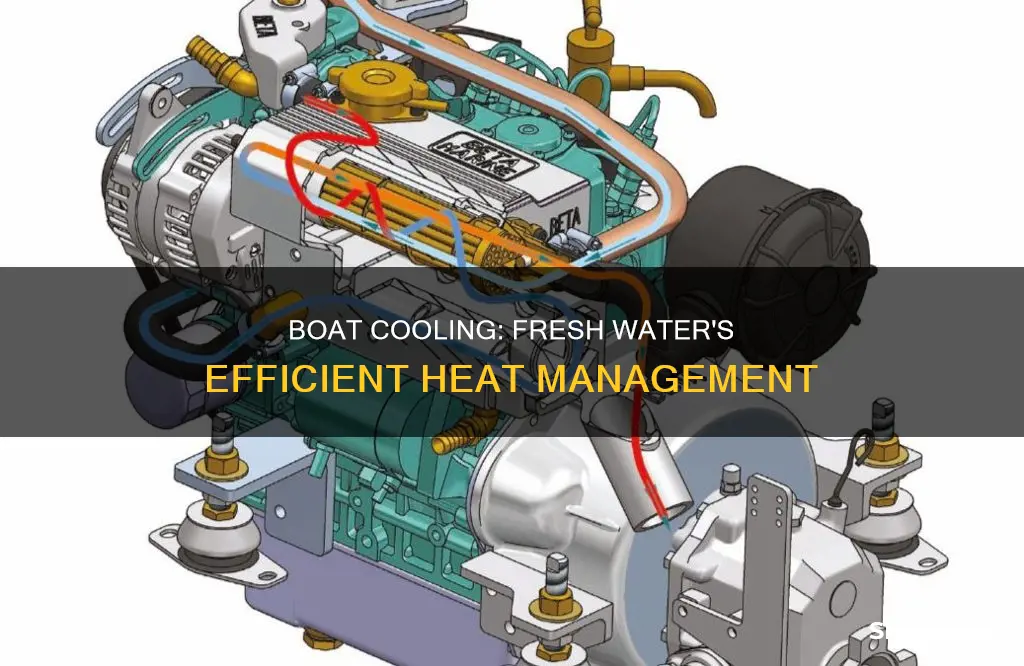

Fresh water cooling systems are an essential component of boat engines, ensuring optimal performance and longevity. This innovative technology utilizes fresh water to regulate engine temperature, preventing overheating and potential damage. The process involves a series of steps: first, the engine's coolant circulates through a network of passages, absorbing heat from the engine block. Then, the heated coolant is directed to a heat exchanger, where it exchanges heat with fresh water, cooling it down. The cooled water is then recirculated back to the engine, maintaining a stable temperature and ensuring efficient operation. This system is particularly crucial for boats, as it provides a reliable and effective method to manage engine heat, even in challenging marine environments.

What You'll Learn

- Water Intake and Pumping: Fresh water is drawn into the system via a pump, often powered by the boat's engine

- Cooling System Design: The system's design ensures efficient heat exchange, often using a radiator or heat exchanger

- Heat Transfer Mechanisms: Heat is transferred from the engine to the water through conduction, convection, and radiation

- Coolant Circulation: A closed loop circulates coolant, absorbing heat and releasing it to the surrounding water

- Temperature Regulation: Sensors and controls maintain optimal engine temperature, preventing overheating during operation

Water Intake and Pumping: Fresh water is drawn into the system via a pump, often powered by the boat's engine

Water intake and pumping are crucial components of a boat's freshwater cooling system. When a boat's engine operates, it generates a significant amount of heat, and without proper cooling, this heat can damage the engine over time. Fresh water cooling systems are designed to absorb this heat and maintain the engine's optimal operating temperature. The process begins with the intake of fresh water, which is a critical step in the cooling mechanism.

The water intake system typically consists of a dedicated water pump, often powered by the boat's engine itself. This pump is designed to draw water from a source, such as a freshwater tank or a nearby water body, and direct it into the cooling system. The pump's efficiency is vital as it needs to provide a consistent and adequate water flow rate to ensure effective cooling. As the engine operates, the pump activates, creating a continuous cycle of water intake and circulation.

