Fixing a leak in a fiberglass boat can be a challenging task, but with the right approach and materials, it is certainly achievable. This guide will provide a step-by-step process to effectively repair and seal leaks, ensuring the boat's structural integrity and longevity. From identifying the source of the leak to choosing the appropriate repair methods and materials, we will cover essential techniques to help boat owners and enthusiasts tackle this issue with confidence.

What You'll Learn

- Identify the leak source: Inspect the boat thoroughly to pinpoint the damaged area

- Clean and prepare: Remove debris and ensure a clean, dry surface for repair

- Choose the right repair method: Select an appropriate technique for the specific leak

- Use appropriate materials: Select the right fiberglass repair resin and filler for a strong bond

- Reinforce and finish: Add structural support and apply a protective coating for long-term repair

Identify the leak source: Inspect the boat thoroughly to pinpoint the damaged area

When dealing with a fiberglass boat leak, the first and most crucial step is to identify the source of the issue. This requires a thorough inspection of the boat's structure, as leaks can occur in various areas, often hidden from plain sight. Start by examining the boat's exterior, looking for any visible signs of damage, such as cracks, holes, or soft spots in the fiberglass. Pay close attention to areas where the hull meets other components, like the cabin floor, transom, or stringers, as these are common weak points. Use a flashlight to illuminate tight spaces and ensure you don't miss any potential issues.

Once you've scanned the exterior, it's time to move inside. Inspect the cabin and cockpit areas, checking for any signs of water intrusion. Look for wet spots on the floor, walls, or ceiling, which could indicate a leak. Feel the surfaces for any dampness or softness, as these might be areas where water has seeped in. Also, inspect the interior compartments and storage areas, as these can sometimes be the source of leaks, especially if they are not properly sealed.

The engine compartment is another critical area to investigate. Leaks here can cause significant damage to the engine and electrical systems. Inspect the engine's gaskets, seals, and hoses for any cracks or deterioration. Check for any signs of water or moisture around the engine and ensure that all wiring is intact and not damaged by water. It's also a good idea to inspect the bilge area, as this is where water from leaks often collects.

Pay attention to the boat's seams and joints, as these are potential weak links. Over time, these areas can become compromised due to UV damage, oxidation, or simply the stress of movement. Carefully examine the gelcoat and underlying layers for any signs of damage or wear. Use a sharp tool to gently probe the surface, as this can help identify areas where the fiberglass has been compromised.

If you find any suspicious areas during your inspection, it's essential to take detailed notes and photographs. This documentation will be invaluable when deciding on the next steps and choosing the appropriate repair method. Remember, the key to successfully fixing a fiberglass boat leak is to act promptly and address the issue at its source.

Super Boat Race: Lake of the Ozarks Champion

You may want to see also

Clean and prepare: Remove debris and ensure a clean, dry surface for repair

When dealing with a fiberglass boat leak, the initial step is to thoroughly clean and prepare the affected area. This process is crucial to ensure a successful repair. Start by carefully inspecting the leak to identify any loose fibers, sharp edges, or other debris that might have accumulated. Use a soft-bristled brush or a vacuum cleaner with a brush attachment to gently remove any visible dirt, sand, or other foreign matter from the surface. Pay close attention to the edges of the leak, as these areas may require extra care to prevent further damage.

Once the debris is cleared, it's essential to ensure the surface is completely dry. Moisture can hinder the bonding process and may lead to additional issues. Use a clean, soft cloth or a towel to absorb any remaining water. If the leak is in a hard-to-reach area, consider using a hairdryer on a low setting to speed up the drying process, being cautious not to apply excessive heat.

After the surface is dry, it's time to smooth out any rough spots. Fiberglass can be prone to becoming brittle and fragile over time, so it's important to address any imperfections. Use fine-grit sandpaper (600-grit or higher) to gently smooth the area, removing any sharp edges or small bumps. This step is vital to create a seamless and even surface for the repair material. Take your time and be thorough, as this will contribute to a stronger and more durable repair.

Additionally, consider using a mild detergent solution to further clean the area. This will help remove any remaining dirt or grime that might interfere with the bonding process. Rinse the area thoroughly with clean water to ensure no detergent residue remains. The goal is to create a pristine environment for the repair, promoting strong adhesion and a long-lasting fix.

By following these steps, you'll create a clean, dry, and prepared surface, setting the foundation for a successful fiberglass boat leak repair. This meticulous preparation is key to ensuring the repair material bonds effectively and provides a seamless finish.

Boats Required to Have Radar: Understanding the Regulations

You may want to see also

Choose the right repair method: Select an appropriate technique for the specific leak

When dealing with a leak in a fiberglass boat, the first step is to carefully assess the damage and choose the most suitable repair method. This decision is crucial as it directly impacts the effectiveness and longevity of the fix. Here's a guide to help you select the right technique:

Identify the Leak's Source: Start by locating the exact point of the leak. Fiberglass boats can have various vulnerabilities, such as seams, hull penetrations, or even damage from impacts. Carefully inspect the affected area to understand the nature and extent of the leak. Is it a small pinhole, a cracked seam, or a larger area of damage? Identifying the source is key to choosing the appropriate repair.

