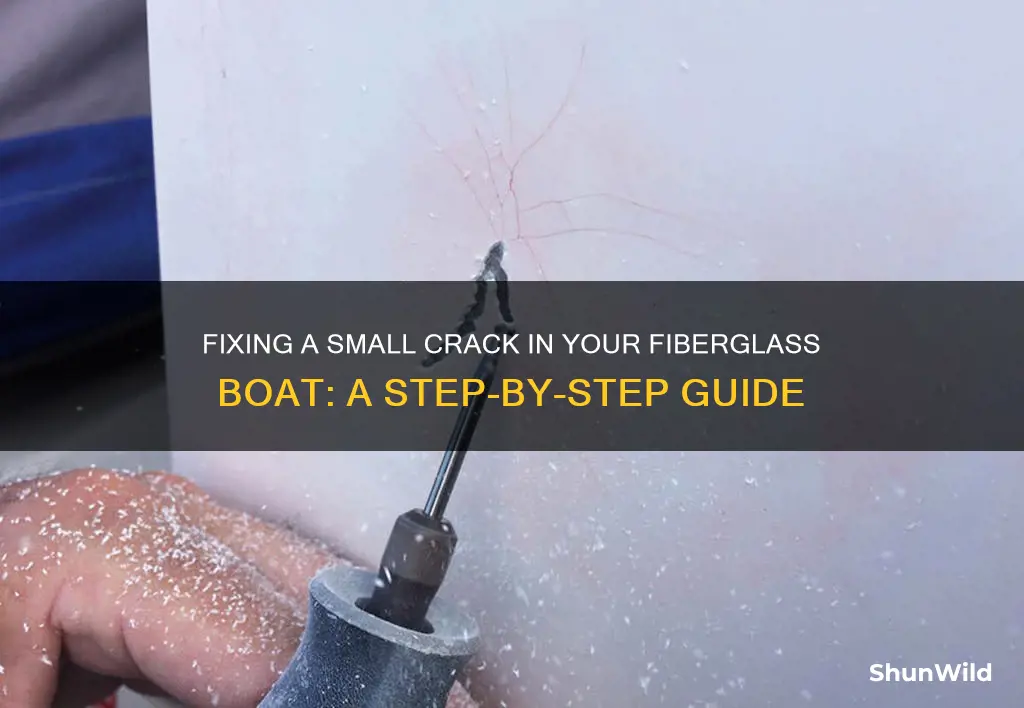

Fixing a small crack in a fiberglass boat can seem daunting, but with the right tools and techniques, it's a manageable task. This guide will walk you through the process of identifying the crack, preparing the area, and applying the appropriate repair materials to ensure your boat is safe and functional again. Whether you're a seasoned boat owner or a novice, understanding how to address these issues is essential for maintaining the integrity of your vessel.

What You'll Learn

- Identify the Crack: Inspect the crack to determine its size, location, and cause

- Prepare the Surface: Clean and roughen the crack area for better adhesion

- Choose a Repair Method: Select the appropriate repair technique, such as filling or bonding

- Use Repair Materials: Apply fiberglass repair resin and cloth to fill and strengthen the crack

- Sand and Finish: Smooth the repair, sand it, and apply a protective coating to restore the boat's appearance

Identify the Crack: Inspect the crack to determine its size, location, and cause

When dealing with a small crack in a fiberglass boat, the first step is to thoroughly inspect the damage to understand its nature and extent. This initial assessment is crucial as it guides the subsequent repair process. Start by carefully examining the crack to determine its size. A small crack is typically defined as one that is less than an inch in length and does not penetrate the gelcoat or the underlying fiberglass layers. Measure the crack's width and length to get an accurate idea of its size. Look for any signs of damage around the crack, such as chipping or delamination, as these can indicate a more serious issue.

Next, identify the location of the crack. Fiberglass boats can have cracks in various areas, including the hull, deck, or even the interior compartments. The location will influence the repair method. For instance, a crack in the hull might require a different approach compared to a crack in the deck. Inspect the surrounding area to understand the structural integrity and potential weak points. Consider the boat's usage and the environmental factors it is exposed to, as these can contribute to the crack's formation.

Understanding the cause of the crack is also essential. Small cracks in fiberglass boats can result from various factors, such as impact damage from rocks or other debris, thermal expansion and contraction due to temperature changes, or even improper installation of accessories. Identifying the cause can help prevent further issues. For example, if the crack is due to a collision with a rock, you might need to reinforce the boat's protective layer or consider additional safety measures. If the crack is a result of thermal stress, ensuring proper ventilation and temperature control during storage and operation can be beneficial.

