Hydraulic tilt and trim systems are essential components of modern boats, offering precise control over the boat's trim and stability. These systems utilize hydraulic cylinders and pumps to adjust the boat's angle and position, allowing for optimal performance and handling. By controlling the tilt and trim, the boat can be levelled, raised, or lowered, ensuring better stability, reduced drag, and improved fuel efficiency. This technology is particularly useful for boats with high-performance engines, as it enables fine-tuning of the boat's attitude for maximum power and control. Understanding how hydraulic tilt and trim works is crucial for boat owners and operators, as it empowers them to optimize their vessel's performance and ensure a safe and comfortable journey on the water.

| Characteristics | Values |

|---|---|

| Function | Adjusts the boat's trim (fore-aft movement) and tilt (side-to-side movement) to optimize performance and handling. |

| Operation | Utilizes hydraulic cylinders and pumps to extend or retract the trim and tilt mechanisms. |

| Control | Typically controlled by a lever or pedal, allowing the operator to adjust the trim and tilt angles. |

| Benefits | Improved boat stability, reduced draft, enhanced fuel efficiency, and better performance in various water conditions. |

| Applications | Commonly used on power boats, particularly those with inboard or outboard motors. |

| Safety | Hydraulic systems are designed with safety features to prevent accidental movement and ensure operator safety. |

| Maintenance | Regular maintenance is required to ensure proper functioning, including checking fluid levels and hydraulic lines. |

| Advantages | Provides precise control, smooth operation, and the ability to fine-tune the boat's position for different activities. |

| Disadvantages | Can be expensive to install and maintain, and may require professional assistance for repairs. |

What You'll Learn

- Hydraulic System: Hydraulics power the tilt and trim mechanism, allowing for precise boat control

- Valves and Pumps: These components regulate fluid flow, enabling movement and adjustment

- Sensors and Feedback: Sensors provide data for accurate positioning and trimming

- Motor Operation: Electric motors drive the hydraulic system, converting energy into motion

- Safety Mechanisms: Built-in safety features prevent over-extension and ensure controlled movement

