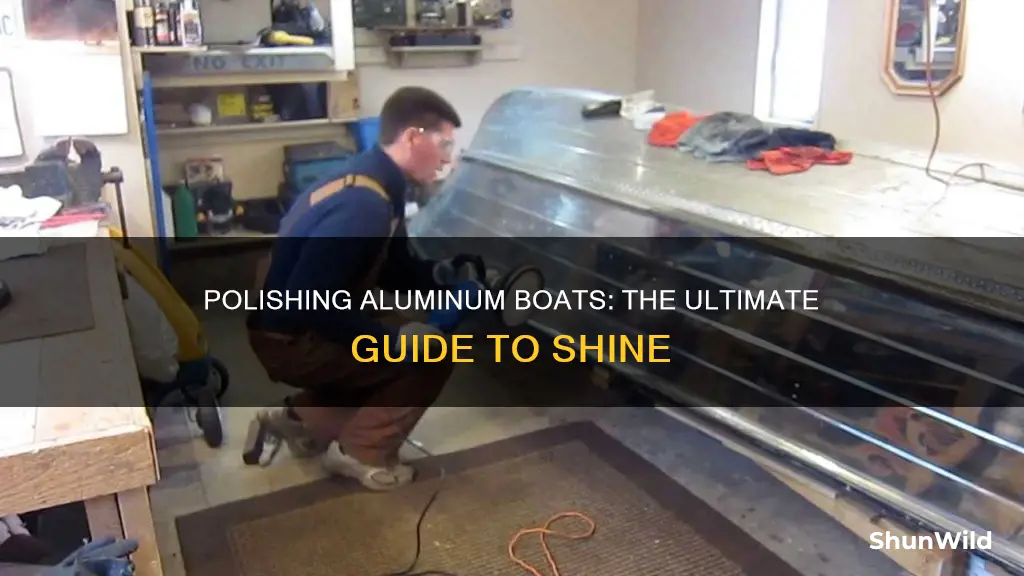

Aluminium boats are a popular choice for boaters due to their durability, lightweight build, and ability to withstand harsh weather conditions. However, over time, their shiny finish tends to dull and oxidize. Restoring the shine on an aluminium boat can be a rewarding experience, but it requires some effort and the right set of tools and techniques. In this guide, we will cover everything from the equipment you'll need to the step-by-step process of polishing your aluminium boat to achieve that desired mirror-like finish.

What You'll Learn

Protective gear and safety precautions

Before you begin polishing your aluminum boat, it is important to take the necessary safety precautions to protect yourself from potential hazards. Here is a list of protective gear you should consider:

- Hearing Protection: Buffing wheels can be extremely loud, so it is important to wear over-ear earmuffs or earplugs to protect your hearing.

- Eye and Face Protection: Goggles or a face shield will help protect your eyes and sensitive areas of your face from flying debris and contaminants.

- Respiratory Protection: A proper respirator or N-95 mask will prevent you from inhaling contaminants and dust particles during the polishing process.

- Clothing: Polishing can be a messy job, so wear old clothes that you don't mind getting dirty.

- Gloves: Gloves will protect your hands from dirt and contaminants, as well as provide a better grip when handling tools and equipment.

In addition to wearing the appropriate protective gear, here are some additional safety precautions to keep in mind:

- Work in a Well-Ventilated Area: Polishing can create dust and fumes, so make sure to work in an open or well-ventilated space to avoid inhaling harmful substances.

- Secure the Boat: Ensure that the boat is in a stable position and will not shift or move during the polishing process.

- Read Instructions: Before using any chemicals or compounds, carefully read the instructions and safety guidelines provided by the manufacturer.

- Regular Breaks: Polishing can be physically demanding, so take regular breaks to rest and avoid overexertion.

- Tool Maintenance: Maintain your tools and equipment according to the manufacturer's instructions to ensure they are in safe working condition.

- Clean-up: After completing the polishing process, properly dispose of any waste and clean your tools and equipment to prevent corrosion or damage.

