Repairing rod holders on a fiberglass boat can be a straightforward process if you follow the right steps. Start by assessing the damage to determine if the holder can be saved or if a replacement is necessary. If the holder is cracked or broken, carefully remove it and clean the area around the mounting holes. Then, use a suitable epoxy resin to fill any gaps and reinforce the structure. Once the resin has cured, reattach the rod holder using marine-grade screws and ensuring a secure fit. This methodical approach will help you restore the functionality and appearance of your boat's rod holders, ensuring a safe and enjoyable fishing experience.

What You'll Learn

- Identify damage: Inspect rod holders for cracks, chips, or loose parts

- Clean and prepare: Remove dirt and debris from the holder

- Repair material: Use epoxy or fiberglass resin to fill and repair holes

- Reinforce structure: Add structural support with glass cloth and resin

- Sand and finish: Smooth the surface and apply a protective coating

Identify damage: Inspect rod holders for cracks, chips, or loose parts

When it comes to maintaining and repairing rod holders on your fiberglass boat, the first step is crucial: identifying any damage. This initial inspection is vital to ensure the safety and functionality of your boat's fishing setup. Here's a detailed guide on how to inspect and identify potential issues with your rod holders:

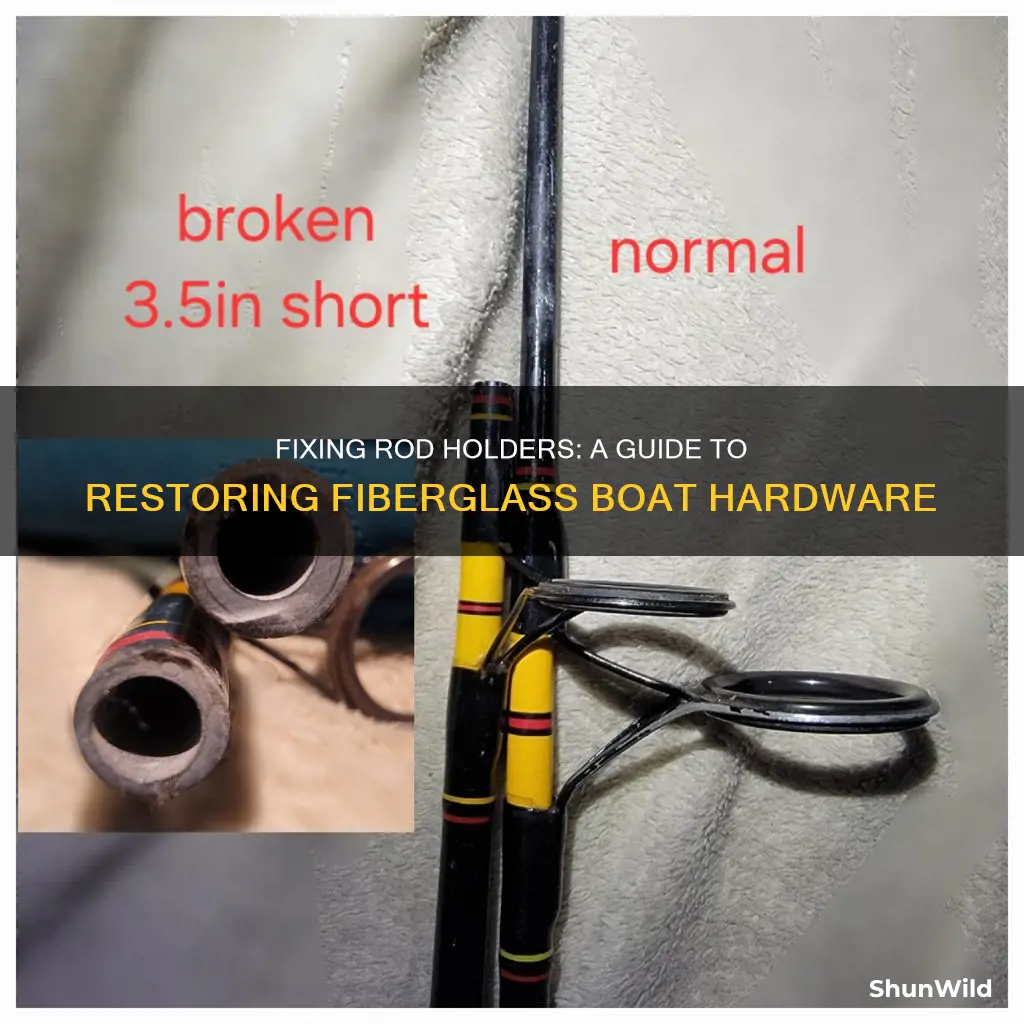

Visual Inspection: Start by thoroughly examining the rod holders. Look for any visible signs of damage or wear. Check for cracks, especially in the areas where the rod holders are attached to the boat's structure. These cracks could be a result of age, impact damage, or poor installation. Inspect the entire length of the rod holders for any chips or fractures, as these can weaken the structure and compromise the safety of your setup. Pay close attention to the joints and connections, as these areas are prone to loosening over time.

Tightness Check: Looseness in the rod holders is a common issue and can lead to accidental rod release. Carefully check all the screws and fasteners to ensure they are tight. If you find any loose parts, make a note of their location and the type of fastener used. Tightening these components will secure the rod holders in place, preventing potential accidents during your fishing trips.

Surface Condition: Examine the surface of the rod holders for any signs of deterioration. Fiberglass, over time, can develop a rough or pitted texture. This may indicate that the surface has been damaged by saltwater, UV radiation, or other environmental factors. Such damage can affect the overall strength and appearance of the rod holders. If you notice significant surface degradation, it might be necessary to consider a more comprehensive repair or replacement.

