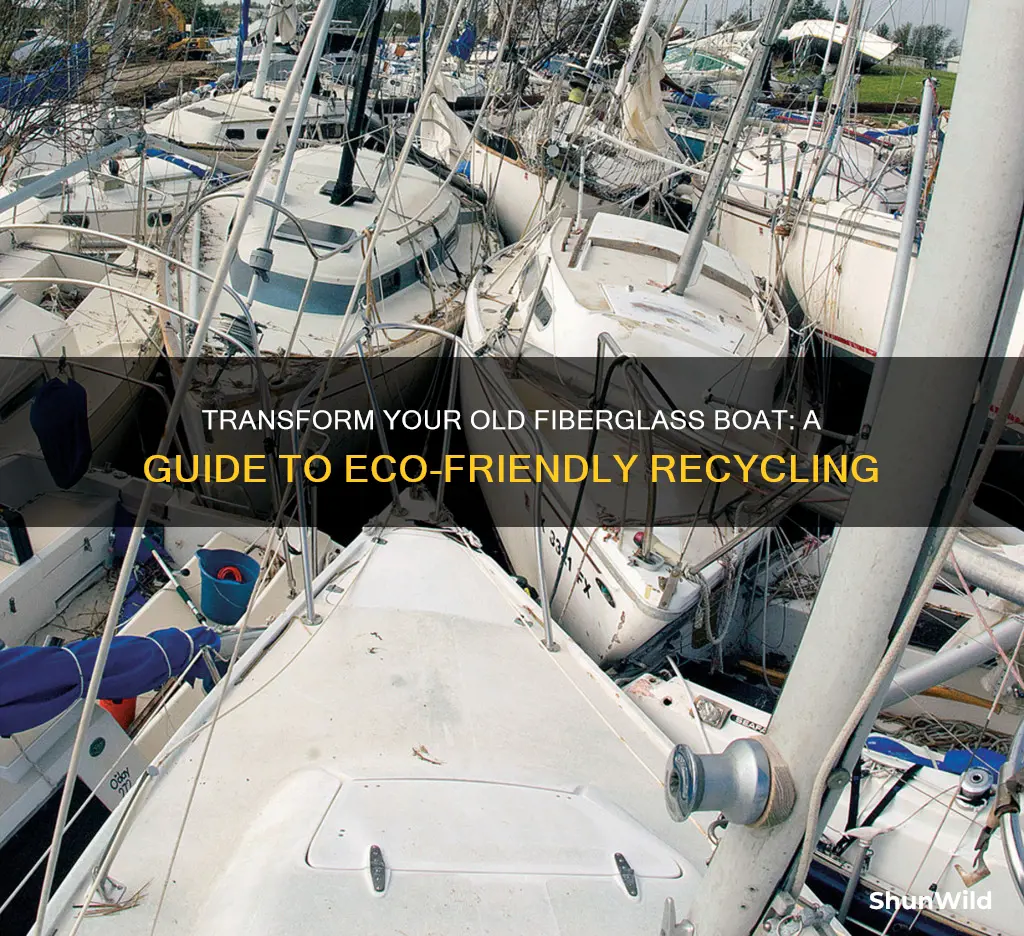

Recycling fiberglass boats is an important step towards sustainability and environmental conservation. Fiberglass, a composite material made from glass fibers and a resin matrix, is commonly used in boat construction due to its strength and durability. However, the disposal of fiberglass boats can be challenging as it is not easily biodegradable. To address this issue, there are several methods and guidelines available to help individuals and businesses properly recycle their fiberglass boats. These methods include specialized recycling facilities that can break down the material into its components, such as glass fibers and resins, which can then be reused in various industries. By following these guidelines, we can ensure that fiberglass boats are recycled responsibly, reducing waste and minimizing the environmental impact of this popular boat material.

