Owning a boat can be a lot of fun, but it also comes with maintenance responsibilities. One common problem that aluminium boat owners face is leaks. Leaks can be caused by loose or missing rivets, widening of seams, and hairline cracks and tears. While major damage should be left to professionals, you can fix minor issues yourself. This article will provide an overview of the process of locating and repairing leaks in an aluminium boat.

What You'll Learn

Seal with a propane torch and epoxy rubber sticks

To stop an aluminium boat from leaking, you can seal it with a propane torch and epoxy rubber sticks. This method is a quick, easy, and inexpensive fix for sealing rivets and cracks in the hull of your aluminium boat.

Firstly, you will need to purchase epoxy rubber sticks, such as the 12-inch-long and half-inch-round Scotchkote sticks from Cabela's. You will also need a propane torch. Ensure you have safety equipment, such as gloves and eye protection, before you begin.

Before you start sealing, you will need to clean the area to be welded with a wire wheel or sandpaper. Remove any paint from the area and then, once the surface is clean, apply a self-etching spray primer.

Now, you can begin sealing. Using the propane torch, heat the aluminium around the rivet or crack. Then, take an epoxy rubber stick and, in a circular rubbing motion, melt the stick over the area to be sealed. Once the epoxy has melted, remove the stick and the heat source, and you're done! This method will create a strong seal that will not leak or come off unless you have a welder for aluminium.

Finally, once the epoxy has cooled and set, you can paint over the sealed area to match your boat's colour.

