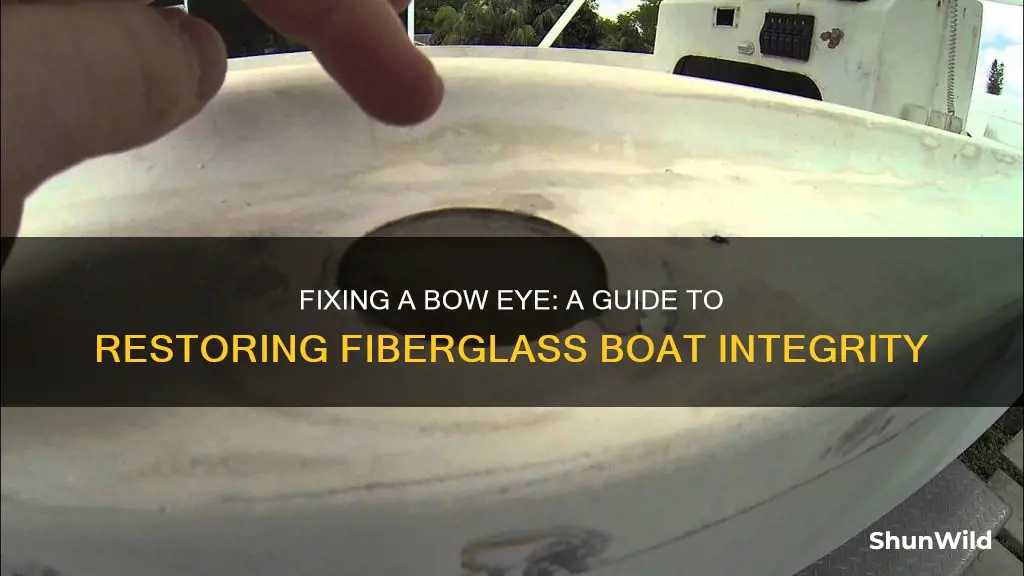

Repairing a damaged bow eye on a fiberglass boat can be a challenging task, but with the right tools and techniques, it is definitely achievable. The bow eye, also known as the bow fitting or bow anchor, is a crucial component that connects the bow of the boat to the anchor or mooring lines. Over time, this area can become worn, cracked, or even separated due to the constant stress of water and weather. This guide will provide a step-by-step approach to repairing the bow eye, ensuring your boat remains safe and functional.

What You'll Learn

- Identify the damage: Inspect the boat's surface to determine the extent of the tear

- Gather tools: Prepare necessary supplies like epoxy, glass cloth, and a heat gun

- Clean the area: Remove dirt and old adhesive with acetone or isopropyl alcohol

- Apply epoxy: Fill the tear with epoxy, following the manufacturer's instructions

- Reinforce with glass: Lay glass cloth over the repair, bonding it with more epoxy

Identify the damage: Inspect the boat's surface to determine the extent of the tear

When it comes to repairing a tear in the bow eye of a fiberglass boat, the first step is crucial: identifying the damage. This initial inspection is essential to ensure you understand the extent of the issue and can choose the appropriate repair method. Here's a detailed guide on how to inspect the boat's surface for tears:

Start by thoroughly examining the bow eye area, which is typically located at the front of the boat, just behind the bow. Use your eyes and hands to feel for any signs of damage. Look for visible tears or holes in the fiberglass surface. Tears can vary in size, from small punctures to larger rips that may extend through multiple layers of the boat's construction. Pay close attention to the edges of the tear, as these areas often provide clues about the damage's severity.

Feel the surface around the tear to assess its depth. Use your fingers to determine if the damage is limited to the outer layer or if it has penetrated deeper into the boat's structure. A tear that goes through the gelcoat and into the fiberglass cloth or even the core material requires more extensive repair. In such cases, you might notice a change in texture or color around the tear, indicating potential internal damage.

Take note of any additional signs that could indicate a more complex issue. For instance, if the tear is accompanied by cracks or delaminations in the surrounding area, it suggests that the structural integrity of the boat has been compromised. Also, check for any signs of water intrusion, as this could lead to further complications and corrosion.

Document the damage by taking photographs from various angles. This visual record will be invaluable when discussing the repair with professionals or when researching DIY solutions. Note the size, shape, and location of the tear, as well as any other relevant details.

Remember, a thorough inspection is key to a successful repair. By carefully examining the boat's surface, you can gather the necessary information to make an informed decision about the repair process, whether it's a simple patch or a more extensive restoration.

