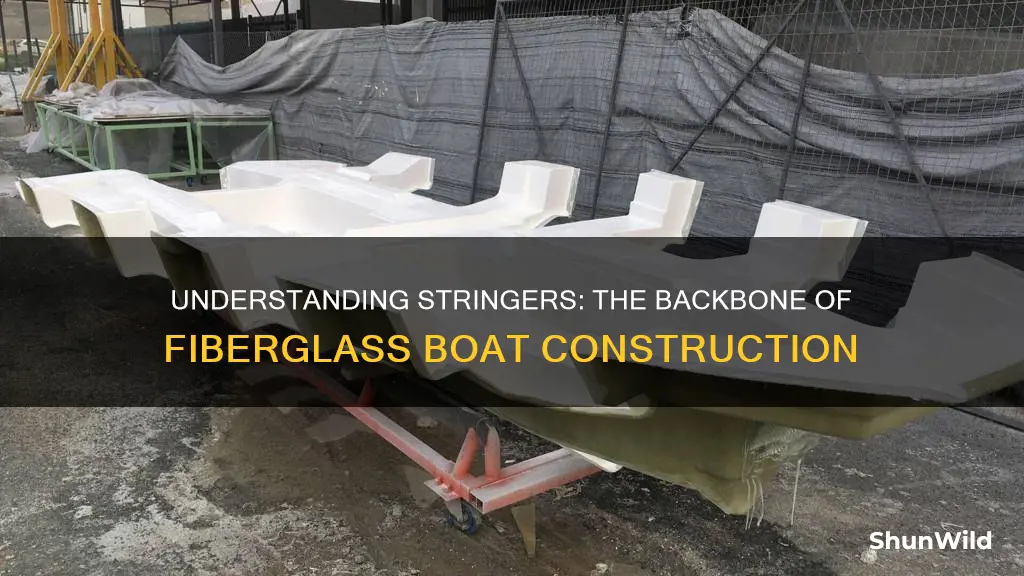

Stringers are an essential component of fiberglass boats, providing structural support and reinforcement to the hull. These are typically thin, rigid members made of materials like wood, aluminum, or even fiberglass, strategically placed along the length of the boat to distribute stress and enhance the boat's overall strength. They run from the keel or bottom of the boat up to the gunwales or sides, providing a sturdy framework that helps maintain the boat's shape and integrity. Stringers are crucial in ensuring the boat can withstand various loads and environmental conditions, making them a vital part of the boat's construction and safety.

What You'll Learn

- Construction: Stringers are internal frames made of wood or metal, providing structural support

- Reinforcement: They reinforce the hull, preventing sagging and ensuring boat rigidity

- Material: Typically made of wood, stringers can be reinforced with fiberglass for added strength

- Placement: Strategically placed along the length of the boat, they run from bow to stern

- Repair: Replacing damaged stringers is a specialized task, often requiring professional boat repair skills

Construction: Stringers are internal frames made of wood or metal, providing structural support

Stringers play a crucial role in the construction of fiberglass boats, serving as internal frames that provide structural integrity and support. These stringers are typically made of wood or metal and are strategically placed within the boat's hull to reinforce key areas. The primary purpose of stringers is to distribute the boat's weight evenly, ensuring that the hull remains rigid and stable, even when subjected to various loads and environmental conditions.

In the construction process, stringers are carefully positioned along the length of the boat, often running from the keel to the gunwale. They are designed to withstand the stresses of the boat's structure, including the weight of the vessel, passengers, fuel, and equipment. By providing a strong backbone, stringers prevent the hull from sagging or deforming, maintaining its shape and stability. This is particularly important in fiberglass boats, as the material is lightweight yet requires robust internal structures to ensure longevity and safety.

The design and placement of stringers can vary depending on the specific requirements of the boat. For instance, in larger vessels, multiple stringers may be used to create a grid-like pattern, offering enhanced structural support. These stringers can be spaced at regular intervals or positioned to target areas of higher stress, such as near the engine or in the bow and stern regions. The choice of material for stringers is also crucial; wood stringers offer a traditional and cost-effective solution, while metal stringers provide increased strength and durability, especially in high-performance or heavy-duty boats.

During the construction phase, skilled craftsmen carefully attach the stringers to the hull using appropriate fasteners. This process requires precision and attention to detail to ensure a secure and seamless integration. The stringers are often bonded or glued to the hull, creating a unified and robust structure. Proper installation of stringers is essential to guarantee the boat's overall strength and safety, as it directly impacts the vessel's ability to withstand various forces and maintain its structural integrity over time.

In summary, stringers are integral components of fiberglass boat construction, providing the necessary structural support to ensure the vessel's stability and longevity. Their strategic placement and robust design contribute to the boat's overall strength, allowing it to handle various loads and environmental challenges. Understanding the role and importance of stringers is essential for boat builders and enthusiasts, as it highlights the intricate craftsmanship required to create a safe and durable fiberglass boat.

Watkins 33: Ocean-Ready or Just a Lake Cruiser?

