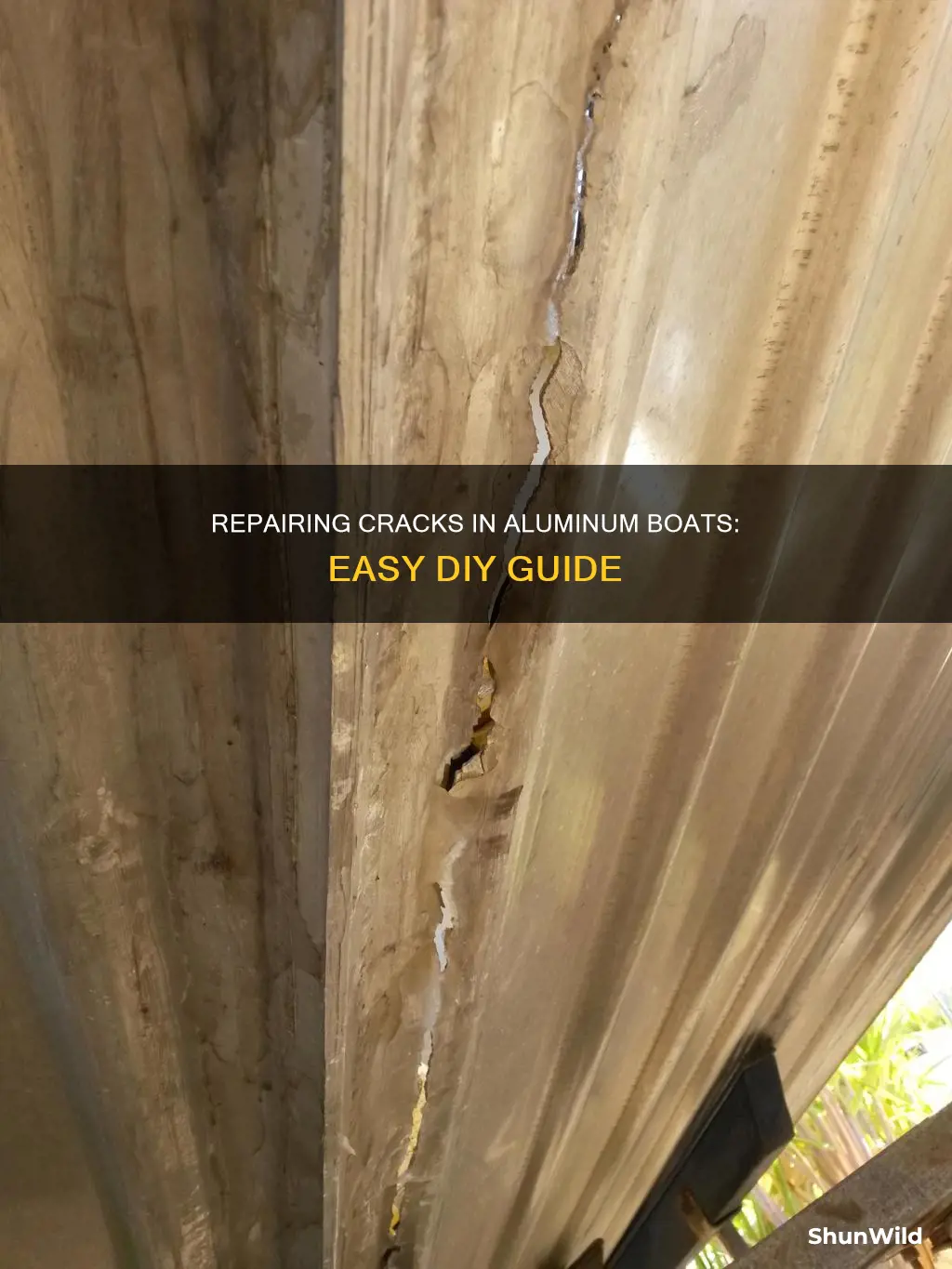

Owning a boat can be a lot of fun, but it also comes with maintenance and repairs. If you have a crack in your aluminum boat, there are several ways to fix it. In this article, we will explore the different methods and provide a step-by-step guide to repairing your boat and getting it back into the water. From welding to epoxy, we will cover the pros and cons of each approach and offer expert advice on getting the best results. So, whether you're an experienced boat owner or a novice, we'll help you navigate the process of fixing that crack and ensure your boat is safe and ready for your next adventure.