Essential Boat Safety Equipment for Michigan Waters

You may want to see also

Gather tools: Prepare necessary supplies like epoxy, glass cloth, and a heat gun

Before you begin the repair process, it's crucial to gather all the necessary tools and materials to ensure a successful fix. Here's a detailed guide on what you need to prepare:

Epoxy Resin and Hardener: This is the primary material for bonding and strengthening the damaged area. Choose an epoxy system suitable for marine environments, as it needs to withstand the harsh conditions of water. Select a two-part epoxy, where you mix the resin and hardener in the correct proportions to achieve optimal curing.

Glass Cloth: You'll require a suitable glass cloth or weave, typically made of fiberglass or a similar material. The cloth should be slightly larger than the damaged area to ensure proper coverage. Opt for a mesh size that provides good strength and flexibility, allowing it to conform to the boat's shape.

Heat Gun: A heat gun is essential for applying heat to the epoxy during the curing process. It helps accelerate the curing time and ensures a stronger bond. Look for a heat gun with adjustable temperature settings, allowing you to control the heat intensity. This tool will be particularly useful if the repair area is in a hard-to-reach spot.

Mixing Bowls and Stir Sticks: You'll need containers to mix the epoxy resin and hardener. Ensure you have enough bowls to accommodate the volume of epoxy you plan to use. Additionally, get some stir sticks or spoons to mix the components thoroughly.

Protective Gear: Safety should always be a priority. Wear gloves to protect your hands from the epoxy and any potential glass fiber particles. Consider wearing a respirator mask to avoid inhaling any fumes, especially when working in a confined space.

Cleaning Supplies: Have some cleaning agents ready to prepare the repair area. This might include isopropyl alcohol or a mild detergent to remove any dirt, grease, or old epoxy residue. A clean surface is crucial for proper adhesion.

By gathering these tools and supplies, you'll be well-prepared to tackle the repair of the bow eye on your fiberglass boat. Each item plays a vital role in ensuring a successful and long-lasting fix.

Grasshopper Boat Ownership: Mystery Unveiled

You may want to see also

Clean the area: Remove dirt and old adhesive with acetone or isopropyl alcohol

To begin the repair process of a damaged bow eye on your fiberglass boat, it's crucial to start with a clean and prepared surface. The first step is to thoroughly clean the area around the bow eye, ensuring that any dirt, grime, or old adhesive is removed. This preparation is essential to ensure a strong bond during the repair process.

Begin by gathering the necessary cleaning supplies. You will need acetone or isopropyl alcohol, which are both effective solvents for removing contaminants. Acetone is particularly useful for dissolving old adhesives and paint, while isopropyl alcohol is excellent for cleaning and sterilizing surfaces. It's important to have a well-ventilated workspace when using these chemicals.

Once you have your supplies, carefully apply the solvent to a clean cloth or cotton ball. Gently rub the area around the bow eye, ensuring that you cover the entire surface. The goal is to lift and remove any dirt, old adhesive residue, or paint that might be present. Take your time and be thorough, as this step is critical for a successful repair.

For stubborn stains or old adhesive, you may need to apply additional pressure and rub more vigorously. However, be cautious not to scratch the fiberglass surface. If you encounter any resistance or feel the fiberglass, reduce the pressure and try a different approach. The key is to be patient and persistent until the area is clean.

After cleaning, it's recommended to rinse the area with water to remove any remaining solvent. Ensure that all traces of the solvent are washed away, as they can leave a residue. Allow the area to dry completely before proceeding with the next steps of your repair. This initial cleaning process will create a smooth and prepared surface, setting the stage for a successful and long-lasting repair of your fiberglass boat's bow eye.

Valheim Boat Shields: Installation Guide for Beginners

You may want to see also

Apply epoxy: Fill the tear with epoxy, following the manufacturer's instructions

When repairing a tear in the bow eye of a fiberglass boat, applying epoxy is a crucial step to ensure a strong and durable fix. Here's a detailed guide on how to proceed:

Gather the Materials: Before you begin, ensure you have all the necessary materials. You'll need the appropriate epoxy resin and hardener, which should be mixed in the correct proportions as per the manufacturer's instructions. Additionally, have some cloth or gauze, a small brush or spatula, and possibly a heat gun or hairdryer for faster curing.

Prepare the Area: Clean the tear area thoroughly. Remove any dirt, old epoxy, or debris. If the tear is small, you might be able to use a putty knife to gently lift the edges of the tear and create a small cavity to work with. For larger tears, you may need to carefully cut away any damaged fiberglass around the tear to create a clean, flat surface.

