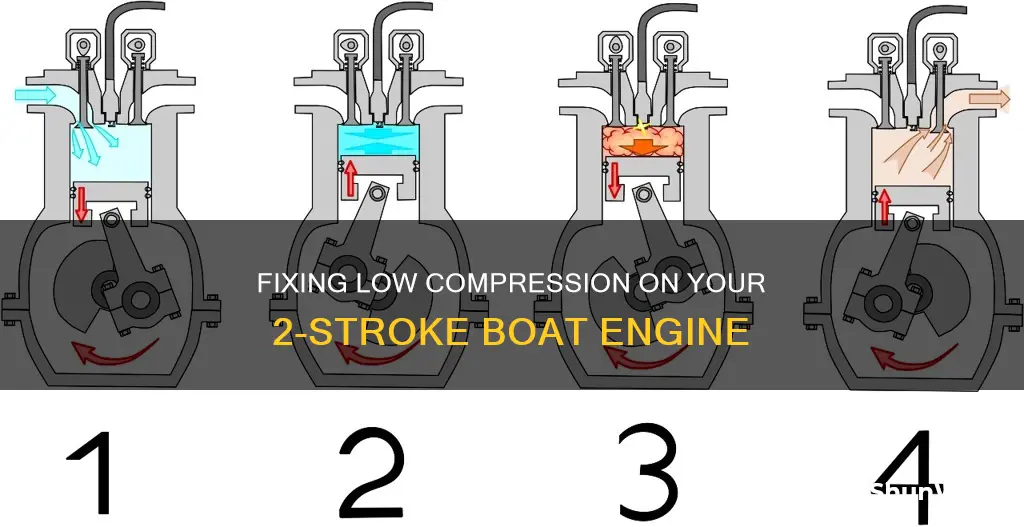

Low compression on a 2-stroke boat engine can be caused by a variety of issues, including problems with the piston or piston rings, head gasket failure, leaking head gasket, worn-out head gasket, carbon-clogged piston rings, broken or worn piston rings, valve issues, worn timing belt, worn camshaft lobe, and cracked cylinder wall. To fix low compression, it is important to identify the root cause and address it accordingly. This may involve replacing damaged parts, such as piston rings, gaskets, or piston, or making adjustments to the carburetor and ignition timing. Regular maintenance and inspection, proper lubrication, and using high-quality fuel can also help boost compression and prevent future issues.

Characteristics of Low Compression in a 2-Stroke Boat Engine and Their Solutions

| Characteristics | Values |

|---|---|

| Difficulty starting the engine | Multiple attempts to start the engine or failure to start altogether |

| Loss of power and performance | Decrease in acceleration, reduced top speed, or a general lack of power |

| Increased fuel consumption | Higher fuel consumption or decreased overall fuel efficiency |

| Root causes | Head gasket failure, leaking head gasket, worn-out head gasket, carbon-clogged piston rings, broken or worn piston rings, valve issues, damaged cylinder walls, etc. |

| Testing | Use a compression tester to detect the source of the problem |

| Solutions | Confirm low compression, identify the cause, replace damaged parts, and test the repair |

What You'll Learn

Check for a cracked piston

To check for a cracked piston, you'll need to disassemble the cylinder head. This includes removing the piston from the cylinder to check the piston rings. When you do this, be sure to cover the open cylinder to stop any debris from falling into the chamber.

The piston is the main moving component of your two-stroke engine. It is the part of the engine that moves up and down and turns the crank. The movement of the piston creates and releases pressure, also called compression.

If the piston is cracked or broken, it may not be turning the crankshaft fully. It could also not be extending or withdrawing into the cylinder properly. Both of these issues could cause a loss of compression and prevent the engine from running properly.

To check the piston, remove the cylinder head and piston from the cylinder. Be sure to cover the cylinder's opening.

A cracked piston is one of the most likely reasons why a two-stroke engine has lost compression. The piston creates the compression needed to run. If there is a crack in the piston, air can escape and cause a lack of compression.