Functionality Test: While inspecting, also test the functionality of the rod holders. Try inserting a rod into the holder and ensure it fits securely. Check for any play or movement in the holder, as this could indicate internal damage or wear. If you notice any issues with the rod's stability, it's essential to address them promptly to avoid losing your catch or causing damage to the boat's structure.

By following these steps, you can effectively identify and address any damage to your rod holders. Regular inspections will help ensure that your fiberglass boat remains safe and reliable for your fishing adventures. Remember, early detection of issues is key to successful repairs and the longevity of your boat's components.

Bay Bridge Boat Show: Location and Highlights

You may want to see also

Clean and prepare: Remove dirt and debris from the holder

Before you begin the repair process, it's crucial to ensure that the rod holder is clean and free from any debris. This step is essential as it prepares the surface for the repair material and ensures a strong bond. Start by rinsing the holder with a garden hose or a pressure washer to remove loose dirt and grime. Pay attention to all areas, including the nooks and crannies, as these can accumulate dirt over time. For a more thorough clean, consider using a mild detergent mixed with water. Apply the solution and use a soft-bristled brush or a sponge to gently scrub the holder, being careful not to scratch the fiberglass surface. Rinse thoroughly afterward to eliminate any soap residue.

Once the initial cleaning is complete, you might want to use a power tool like an angle grinder with a wire brush attachment to remove stubborn dirt and old paint or corrosion. This step is particularly useful if the rod holder has been exposed to harsh environmental conditions or has accumulated significant wear and tear. After cleaning, inspect the holder to identify any remaining debris or imperfections. You can use a fine-grit sandpaper (e.g., 1200-grit) to smooth out any rough patches and ensure a smooth surface for the repair. Always work in a well-ventilated area and wear protective gear, such as gloves and safety goggles, to avoid any potential hazards.

For a more thorough clean, consider using a degreaser or a specialized cleaner designed for marine applications. These products can help break down and remove stubborn grease and grime that might be present on the holder. Apply the cleaner according to the manufacturer's instructions, allowing sufficient time for it to work, and then rinse thoroughly. This step is especially important if the rod holder has been used for fishing, as it can accumulate fish oil and other contaminants.

After cleaning, it's a good idea to inspect the holder for any signs of damage, such as cracks, chips, or holes. If you notice any significant damage, it might be best to consult a professional for advice on the most appropriate repair method. However, for minor repairs, you can proceed with the preparation by ensuring the surface is completely dry before moving on to the next step.