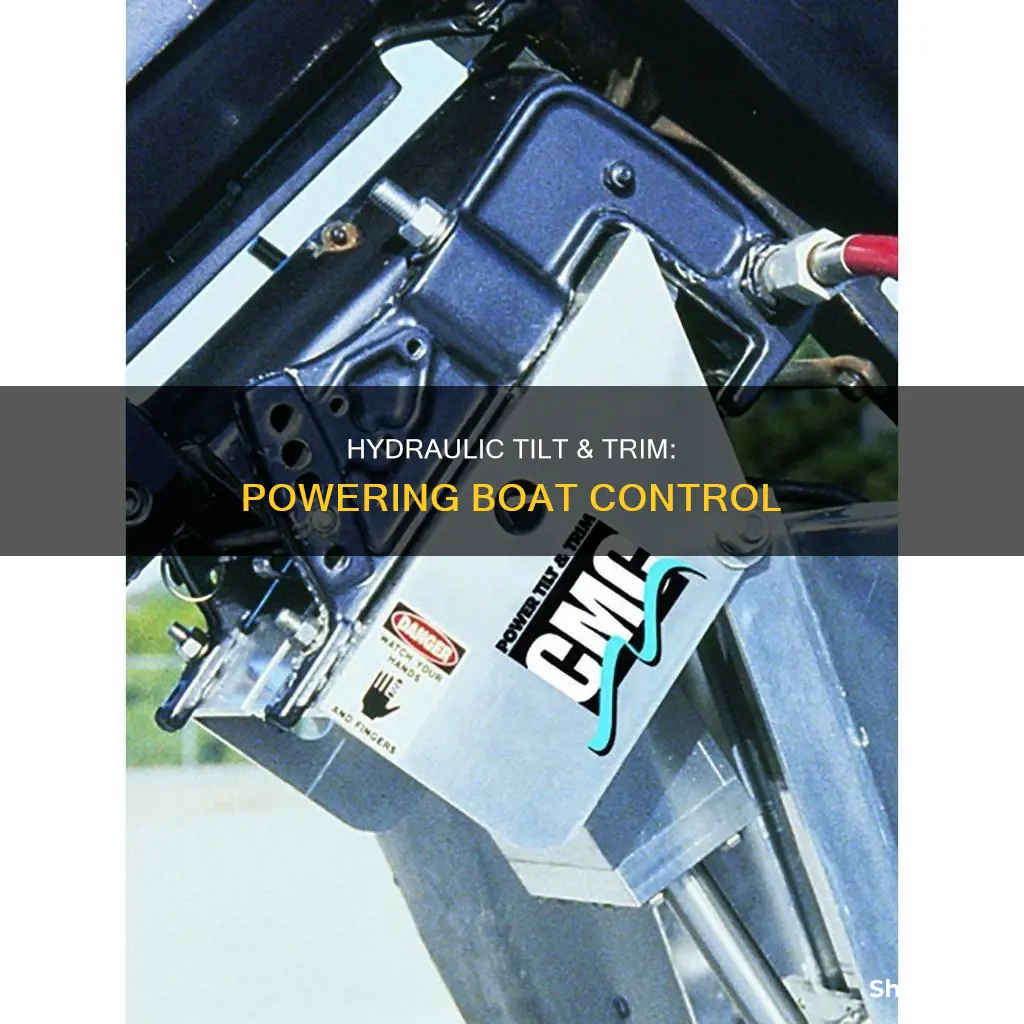

Hydraulic System: Hydraulics power the tilt and trim mechanism, allowing for precise boat control

The hydraulic system is a powerful and efficient method used to control the tilt and trim of a boat, offering precise adjustments to enhance both performance and comfort. This mechanism is particularly useful for larger vessels, where manual adjustments can be cumbersome and time-consuming. The hydraulic power system operates by utilizing pressurized fluid, typically hydraulic oil, to transmit force and motion. This fluid is contained within a closed loop, ensuring a constant and reliable power source for the tilt and trim mechanism.

At the heart of this system is a hydraulic cylinder, which is a cylindrical chamber with a piston inside. When hydraulic fluid is pumped into the cylinder, it exerts pressure on the piston, causing it to move. This linear motion is then transferred to the boat's tilt and trim mechanism. The cylinder is connected to the boat's frame, and its movement is controlled by a series of valves and pumps. These valves regulate the flow of hydraulic fluid, allowing for precise control over the speed and direction of the tilt and trim action.

The process begins when the operator activates the control system, typically located in the boat's helm or console. This action triggers the hydraulic pump, which starts the flow of pressurized fluid. The fluid travels through the hydraulic lines, which are designed to withstand high pressure, to the hydraulic cylinder. As the fluid enters the cylinder, it pushes the piston, causing the boat to tilt or trim accordingly. The force and speed of this movement are directly proportional to the amount of fluid directed to the cylinder, providing a smooth and controlled action.

One of the key advantages of this hydraulic system is its ability to provide fine-tuned control. The operator can adjust the tilt and trim positions with minimal effort, ensuring the boat is always in the optimal configuration for the given conditions. This is especially beneficial when navigating through varying water depths or when loading and unloading cargo, as it allows for quick and precise adjustments. The system's responsiveness and accuracy contribute to a more comfortable and controlled boating experience.

Furthermore, the hydraulic tilt and trim system offers a level of safety and reliability. The closed-loop design of the hydraulic system ensures that the fluid is always under control, reducing the risk of leaks or system failures. This is crucial for marine applications, where the consequences of a malfunctioning system could be severe. Regular maintenance and monitoring of the hydraulic fluid levels and pressure can further enhance the system's longevity and performance.

Peace Boat's Docking Locations: A Traveler's Guide

You may want to see also

Valves and Pumps: These components regulate fluid flow, enabling movement and adjustment

Valves and pumps are integral to the hydraulic tilt and trim system on boats, playing a crucial role in regulating fluid flow and enabling precise movement and adjustment of the boat's trim. These components work in harmony to ensure smooth and controlled operation of the boat's hull and engine positioning.

Valves, typically solenoid-operated, are responsible for controlling the flow of hydraulic fluid. When activated, the valve opens or closes, allowing or restricting the passage of fluid. This action directly impacts the pressure and direction of the fluid, which in turn affects the boat's trim. For example, when the valve is open, hydraulic fluid flows freely, allowing the boat to move up or down, depending on the direction of the fluid. Conversely, closing the valve restricts fluid flow, preventing movement and maintaining the boat's current trim position.