Once the water is drawn into the system, it enters a series of passages or channels specifically designed to maximize surface area and facilitate heat exchange. These passages are often made of materials with high thermal conductivity, such as aluminum or copper, to enhance the cooling process. The water flows through these passages, absorbing heat from the engine's components, such as the cylinder head and block. This heat absorption helps regulate the engine's temperature, preventing overheating during extended periods of use.

The pumping mechanism ensures that the water is continuously circulated, creating a closed-loop system. After passing through the engine, the water may pass through a radiator or heat exchanger, where it releases the absorbed heat to the surrounding air. This process is essential for maintaining the engine's performance and longevity, especially during prolonged voyages or when the boat is stationary for extended periods.

In summary, the water intake and pumping process is a vital aspect of a boat's freshwater cooling system. By utilizing a dedicated pump powered by the engine, fresh water is efficiently drawn into the system, facilitating heat exchange and engine cooling. This method ensures that the boat's engine operates within safe temperature limits, providing reliable performance even in demanding marine environments. Proper maintenance of the water intake and pumping system is essential to guarantee its effectiveness over time.

Transferring a Boat Title: Texas to Louisiana

You may want to see also

Cooling System Design: The system's design ensures efficient heat exchange, often using a radiator or heat exchanger

The cooling system design on a boat is a critical component to ensure optimal performance and longevity of the vessel's engine. The primary goal is to maintain the engine's operating temperature within a safe range, preventing overheating and potential damage. This is particularly important for marine applications where the engine is exposed to varying environmental conditions and the limited space available for cooling components.

Efficient heat exchange is the key principle behind the design of these cooling systems. This is typically achieved through the use of radiators or heat exchangers, which are designed to maximize the surface area for heat dissipation. The radiator is a common and effective component, often made of aluminum or copper, with a series of fins that increase the surface area in contact with the air. As the engine operates, the coolant flows through the radiator, absorbing heat from the engine block and transferring it to the surrounding air, which is then dissipated into the environment.

The design of the cooling system involves careful consideration of several factors. Firstly, the coolant flow rate is crucial; a higher flow rate can increase heat exchange efficiency, but it must be balanced with the engine's capacity to handle the additional coolant. The system's ability to maintain a consistent coolant temperature is also essential, as large temperature fluctuations can impact the engine's performance and longevity.

In addition to radiators, heat exchangers are another critical component of the cooling system design. These devices transfer heat from one fluid to another without mixing the two, which is particularly useful in marine applications where the engine's coolant and the surrounding seawater must remain separate. Heat exchangers can be designed in various configurations, such as shell-and-tube or plate-and-frame, each offering unique advantages in terms of heat transfer efficiency and compactness.

The overall design of the cooling system should also consider the installation and maintenance aspects. This includes the placement of the radiator and heat exchangers to ensure optimal airflow and easy access for maintenance. Regular maintenance, such as checking coolant levels and replacing filters, is essential to keep the cooling system operating efficiently and prevent any potential issues.

Understanding Boat Primer Solenoids: How They Work

You may want to see also

Heat Transfer Mechanisms: Heat is transferred from the engine to the water through conduction, convection, and radiation

The cooling system of a boat's engine relies on efficient heat transfer mechanisms to maintain optimal operating temperatures. When an engine runs, it generates a significant amount of heat, which needs to be dissipated to prevent overheating and potential damage. The primary method of heat transfer in this process is through the interaction of the engine's components with the surrounding fresh water.

Conduction is the initial step in this heat transfer process. The engine block, made of a metal material with high thermal conductivity, comes into direct contact with the engine cooling water. As the engine operates, the metal components heat up, and this heat is conducted through the engine block to the water. The water, being in direct contact with the hot engine parts, absorbs the heat energy, raising its temperature. This conduction process is crucial as it allows the engine to transfer its excess heat to the cooling system.