By following these protective gear recommendations and safety precautions, you can help ensure that your aluminum boat polishing project is completed safely and effectively. Remember, your safety should always be a top priority.

Repairing a Leaking Boat: A Step-by-Step Guide

You may want to see also

Choosing the right tools

When it comes to choosing the right tools to polish an aluminium boat, there are several key considerations to keep in mind. Firstly, safety should always be the top priority. As such, it is important to select the appropriate protective gear, including hearing protection in the form of over-ear earmuffs or earplugs, as buffing wheels tend to be loud. Goggles or a face shield will safeguard your eyes and sensitive areas of your face from flying debris, while a proper respirator or N-95 mask will protect you from inhaling contaminants. Gloves are also recommended to keep your hands clean, as they will be closest to the tools and the surface you are working on.

For the actual polishing process, the most important tool you will need is a reliable buffing and polishing tool. An orbital rotary buffing tool, similar to the ones used for waxing cars, is a good option. It is important to avoid using an angle grinder, as their high RPMs make them unsuitable for polishing. Corded buffers are generally recommended over battery-powered ones as they are more reliable and cost-effective. Additionally, consider investing in a rotary tool, as it can be used for multiple purposes, such as waxing and polishing cars.

To achieve a mirror-like finish, you will need to follow three stages: the cutting stage, intermediate buffing, and final polish. Each stage requires progressively softer pads and finer buffing compounds. You will need three different types of wheels and buffing compounds: coarse, medium, and fine. The wheels typically come in sizes ranging from 7 inches to 12 inches, so be sure to select the size that is compatible with your rotary tool. Buffing compounds usually come in the form of bars and contain small amounts of sandpaper, which assist in the polishing process.

In addition to the buffing wheels and compounds, you may also need a specialised rake or a block of wood to remove the aluminium buildup from the wheel. This step is crucial, as the buildup can scratch your boat and hinder the polishing process.

Exploring the Intricacies of Dock Boats

You may want to see also

Stages of polishing

Stage 1: The Cutting Stage

First, ensure you are in a well-ventilated area and put on your safety gear: a respirator, goggles, and hearing protection. Next, fire up your rotary tool and apply some coarse buffing compound. You will use the side of the wheel to polish. Hold the rotary tool in your dominant hand and the bar in the other. Press the wheel against the bar for about 5 seconds to ensure the wheel is fully coated with the compound.

Now you are ready to start polishing! Make sure the boat is in a stable position where you can firmly press down with the rotary tool without it moving. Press down evenly but firmly on the boat with the side of the wheel, and sweep over a 3x3 section. Once the tool is no longer taking off material, stop polishing.

Stage 2: Intermediate Buffing

Get the aluminium off your wheel and apply more buffing compound. A specialised rake is a small metal tool you can buy online for under $10, or you can use a block of wood. Press your (still running) buffing wheel against it for about half a second to scrape off the aluminium buildup. Reapply the buffing compound, and go back to polishing. Repeat these steps as soon as you notice the rotary tool not polishing.

Stage 3: Final Polish

Once you've completed the first stage, take your shop towels or a pressure washer and clean off the buildup from the boat. It should be noticeably shinier already, but not quite a mirror finish. Move on to the next 2 stages, changing out your buffing wheel and polishing compound accordingly. After each stage, the boat will be noticeably shinier.

Stage 4: Waxing

After you finish stage 3, you will be left with a mirror finish! To maintain that shine, it is highly recommended to wax your boat every few months. You can use the same rotary buffing tool; all it takes is a microfiber pad and some wax. Any automotive wax will work just fine. Apply some wax onto your wheel and wax the entire boat. Wait about 10 minutes for the coating to become hazy, then buff it to a shine.

Eliminating Odor from Boat Shoes: A Step-by-Step Guide

You may want to see also

Removing oxidation

Aluminium boats are prone to oxidation, which causes a dull, cloudy appearance. To remove oxidation and restore shine, follow these steps:

Prepare your work area and gather your equipment:

- Find a well-ventilated area to work in.

- Put on the appropriate safety gear, including respirators, goggles, and hearing protection.