How Manhattan Was Won Through a Boat Race

You may want to see also

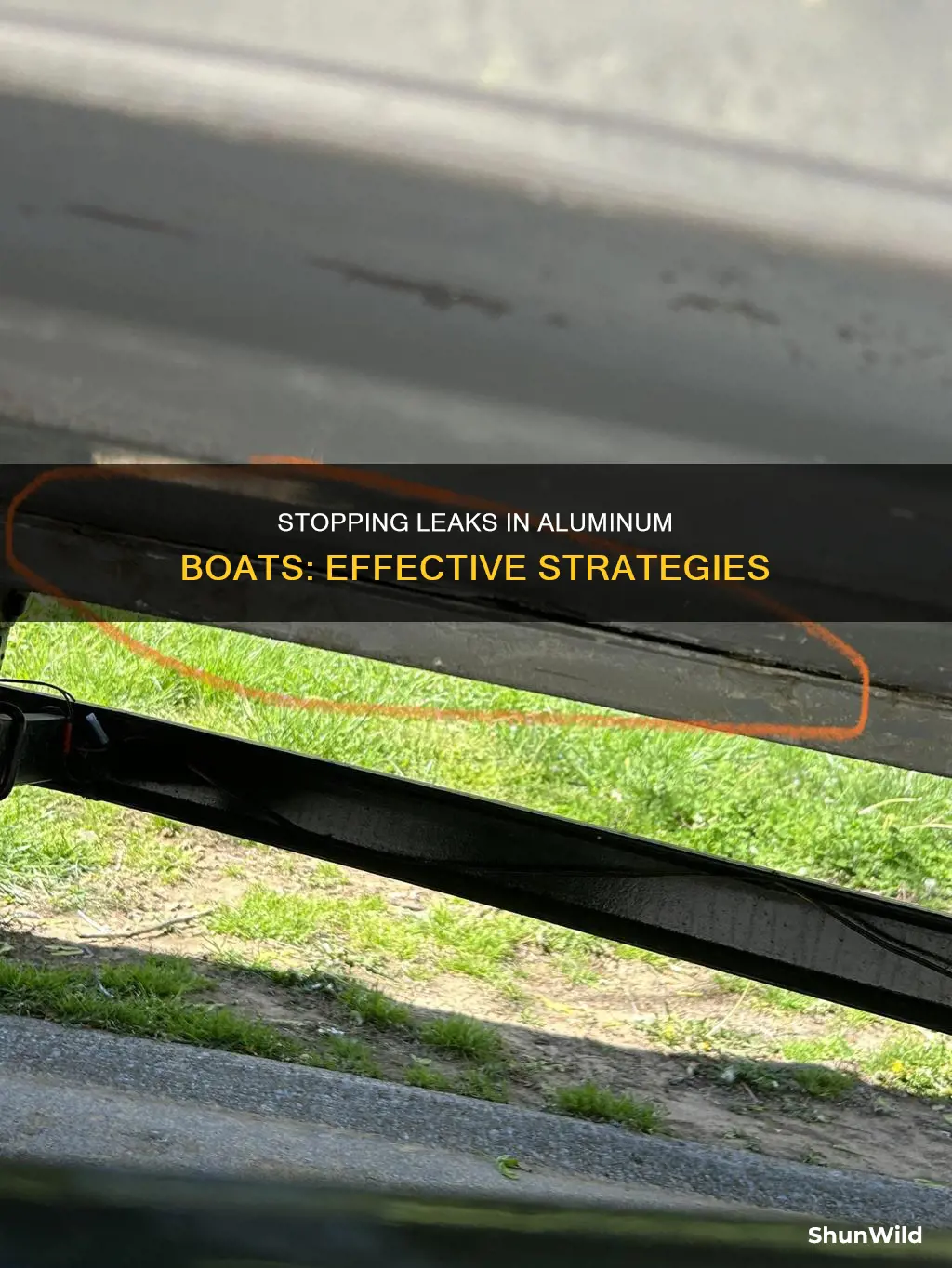

Use a stiff wire brush to roughen the surface

Before you start repairing your aluminium boat, you need to find the leak. Keep the boat level and hooked up to your tow vehicle. Then, use a garden hose to fill the boat with one or two inches of water, keeping a close eye on the aluminium underside for any signs of dripping or leaking. If you spot the leak immediately, use a waterproof marker to highlight the area. If not, continue filling the boat with water. Once you've located the leak, drain the water and raise the bow, leaving the boat in this position for two days so it can dry completely.

Now that you've found the leak and allowed the boat to dry, it's time to prepare the surface for repairing. Use a stiff wire brush to lightly roughen the area that needs to be fixed. This step is crucial as it helps the bonding agents adhere better to the aluminium surface, especially if the original area is smooth and shiny. Make sure to wear safety glasses and latex gloves to protect yourself from any debris or chemicals.

You can use a propane torch to heat the aluminium and melt the epoxy over the affected area. Alternatively, you can opt for epoxy putty sticks, marine adhesive sealant, or a product like JB Weld Clear Silicone All-Purpose RTV Sealant and Adhesive. Remember to follow the product directions carefully, as the work time allowed is usually quite short. For example, with epoxy, you need to knead the compounds by hand for one minute to mix them properly, and then you have about two minutes to apply it to the aluminium surface.

Once the epoxy has cured, you'll be left with a permanent steel-hard shell, and your boat will be ready to hit the water again! Just remember to give it sufficient time to cure before getting wet.

Pool Noodles: A Viable Option for Boat Flotation?

You may want to see also

Apply a coat of primer and paint

Once you have identified the areas that need repairing, it is time to prepare the surface for painting. Use a wire wheel or sandpaper to clean away the paint from the area. You can also use a stiff wire brush to lightly rough up the surface, especially if the original area is shiny and smooth. This step will allow the primer to adhere better to the aluminium. Make sure the surface is fully dry before applying any primer.

After the surface has been prepared, it is time to apply the primer. Choose a self-etching spray primer that is suitable for aluminium surfaces. Follow the instructions on the primer and apply it to the bare aluminium, covering the entire area that will be painted, including a small overlap. Allow the primer to dry completely according to the manufacturer's instructions.

