Reinforcing the transom on an aluminum boat is a crucial step in ensuring the safety and longevity of your vessel. The transom, being the vertical reinforcement at the rear of the boat, plays a critical role in strengthening the stern and serving as a mounting point for the engine. A weak or damaged transom can lead to instability, steering difficulties, and even structural failure, so it is important to reinforce it properly. This process involves carefully planning and executing a set of steps, from removing the old transom to reattaching hardware, and can be done by almost anyone with basic materials.

| Characteristics | Values |

|---|---|

| Materials | Sturdy piece of aluminum sheet, marine-grade plywood, carpenters glue, epoxy resin, marine-grade screws and bolts, measuring tape, pencil, level |

| Step 1 | Remove the old transom by detaching accessories or parts attached to it, such as the motor, ladder, or any other hardware |

| Step 2 | Measure and cut the new transom using the old transom as a guideline |

| Step 3 | Apply glue and attach the plywood to the boat |

| Step 4 | Apply epoxy resin for additional strength and waterproofing |

| Step 5 | Attach the aluminum sheet |

| Step 6 | Seal the edges to prevent water penetration |

| Step 7 | Reattach hardware such as the motor and ladder |

| Step 8 | Final inspection and testing to ensure the reinforced transom is stable and secure |

What You'll Learn

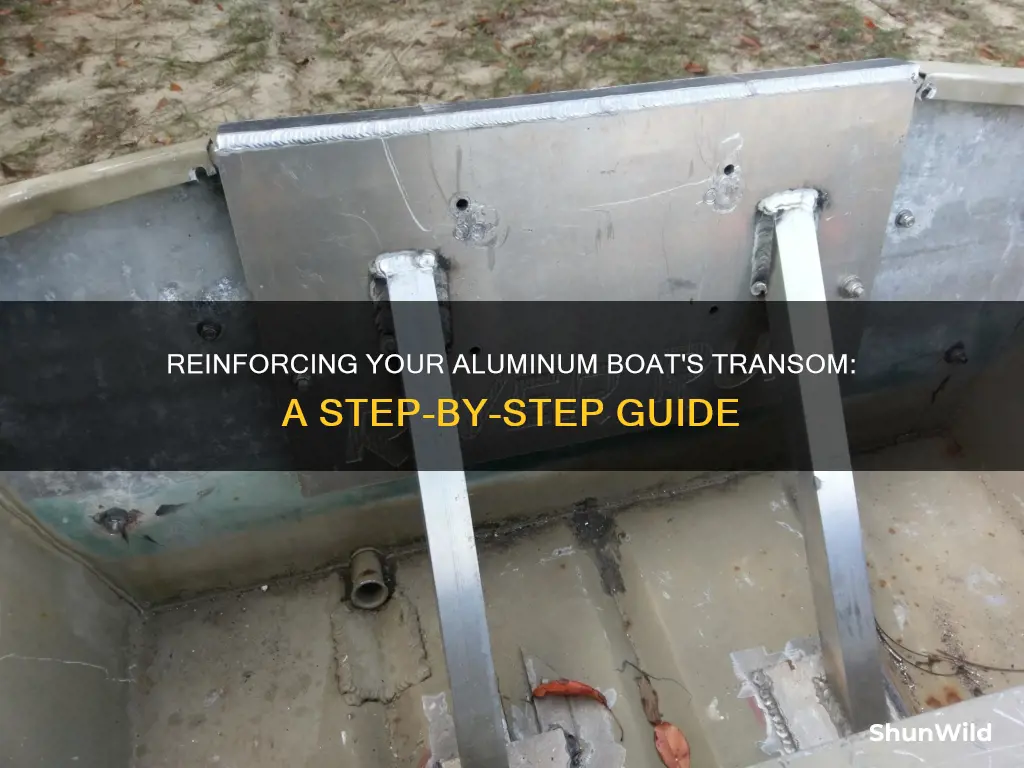

Removing the old transom

Firstly, identify all the rivets that run through the transom. In most cases, you will find 16 rivets, but the number may vary depending on the boat. It is important to mark the rivets with a Sharpie to ensure you only drill out the ones that need to be removed. Use a spring-loaded punch to create a divot on the rivet head, which will help guide your drill and prevent it from slipping. Drill out the marked rivets, being careful not to make the holes in the hull any bigger than necessary. Once all the rivets are removed, the transom should be loose and ready for removal.