Mix the Epoxy: Carefully follow the instructions provided by the epoxy manufacturer. Typically, you'll mix the resin and hardener in a clean container, ensuring the correct ratio. Over-mixing can lead to a messy application, while under-mixing may result in a weak bond. Mix the epoxy thoroughly until it is smooth and free of any lumps.

Apply the Epoxy: Using a small brush or spatula, carefully apply a thin layer of epoxy into the tear. Ensure you fill the entire tear, including any gaps or voids. Work quickly but carefully, as epoxy sets rapidly. If the tear is large, you might need to apply multiple thin layers, allowing each layer to cure before adding more. Be mindful not to apply too much pressure, as this can cause the epoxy to bulge or ooze.

Sanding and Finishing: Once the epoxy has cured, sand the repaired area gently with fine-grit sandpaper. This will help blend the repair into the surrounding fiberglass. You can use a heat gun or hairdryer to speed up the curing process and make sanding easier. After sanding, wipe away any dust and consider applying a clear coat or primer to protect the repair and ensure a smooth finish.

Mansfield Dam Boat Ramp: Open or Closed?

You may want to see also

Reinforce with glass: Lay glass cloth over the repair, bonding it with more epoxy

The process of reinforcing a fiberglass boat's bow eye with glass is a crucial step in ensuring the structural integrity of the vessel. Here's a detailed guide on how to execute this repair effectively:

Gather Materials: Before you begin, ensure you have all the necessary materials. This includes a suitable epoxy resin, a hardener, and a glass cloth or fiber glass cloth. The epoxy should be chosen based on its compatibility with fiberglass, and it's essential to follow the manufacturer's instructions for mixing ratios. You'll also need a small brush or roller for application.

Prepare the Repair Area: Clean the damaged area thoroughly to remove any dirt, old epoxy, or debris. Ensure the surface is smooth and free of contaminants. If the damage is extensive, consider cutting back the damaged area to create a clean, flat surface for bonding. Use a file or sandpaper to achieve a smooth finish, and wipe away any dust with a damp cloth.

Apply Epoxy: Start by applying a thin layer of epoxy to the prepared repair area. Use the brush or roller to ensure an even coating. Allow this layer to dry slightly, following the epoxy manufacturer's guidelines for curing time. This initial layer acts as a primer, providing a strong bond for the glass cloth.

Lay the Glass Cloth: Once the epoxy is ready, carefully lay the glass cloth over the repair area. Ensure it covers the entire damaged section, including any holes or cracks. Use your hands or a roller to press the glass cloth firmly against the epoxy, creating a tight bond. Smooth out any wrinkles or bubbles by gently patting or rolling the cloth.

Bonding and Curing: After the glass cloth is in place, apply another layer of epoxy to bond it securely. Make sure the epoxy seeps into the gaps between the glass cloth and the surrounding fiberglass. Allow this layer to cure according to the epoxy's instructions. The curing time will vary depending on the epoxy used, so follow the manufacturer's recommendations.

Sand and Fair: Once cured, sand the entire repair area to create a smooth surface. Use fine-grit sandpaper to avoid scratching the surrounding fiberglass. This step ensures a seamless blend between the repair and the original boat structure. After sanding, wipe away any dust and inspect the repair. If necessary, apply additional layers of epoxy and glass to further strengthen the area.

Remember, patience and precision are key during this process. Take your time to ensure a thorough and effective repair, and always follow safety guidelines when working with epoxy and glass.

The World's Most Admired Boat Passengers

You may want to see also

Frequently asked questions

Repairing a bow eye on a fiberglass boat typically involves a few steps. First, assess the extent of the damage; if it's a small crack or chip, you can use a fiberglass repair kit with a filler compound to fill and smooth the area. For more significant damage, consider using a fiberglass repair tape and resin to reinforce and strengthen the affected area. Always ensure you follow the manufacturer's instructions for the chosen repair method.

For fiberglass repairs, you'll need a few essential tools and materials. These include a fiberglass repair kit with a suitable filler compound, a fiberglass repair tape (also known as glass cloth), epoxy resin, a heat gun or hairdryer for curing, and a primer to ensure proper adhesion. It's recommended to use products specifically designed for marine applications to ensure durability.

A temporary fix can be useful to get your boat back on the water, but it's essential to understand that it might not provide a long-lasting solution. For a full repair, it's best to assess the damage and consider the structural integrity of the bow eye. If the damage is extensive or the eye is significantly compromised, consulting a professional marine repair technician is advisable to ensure a safe and effective repair.