If your engine will start but won't hold compression or sputters and dies when you accelerate, there's probably an issue with your piston.

Boat Insurance: Comprehensive Coverage Explained

You may want to see also

Check for a blown head gasket

A blown head gasket is a severely damaged or cracked gasket that is no longer doing its job. The head gasket’s main purpose is to create a seal between the engine block and the cylinder head. This seal contributes to the compression within the engine. A blown head gasket will allow air, oil, and fuel to escape the main engine chamber, causing a loss of compression.

There are several ways to check for a blown head gasket. One way is to remove the cylinder head and piston from the cylinder and inspect the head gasket. If the gasket is blown, you will notice that the metal piece is broken or cracked and may appear rusty. Another way to check for a blown head gasket is to inspect the spark plugs. If one or more spark plugs are significantly cleaner than the others, it may indicate a head gasket leak. Typically, you will get water entering the combustion chamber, and the residue on the spark plugs will be spotty rather than shaded. If they are all burning nice and brown and slightly damp-looking, your head gasket should be fine.

Additionally, you can try running the engine with the cowl off and see if water is squirting out. If your boat has a plastic water line, try running the engine with the cowl off and see if you can identify where the leak is coming from. If there is no performance issue with your engine, the problem may be something simple, like a loose gasket or faulty temperature gauge.

If you suspect a blown head gasket, it is important to address the problem immediately. The head gasket is crucial for maintaining compression within the engine, and a loss of compression can cause the engine to misfire, perform poorly, or not start at all.

Bass Import: Boat or Plane?

You may want to see also

Check for a leaking head gasket

To check for a leaking head gasket on a 2-stroke boat engine, you'll need to locate the joint between the cylinder head and the cylinder block. The cylinder head is the metal "cap" on top of the engine, where the spark plugs protrude through. Examine the joint all the way around the engine for signs of metal discolouration or buildup of black deposits, which could indicate a leaking head gasket.

Next, use a very fine feeler gauge or wire to check the width of the head/block joint. The gap should be less than 0.001 inches, and ideally, it should be unmeasurable. If you notice a gap larger than the recommended width, this could indicate a blown head gasket.

Another way to check for a leaking head gasket is to disconnect the spark plug lead, then crank the engine by pulling the starter cord a few times. Listen carefully at the head/block joint for any escaping air, which would indicate a leak.

Finally, reconnect the spark plug lead and start the engine, then carefully feel around the head/cylinder joint for any streams of escaping exhaust gases. Be cautious, as these gases will be hot. If you find any streams of hot gas escaping, it is likely that your head gasket is leaking and will need to be replaced.

It is important to note that checking for a leaking head gasket requires working on an engine, which can be dangerous if not done properly. Always exercise caution and consult a professional mechanic if you are unsure about any part of the process.

Diving Boat Ownership: Who's in Control?

You may want to see also

Check for carbon-clogged piston rings

Carbon-clogged piston rings are a common cause of low compression in your boat engine. The combustion cycle of an outboard motor leaves behind carbon residue, which, when it piles up, can cause the piston rings to get stuck and fail to create a seal against the cylinder walls. This can lead to a loss of compression and damage to the outboard.

To check for carbon-clogged piston rings, you will need to disassemble the cylinder head and remove the piston from the cylinder. It is important to cover the open cylinder to prevent any debris from falling into the chamber. Once the piston is removed, you can inspect the piston rings for any signs of carbon buildup or clogging.

The piston rings are located on the outside of the piston and are typically made of cast iron or steel. They play a crucial role in sealing the area between the piston and the cylinder, reducing air loss and increasing compression. If the piston rings are cracked, worn, or clogged with carbon, they may not be sealing properly, allowing air to escape from the cylinder and resulting in a loss of compression.

When inspecting the piston rings, it is important to also check the side clearance, ring backlash, and end clearance. The side clearance of the piston ring should be measured with a feeler gauge, with a new piston ring having a clearance of 0.02-0.05 mm and a wear limit of 0.15 mm. The ring backlash can be measured by placing the piston ring in the piston ring groove and using a depth vernier caliper to measure the value of the outer cylindrical surface of the ring sinking into the ring bank. The end clearance can be checked by pressing the piston ring vertically into the cylinder about 15 mm and then using a feeler gauge to measure the clearance.