| Characteristics | Values |

|---|---|

| First steps to repair | Remove the boat from the water and place it on a flat surface. Clean the area with acetone and rags. |

| Dent repair | Use an anvil and hammer to lift the dents. Straighten and tap out to flatten the body. |

| Repair preparation | Measure the crack. Use aluminium strips to create a container for the brazen rod. Apply adhesive to the tips and affix it to the base. |

| Repairing holes and cracks | Create a v-shaped channel with a drill motor and a grinding cone. Sand the area with 220-grit sandpaper. Use a wire brush to scrape the area. Apply consistent heat from a heat source to fix the brazen rods on the sides. Alternatively, use a TIG or MIG welder, or epoxy resin. |

What You'll Learn

Drill holes at crack ends, cut groove along crack, then weld

To fix a crack in an aluminium boat, you should first drill small holes at each end of the crack. This is done to prevent the crack from extending further due to the heat from the welding arc. The holes should be drilled with a skinny wheel or a bolt hole with no sharp edges to avoid tearing.

Next, use a skinny wheel to cut a groove along the length of the crack. This will make it easier to weld the crack shut. Once the groove is cut, you can begin the welding process.

It is important to note that the type of welding used will depend on whether the boat is welded or riveted together. If the boat is welded, you can use any type of welding to repair the crack. If it is riveted, TIG welding is recommended to avoid damaging the seal.

Additionally, the type of filler used for welding will depend on whether the boat is anodized. For anodized aluminium, use 5356 filler, and for non-anodized aluminium, use 4043 filler.

Rent Paddle Boats on Wallkill River: Best Locations

You may want to see also

Use marine epoxy and a lot of crap weld

To fix a crack in an aluminium boat using marine epoxy and a lot of crap weld, follow these steps:

First, you need to prepare the area to be repaired. Clean and prep the surfaces on both the inside and outside of the crack. Use a grinder to clean the area down to bare aluminium. Drill a small hole at each end of the crack. Use a skinny wheel to cut a groove along the length of the crack.

Next, apply a "snake" of JB weld marine epoxy putty to the crack. Make the "snake" about 2 inches longer than the crack itself so that you have about an inch of overhang on either side. Knead the putty to activate it. Lay the "snake" and push it into place very evenly. It should ooze out of the crack and come out of the bottom of the boat, which is fine. Smooth out the epoxy putty from the inside of the boat, and then move to the outside and smooth out any excess. Allow the epoxy to cure fully, then sand it smooth.

After the first application of epoxy has cured, apply a second "snake" of epoxy on the outside of the crack. Smooth it out and let it cure.

Finally, prime and paint the fully cured and sanded repair.

This method may not last forever, but it can buy you a few more seasons for a low cost and is a good option if welding is not available. However, keep in mind that cracks in aluminium boats are often caused by stress, and a weld will provide a more permanent solution.

Timberland Boat Shoes: Styling Tips for a Smart Casual Look

You may want to see also

Use a boat repair kit with epoxy

Repairing cracks in an aluminium boat can be done in several ways, one of which is using a boat repair kit with epoxy. This method can be a temporary solution to buy you a few more seasons on the water, but it may not last forever. Here is a step-by-step guide on how to fix a crack in an aluminium boat using a boat repair kit with epoxy:

Step 1: Clean and Prepare the Crack

Before applying any epoxy, it is important to clean and prepare the surfaces around the crack. Use a grinder to clean the area down to bare aluminium, removing any paint, grease, or other contaminants. Ensure you work on both the inside and outside of the crack.