Consider the Repair Options: There are several methods to repair a fiberglass boat leak, each with its advantages and limitations. Here are some common techniques:

- Resin Injection: This method is ideal for small holes or cracks. It involves injecting a specialized epoxy resin into the damaged area, filling the void and creating a strong bond. Resin injection is a precise process and may require multiple applications for larger leaks.

- Fiberglass Patching: For larger damage, a fiberglass patch is often used. This involves cutting out the damaged section, cleaning the area, and applying a layer of resin before placing a pre-cut fiberglass patch. The patch is then reinforced with additional layers of cloth or weave, ensuring structural integrity.

- Seam Sealing: If the leak is near a seam, sealing it is essential. This method requires carefully cleaning the seam area, applying a suitable sealant, and ensuring a tight fit. It's crucial to use a sealant compatible with fiberglass to avoid future issues.

Prepare the Repair Area: Before proceeding, ensure the boat's surface is clean and free of debris. Rinse the affected area with water and mild detergent, then dry it thoroughly. This preparation step ensures better adhesion and bonding during the repair process.

Choose the Right Technique: The selection of the repair method depends on the leak's characteristics and the boat's overall condition. For instance, if the leak is a small, isolated issue, resin injection might be sufficient. However, for larger damage or multiple leaks, a comprehensive approach like fiberglass patching and reinforcement might be necessary. Always consider the boat's age, previous repairs, and the desired level of structural integrity when making your decision.

The Sanger DX2: Best Barefoot Boat?

You may want to see also

Use appropriate materials: Select the right fiberglass repair resin and filler for a strong bond

When dealing with a leak in a fiberglass boat, one of the most critical aspects of the repair process is choosing the right materials to ensure a strong and durable bond. The key to a successful repair lies in selecting the appropriate fiberglass repair resin and filler, as these components will form the foundation of the fix.

Fiberglass repair resins come in various types, each with unique properties. The most common types include epoxy and polyester resins. Epoxy resins are known for their exceptional strength and adhesion, making them ideal for structural repairs. They create a hard, durable bond that can withstand the rigors of marine environments. On the other hand, polyester resins are more flexible and impact-resistant, which is beneficial for repairing non-structural areas or where some flexibility is required. It's essential to assess the specific needs of the repair to choose the right resin type.

Filler materials play a crucial role in filling the voids and creating a smooth surface for the repair. There are two primary types of fillers: woven and non-woven. Woven fillers, such as glass cloth or mat, provide excellent structural support and are often used in load-bearing applications. Non-woven fillers, like fiberglass mesh or tape, are more flexible and can be used for repairs where some movement is expected. The choice of filler depends on the size and shape of the leak, as well as the desired strength and flexibility of the repair.

When selecting the resin and filler, consider the following factors: the type of fiberglass used in the boat, the size and depth of the leak, and the desired strength and durability of the repair. For instance, if the leak is in a structural component, an epoxy resin with a woven filler might be the best choice. For non-structural areas, a polyester resin with a non-woven filler could provide a flexible and impact-resistant repair.

Additionally, it is essential to follow the manufacturer's instructions for mixing and applying the resin and filler. Proper mixing ensures the correct chemical reaction, creating a strong and cohesive bond. Applying the repair material at the right temperature and humidity levels is also crucial for optimal results. Taking the time to carefully select and prepare the materials will significantly contribute to the success and longevity of the fiberglass boat repair.

The Evolution of Boat Shoe Badges: A Style Guide

You may want to see also

Reinforce and finish: Add structural support and apply a protective coating for long-term repair