Choosing the Right Boat for Niagara Falls

You may want to see also

Repair material: Use epoxy or fiberglass resin to fill and repair holes

When it comes to repairing rod holders on a fiberglass boat, using epoxy or fiberglass resin is a common and effective method to fill and repair holes. These materials are strong, durable, and can provide a seamless finish, making them ideal for restoring the structural integrity of the boat's rod holders. Here's a step-by-step guide on how to approach this repair:

Preparation: Before you begin, ensure the area around the holes is clean and free of any debris or old material. Use a wire brush or sandpaper to roughen the surface, creating a better bond for the resin. If the damage is extensive, consider removing the damaged section carefully to create a flat surface for the repair.

Mixing the Resin: Epoxy and fiberglass resins are typically sold in two parts: a resin and a hardener. Carefully mix the two parts according to the manufacturer's instructions. This process ensures the correct ratio of resin to hardener, which is crucial for the material's curing process. Stir the mixture thoroughly to avoid any lumps, and ensure it has a smooth, consistent consistency.

Application: Now, it's time to apply the repair material. Use a small brush or a putty knife to carefully fill the holes and any damaged areas. Ensure you cover the entire damaged section, creating a thick layer of the resin mixture. You can also use a vacuum bag system to apply the resin, which is especially useful for larger repairs, as it creates a uniform pressure and ensures a smooth finish.

Sanding and Finishing: Once the resin has cured, which can take several hours or even overnight, carefully sand the repaired area. Use fine-grit sandpaper to smooth out the surface and blend it seamlessly with the surrounding fiberglass. This step is crucial to ensure the repair is inconspicuous and the boat's aesthetics are maintained. After sanding, wipe away any dust or debris, and consider applying a fiberglass cloth or tape to reinforce the repair, especially if the rod holders are under significant stress.

Final Touches: With the repair complete, inspect the boat's rod holders to ensure the structural integrity is restored. Test the strength of the repair by applying pressure or using the rod holders as intended. If everything feels secure, you can add a final touch by applying a suitable marine paint or varnish to the repaired area, ensuring it blends in with the boat's existing color scheme.

Epoxy and fiberglass resin repairs can be a bit technical, but with the right preparation and attention to detail, you can effectively restore the functionality and appearance of your boat's rod holders.

When to Italicize Titles: The Open Boat Example

You may want to see also

Reinforce structure: Add structural support with glass cloth and resin

When reinforcing the structure of rod holders on a fiberglass boat, using glass cloth and resin is a popular and effective method. This technique not only repairs the existing damage but also significantly enhances the overall structural integrity of the boat's components. Here's a step-by-step guide to achieving this:

Preparation: Begin by thoroughly cleaning the damaged area of the rod holder. Ensure there is no dirt, debris, or old resin residue. This step is crucial as it provides a clean surface for the new resin to adhere to. If there is any significant damage, such as cracks or holes, consider filling them with a suitable fiberglass filler to create a smooth and even surface. Allow the filler to cure completely before proceeding.

Gather Materials: You'll need a few essential materials for this repair. Start with a high-quality epoxy resin, preferably one designed for marine applications, as it offers excellent adhesion and durability in saltwater environments. Glass cloth, also known as fiberglass cloth, should be chosen based on the thickness and weave suitable for your project. A suitable catalyst for the resin is also necessary to initiate the curing process. Additionally, have some masking tape and a heat gun or hairdryer ready for applying heat during the curing process.

Application Process: Start by laying the glass cloth over the prepared rod holder, ensuring complete coverage of the damaged area. Wet the cloth slightly with water to make it more pliable and easier to work with. Carefully spread a thin layer of resin over the cloth, being mindful not to saturate it. Allow the resin to sit for a few minutes until it becomes tacky. Then, using a rolling pin or a similar tool, smooth out any air bubbles and ensure the resin is evenly distributed. Apply heat gently with the hairdryer or heat gun to facilitate the curing process and remove any remaining bubbles. Repeat this process for additional layers, allowing each layer to cure before applying the next.