Once the primer is dry, it is time to apply the paint. Choose a paint that is suitable for aluminium boats and that matches the colour of your boat. Again, follow the instructions on the paint and apply it to the primed area. Make sure to cover the entire area, including a small overlap, for a consistent and professional finish. Allow the paint to dry completely before using the boat.

By following these steps, you will have a sealed and protected aluminium boat surface that not only looks good but also helps prevent future leaks.

Maintaining Your Boat Dock: A Step-by-Step Guide

You may want to see also

Fix with J-B Weld Clear Silicone All-Purpose RTV Sealant and Adhesive

Fixing an aluminium boat leak is not as complicated as you may think. It can be done in a few hours, and you'll be set for the foreseeable future.

J-B Weld Clear Silicone Sealant and Adhesive is a great option for fixing your aluminium boat leak. It is a general-purpose sealant adhesive, RTV (Room Temperature Vulcanized) Silicone, designed for use in household or mechanical assembly applications. The sealant is clear and forms a tough, waterproof, weather-resistant seal on most surfaces. It will not shrink or crack and is sensor-safe.

To use the J-B Weld Clear Silicone Sealant and Adhesive, follow these steps:

- For the best results, clean and dry the surface area.

- Apply an even, continuous 1/4-inch bead of silicone to one surface area. Surround all bolt holes with silicone.

- Reconnect parts while the silicone is wet.

- Hand-tighten until the silicone begins to squeeze out.

- Allow the silicone to dry for 1 hour, then tighten an additional 1/2 turn.

- Scrape or cut away any excess cured sealant. The silicone will fully cure in 24 hours.

This product is ideal for automotive, ceramic, cloth, carpet, glass, rubber, windshields, windows, lens housings, door frames, tubs, showers, and aquariums. It is easy to use and will provide a strong and reliable seal for your aluminium boat.

Other products that can be used to fix aluminium boat leaks include Flex Seal, Marine Goop, and JB Weld. For larger holes, you may need to weld or rivet the boat.

Boat Registration Numbers: Placement Guide for Washington State

You may want to see also

Re-rivet with closed-in rivets and rivet burrs

Re-riveting your aluminium boat with closed-in rivets and rivet burrs is a great way to stop leaks without breaking the bank. This method is also a lot less time-consuming than re-riveting the entire boat, which could cost you more than simply buying a new boat.

Closed-in rivets are self-sealing and do not let water through, while the burrs or washers prevent the rivets from punching through the surface of the boat. To re-rivet your aluminium boat, you will need to order closed-in rivets and rivet burrs, a rivet gun, a through-hull marine adhesive sealant, and a power drill. You will also need to ensure you have a screwdriver that is smaller than the diameter of the hole of the rivets.

First, drill into the centre of the old rivet and punch it through with your screwdriver. Next, place the new rivet into the gun, and apply the marine sealant around it. Set the burr for reinforcement on the inside of the boat, and then punch in the new rivet. Finally, wipe off any excess sealant, and you're done!

It is important to note that you will need to clean the area before applying any sealant. Make sure to sand off any dirt that will prevent proper sealing, and ensure the surfaces are fully dry before applying any solutions.

Repairing Cracked Boat Console: A Comprehensive Guide

You may want to see also

Frequently asked questions

Keep your boat level and hooked up to your tow vehicle. With a garden hose, fill the boat with an inch or two of water, paying careful attention to the aluminum underside for any drips or leaks. Once found, use a waterproof marker to highlight areas that need attention. If none are noticed, continue with the filling process.

You can use Epoxy Putty Sticks, Marine Adhesive Sealant, J-B Weld Clear Silicone All-Purpose RTV Sealant and Adhesive, Flex Seal, or Green aluminum boat epoxy sticks.

Following the product directions is crucial for the best results. Epoxy requires hand kneading for one minute to mix the two compounds. It then must be forced and flattened onto the aluminum within two minutes. When repairing rivets, cover the entire area, including a half-inch overlap. The same goes for cracks or holes.