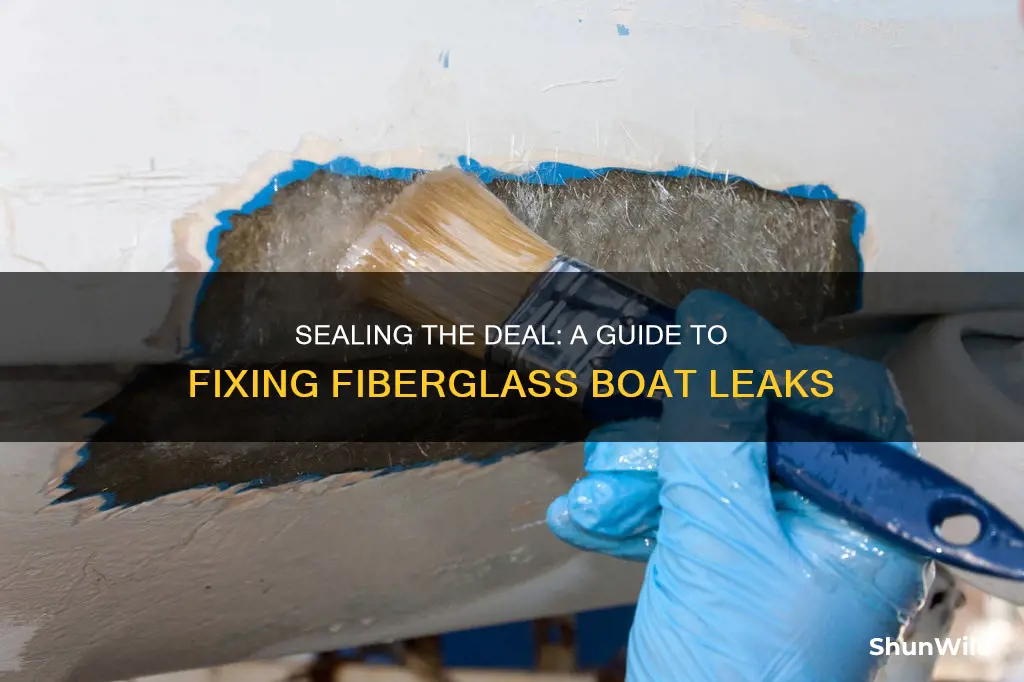

When dealing with a fiberglass boat leak, reinforcing and finishing the repair is crucial for ensuring long-term durability and protection. This process involves adding structural support to the damaged area and applying a protective coating to prevent further issues. Here's a step-by-step guide to achieving a successful repair:

Reinforcing the Structure: Start by assessing the extent of the damage and identifying the weak points in the boat's structure. Fiberglass is a lightweight material, but it can be fragile, especially when compromised by a leak. Use a high-strength epoxy resin to fill and reinforce the damaged area. Carefully inject the resin into the voids and gaps, ensuring it reaches all affected areas. Allow sufficient time for the resin to cure, providing a solid and durable base for further repairs. Consider adding fiberglass cloth or tape to the reinforced area for added strength. This layer of reinforcement will help distribute stress more evenly and prevent future leaks.

Structural Support: After the initial reinforcement, it's essential to provide additional structural support. This is particularly important for larger leaks or areas where the boat's integrity is compromised. Use epoxy-resin-impregnated fiberglass cloth or tape to create a composite layer over the damaged section. This technique, known as 'patching,' adds strength and stability to the boat's structure. Ensure the patch is securely bonded to the surrounding fiberglass using the appropriate epoxy adhesive. For a seamless finish, carefully blend the patch with the original boat surface.

Protective Coating Application: Once the structural repairs are complete, it's time to apply a protective coating. Choose a marine-grade epoxy or polyurethane varnish specifically designed for fiberglass boats. These coatings provide excellent protection against UV rays, water intrusion, and chemical damage. Prepare the surface by ensuring it is clean, dry, and free of any debris. Apply the coating in thin, even layers, allowing each layer to cure before applying the next. This process creates a protective barrier that safeguards the boat's structure and helps prevent future leaks.

Finishing Touches: After the protective coating is applied, inspect the repair thoroughly. Ensure there are no visible defects or imperfections that could compromise the integrity of the repair. If necessary, apply additional layers of the protective coating to achieve the desired thickness and finish. Consider using a marine-grade clear coat to enhance the appearance and provide an extra layer of protection. With proper reinforcement and finishing, your fiberglass boat leak will be effectively repaired, ensuring a safe and reliable vessel for your aquatic adventures.

Exploring Oceans in a 20-Foot Searunner: Good Idea?

You may want to see also

Frequently asked questions

Locating the leak can be challenging, but there are a few methods to help pinpoint the issue. Start by inspecting the boat's structure and looking for any visible signs of damage, such as holes, cracks, or delamination. Pay attention to areas where the hull meets other components, like the transom, stringers, or the bottom. You can also use a strobe light or a flashlight to shine into the boat's interior and look for any water accumulation or damp spots. If the leak is in the cabin, check for any water seeping through windows or vents.

Repairing a fiberglass boat leak requires a few essential tools and materials. You'll need a fiberglass repair kit, which typically includes a fiberglass cloth, resin, hardener, and a filler compound. Additionally, you'll require a heat gun or hairdryer to apply heat and cure the repair materials. It's also recommended to have a respirator and gloves for protection during the repair process. For larger leaks, you might need a fiberglass repair tape and a suitable adhesive to reinforce the repair.

While some minor leaks can be temporarily patched by boat owners, it's generally recommended to seek professional help for a proper and long-lasting repair. Fiberglass boat repairs can be complex, especially if the leak is extensive or in a critical area. Professionals have the expertise and experience to assess the damage accurately and provide a reliable solution. They can also ensure that the repair is structurally sound and meets the manufacturer's specifications. DIY repairs might be suitable for small leaks, but for a thorough and safe fix, consulting a professional is advisable.

The repair process typically involves several steps. First, thoroughly clean the damaged area and ensure it is dry. Then, prepare the repair materials according to the kit instructions. Apply the resin and hardener to the leak area, ensuring complete coverage. Lay the fiberglass cloth over the repair site and gently press it into place. Use the heat gun or hairdryer to cure the resin, following the recommended temperature and timing. Once cured, sand the repair area smooth and apply a suitable primer and paint to match the boat's finish. Finally, test the boat's buoyancy and ensure all repairs are secure before returning to the water.