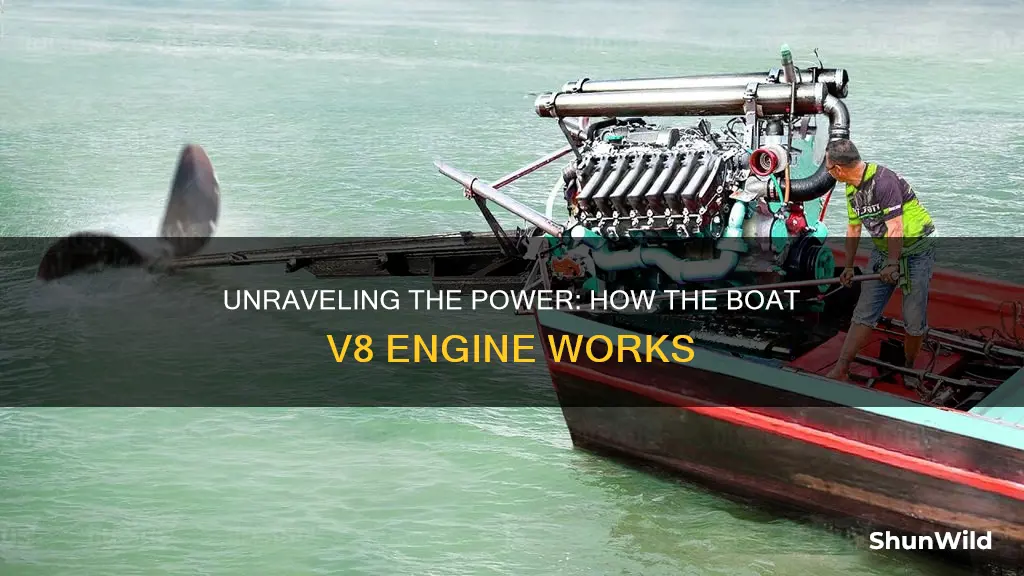

The V8 engine in boats is a powerful and efficient propulsion system that utilizes a unique design to generate thrust. This technology is a marvel of engineering, combining eight cylinders arranged in a V-shape to create a compact and lightweight power source. The V8 engine operates by compressing air and fuel, igniting the mixture in each cylinder, and converting the resulting energy into forward motion. This innovative design not only provides exceptional performance but also ensures a smooth and quiet ride, making it a popular choice for recreational and commercial boating applications. Understanding the mechanics of the V8 engine is essential for boat owners and enthusiasts to appreciate the technology behind this impressive marine propulsion system.

What You'll Learn

- Engine Architecture: V8 boat engines have a unique layout with multiple cylinders

- Fuel Injection: Precision fuel delivery ensures optimal combustion and performance

- Ignition System: Spark plugs ignite the air-fuel mixture, initiating the power stroke

- Cooling System: Efficient cooling maintains engine temperature, preventing overheating during operation

- Exhaust System: Designed to expel combustion gases, ensuring efficient power generation

Engine Architecture: V8 boat engines have a unique layout with multiple cylinders

The V8 engine architecture is a distinctive feature of boat engines, offering a unique layout that sets it apart from other marine propulsion systems. This design is characterized by its eight cylinders arranged in two rows, forming a 'V' shape, hence the name 'V8'. Each cylinder is positioned at an angle, typically 90 degrees, to its neighboring cylinder, creating a compact and efficient layout. This arrangement allows for a shorter engine length compared to straight-line configurations, making it ideal for boats where space is a premium.

In a V8 engine, the cylinders are connected to a common crankshaft, which is a vital component responsible for converting the reciprocating motion of the pistons into rotational motion. The crankshaft's design is crucial, as it must handle the simultaneous movement of multiple pistons, ensuring smooth power delivery. The engine's layout also includes a timing system, which synchronizes the opening and closing of the valves, allowing for efficient intake and exhaust of air-fuel mixtures.

One of the key advantages of the V8 layout is the even distribution of weight and mass. With cylinders positioned at an angle, the engine's center of gravity is lower, contributing to better handling and stability on the water. This design also reduces vibration, providing a smoother operation and minimizing fatigue on the boat's structure.

The V8 engine's architecture also influences its performance characteristics. With eight cylinders, the engine offers a balanced power output, providing a smooth and responsive acceleration. This configuration allows for efficient combustion, as the air-fuel mixture can be evenly distributed across the cylinders, resulting in optimal power generation.

Furthermore, the V8 layout facilitates easy maintenance and access to engine components. The angled cylinders provide a clear view of the engine's internal workings, making it simpler for technicians to perform routine checks and repairs. This accessibility is particularly beneficial for boat owners and maintenance teams, ensuring quick response times for any potential issues.