You may want to see also

Reinforcement: They reinforce the hull, preventing sagging and ensuring boat rigidity

Stringers are an essential component in the construction of fiberglass boats, providing structural integrity and reinforcement to the hull. These structural elements are typically long, narrow strips of material, often made of fiberglass or other composite materials, that run along the length of the boat's hull. The primary purpose of stringers is to provide additional support and strength to the boat's structure, especially in areas prone to sagging or stress.

In a fiberglass boat, the hull is a complex structure, and it requires careful reinforcement to ensure it can withstand the forces exerted by water and the boat's weight. Stringers are strategically placed within the hull to address specific areas of concern. These areas often include the midsection, where the boat's weight is concentrated, and the chines, which are the curved sections where the hull meets the gunwales. By incorporating stringers in these critical areas, boat builders can effectively combat sagging and maintain the hull's rigidity.

The design and placement of stringers are crucial to their effectiveness. They are typically positioned at regular intervals along the hull, forming a grid-like pattern. This arrangement allows for even distribution of stress and provides a robust framework for the boat's structure. Stringers can be attached to the hull in various ways, such as being bonded directly to the gelcoat or integrated into the mold during the manufacturing process. This ensures a seamless and strong connection between the stringers and the hull.

One of the key advantages of using stringers is their ability to distribute loads evenly. When a boat is in use, various forces act upon it, including the weight of passengers, fuel, and equipment. Stringers help to absorb and transfer these loads, preventing excessive stress on specific areas of the hull. This even distribution of weight is vital for maintaining the boat's structural integrity and ensuring a safe and stable ride.

Furthermore, stringers contribute to the overall longevity of the boat. By reinforcing the hull, they help prevent sagging, which can lead to structural weaknesses over time. Sagging can cause the hull to become misshapen, affecting its performance and aesthetics. With proper reinforcement, stringers ensure that the boat retains its original shape and structural stability, even after prolonged use and exposure to the elements. This is particularly important for fiberglass boats, as they are susceptible to damage from UV rays and environmental factors.

Salvaging a Flooded Boat Engine: Steps to Take

You may want to see also

Material: Typically made of wood, stringers can be reinforced with fiberglass for added strength

Stringers are an essential component of a fiberglass boat's structure, providing structural integrity and support to the hull. These stringers are typically made of wood, a traditional and cost-effective material for boat building. Wood has been a popular choice for stringers due to its natural strength and ability to be easily shaped and joined. The wooden stringers are often constructed with a series of longitudinal members running along the length of the boat, providing a strong backbone to the hull. This design helps distribute the stress and loads acting on the boat, ensuring it can withstand various conditions on the water.

In some cases, to enhance the strength and durability of the stringers, they can be reinforced with fiberglass. Fiberglass, a composite material made of glass fibers and a resin matrix, offers excellent strength-to-weight ratios and is highly resistant to corrosion and impact. By incorporating fiberglass into the stringer design, boat builders can create a more robust and lightweight structure. The fiberglass reinforcement can be applied in various ways, such as wrapping the stringers with layers of fiberglass cloth and resin or embedding fiberglass strands within the wooden structure. This process adds an extra layer of protection against wear and tear, making the stringers more capable of withstanding the stresses of marine environments.

The use of wood and fiberglass in stringers is a strategic choice, as it combines the natural strength and workability of wood with the added benefits of fiberglass's durability and corrosion resistance. This combination ensures that the stringers can provide the necessary support while also being able to withstand the harsh conditions of saltwater and UV exposure. Properly designed and constructed stringers, whether made entirely of wood or reinforced with fiberglass, play a critical role in maintaining the structural integrity of the boat, ensuring its stability, and contributing to its overall safety and longevity.

In summary, stringers in a fiberglass boat are typically constructed from wood, a traditional and strong material, and can be further reinforced with fiberglass for enhanced strength and durability. This combination of materials allows for the creation of a robust and lightweight structure, capable of withstanding the challenges of marine environments. Understanding the composition and importance of stringers is key to appreciating the overall design and safety features of a fiberglass boat.

Removing Interior Boat Siding: A Step-by-Step Guide

You may want to see also

Placement: Strategically placed along the length of the boat, they run from bow to stern

Stringers are an essential component of a fiberglass boat's structural integrity, providing strength and stability to the hull. These structural elements are typically long, thin metal or wooden frames that run along the length of the boat, from the bow (front) to the stern (back). The primary purpose of stringers is to distribute the boat's weight evenly and reinforce the hull, especially in areas prone to stress and pressure.

In a fiberglass boat, stringers are strategically placed to provide additional support to the hull, particularly in areas where the boat's design may have thinner or weaker structural elements. They are often used in conjunction with other structural components like frames, bulkheads, and stringer knees to create a robust and durable boat. The placement of stringers is critical to ensure optimal performance and safety.

When designing the placement of stringers, boat builders consider various factors. Firstly, the length and width of the boat determine the number and spacing of stringers. Longer boats may require more stringers to maintain structural integrity, while wider boats might have stringers spaced closer together to handle the additional width. Secondly, areas with higher stress, such as the transom (rear) or the sides near the waterline, often receive additional stringers for reinforcement.