What You'll Learn

- Disassemble: Carefully take apart the boat, separating fiberglass components from other materials

- Sort Materials: Categorize fiberglass into usable and unusable parts for recycling

- Clean and Prepare: Rinse and dry fiberglass, removing any contaminants for better recycling

- Find Recycling Centers: Research local facilities accepting fiberglass waste for proper disposal

- Reuse and Repurpose: Explore creative ways to repurpose fiberglass, such as in art or construction

Disassemble: Carefully take apart the boat, separating fiberglass components from other materials

Disassembly is a crucial step in the process of recycling a fiberglass boat, ensuring that the materials can be effectively sorted and processed for reuse. This process requires careful planning and execution to handle the delicate nature of fiberglass while also considering the safety of the individual performing the task.

Begin by assessing the boat's structure and identifying the various components. Fiberglass boats often consist of a hull, deck, and potentially a cabin or additional compartments. The goal is to separate these parts, focusing on the fiberglass elements. Start by draining any fuel or water systems to prevent spills during disassembly. This initial step ensures the safety of the environment and the individual working on the boat.

Carefully remove any hardware, such as screws, bolts, and fasteners, that secure the different parts together. It is essential to keep track of these fasteners and label or color-code them to ensure they are returned to the correct locations during reassembly or recycling. Fiberglass is a composite material, and its components include a resin matrix and reinforcing fibers. When separating the fiberglass, aim to extract the fibers while minimizing damage to the resin. One method is to use a sharp knife or a utility blade to carefully cut along the seams and joints, separating the fiberglass panels or sections. Take your time to avoid cutting through other materials like wood or metal reinforcements.

As you disassemble, pay attention to the different types of fiberglass used in the boat's construction. Some areas may have thicker layers of fiberglass, while others might have additional materials like foam or balsa wood for structural support. Properly identifying these materials will guide the recycling process, as some may require specific handling methods. For instance, foam insulation should be removed and recycled separately to avoid contamination.

Once the boat is thoroughly disassembled, you will have a collection of fiberglass components, including panels, stringers, and other structural elements. These can be further processed through recycling facilities that specialize in composite materials. The goal is to recycle the fiberglass fibers and reuse the resin for new composite products, contributing to a more sustainable approach to boat recycling.

The Boys in the Boat: Nudity and Artistry

You may want to see also

Sort Materials: Categorize fiberglass into usable and unusable parts for recycling

When it comes to recycling a fiberglass boat, the first crucial step is to carefully sort and categorize the materials. This process ensures that the recycling efforts are efficient and effective, allowing for the proper disposal and potential reuse of various components. Here's a detailed guide on how to sort fiberglass into usable and unusable parts:

Usable Fiberglass Parts:

- Structural Components: Start by identifying the main structural elements of the boat. This includes the hull, deck, and any internal frames or ribs. These parts are often made of high-quality fiberglass, reinforced with glass fibers and a resin matrix. Inspect these components for any signs of damage or wear but that are still structurally sound. You can potentially reuse these parts or find alternative applications for them.

- Panels and Skins: Fiberglass boats often feature panels and skins that cover the exterior. These can be removed and inspected for reuse. Look for panels with minimal damage, cracks, or delamination. Some panels might be suitable for repairs or can be used as templates for new projects.

- Accessories: Check for any removable accessories like seats, consoles, or storage compartments. These items can be carefully taken apart and sorted. For example, the seats might be made of fiberglass-reinforced foam, which can be recycled separately.

Unusable Fiberglass Parts:

- Damaged or Cracked Sections: Identify areas with visible damage, such as large cracks, holes, or significant structural weaknesses. These parts are likely unusable and should be marked for disposal. Proper disposal methods should be followed to prevent environmental hazards.

- Delaminated Panels: Delamination occurs when the layers of fiberglass separate, often due to age or impact. These panels are no longer structurally sound and should be removed. It's important to handle delaminated materials carefully to avoid spreading the damage to other parts.

- Contaminated or Compromised Fiberglass: If the fiberglass has been exposed to excessive moisture, chemicals, or other contaminants, it may be compromised and unusable. This is especially true for areas near the waterline or in areas prone to corrosion. These parts should be discarded to prevent further degradation.

During the sorting process, it's essential to document the condition and potential reuse of each part. Create a detailed inventory or checklist to ensure nothing is overlooked. Properly disposing of unusable fiberglass is crucial to minimize environmental impact. Consider contacting local recycling centers or specialized waste management services that handle construction and marine debris.