Step 2: Apply Epoxy Putty

Knead the two-part epoxy putty, which will activate and be ready for application. Apply a "snake" of the epoxy putty onto the crack, making it about 2 inches longer than the crack itself to ensure an inch of overhang on each side. Push the epoxy into the crack and smooth it out evenly, both from the inside and the outside. Allow the epoxy to cure fully.

Step 3: Sand and Apply a Second Layer

Once the first layer of epoxy has cured, sand it smooth. Then, apply a second "snake" of epoxy on the outside of the crack, again smoothing it out evenly. Let this second layer cure fully.

Step 4: Prime and Paint

After the epoxy has cured, prime and paint the repaired area. Sand the cured epoxy as needed to ensure a smooth surface for painting.

Tips and Tricks:

- Always wear gloves and eye protection when working with epoxy and other chemicals.

- Ensure proper ventilation during the repair process.

- Some epoxies can be applied in temperatures as low as 40°F (4°C), but it is important to store the epoxy cartridge at room temperature (60-90°F or 15-32°C) when not in use.

- For small pinholes or leaks, a simple epoxy sealant can be used without the need for a patch.

Finding the Last Owner of a Boat: A Step-by-Step Guide

You may want to see also

Use a brazing rod and a heat source

To fix a crack in an aluminium boat using a brazing rod and a heat source, follow these steps:

First, bring the boat onto land and place it on a flat surface. Remove any water, algae, and mud stains from the affected area using acetone and rags. Wear protective gear, such as a mask and gloves, when working with chemicals. If there are any inward dents in the metal, use an anvil and hammer to pound them out.

Next, determine the size of the crack. Measure the crack and use aluminium strips to create a container for the brazing rod. Apply adhesive to the tips of the strips and attach them to the base.

Now it's time to repair the crack. Create a V-shaped channel along the crack using a drill motor and a grinding cone. This will provide more area for the braze weld. Sand the area with 220-grit sandpaper, ensuring that it overlaps on all sides. Use a wire brush to scrape the area with crosshatch strokes, creating an uneven surface for better adhesion.

Finally, apply heat to the brazing rods using a consistent heat source such as a propane torch. The aluminium should be hot enough to melt the brazing rods and form a bond. Be careful not to apply too much heat, as it can damage the boat.

Another option for repairing cracks in aluminium boats is to use a TIG welder to weld aluminium sheets onto the crack. However, be cautious as welding can create stress points that may lead to future cracks.

Hydrofoils for Boats: Worth the Upgrade?

You may want to see also

Use a patch and rivets

If your aluminium boat is riveted, then you should use a patch and rivets to fix a crack.

First, bring the boat onto land and place it on a flat surface. If possible, position the boat so that the crack is facing upwards. Clean the area with acetone and rags, removing water, algae and mud stains. Wear a mask and gloves for protection.

Next, determine the size of the crack. Measure it, then use aluminium strips to create a container for the brazen rod to settle in. Apply adhesive to the tips and affix it to the base.

Now it's time to repair the crack. Create a v-shaped channel with a drill motor and a grinding cone. Sand the area with 220-grit sandpaper, ensuring it overlaps on every side. Use a wire brush to scrape the area with crosshatch strokes, which will ensure an uneven area on the surface.

Finally, use a consistent heat source, such as a propane torch, to fix the brazen rods to the sides. You can also use a TIG welder to weld aluminium sheets onto the crack.

How Jet Screws Propel Boat Engines Efficiently

You may want to see also

Frequently asked questions

The best way to fix a crack in an aluminium boat is to weld it. If you are not equipped to weld yourself, you can take the boat to a welding shop.

If welding is not an option, you can use epoxy to repair the crack. Epoxy repair kits are rising in popularity due to their ease of use and availability.

First, bring the boat onto land and clean the area around the crack. Then, determine the size of the crack and use aluminium strips to create a container for the brazen rod to settle in. Apply adhesive to the tips of the strips and attach them to the base. Next, create a v-shaped channel with a drill motor and a grinding cone. Sand the area with 220-grit sandpaper and use a wire brush to scrape the area. Finally, use a heat source such as a propane torch to fix the brazen rods to the sides.