Flooding a boat engine is a common cause of boat breakdowns, especially in cold weather. If your boat engine has flooded with seawater, it's important to identify and remedy the source of the flooding before attempting to start the engine again. To get your engine running again, you'll need to drain the oil and replace it with a fresh filter, then crank the engine with the accelerator pedal pushed to the floor. If your engine has been flooded for more than 24 hours, you may need to take additional steps to prevent corrosion.

What to do when you flood a boat engine

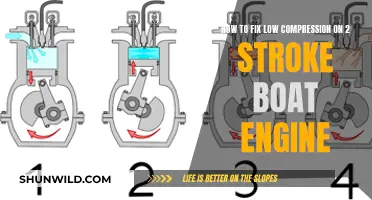

| Characteristics | Values |

|---|---|

| How to identify a flooded engine | A strong smell of gasoline, wet spark plugs, and difficulty restarting the engine |

| How to prevent engine flooding | Avoid leaving the choke on for long periods and regularly inspect the compression system |

| How to fix a flooded engine | Open the throttle wide with no choke, wait a few seconds, then try to start the engine |

| How long to wait before attempting to start a flooded engine | 10-20 minutes, or 30+ minutes depending on the severity of the problem |

What You'll Learn

Identify the source of flooding and fix it

If your boat engine is flooded with seawater, you must identify and fix the source of flooding before operating the engine again. Here are the steps to identify and address the issue:

Step 1: Understand the Causes of Flooding

Firstly, understand the potential causes of seawater flooding in boat engines. This can occur due to incorrect installation, a malfunctioning anti-siphon valve, or excessive cranking while bleeding the fuel system. Addressing these issues is crucial before proceeding.

Step 2: Take Initial Precautions

Before attempting any repairs, open or turn off the start battery switch and shut off the fuel supply. Put on safety gear, such as safety glasses, to protect yourself during the process.

Step 3: Remove Injectors or Glow Plugs

If your setup includes injectors or glow plugs, remove them carefully. Cover the exposed holes with rags to ensure they remain clear and unobstructed. This step is important to prevent any further issues.

Step 4: Manually Turn Over the Engine

Engage a socket wrench with the alternator pulley to manually turn over the engine. This process is often called "barring." You may need to press down on the slack side of the belt to keep it from slipping during this step. Ensure you make at least two full revolutions slowly.

Step 5: Check for Resistance

If you feel any resistance while turning the engine, stop immediately. Resistance could indicate that a valve is seized. If the engine turns freely, you can proceed to the next step.

Step 6: Crank the Engine

Use the starter to crank the engine for approximately 5 to 10 seconds. If the engine turns over without issues, you can proceed to reinstall the injectors or glow plugs.

Step 7: Drain and Replace Oil and Filter

Drain the oil and replace both the oil and the filter. Removing the valve-cover oil-fill cap will allow water vapour to escape more easily. This step is crucial to prevent water damage to the engine.

Step 8: Start the Engine and Let it Idle

After changing the oil and filter, start the engine and let it run for about five minutes. Then, perform another oil and filter change. Check the appearance of the oil; if it appears milky, it could indicate water leakage past the piston rings and into the crankcase.

Step 9: Repeat Oil Change and Run the Engine

After the initial oil change and idling, repeat the process. Run the engine under moderate load, this time with the valve-cover cap in place. Aim to achieve an oil temperature of 200 degrees Fahrenheit or as close as possible.

Step 10: Final Oil Change

Perform one last oil change after the engine has run under moderate load. At this point, the oil should no longer have a milky appearance. Run the engine normally and check the oil level and quality frequently for any signs of moisture.

Step 11: Address Cylinder Water Ingress

If water has entered the cylinders, remove the injectors and turn them over by hand. This step is crucial to prevent water-related damage to the engine.

Step 12: Check for Corrosion

If the engine has been flooded with water for more than 24 hours, corrosion may have already set in. In this case, you will need to remove the valve cover and inspect for visible damage to the valve train.

Step 13: Apply Kerosene or Similar Fluid

Pour a generous amount of kerosene, light motor oil, or automatic transmission fluid over the valve train. Tap each rocker arm over the valve with a light plastic-head hammer. Observe the movement of the valves and rocker arms. If any components seem sticky or don't move immediately, there may be valve, valve train, or piston damage.

Step 14: Make a Decision on Cylinder Head Removal

If all valves and rockers move freely and the engine turns freely when barred over, disable the run function to prevent accidental engine startup. Turn on the battery switch and spray fogging oil into the air intake while cranking the engine for 30 seconds.

By following these steps, you can effectively identify and address the source of flooding in your boat engine. It is important to work systematically and take the necessary precautions to ensure a safe and effective resolution.

The Boat's Journey: Frodo, Gandalf, and Their Escape

You may want to see also

Disconnect the gas line and turn the engine over

Disconnecting the gas line and turning the engine over is a simple fix for a flooded boat engine. This is what you should do:

Firstly, disconnect the gas line where it attaches to the motor. Keep cranking the engine and trying to start it. Eventually, you will hear the engine fire as the extra gas is released. As soon as the engine fires, reconnect the fuel line.

If you are unsure whether your engine is flooded, there are a few signs to look out for. Firstly, a flooded engine will often make a loud, high-pitched whirring sound as it tries to start up but can't. This is caused by an excess of fuel, which requires more air to clear it and "dry" the spark plugs. You may also notice a strong smell of petrol, as the fuel sits in the engine.