Lake Ray Hubbard: Boat Ramps Availability and Accessibility

You may want to see also

Fuel Injection: Precision fuel delivery ensures optimal combustion and performance

Fuel injection is a critical component in the operation of a boat's V8 engine, playing a pivotal role in achieving optimal performance and efficient combustion. This system is designed to precisely deliver fuel to the engine's cylinders, ensuring a balanced and controlled combustion process. The primary objective of fuel injection is to provide the engine with the exact amount of fuel required at any given moment, taking into account various factors such as engine speed, load, and temperature. This level of precision is crucial for maximizing power output while maintaining fuel efficiency.

In a V8 engine, fuel injection operates by using an intricate network of injectors strategically positioned near the engine's cylinders. These injectors are responsible for spraying a fine mist of fuel into the combustion chamber, ensuring complete mixing with the air-fuel mixture. The timing and amount of fuel delivered are precisely controlled by the engine's electronic control unit (ECU), which continuously monitors engine parameters and adjusts the fuel injection accordingly. This real-time adjustment capability allows for rapid response to changes in engine load, ensuring that the engine always receives the optimal fuel-air mixture.

The precision of fuel delivery is achieved through a process known as electronic fuel injection (EFI). EFI systems use sensors to measure various engine parameters, such as air intake, temperature, and pressure. This data is then fed to the ECU, which calculates the precise fuel injection requirements. The ECU sends signals to the injectors, instructing them to release the exact amount of fuel needed for efficient combustion. This electronic control ensures that the engine receives the right amount of fuel, even under varying operating conditions, resulting in improved performance and reduced emissions.

One of the key advantages of fuel injection is its ability to optimize combustion. By delivering fuel directly to the combustion chamber, the system ensures that the fuel-air mixture is thoroughly mixed, promoting complete combustion. This results in increased power output and improved engine efficiency. Additionally, fuel injection helps to maintain a consistent engine performance across a wide range of speeds and loads, providing a smooth and responsive driving experience.

In summary, fuel injection is a sophisticated system that ensures the precise delivery of fuel to a boat's V8 engine. By utilizing electronic control and strategic injector placement, it achieves optimal combustion, enhances performance, and contributes to the overall efficiency of the engine. This technology is a testament to the continuous advancements in marine engine design, allowing boats to operate with improved power, responsiveness, and environmental friendliness.

Boat Windshield Repairs: Where to Go?

You may want to see also

Ignition System: Spark plugs ignite the air-fuel mixture, initiating the power stroke

The ignition system in a boat V8 engine is a critical component responsible for initiating the combustion process, which ultimately drives the engine's power stroke. This system is designed to deliver a precise and controlled spark at the right moment, ensuring efficient and powerful performance. Here's a detailed breakdown of how it works:

Spark Plugs and Their Role: At the heart of the ignition system are the spark plugs, which are specialized electrodes that create a high-voltage spark. These plugs are strategically positioned within the engine's cylinders, typically at the top of the combustion chamber. When the engine's control unit (ECU) sends a signal, the spark plugs ignite the air-fuel mixture, which is a carefully balanced blend of air and fuel injected into the cylinder. This spark is the initial step in the combustion process, creating a controlled explosion that drives the pistons downward, generating power.

Ignition Timing: Timing is crucial in the ignition process. The ECU precisely controls the timing of the spark by monitoring various engine parameters such as speed, load, and temperature. This timing is critical because it ensures that the spark occurs when the air-fuel mixture is most receptive to ignition, optimizing combustion. The ideal spark timing is when the piston is at the top of its compression stroke, creating maximum pressure for efficient power generation.

High-Voltage Spark Creation: To create the spark, the ignition system uses a high-voltage current, typically generated by a coil or ignition module. This high voltage is then stepped down to a lower voltage suitable for the spark plug electrodes. The spark plug's electrodes are designed to withstand the extreme temperatures and pressures within the cylinder. When the current flows through the electrodes, it creates a gap, and the rapid ionization of the air-fuel mixture within this gap produces the visible spark.

Ignition System Components: The ignition system consists of several components working together. These include the ignition coil, which transforms the low voltage from the battery into high voltage, and the ignition module or control unit, which manages the timing and delivery of the spark. Additionally, there are ignition wires that carry the high-voltage spark from the coil to the spark plugs, ensuring a reliable and efficient spark delivery.

Power Stroke Initiation: With the spark plug igniting the air-fuel mixture, the power stroke begins. The rapid combustion of the mixture causes a controlled explosion, pushing the pistons downward with immense force. This power stroke is the primary source of the engine's power, and the efficiency of this process directly impacts the engine's performance and fuel consumption. The ignition system's precision and reliability are vital to ensuring that each cylinder fires consistently, contributing to the overall smoothness and power of the boat V8 engine.

Lights on Jon Boats: Texas Law Requirements

You may want to see also

Cooling System: Efficient cooling maintains engine temperature, preventing overheating during operation

The cooling system is a critical component of any V8 engine, especially in the context of boats, where the engine operates in a unique environment. Efficient cooling is essential to ensure optimal performance and longevity of the engine, preventing overheating, which can lead to severe damage. The primary goal of the cooling system is to maintain the engine's operating temperature within a safe range, allowing for efficient combustion and power generation.