Before removing the transom, it is worth considering whether you plan to do any additional hull work. If so, now is the perfect time to sand, paint, or apply a bed liner to the interior and exterior of the boat.

Next, carefully remove the old transom. Depending on the design of your boat, you may need to remove additional components to access the transom fully. This could include side pieces, the vertical brace, or the piece at the bottom of the transom. Take your time and work methodically to avoid causing any unnecessary damage.

Once the transom is removed, take the opportunity to inspect the surrounding areas for any signs of damage or weakness. Pay close attention to the welds between the transom and the bottom of the boat, as these are critical to the structural integrity of the vessel. If you notice any cracks or failures, they will need to be addressed before installing the new transom.

Finally, clean the area thoroughly to remove any debris, residue, or old sealant. This will ensure that the surface is ready for the new transom and create a smooth finish.

Remember to take appropriate safety precautions throughout the process, including wearing protective gear such as gloves and eye protection. It is also advisable to work with a partner or assistant, especially when handling heavy components or using power tools.

DMCA Protection for Boat Hull Designs: Yes or No?

You may want to see also

Measuring and cutting the new transom

To reinforce your aluminium boat's transom, you will need to start by measuring and cutting the new transom. This process requires careful planning and execution, as well as the gathering of necessary materials.

Firstly, you will need to remove the old transom. Detach any accessories or parts attached to it, such as the motor, ladder, or any other hardware. Carefully remove the screws or bolts holding the old transom in place, and handle with care to avoid damaging the boat's hull. Once the old transom is removed, inspect the area for any signs of wear or damage that must be addressed before installing the new, reinforced transom.

Now, you are ready to measure and cut the new transom. Using the old transom as a guideline, take measurements and mark the dimensions on the marine-grade plywood. Ensure you account for any additional reinforcements you intend to add. Precision is critical at this stage, as an improperly sized transom can cause stability issues. Cut the plywood using an appropriate tool, and then check the fit by placing it in the transom area. Make any necessary adjustments before proceeding.

It is important to note that you should only proceed to the next step once you are satisfied with the fit of the plywood. The following steps involve the application of glue and epoxy resin, which will make it difficult to make adjustments.

These detailed instructions on measuring and cutting the new transom for your aluminium boat will help ensure the stability and safety of your vessel for future adventures.

Boat Found Under Twin Towers: What's the Story?

You may want to see also

Applying glue and attaching the plywood

To attach the plywood, you'll first need to apply a generous amount of carpenter's glue to the side of the plywood that will be attached to the boat. Make sure the glue is spread evenly across the entire area for a secure fit.

Next, position the plywood in the transom area and press it firmly against the boat. Check that it is level and make any necessary adjustments. Once you're happy with the positioning, attach the plywood using marine-grade screws or bolts. Be careful not to over-tighten, as this could cause the plywood to crack. Allow the glue to dry fully before moving on to the next step.

After the glue has dried, you'll add an aluminium sheet for further reinforcement. First, measure and cut the aluminium sheet to match the size of the plywood. Then, place the aluminium sheet onto the plywood, ensuring it aligns correctly. Securely fasten the aluminium sheet to the plywood using marine-grade screws or bolts, distributing them evenly to ensure even pressure and a secure fit.

The Mystery of Unregistered Boats: Navigating Without a Title

You may want to see also

Adding an aluminium sheet

Firstly, you'll need to gather the necessary materials. For this step, you will require a sturdy piece of aluminium sheet, marine-grade plywood, carpenter's glue, epoxy resin, marine-grade screws and bolts, and tools for measuring, marking, and levelling.

Now, let's get into the process:

- Remove the Old Transom: Start by carefully detaching any parts attached to the old transom, such as the motor, ladder, or other hardware. Store these parts safely. Then, remove the old transom by unscrewing or unbolting it. Be cautious not to damage the hull during this process. Finally, inspect the exposed area for any wear or damage.