Pumps are another essential component, generating the necessary pressure to move the hydraulic fluid. These pumps are often electric or mechanical, designed to create a controlled flow of fluid. The pump's output determines the force and speed of the hydraulic system. Higher pump pressure results in faster and more responsive trim adjustments, while lower pressure provides smoother, more gradual movements. The pump's efficiency and capacity are critical factors in ensuring the hydraulic system can handle the boat's trim requirements.

The combination of valves and pumps allows for fine-tuning of the boat's trim. By adjusting the valve settings and pump output, operators can customize the system's performance. This customization is particularly useful for boats with varying loads or those operating in different water conditions. For instance, a boat with a heavy engine or carrying additional passengers might require more powerful pumps and valves to maintain optimal trim.

In summary, valves and pumps are the key regulators in the hydraulic tilt and trim system, controlling fluid flow and pressure to enable precise boat movement. Their proper selection and calibration are essential to ensure the system functions efficiently and effectively, providing the desired level of control and comfort for the boat's operator. Understanding these components' roles is vital for anyone working with or maintaining a boat's hydraulic tilt and trim mechanism.

Cutting Aluminum Boat Seats: A Step-by-Step Guide

You may want to see also

Sensors and Feedback: Sensors provide data for accurate positioning and trimming

Hydraulic tilt and trim systems on boats utilize a network of sensors and feedback mechanisms to ensure precise control over the vessel's trim and tilt angles. These sensors play a crucial role in providing real-time data, allowing the system to make accurate adjustments. The primary sensors used in this setup include angle sensors and position sensors. Angle sensors, typically mounted on the boat's hull or transom, measure the tilt angle of the vessel relative to the waterline. This information is vital for understanding the boat's orientation and its impact on performance and stability. Position sensors, on the other hand, monitor the actual position of the trim tabs or actuators. These sensors provide feedback on the current trim angle, enabling the system to make fine-tuned adjustments to achieve the desired trim.

The data collected by these sensors is then processed by the hydraulic system's control unit. This unit acts as the brain of the system, interpreting the sensor inputs and making decisions to adjust the trim and tilt. When the system receives feedback indicating a deviation from the desired trim angle, it calculates the necessary hydraulic pressure to counteract this deviation. For instance, if the boat is leaning too far to one side, the sensors will detect this, and the control unit will activate the corresponding hydraulic cylinder to counteract the tilt, bringing the boat back to its optimal trim.

This feedback loop is essential for maintaining stability and performance. By continuously monitoring the boat's position and angle, the system can make rapid adjustments, ensuring that the vessel remains level and balanced. This is particularly important during various boating activities, such as cruising, docking, or maneuvering in tight spaces, where precise control is required. The sensors and feedback system work in harmony to provide a smooth and responsive operation, allowing the boat to adapt to changing conditions and maintain optimal performance.

In summary, the sensors and feedback mechanism are integral to the hydraulic tilt and trim system's functionality. They provide the necessary data for accurate positioning and trimming, ensuring the boat's stability and performance. With this technology, boaters can enjoy a more controlled and responsive experience, making it easier to navigate and operate the vessel in various conditions. The continuous monitoring and adjustment capabilities of this system contribute to a safer and more efficient boating experience.

Understanding Boat Primer Solenoids: How They Work

You may want to see also

Motor Operation: Electric motors drive the hydraulic system, converting energy into motion

The hydraulic tilt and trim system on a boat is a crucial component that allows for precise control of the vessel's angle and position relative to the water. This system is designed to enhance boat handling, improve stability, and provide a more comfortable ride by adjusting the boat's trim and tilt. At the heart of this mechanism are electric motors, which play a pivotal role in driving the hydraulic system and converting electrical energy into the mechanical motion required to operate the boat's trim and tilt features.

When the operator engages the electric motor, it initiates the hydraulic process by activating a pump, typically an electric or hydraulic pump, which is responsible for generating the necessary pressure to move hydraulic fluid. This pump is a critical component as it provides the force required to drive the hydraulic cylinders, which are the key elements in the tilt and trim mechanism. The pump's operation is precise and responsive, ensuring that the hydraulic fluid is directed and controlled accurately.

The hydraulic fluid, often a specialized type of oil, is directed through lines to the hydraulic cylinders, which are strategically positioned on the boat's hull. These cylinders contain a piston that, when actuated by the fluid, extends or retracts, causing the boat to tilt or trim accordingly. The electric motor's power and control are such that it can precisely adjust the fluid flow, allowing for fine-tuned control over the boat's movement. This level of precision is essential for smooth and controlled adjustments, ensuring the boat responds accurately to the operator's commands.