Curing and Finishing: After the final layer of resin is applied and cured, inspect the repair. Ensure the glass cloth is securely bonded to the rod holder. If needed, apply additional layers of resin and cloth to further strengthen the structure. Once satisfied with the repair, carefully remove the masking tape, being cautious not to damage the freshly cured resin. Finally, sand the entire area smooth to ensure a seamless blend with the surrounding fiberglass.

By following these steps, you can effectively reinforce the structure of rod holders on your fiberglass boat, ensuring they are sturdy and durable for years to come. This method provides a strong and long-lasting solution, making it an excellent choice for boat owners seeking to restore and strengthen their vessel's components.

Louisville Boat & RV Show: Dates and Details

You may want to see also

Sand and finish: Smooth the surface and apply a protective coating

Before you begin the repair process, it's essential to ensure you have the right tools and materials. You'll need fine-grit sandpaper (e.g., 400-grit or higher), a power sander or a handheld sander, a clean cloth, and a suitable marine-grade epoxy resin or a clear gelcoat. Safety gear, such as gloves and a respirator, is also recommended due to the potential dust and fumes from the sanding process.

Start by thoroughly cleaning the damaged area of the rod holder. Remove any old paint, corrosion, or debris using a wire brush or a scrub brush. This step is crucial to ensure proper adhesion of the new material. Once the surface is clean, inspect it for any remaining damage or imperfections. If there are small holes or deep scratches, consider filling them with a suitable filler material, such as a two-part epoxy putty, to create a smooth and even surface.

Now, it's time to sand the area. Begin with a higher grit (finer) sandpaper to remove any remaining imperfections and create a smooth base. Gradually move to lower grit sandpaper (coarser) to achieve a more uniform surface. Work in small sections, applying gentle pressure and overlapping strokes to ensure an even finish. Pay close attention to the edges and contours of the rod holder, as these areas may require more careful sanding to avoid creating sharp edges.

After sanding, wipe away any dust or debris using a clean, damp cloth. Ensure the surface is completely dry before proceeding. Apply a thin layer of the marine-grade epoxy resin or clear gelcoat, following the manufacturer's instructions for mixing and application. Use a small brush or a putty knife to spread the material evenly across the repaired area, ensuring full coverage. Allow the first coat to cure according to the product's guidelines.

Once the first coat is cured, inspect the surface and apply additional coats if necessary to build up the desired thickness. Sand each coat smooth before applying the next, ensuring a seamless finish. Finally, once you've achieved the desired smoothness and the epoxy is fully cured, you can apply a protective coating, such as a marine-grade clear paint or a specialized gelcoat, to protect the repair and restore the rod holder's original appearance. This step is crucial to ensure the longevity of the repair and to maintain the boat's overall aesthetics.

Fresh Off the Boat: A Conclusion to the Huang Family's Story

You may want to see also

Frequently asked questions

Repairing a rod holder on a fiberglass boat typically involves a few steps. First, assess the damage; if the holder is cracked or broken, you might need to replace it entirely. Clean the area around the damage to ensure a strong bond. Use a suitable epoxy resin or marine-grade adhesive to fill the crack or gap, following the manufacturer's instructions. Allow sufficient curing time before handling the repair. For a more permanent solution, consider reinforcing the holder with fiberglass cloth and resin to create a sturdy repair.

Yes, a temporary fix can be useful while you plan for a more permanent repair or replacement. You can use a strong marine-grade epoxy to secure the holder in place, ensuring it doesn't move or wobble. This can be done by filling the crack with epoxy and clamping the holder in position until it sets. However, remember that this is a temporary measure, and a more comprehensive repair is recommended for long-term durability.

Rod holders on fiberglass boats can encounter various problems. Common issues include cracks or breaks in the holder itself, especially at the mounting points or where the holder meets the boat's surface. Corrosion and wear and tear from exposure to sunlight and saltwater can also weaken the holder over time. Additionally, improper installation or mounting hardware issues might lead to the holder becoming loose or unstable. Regular inspection and maintenance can help identify these problems early on.