Remember, the goal is to maximize the recycling potential while ensuring the safety and integrity of the remaining materials. By categorizing the fiberglass into usable and unusable parts, you set the foundation for a successful recycling process, contributing to a more sustainable approach to boat maintenance and disposal.

Engines of PT Boats: How Many Motors Powered These Vessels?

You may want to see also

Clean and Prepare: Rinse and dry fiberglass, removing any contaminants for better recycling

When it comes to recycling a fiberglass boat, the initial step is crucial to ensure the material can be effectively repurposed. The process begins with a thorough cleaning and preparation of the fiberglass itself. This initial phase is essential as it helps to remove any contaminants that might hinder the recycling process, ensuring a cleaner and more sustainable outcome.

The first action is to rinse the fiberglass surface. This can be done using a garden hose or a power washer, ensuring that all visible dirt, grime, and any loose debris are washed away. It's important to pay attention to all nooks and crannies, as fiberglass can have intricate designs and textures that may trap contaminants. For hard-to-reach areas, consider using a soft-bristled brush to gently scrub the surface, removing any stubborn dirt without causing damage.

After rinsing, the fiberglass needs to be thoroughly dried. Moisture can be a concern during the recycling process, so ensure the surface is completely dry. You can use a shop vac or a leaf blower to speed up the drying process, especially in areas where water might have accumulated. Proper drying is critical to prevent any mold or mildew issues, which could complicate the recycling efforts.

Once the fiberglass is clean and dry, the next step is to identify and remove any contaminants that might still be present. This includes checking for any remaining dirt, rust, or corrosion. For rust removal, a wire brush or a specialized rust remover can be used, ensuring that the surface is clean and free of any metal residue. Similarly, any remaining paint or stickers should be carefully scraped off, leaving the fiberglass in its original state.

By following these steps, you are ensuring that the fiberglass boat is ready for the recycling process, free from any contaminants that could compromise its quality. This preparation phase is a critical part of responsible recycling, allowing for a more efficient and effective transformation of the material into new products.

Unraveling the Mystery: How Automatic Power Trim Works on Boats

You may want to see also

Find Recycling Centers: Research local facilities accepting fiberglass waste for proper disposal

When it comes to recycling your fiberglass boat, finding the right recycling centers is crucial. Here's a step-by-step guide to help you locate facilities that can handle fiberglass waste properly:

Research Online: Start by searching online for "recycling centers near me" or "fiberglass recycling facilities in [your city/state]." This initial search will provide you with a list of potential options. Look for websites or directories that specifically mention recycling hazardous materials or construction waste. Many recycling centers have dedicated pages outlining their services and accepted materials.

Check Local Directories: Explore local business directories, community websites, or government portals. These platforms often provide listings of recycling centers, waste management facilities, and environmental organizations. They may offer details on the types of materials they accept, including fiberglass.

Contact Waste Management Companies: Reach out to local waste management companies or municipal solid waste agencies. These organizations often have partnerships with specialized recycling centers. They can provide information on facilities that handle construction and hazardous waste, which may include fiberglass.

Visit Recycling Center Websites: Once you have a list of potential centers, visit their official websites. Look for pages that describe their services, accepted materials, and drop-off procedures. Some centers may provide online forms to schedule drop-offs or request specific services. Ensure that they accept fiberglass waste and understand the proper handling and disposal methods.

Inquire About Specialized Recycling: Fiberglass is a composite material, and its recycling process can vary. Some recycling centers may have experience with composite materials and can provide guidance or specialized services. Contact these centers to inquire about their capabilities and any specific requirements for fiberglass recycling.

Remember, proper disposal of fiberglass is essential to minimize environmental impact. By researching and identifying the right recycling centers, you contribute to a more sustainable approach to boat recycling, ensuring that the materials are handled and recycled responsibly.

