Values |

|---|---|

| How it works | Draws water from under the boat through an intake and into a pump-jet inside the boat, before expelling it through a nozzle at the stern |

| Development | Developed by New Zealand engineer Sir William Hamilton in the mid-1950s |

| Purpose | To create a boat that could run up New Zealand's fast-flowing rivers that were too shallow for propellers |

| Comparison to propeller boats | More manoeuvrable, safer for swimmers and marine life, and more efficient at high speeds |

| Steering | Accomplished by moving the nozzle to either side, or by using small gates on either side that deflect the jetstream |

| Reversing | Achieved by lowering a deflector into the jetstream to redirect thrust forces forward |

| Speed | Jetboats are more efficient than propeller boats at speeds over 20 knots (37 km/h; 23 mph) |

| Engine | Requires an engine that can spin the pump at high RPMs to generate large amounts of thrust |

| Maintenance | Jet boats have fewer moving parts, resulting in less wear and tear and reduced maintenance |

What You'll Learn

Jet boats use a propeller, or impeller, inside a housing

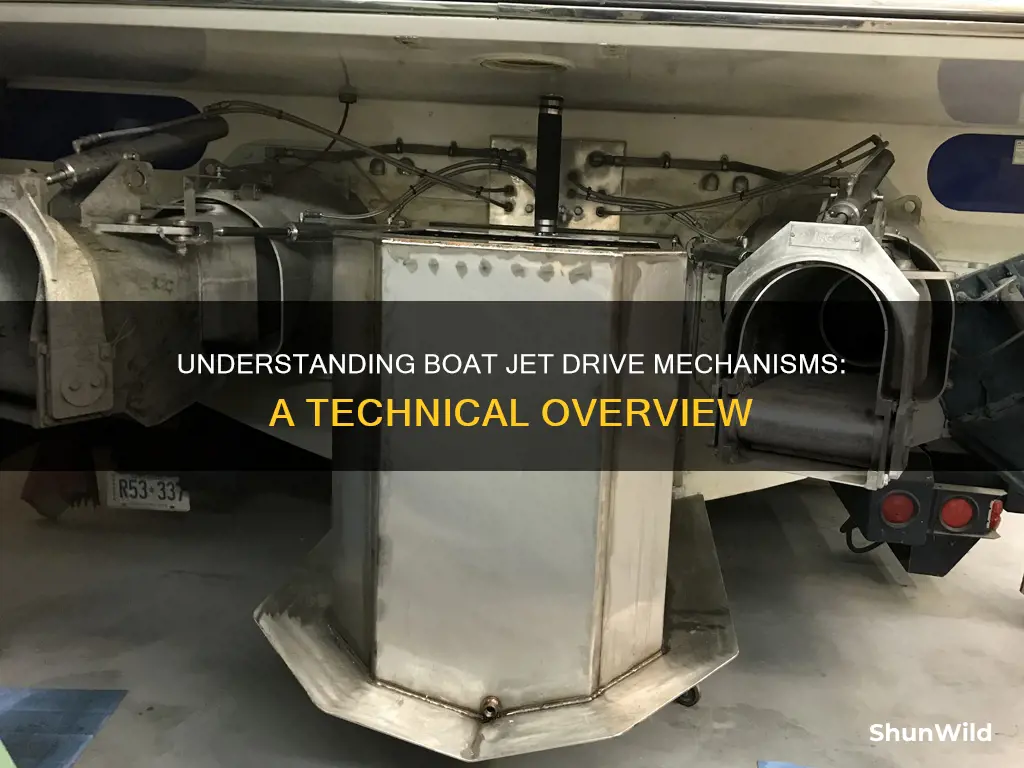

The waterjet unit draws water from beneath the hull, where it passes through a series of impellers and stators, known as stages, which increase the velocity of the waterflow. Most modern jets are single-stage, while older waterjets may have up to three stages. The tail section of the waterjet unit extends out through the transom of the hull, above the waterline. This jetstream exits the unit through a small nozzle at high velocity to push the boat forward. Steering is achieved by moving this nozzle from side to side or, less commonly, by using small gates on either side to deflect the jetstream.

Replacing Vinyl Headliner in Your Hunter Sail Boat

You may want to see also

Water is drawn in through an intake in the bottom of the boat

The intake is usually at the bottom of the hull, and the pump can be of a centrifugal design for high speeds, or an axial flow pump for low to medium speeds. The axial-flow pump is the most common type, producing high volumes of water at lower velocity, making it well-suited to larger craft. The water pressure inside the inlet is increased by the pump and forced backward through the nozzle.