If you suspect that carbon buildup is the issue, there are products available that can be added to the fuel to help clean out the carbon and stabilize the compression. However, if the piston rings are severely clogged or damaged, they may need to be replaced.

Boat Trips with Newborns: Safe or Not?

You may want to see also

Check for broken or worn piston rings

Piston rings play a crucial role in creating compression in a two-stroke engine. If your piston rings are cracked or worn, they may not seal properly as the piston moves, allowing air to escape from the cylinder and preventing your engine from creating the pressure required to run.

To check for broken or worn piston rings, you'll need to perform a compression test and inspect the spark plug. Here are the steps you can follow:

- Remove the cylinder head and piston: Before conducting any tests, you'll need to disassemble the cylinder head. This involves removing the piston from the cylinder to access the piston rings. Be sure to cover the open cylinder to prevent debris from falling into the chamber.

- Perform a compression test: Purchase a compression gauge to test the compression in each cylinder. Disable the engine to ensure it doesn't start during the test. Remove the ignition coil and spark plug from the cylinder you're testing, insert the compression gauge extension, and screw it in. Crank the engine and observe the gauge until you reach maximum compression. A healthy two-stroke engine cylinder should have a compression reading of 110-130 PSI. If your reading is below 90 PSI, you likely have low compression.

- Inspect the spark plug: Check the spark plug for oil fouling or carbon buildup. Worn piston rings can cause oil to enter the combustion chamber, leading to oil fouling on the spark plug.

- Compare cylinders: If you have multiple cylinders, compare the compression readings between them. If one cylinder shows significantly lower compression than the others, it may indicate a piston ring issue in that particular cylinder.

- Examine piston rings: Once you've disassembled the cylinder head, carefully inspect the piston rings for any signs of damage, cracks, or excessive wear. Piston rings typically sit on the outside of the piston and are made of cast iron or steel.

- Check for excessive smoke: Worn piston rings can cause your engine to emit excessive smoke from the exhaust. If you notice blue or gray smoke, it may indicate that oil is burning along with the fuel due to piston ring wear.

- Monitor oil consumption: Keep an eye on your engine's oil consumption. If it starts consuming more oil than usual, it could be a sign that the piston rings are not sealing the combustion chamber effectively, allowing oil to bypass into the cylinder.

- Evaluate engine performance: Bad piston rings can affect engine performance, resulting in rough idling, reduced acceleration, and overall sluggishness. If you experience a noticeable decrease in engine power or responsiveness, it could be due to worn piston rings.

If, after performing these checks, you suspect that your piston rings are indeed broken or worn, the best course of action is to replace them. Replacing piston rings typically requires disassembling the engine and removing the piston from the cylinder, so it's recommended to seek assistance from a qualified mechanic or experienced DIY enthusiast.

Annapolis Boat Show: Dates and Details for Boating Enthusiasts

You may want to see also

Frequently asked questions

If your engine has low compression, it will be difficult to start, and you may experience loss of power and increased fuel consumption.

Low compression can be caused by a number of factors, including a damaged piston or piston rings, a blown head gasket, or carbon deposits on the piston and cylinder walls due to low-quality fuel.

To fix low compression, you need to identify and replace the faulty part, whether it's the piston, piston ring, head gasket, or valves. Regular maintenance, such as cleaning the carburettor and changing the engine oil, can also help prevent low compression.

The cost of fixing low compression will depend on the specific issue and the extent of the damage. A professional mechanic will typically charge between $100 and $200 for fixing low compression in one cylinder. However, the cost of replacing a damaged head gasket or piston rings can be significantly higher, ranging from $1000 to $4000.

While it is possible to drive a boat with low compression in one cylinder, it is not advisable as it can cause further damage to the engine. The boat will still run but will experience rough movements and may stop from time to time.