- Gather your polishing equipment: a reliable buffing and polishing tool, such as an orbital rotary buffing tool, and the necessary buffing wheels and compounds.

Understand the polishing process:

Aluminium polishing typically involves three stages: cutting, intermediate buffing, and final polish. Each stage uses progressively softer pads and finer buffing compounds to achieve a mirror-like finish.

Apply the coarse buffing compound:

- Start by firing up your rotary tool.

- Apply some coarse buffing compound to the side of the wheel.

- Gently press the wheel against the bar for about 5 seconds to ensure the entire wheel is coated.

Begin the polishing process:

- Position your boat in a stable manner.

- Press down evenly but firmly on the boat with the side of the wheel, sweeping over a small section at a time.

- Continue polishing until you no longer notice the tool taking off material.

- Remove the aluminium buildup from your wheel using a specialised rake or a block of wood.

- Reapply the buffing compound and repeat the process as needed.

Repeat the process with finer buffing compounds:

- After completing the first stage, clean off the buildup from the boat using shop towels or a pressure washer.

- Proceed to the next two stages, changing out your buffing wheel and polishing compound accordingly.

- Use progressively finer buffing compounds and softer pads with each stage.

Maintain your boat's shine:

- Consider waxing your boat every few months to preserve the mirror finish.

- Use a microfiber pad and any automotive wax, applying it to the entire boat.

- Wait about 10 minutes for the coating to become hazy, then buff it to a shine.

Remember, polishing aluminium boats can be a time-consuming and labour-intensive process. It requires patience and attention to detail. Always prioritise safety and take the necessary precautions to protect yourself from potential hazards.

Boat Safety 101: Tips for Sailing with Your Infant

You may want to see also

Maintaining the shine

Now that your boat has a mirror-like finish, you'll want to keep it that way. Here are some tips to maintain the shine:

Waxing: Apply a coat of wax to your boat every few months. You can use the same rotary buffing tool you used for polishing, along with a microfiber pad and any automotive wax. Spread the wax onto your wheel and apply it to the entire boat. After about 10 minutes, when the coating becomes hazy, buff it to a shine. This will keep your mirror finish looking brand new.

Protective Coatings: Consider applying a protective coating to your freshly polished boat. Products like Sharkhide and Vinyl Chrome can help protect your boat from salt and other elements, preventing oxidation and corrosion. These coatings can be applied over the wax coating for added protection.

Regular Cleaning: Regularly cleaning your boat will also help maintain its shine. Use a mild boat soap or liquid car wash soap and a soft cloth or sponge to gently wash away any dirt, grime, or salt water residue. Rinse the boat thoroughly with fresh water after each use to prevent the build-up of contaminants that can dull the finish.

Storage: When not in use, store your boat in a covered area, such as a garage or boat house. If possible, keep it covered with a boat cover specifically designed for your boat's make and model. This will protect it from the elements, including sunlight, which can fade and dull the finish over time.

By following these simple maintenance tips, you can keep your aluminum boat looking shiny and new for years to come. Remember, a little bit of regular care goes a long way in maintaining the shine and protecting your investment.

Kayak Naming Traditions: Like Boats or Different?

You may want to see also

Frequently asked questions

There are several products that can be used to polish aluminum boats, including Mothers Polishing Compound, Jewelers Rouge, Heavy Metal Green, and Flitz.

You will need safety equipment such as hearing protection, goggles, a face shield, and a respirator or N-95 mask. For the polishing process itself, you will need a reliable buffing and polishing tool, such as an orbital rotary buffing tool. You will also need buffing wheels and compounds in varying levels of coarseness, from coarse to fine.

The process typically involves three stages: the cutting stage, intermediate buffing, and the final polish. Each stage uses progressively softer pads and finer buffing compounds. It is important to work in small sections at a time and to maintain control of your buffing tool, especially around corners and curves.

To maintain the shine, it is recommended to wax your boat every few months. You can use a microfiber pad, automotive wax, and a rotary buffing tool to apply the wax.