Understanding Bass Boat Drain Holes and Their Functions

You may want to see also

Reuse and Repurpose: Explore creative ways to repurpose fiberglass, such as in art or construction

The process of recycling a fiberglass boat can be an opportunity to unleash your creativity and give new life to this versatile material. Here are some ideas for reusing and repurposing fiberglass, showcasing its potential in various creative endeavors:

Artistic Expressions:

Fiberglass is an excellent medium for artists seeking unique textures and forms. Consider creating sculptures or installations that showcase the material's strength and flexibility. You can mold and shape fiberglass to form intricate designs, from abstract art pieces to realistic animal sculptures. The smooth surface allows for detailed carving and painting, enabling artists to achieve a wide range of visual effects. Imagine a series of fiberglass wall hangings that capture the fluidity of the ocean or a collection of decorative bowls crafted from recycled boat parts, each with its own distinct pattern.

Architectural Innovations:

In the construction industry, fiberglass can be an eco-friendly alternative to traditional building materials. Its durability and lightweight nature make it ideal for various architectural applications. For instance, you could design and build unique furniture pieces, such as chairs or tables, with a fiberglass frame and a natural wood or metal top. This approach not only reduces waste but also adds an element of organic beauty to modern interiors. Additionally, fiberglass can be used for creating decorative screens, partitions, or even exterior cladding, providing a lightweight and weather-resistant solution for building envelopes.

Functional Furniture:

Repurposing fiberglass boat components can lead to innovative furniture designs. The material's strength allows for the creation of sturdy tables, benches, or even outdoor seating areas. You can cut and shape the fiberglass to form tabletops, benches, or backrests, ensuring a durable and weather-resistant finish. Consider a series of outdoor dining tables with a fiberglass top and a reclaimed wood base, offering a unique and sustainable dining experience. This approach not only reduces waste but also adds a touch of industrial-chic to outdoor spaces.

Educational Initiatives:

For those interested in teaching and learning, fiberglass can be a valuable resource for educational projects. It can be used to create models, prototypes, or even full-scale structures for architectural or engineering studies. Students can learn about material properties, design principles, and sustainable practices by working with fiberglass. Imagine a school project where students design and build a miniature boat using recycled fiberglass, fostering creativity and an understanding of marine engineering.

By embracing these creative avenues, you can contribute to a more sustainable future while exploring the endless possibilities of fiberglass reuse. It encourages a circular economy, reducing waste and inspiring innovation in various fields.

Fixing a Small Crack in Your Fiberglass Boat: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Recycling a fiberglass boat is a great way to reduce waste and give new life to an old vessel. Start by contacting your local recycling center or waste management facility to inquire about their specific guidelines for fiberglass. Many facilities accept fiberglass for recycling, but it's important to prepare the boat properly. Remove any non-fibreglass components like engines, electronics, and hardware, and ensure the boat is clean and dry. Some facilities may require the boat to be cut into smaller pieces, so check their requirements beforehand.

While it is possible to recycle fiberglass yourself, especially for smaller boats, it is generally recommended to seek professional assistance for larger or more complex vessels. Professional recyclers have the expertise and equipment to handle the process efficiently and safely. They can also ensure that the fiberglass is properly sorted, shredded, or processed for recycling. If you choose to do it yourself, make sure to follow local regulations and guidelines for waste disposal.

Recycling fiberglass boats offers several advantages. Firstly, it helps reduce the environmental impact of waste disposal, as fiberglass can take up a significant amount of space in landfills. By recycling, you contribute to a more sustainable approach to waste management. Secondly, recycling fiberglass can lead to the recovery of valuable materials, such as glass fibres and resins, which can be reused in various industries, promoting a circular economy.

Preparation is key to a successful recycling process. Start by draining any fuel or water from the boat to prevent contamination. Remove all loose items, such as anchors, ropes, and personal belongings. If the boat has any non-fibreglass components, like wood or metal, separate them for proper disposal. Clean the boat's surface to remove any dirt or grime. For larger boats, consider cutting it into manageable sections to facilitate transportation and recycling.

The recycled fiberglass material can be processed in various ways. It is often shredded or ground into small particles, which can then be used in the production of new products. These particles can be combined with resins to create new fiberglass sheets or composites. The recycled material can find its way into construction projects, automotive parts, or even furniture, giving the fiberglass a new lease of life and reducing the demand for virgin resources.