The design of the nozzle is important for the overall performance of the boat. Nozzle design, along with engine power, must be considered when choosing a water-jet drive system. The nozzle provides steering, and plates, similar to rudders, can be attached to redirect the water flow. The more water flow, the more control the boat has. If there is no water flow, the boat has no steering ability, which is why jet boats need the engine to be running to steer.

The water intake and pump system means that jet boats are highly manoeuvrable. They can be reversed from full speed and perform a "crash stop", coming to a stop within their own length. They can also perform a "jet spin", where the throttle is cut, the steering is turned sharply, and the throttle is opened again, causing the boat to spin with a large spray of water.

Troubleshooting Guide: Boat Not Starting? Try These Steps

You may want to see also

Water is forced out through a nozzle at the rear of the boat

Water is drawn in through the intake at the bottom of the boat's hull, before being forced out through a nozzle at the rear of the boat. This process is known as a pump-jet, hydrojet, or water jet. The mechanical arrangement may be a ducted propeller (axial-flow pump), a centrifugal pump, or a mixed flow pump, which is a combination of both centrifugal and axial designs. The design also incorporates an intake to provide water to the pump and a nozzle to direct the flow of water out of the pump.

The nozzle provides the steering of the pump-jets. Plates, similar to rudders, can be attached to the nozzle to redirect the water flow. This is similar to the principles of air thrust vectoring, a technique long used in rockets and military jet-powered aircraft. This provides pumpjet-powered ships with superior agility at sea.

The axial-flow waterjet's pressure is increased as the flow passes through the impeller blades and stator vanes. The pump nozzle then converts this pressure energy into velocity, thus producing thrust. Axial-flow waterjets are the most common type of pump and produce high volumes at lower velocity, making them well-suited to larger low-to-medium-speed craft.

Mixed-flow waterjet designs incorporate aspects of both axial flow and centrifugal flow pumps. Pressure is developed by both diffusion and radial outflow. Mixed flow designs produce lower volumes of water at high velocity, making them suited for small to moderate craft sizes and higher speeds.

Why Are Most Boat Names Feminine?

You may want to see also

Steering is achieved by turning the nozzle

The steering of a jet boat is achieved by turning the nozzle, which changes the direction of the water forced out of the back of the boat, causing the craft to change direction. This is similar to the principles of air thrust vectoring, which has been used in rockets, missiles and military jet-powered aircraft.

The nozzle is the component that directs the flow of water out of the pump. By moving the nozzle from side to side, the boat is steered. This is also known as a steerable nozzle, which creates vectored thrust. This method of steering is only possible when the engine is running, as the jetboat relies on the flow of water through the nozzle for control.

The nozzle can also be used to achieve reverse thrust. A deflector is lowered into the jetstream after it leaves the outlet nozzle, redirecting the thrust forward to slow the boat or provide reverse thrust. When the deflector is lowered halfway, forward and reverse thrust are equal, and the boat maintains a fixed position, but steering is still possible, allowing the vessel to turn on the spot—something impossible with a conventional single propeller.

Repairing Screw Holes: Restoring Your Boat's Gelcoat Like a Pro

You may want to see also

Jet boats are highly manoeuvrable

The high manoeuvrability of jet boats is due to their propulsion system. Unlike conventional propeller systems, jet boats use a pump-jet, hydrojet, or water jet system that draws water from under the boat through an intake and into a pump-jet inside the boat, before expelling it through a nozzle at the stern. The nozzle can be moved to either side, or small gates on either side can be used to deflect the jetstream, allowing the boat to be steered.

Jet boats also have superior steering at slow speeds compared to conventional propeller boats. At slow speeds, a jet boat will lose some steering control as less water is pumped through the jet unit. However, this can be overcome by lowering the reverse deflector slightly and increasing the throttle, allowing the operator to increase thrust and control without increasing boat speed.

The jet boat's manoeuvrability is further enhanced by its hull design. Jet boats use a conventional planing hull, with only the rear portion of the hull displacing water. This reduces drag and greatly enhances speed and manoeuvrability, so jet boats are typically operated at planing speed. Jet boats can be operated safely in very shallow water, with as little as 7.5 cm (3 inches) of water.

Exploring Paddle Boat Rental Costs and Options

You may want to see also