The stringers are typically attached to the hull using specialized fasteners or bonded directly to the fiberglass using appropriate adhesives. This ensures a strong and secure connection, allowing the stringers to effectively transfer the boat's weight and forces. Proper placement and secure attachment of stringers are crucial to the boat's overall strength and longevity.

In summary, stringers in a fiberglass boat are strategically positioned along the hull's length, providing essential structural support. Their placement is carefully considered to reinforce weak areas and distribute weight evenly. By incorporating stringers into the boat's design, manufacturers can ensure a sturdy and reliable vessel capable of withstanding various stresses and pressures encountered during operation.

Troubleshoot Your Boat: Diagnosing a Bad Starter

You may want to see also

Repair: Replacing damaged stringers is a specialized task, often requiring professional boat repair skills

Stringers are an essential component of a fiberglass boat's structure, providing structural integrity and support to the hull. They are typically long, narrow frames made of wood or metal that run along the bottom of the boat, often in a longitudinal direction. These stringers are crucial in distributing the boat's weight and providing a sturdy foundation for the hull. Over time, stringers can become damaged due to various factors such as impact, corrosion, or simply the aging process. When this happens, it is crucial to address the issue promptly to ensure the boat's safety and longevity.

Replacing damaged stringers in a fiberglass boat is a specialized repair task that requires a high level of skill and expertise. This process involves several intricate steps and should only be attempted by professionals with experience in boat repair. Here's an overview of the repair process:

Assessment and Preparation: The first step is to thoroughly inspect the boat to identify the extent of the damage. This includes examining the stringers for any cracks, holes, or structural deformations. Professionals will also assess the surrounding areas to ensure that the damage is isolated and won't affect other parts of the boat. Once the assessment is complete, the repair team will prepare the work area, ensuring it is clean and safe.

Removing the Old Stringer: After the assessment, the damaged stringer needs to be carefully removed. This process requires precision to avoid causing further damage to the hull. Professionals will use specialized tools to cut and remove the old stringer, ensuring that the surrounding fiberglass is not compromised. It is crucial to handle this step with care to maintain the structural integrity of the boat.

Fabrication of the New Stringer: With the old stringer removed, the next step is to create a new one. This involves taking precise measurements and using the appropriate materials, often a similar type of wood or metal to the original. The new stringer must be crafted to fit perfectly within the boat's structure, providing the necessary support. This step requires a high level of craftsmanship and attention to detail.

Reinforcement and Bonding: Once the new stringer is fabricated, it needs to be securely attached to the hull. This involves reinforcing the bond between the stringer and the fiberglass using specialized adhesives and bonding techniques. Professionals will ensure that the new stringer is firmly in place, providing the required structural support. Proper bonding is critical to the success of the repair.

Finishing and Testing: After the new stringer is installed, the repair area is carefully finished to match the surrounding hull. This may involve sanding, filling, and painting to ensure a seamless blend. Finally, the boat undergoes thorough testing to ensure the structural integrity of the repair. Professionals will perform load tests and inspections to verify that the stringers can withstand the expected stresses.

Replacing damaged stringers is a complex process that demands a high level of skill and knowledge. It is a specialized task that should only be undertaken by experienced boat repair professionals to ensure the boat's safety and longevity. Proper repair techniques and materials are essential to maintaining the structural integrity of the fiberglass boat.

Powering the Waves: Unveiling the Mechanics of Electric Boats

You may want to see also

Frequently asked questions

Stringers are structural components typically made of wood or aluminum and are an essential part of a boat's hull design. They run longitudinally along the bottom of the boat, providing additional strength and support to the hull. Stringers help distribute the weight of the boat and its contents evenly, ensuring structural integrity and stability.

In a fiberglass boat, stringers play a crucial role in reinforcing the hull. Fiberglass is a lightweight and durable material, but it can be prone to structural weaknesses without proper reinforcement. Stringers add strength to the hull, especially in areas that bear significant loads, such as the bow, stern, and sides. They help prevent hull distortion, cracking, and damage from impacts or heavy loads.

The installation process varies depending on the boat's design and manufacturer's specifications. Typically, stringers are fitted into pre-drilled holes or slots in the hull. They are then secured using screws, bolts, or other fastening methods. Some boats may have stringers that are permanently bonded to the hull using specialized adhesives, ensuring a strong and durable connection.

Yes, stringers can be repaired or replaced if they become damaged or worn over time. If a stringer is cracked or broken, it can be carefully removed, repaired, or replaced. This process often requires specialized tools and knowledge of boat construction. It is recommended to consult a professional boat repair technician or the boat manufacturer's guidelines for proper repair procedures.

Stringers are commonly used in various boat types, especially those with a deep-v hull design, such as powerboats, sailboats, and fishing boats. However, not all boats utilize stringers. Some smaller, shallower-hulled boats may rely on other structural elements or composite materials for strength. The use of stringers depends on the boat's size, intended purpose, and design philosophy.