- Measure and Cut the New Transom: Use the old transom as a reference to measure and mark the dimensions on the marine-grade plywood. Ensure you account for any additional reinforcements. Cut the plywood with precision to match the required size. Double-check the fit by placing it in the transom area, and make any necessary adjustments.

- Apply Glue and Attach the Plywood: Spread a generous amount of carpenter's glue onto the side of the plywood that will face the ship. Position the plywood in the transom area, pressing it firmly against the boat. Check for level, and adjust as needed. Secure the plywood in place using marine-grade screws or bolts, being careful not to over-tighten to avoid cracking the wood. Allow the glue to dry completely.

- Apply Epoxy Resin: Once the glue has dried, mix and apply a layer of epoxy resin to the entire surface of the plywood. This will add strength and waterproofing. Make sure to cover all areas, especially the edges. Allow the epoxy to cure fully; this step may take several hours or a couple of days, depending on the product.

- Attach the Aluminium Sheet: Measure and cut the aluminium sheet to match the size of the plywood. Place the aluminium sheet onto the plywood, ensuring proper alignment. Securely fasten the aluminium sheet to the plywood using marine-grade screws or bolts, distributing them evenly for even pressure. Inspect your work to ensure a secure fit.

- Seal the Edges: Apply a high-quality marine sealant along the edges where the aluminium sheet meets the boat. This step will provide additional protection against water penetration. Follow the manufacturer's instructions for drying time.

By following these steps, you will successfully reinforce your aluminium boat's transom with an aluminium sheet, ensuring its longevity, stability, and safety for future adventures on the water.

Camouflaging Your Boat: Painting Tips and Tricks

You may want to see also

Reattaching hardware

Once you have reinforced the transom on your aluminum boat, it is time to reattach the hardware. This includes the motor, ladder, and any other accessories. Ensure that you securely fasten each component using marine-grade screws or bolts. It is crucial to replace any hardware that shows signs of wear or damage to maintain the integrity and safety of your vessel.

When reattaching the motor, carefully follow the manufacturer's instructions and safety guidelines. Make sure the motor is correctly aligned and securely mounted to the transom. Check all the bolts and screws to ensure they are tight and secure. If you have replaced the motor with a newer model, ensure that it is compatible with the transom and that the weight distribution is appropriate.

For accessories such as ladders, swim platforms, or additional seating, use marine-grade hardware to securely attach them to the transom. These accessories can improve the functionality and safety of your boat, but only if they are properly installed. Ensure that the hardware is not rusted or corroded and that the accessories are firmly attached.

If you have added any electronic components, such as navigation lights or a fish finder, make sure the wiring is secure and protected from water intrusion. Check that all connections are soldered and insulated properly. Test the electronics to ensure they are functioning correctly.

After reattaching all the hardware, conduct a thorough final inspection of your work. Check the stability of the reinforced transom and ensure there are no loose screws or bolts. Inspect the sealant around the edges of the transom for any gaps or cracks that could allow water infiltration. Look for any areas that might have been missed during sealing and apply additional sealant if necessary.

Finally, test your boat in the water. Start in calm, shallow waters and gradually move to deeper areas. Observe the boat's performance and handling. Listen for any unusual noises or vibrations that could indicate a problem. If you notice any issues, address them immediately.

Remember to perform regular inspections and maintenance on your boat's transom to ensure its longevity and safety. Check for any signs of damage, corrosion, or water infiltration. By taking proper care of your reinforced transom, you can enjoy many more safe and enjoyable boating adventures.

Choosing Boat Dock Features: What to Consider

You may want to see also

Frequently asked questions

You will need a sturdy piece of aluminum sheet, marine-grade plywood, carpenter's glue and epoxy resin, marine-grade screws and bolts, and measuring tape, a pencil, and a level.

The first step is to remove the old transom by detaching any accessories or parts attached to it, such as the motor or ladder, and then carefully removing the screws or bolts holding it in place.

After removing the old transom, you should measure and cut the new transom, using the old transom as a guideline. Ensure you account for any additional reinforcements you plan to add.

To attach the new transom, apply carpenter's glue to the plywood, position it in place, and attach it using marine-grade screws or bolts. Once the glue is dry, apply epoxy resin for additional strength and waterproofing.