In a boat V8 engine, the cooling system typically involves a combination of several key elements. Firstly, the engine block is designed with a network of passages and channels that allow coolant to flow through it. This coolant is usually a mixture of water and a special additive that prevents freezing and corrosion. As the engine operates, the coolant absorbs heat from the engine block, carrying it away from the critical components.

The coolant then enters the radiator, a vital component of the cooling system. The radiator is often located near the front of the boat and is designed to facilitate efficient heat exchange with the surrounding air. Coolant passes through the radiator's core, where it is cooled by the airflow generated by the boat's movement. This cooling process is crucial as it helps maintain the engine's temperature, especially during high-performance operations or when the boat is stationary and not moving.

Additionally, some boat engines incorporate a cooling fan system to enhance heat dissipation. These fans are strategically positioned to direct cool air onto the engine block and radiator, further improving the cooling efficiency. The fans are often electrically or hydraulically powered, allowing for precise control of their speed and operation based on engine temperature.

Effective cooling is vital to the overall performance and reliability of the boat V8 engine. It ensures that the engine operates at its optimal temperature, preventing overheating, which can cause engine damage, reduced power output, and even catastrophic failure. By maintaining the engine's temperature, the cooling system contributes to the longevity of the engine and the overall safety of the boat.

Showering on a Boat: A Step-by-Step Guide

You may want to see also

Exhaust System: Designed to expel combustion gases, ensuring efficient power generation

The exhaust system plays a critical role in the performance and efficiency of a boat's V8 engine. Its primary function is to efficiently expel the hot, high-pressure combustion gases produced during the engine's operation, ensuring optimal power generation and overall engine health. This system is designed to manage the flow of gases from the engine's cylinders to the atmosphere, minimizing back pressure and maximizing power output.

In a V8 engine, the exhaust system typically consists of several components working in harmony. The first component is the cylinder head, which houses the valves and spark plugs. After the combustion process, the exhaust valves open to release the hot gases into the exhaust manifold. The exhaust manifold is a cast-iron or stainless steel pipe that collects the gases from all eight cylinders and directs them towards the next component.

The next crucial part is the catalytic converter, an essential element in modern exhaust systems. This device is designed to reduce harmful emissions by converting toxic gases like carbon monoxide and nitrogen oxides into less harmful substances. It does this through a series of chemical reactions, ensuring that the exhaust gases meet environmental standards before they are released into the atmosphere.

Following the catalytic converter, the exhaust system continues with a series of pipes and mufflers. Mufflers are designed to reduce engine noise by dampening the sound of the exhaust gases. They achieve this by using baffles and chambers to slow down and disperse the gases, minimizing the loud, high-pitched noise typically associated with powerful engines.

Finally, the exhaust system terminates with a tailpipe, which is the visible end of the system. This pipe is designed to efficiently direct the exhaust gases away from the boat, ensuring that the engine's power is not compromised by excessive back pressure. The entire system is carefully engineered to maintain a balance between power generation and environmental considerations, making it a vital component of any high-performance boat engine.

Best Wheel Chocks for Boat Trailers: Safe and Secure

You may want to see also

Frequently asked questions

The V8 engine is a type of internal combustion engine commonly used in boats and other watercraft. It operates on the principle of four-stroke or four-cycle combustion, where a piston moves up and down in a cylinder, driven by a camshaft. The process involves four distinct strokes: intake, compression, power, and exhaust. During the intake stroke, the piston moves downward, allowing a mixture of air and fuel to enter the cylinder. The compression stroke then compresses this mixture, increasing its pressure and temperature. The power stroke follows, where the fuel-air mixture is ignited, causing a rapid expansion of gases that pushes the piston downward, generating power. Finally, the exhaust stroke expels the combustion gases from the cylinder through an exhaust valve. This process is repeated for each cylinder in the V8 configuration, providing efficient power generation for the boat's propulsion system.

The V8 engine offers several advantages for boating applications. Firstly, its compact design allows for a smaller engine package, making it suitable for boats with limited space. The V8 configuration also provides excellent power-to-weight ratios, resulting in better performance and acceleration. With eight cylinders, the engine can deliver a smooth and consistent power output, ensuring a responsive and efficient boating experience. Additionally, the V8 engine's ability to produce high torque at lower RPMs (revolutions per minute) makes it well-suited for cruising and maintaining speed in various water conditions.

The camshaft plays a critical role in the operation of a V8 boat engine. It is responsible for controlling the opening and closing of the engine's valves (intake and exhaust) at precise timings. The camshaft is driven by a timing belt or chain, which ensures synchronized movement with the crankshaft. As the crankshaft rotates, it triggers the camshaft to lift the valves at specific points during the engine cycle. This action allows the intake valves to open during the intake stroke, letting the fuel-air mixture into the cylinder, and the exhaust valves to open during the exhaust stroke, releasing the combustion gases. The camshaft's precise control over valve timing is essential for efficient combustion, power generation, and overall engine performance.