During this inspection, take detailed notes and make sketches if necessary. Documenting the crack's characteristics will ensure that you have a clear reference for the repair process. It is also a good idea to take photographs from different angles to capture the full extent of the damage. This documentation will assist in communicating the issue to a professional or in guiding your own repair efforts if you choose to tackle it as a DIY project.

Boat Batteries: 12 or 24 Volts for Interstate Travel?

You may want to see also

Prepare the Surface: Clean and roughen the crack area for better adhesion

When repairing a small crack in a fiberglass boat, proper surface preparation is crucial for ensuring a strong and durable bond between the repair material and the existing structure. The first step in this process is to thoroughly clean the crack area. Start by rinsing the entire area with clean water to remove any dirt, grime, or old repair materials that may be present. Use a soft-bristled brush or a non-abrasive sponge to gently scrub the area, ensuring that you remove any loose particles or contaminants. Pay close attention to the edges of the crack, as these areas can be particularly dirty and may require extra cleaning.

Once the area is clean, it's time to roughen the surface. Fiberglass is a smooth material, and a smooth surface can lead to a weak bond. To address this, you can use a variety of methods to create a rough texture. One common technique is to use a fine-grit sandpaper, typically 400-grit or higher. Gently sand the area around the crack, following the direction of the fiberglass weave. This will create a subtle texture that will provide better adhesion for the repair material. Alternatively, you can use a power tool like a random-orbit sander with a similar grit to achieve a more aggressive texture. Be cautious when using power tools to avoid damaging the surrounding fiberglass.

After sanding, inspect the surface to ensure it has a consistent, slightly textured appearance. If the texture is too aggressive, you can use a finer-grit sandpaper to smooth it out slightly. The goal is to create a surface that is rough enough to provide excellent adhesion but not so rough that it becomes difficult to work with. Once you're satisfied with the texture, wipe away any remaining dust or debris with a clean cloth dampened with water. This final step ensures that the surface is clean and ready for the next phase of the repair process.

Remember, proper surface preparation is a critical step in the fiberglass repair process, as it sets the foundation for a strong and long-lasting bond. Taking the time to clean and roughen the crack area will significantly contribute to the overall success of your repair.

Boat Launch Access at Cassadaga Lake: Public or Private?

You may want to see also

Choose a Repair Method: Select the appropriate repair technique, such as filling or bonding

When dealing with a small crack in a fiberglass boat, the first step is to carefully assess the damage and choose the most suitable repair method. This decision will depend on the size and location of the crack, as well as the overall condition of the boat's structure. Here's a guide to help you select the appropriate repair technique:

Filling the Crack:

One common approach is to use a filling or putty method. This technique is ideal for small, shallow cracks. Start by cleaning the area around the crack to remove any dirt or debris. Ensure the surface is smooth and free of contaminants. Then, apply a suitable fiberglass repair filler or putty specifically designed for marine applications. These fillers are typically easy to work with and can be shaped to fill the crack. Allow the filler to cure according to the manufacturer's instructions, which may involve waiting for a specific time or applying heat. Once cured, sand the filled area to create a smooth surface, ensuring it blends seamlessly with the surrounding fiberglass.

Bonding Technique:

For more extensive cracks or those that are deeper, bonding is a preferred method. This process involves bonding a new piece of fiberglass to the damaged area, creating a strong and durable repair. Begin by cleaning the crack and its surrounding area, ensuring it is free from any contaminants. Then, apply a bonding agent or a specialized marine adhesive to both the crack and the new fiberglass piece you will use for the repair. Carefully position the new fiberglass layer, ensuring it aligns perfectly with the original surface. Use a roller or a weight to apply pressure and create a strong bond. Allow the adhesive to cure as per the instructions, and then sand the bonded area to achieve a smooth finish.

It's important to note that before proceeding with any repair, you should consider the overall condition of the boat. If the crack is in a critical area, such as near the hull or in a structural component, it may be best to consult a professional marine repair specialist to ensure the integrity of the boat is maintained. Additionally, always wear appropriate safety gear, including gloves and a respirator, when working with any chemicals or adhesives to ensure a safe and healthy repair process.

Boat Shoes and Socks: A Guide for Men

You may want to see also

Use Repair Materials: Apply fiberglass repair resin and cloth to fill and strengthen the crack

When it comes to repairing a small crack in a fiberglass boat, using the right materials is crucial to ensure a strong and durable fix. One of the most effective methods is to employ fiberglass repair resin and cloth, which can help fill and strengthen the crack. Here's a step-by-step guide on how to proceed with this technique:

Start by preparing the area around the crack. Clean the surface thoroughly to remove any dirt, grease, or old residue. This ensures proper adhesion of the repair materials. If the crack is deep, consider using a fiberglass filler to create a smooth surface before proceeding. Allow the filler to cure according to the manufacturer's instructions.