If your engine has been flooded with seawater, the steps are a little different. Firstly, open or turn off the start battery switch, and then turn off the fuel supply. Put on safety glasses, and remove the injectors or glow plugs. Cover the exposed holes with rags, and then turn over the engine manually, engaging a socket wrench with the alternator pulley. Make at least two full revolutions slowly. If the engine turns freely, you can then crank the engine using the starter for five to ten seconds, and then reinstall the injectors or glow plugs.

If your engine is flooded with water, this could cause serious damage, so it's important to get it checked out by a professional.

Best Places for Boat Living: An Idyllic Guide

You may want to see also

Remove the plugs and turn over by hand

If your boat engine has flooded with seawater, it is important to act quickly to prevent irreversible damage. The first step is to identify and remedy the source of the flooding. If the flooding is due to improper installation, a malfunctioning anti-siphon valve, or excessive cranking while bleeding the fuel system, address these issues immediately.

Once the source of the flooding has been addressed, it is time to remove the plugs and turn over the engine manually. This process, also known as "barring," involves engaging a socket wrench with the alternator pulley. You may need to press down on the slack side of the belt to keep it from slipping. Make at least two full revolutions slowly, and if you feel any resistance, stop, as a valve may be seized.

If the engine turns freely, you can proceed to the next step. Reinstall the plugs, then crank the engine using the starter for five to ten seconds. After cranking, drain the oil and replace it along with the filter. It is important to check the appearance of the oil, as milky oil could indicate that water has leaked past the piston rings and into the crankcase.

If the engine has been flooded with seawater for more than 24 hours, additional steps may be necessary. Corrosion may have already set in, so it is important to inspect the valve train for visible damage. If the valves and rocker arms do not move freely, there is a possibility of valve, valve train, and piston damage, and a decision must be made whether to remove the cylinder head.

Best Snacks for a Boat Trip: Quick, Easy, Delicious

You may want to see also

Dry the plugs and reinstall

If your spark plugs are wet, you can dry them and reinstall them. If you have a cigarette lighter, you can heat the plugs before replacing them. However, be sure to keep the cigarette lighter away from the fuel system and open spark plug points. Alternatively, you can dry them with compressed air or by laying them out in the sun.

If you have glow plugs, you can reinstall them after turning over the engine manually. This is often called 'barring'. To do this, engage a socket wrench with the alternator pulley. You may need to press down on the slack side of the belt to keep it from slipping. Make at least two full revolutions slowly. If you feel any resistance, stop, as a valve may have seized. If the engine turns freely, you can then crank the engine using the starter for five to ten seconds.

Boynton Beach Boat Parade: Where the Magic Begins

You may want to see also

Check the carburetor and fuel injectors

If your boat engine has flooded with seawater, it is important to identify and remedy the source of the flooding before operating the engine again. If the flooding has occurred within the past 24 hours, you can take the following steps to check the carburetor and fuel injectors:

Step 1:

Open or turn off the start battery switch and turn off the fuel supply. Put on safety glasses for protection.

Step 2:

Remove the injectors or glow plugs. Cover the exposed holes with rags and stay clear of them.

Step 3:

Turn over the engine manually, also known as "barring", by engaging a socket wrench with the alternator pulley. You may need to press down on the slack side of the belt to keep it from slipping. Make at least two full revolutions slowly. If you feel any resistance, stop, as a valve may be seized. If the engine turns freely, you can proceed to the next step.

Step 4:

Reinstall the injectors or glow plugs and crank the engine using the starter for 5 to 10 seconds.

Step 5:

Drain the oil and replace it with fresh oil and a new filter. Remove the valve-cover oil-fill cap to facilitate the escape of water vapour.

Step 6:

Start the engine and let it run for about five minutes. Then, drain and replace the oil and filter again. Check the appearance of the oil; if water has leaked past the piston rings and into the crankcase, the oil will appear milky.

Step 7:

Start the engine again and let it idle with no load for five minutes. After two no-load runs and oil changes, carry out a final oil change. Run the engine under a moderate load, with the valve-cover cap in place, aiming to achieve an oil temperature of 200 degrees Fahrenheit or as close to this as possible.

Step 8:

Check the oil frequently for any signs of moisture. If the engine has been flooded with seawater for more than 24 hours, corrosion may have set in, and additional steps will be necessary.

Winterizing Your Bass Boat: A Step-by-Step Guide

You may want to see also

Frequently asked questions

A strong smell of gasoline, wet spark plugs, and difficulty restarting the engine are signs of a flooded boat engine.

A flooded boat engine is caused by too much gasoline inside the combustion cylinder and not enough oxygen to burn all the gasoline. This can be due to bad spark plugs, a faulty cylinder compression system, or leaving the choke on for too long.

To fix a flooded boat engine, open the throttle wide (with no choke) and wait a few seconds before trying to start the engine. This will send air into the cylinder to compensate for the excess gasoline. If the spark plugs are soaking wet, dry them first before attempting to start the engine.

On average, 10-20 minutes is enough time for the gasoline to clear from a flooded boat engine. However, in more severe cases, you may need to wait 30 minutes or longer.

To prevent your boat engine from flooding, avoid leaving the choke on for extended periods of time. Regularly inspect your compression system and spark plugs to ensure they are functioning properly.