The conversion of electrical energy into mechanical motion is a key advantage of this system. Electric motors provide the necessary power and control, ensuring that the hydraulic system can be activated and adjusted with minimal effort from the operator. This efficiency is particularly beneficial for frequent adjustments, as the electric motor's response time is rapid, allowing for quick and seamless changes in the boat's trim and tilt.

In summary, the electric motor's role in driving the hydraulic system is fundamental to the functionality of the tilt and trim mechanism on a boat. By converting electrical energy into the mechanical force required to operate the hydraulic cylinders, the system ensures precise control over the boat's angle and position, ultimately enhancing the overall performance and comfort of the vessel. This efficient and responsive system is a testament to the ingenuity of marine engineering, providing boaters with a seamless and controlled experience on the water.

Mr Wonderful's Boat Accident: What Happened to Ken?

You may want to see also

Safety Mechanisms: Built-in safety features prevent over-extension and ensure controlled movement

Hydraulic tilt and trim systems on boats are designed with several safety mechanisms to ensure the controlled movement of the boat's hull and provide a secure experience for the operator. These safety features are crucial to prevent over-extension and potential damage to the boat or injury to the operator.

One key safety mechanism is the pressure relief valve, which is an essential component of the hydraulic system. This valve is designed to open and release pressure when the system exceeds a certain threshold, typically due to excessive force or rapid movement. By allowing excess pressure to escape, the valve prevents the hydraulic fluid from becoming too pressurized, which could lead to system failure or damage. This feature is particularly important during aggressive maneuvers or when the boat encounters sudden changes in water conditions.

Additionally, hydraulic tilt and trim systems often incorporate a limit switch or sensor system. These sensors are strategically placed to detect the maximum and minimum limits of the boat's movement. When the system reaches these limits, the sensors trigger a response, such as a mechanical stop or an electronic signal, to prevent further extension or retraction. This ensures that the boat's hull does not exceed its designed range of motion, reducing the risk of collision with other boats, docks, or underwater obstacles.

The design of the hydraulic cylinders themselves also contributes to safety. These cylinders are typically constructed with robust materials and precise manufacturing processes to ensure they can withstand the forces applied during operation. Over-extension can be prevented by the use of durable seals and piston rods, which maintain a tight seal even under high pressure. This design minimizes the risk of fluid leakage and ensures that the system operates smoothly and safely.

Furthermore, the hydraulic fluid used in these systems is carefully selected to provide optimal performance and safety. It is formulated to withstand high temperatures and pressures, reducing the chances of fluid degradation or contamination. Proper fluid maintenance, including regular checks and replacements, is essential to ensure the system's longevity and reliability, especially in harsh marine environments.

In summary, the safety mechanisms in hydraulic tilt and trim systems are integral to their functionality and the overall safety of the boat. These features, including pressure relief valves, limit switches, cylinder design, and fluid selection, work together to prevent over-extension, ensure controlled movement, and provide a secure operating environment for the boat and its operator.

Bennington Boats: Worth the Investment?

You may want to see also

Frequently asked questions

Hydraulic tilt and trim is a system used on boats to adjust the angle and position of the boat's transom (rear) and the engine mount. It allows for precise control of the boat's trim, which refers to the boat's overall shape and balance when it's in the water. This system is particularly useful for optimizing performance, handling, and fuel efficiency.

The hydraulic tilt and trim system operates using hydraulic cylinders and pumps. These cylinders are mounted on the boat's transom and engine, and they extend or retract to adjust the boat's trim. The hydraulic pump provides the necessary pressure to move these cylinders, and it can be controlled by the operator through a control lever or a digital interface.

This system offers several advantages. Firstly, it provides fine-tuned control over the boat's trim, allowing for better handling and stability in various water conditions. Secondly, it helps optimize the boat's performance by ensuring the propeller is in the correct position for efficient power transmission. Additionally, hydraulic tilt and trim can improve fuel efficiency by reducing cavitation and minimizing the boat's draft.

Yes, most hydraulic tilt and trim systems have a manual override feature. This allows the operator to adjust the trim manually using a mechanical crank or a manual lever. While it may require more physical effort, this feature ensures that the boat can still be trimmed in case of a hydraulic system failure or when the power is off.