Next, you'll need to mix the fiberglass repair resin according to the package instructions. Typically, you'll combine the resin and a hardener to create a viscous liquid. Stir the mixture thoroughly to ensure a consistent consistency. The resin should be free of any lumps or clumps.

Now, it's time to apply the resin and cloth. Cut a piece of fiberglass cloth slightly larger than the crack. Dip the cloth into the resin, ensuring it's fully saturated. Carefully lay the cloth over the crack, pressing it gently to adhere to the surface. You can use a roller or a heavy object to apply pressure and remove any air bubbles. Make sure the resin flows into the crack, filling it completely.

After the resin has been applied, you'll need to blend the repair. Use a putty knife or a similar tool to smooth the surface, creating a seamless finish. Remove any excess resin and ensure the repair is flush with the surrounding fiberglass. Allow the resin to cure according to the manufacturer's guidelines, which may take several hours or even overnight.

Once cured, sand the repair area to blend it with the original fiberglass. This step is essential to ensure a smooth and professional finish. You can use fine-grit sandpaper to achieve a smooth surface. Finally, apply a suitable fiberglass paint or gelcoat to match the boat's original color, if desired. This multi-step process will help you effectively repair the small crack, restoring the structural integrity and appearance of your fiberglass boat.

Building Your Own Boat Dock: Easy Plans for Success

You may want to see also

Sand and Finish: Smooth the repair, sand it, and apply a protective coating to restore the boat's appearance

Before you begin the repair process, it's crucial to ensure the area around the crack is clean and free of any debris. Use a mild detergent and water solution to gently clean the surface, ensuring you remove any dirt or grime that might interfere with the bonding process. Rinse the area thoroughly and allow it to dry completely before proceeding.

The next step is to smooth the repair area. Carefully fill the crack with a suitable fiberglass repair kit, following the manufacturer's instructions. This kit will typically include a resin and a hardener that, when mixed, create a strong, durable material. Apply the mixture to the crack, ensuring it is level with the surrounding surface. Use a putty knife or a similar tool to spread the material evenly and create a smooth, seamless finish. Allow the initial layer to set according to the kit's instructions.

Once the initial layer is set, you can begin sanding. Start with a coarse-grit sandpaper (around 60-grit) to remove any excess material and create a smooth surface. Work in small sections, sanding gently but firmly. After removing the bulk of the material, switch to a finer-grit sandpaper (120-grit or higher) to achieve a smoother finish. Continue sanding until the repair area is flush with the surrounding fiberglass.

After sanding, it's time to prepare the surface for the final finish. Use a clean cloth to wipe away any dust or debris, ensuring a smooth and clean base for the protective coating. Then, apply a suitable fiberglass gelcoat or a clear marine-grade paint. Follow the manufacturer's instructions for application, ensuring an even and thin layer. Allow the coating to cure according to the product's guidelines.

Finally, once the protective coating is cured, your fiberglass boat repair will be complete. The process of sanding and finishing not only restores the boat's appearance but also ensures the structural integrity of the repair. Regular maintenance and care will help preserve the boat's beauty and longevity. Remember, proper preparation and attention to detail are key to a successful repair.

Exploring the English Channel: Dunkirk to Dover by Boat

You may want to see also

Frequently asked questions

Repairing a small crack in a fiberglass boat can be done with a few simple steps. First, ensure you have the right materials: fiberglass repair kit, which includes a filler, cloth, and resin; a heat gun or hairdryer; and a small brush or spatula. Clean the crack to remove any dirt or debris, then apply the resin and mix it thoroughly. Fill the crack with the resin and gently press the cloth into the mixture to create a smooth surface. Allow it to set for the recommended time, then sand it down to a smooth finish. Finally, apply a fiberglass repair tape and a clear coat to protect the repair.

For small cracks, a simple and effective method is to use a fiberglass repair kit. Start by cleaning the area around the crack. Then, apply the resin and mix it according to the kit's instructions. Use a small brush to apply the mixture into the crack, ensuring it's filled completely. After it sets, sand the area to create a smooth surface. You can also use a putty knife to carefully fill the crack and then smooth it out.

While it's possible to use temporary fixes, it's generally recommended to perform a proper repair for long-term results. For a small crack, you can use a quick-drying epoxy or a two-part filler from a repair kit. These can provide a strong bond and a smooth finish. However, for a more permanent solution, it's best to cut out the damaged area, apply a new piece of fiberglass, and bond it with resin. This ensures the structural integrity of the boat and prevents further issues.