Convection plays a vital role in the subsequent stages of heat dissipation. As the engine water mixture heats up, it undergoes a process of convection. The heated water expands and becomes less dense, causing it to rise. This creates a circulation pattern where the hot water moves away from the engine, carrying the heat with it. The rising water is then cooled as it comes into contact with the cooler parts of the cooling system, such as the heat exchanger or the radiator. This cooling effect is essential to prevent the engine from overheating and to maintain the water's temperature at an optimal level.

Radiation is another significant heat transfer mechanism in this system. The engine, particularly the exhaust manifold and other hot surfaces, emits thermal radiation. This radiation carries heat energy away from the engine and into the surrounding water. The water absorbs this radiant heat, further contributing to the overall cooling process. Radiation is an efficient way to transfer heat, especially in the upper regions of the cooling system, where the water may be less dense and more susceptible to radiation.

In summary, the cooling of a boat's engine involves a combination of conduction, convection, and radiation. Conduction allows the engine to transfer heat to the water through direct contact, while convection ensures the continuous movement of heated water, facilitating heat dissipation. Radiation further enhances the cooling process by emitting and absorbing heat energy. These mechanisms work in harmony to maintain the engine's temperature within safe limits, ensuring its efficient and reliable operation during maritime adventures.

Understanding Outdrive Engines: Powering Your Boat's Performance

You may want to see also

Coolant Circulation: A closed loop circulates coolant, absorbing heat and releasing it to the surrounding water

The freshwater cooling system on a boat is an essential component to ensure optimal engine performance and longevity, especially in marine environments where temperatures can vary significantly. At its core, the system relies on a closed loop circulation of coolant, which plays a vital role in heat exchange. This process is designed to maintain the engine's operating temperature within a safe range, preventing overheating and potential damage.

The closed loop system begins with a coolant reservoir, typically located beneath the engine or in a dedicated compartment. This reservoir stores the coolant, often a mixture of water and a special additive designed to protect the engine components. From here, the coolant is pumped through a network of passages and channels, forming a closed circuit. The pump ensures a consistent flow, allowing the coolant to circulate continuously.

As the coolant circulates, it absorbs heat from various engine components, such as the cylinder head, block, and exhaust manifold. This heat transfer is facilitated by the coolant's ability to carry thermal energy. The absorbed heat raises the coolant's temperature, and as it continues through the loop, it encounters a heat exchanger, often referred to as a coolant radiator. This radiator is strategically positioned to allow the coolant to flow through it, exposing the fluid to the surrounding air. Here's where the magic happens: the coolant releases the accumulated heat to the cooler air, effectively cooling down the engine.

The design of the radiator is crucial to the system's efficiency. It typically consists of multiple fins and tubes, providing a large surface area for heat dissipation. As the coolant passes through the radiator, the fins facilitate the transfer of heat to the surrounding water, which then cools the coolant further. This process ensures that the engine remains at an optimal temperature, even during extended periods of operation.

Once the coolant has passed through the radiator, it returns to the engine, completing the closed loop. The continuous circulation ensures that the engine is constantly being cooled, preventing overheating and maintaining its performance. This system is particularly important for boats, as it allows them to operate efficiently in various water temperatures, from calm lakes to turbulent seas. Proper maintenance, including regular coolant checks and top-ups, is essential to ensure the system's longevity and the boat's overall reliability.

Ra's Mythical Boat Journey in Ancient Egyptian Lore

You may want to see also

Temperature Regulation: Sensors and controls maintain optimal engine temperature, preventing overheating during operation

The temperature regulation system on a boat is a critical component, ensuring the engine operates efficiently and safely. It primarily relies on a combination of sensors and controls to maintain optimal engine temperature, preventing overheating, which could lead to severe engine damage. This system is designed to monitor and regulate the engine's cooling process, especially when using fresh water as the primary cooling medium.

At the heart of this system are temperature sensors, typically located in the engine block and the coolant passages. These sensors provide real-time data on the engine's temperature, allowing the system to make immediate adjustments. When the engine is running, the sensors constantly monitor the coolant temperature, ensuring it remains within a safe operating range. If the temperature rises too high, the system can take corrective actions to prevent overheating.

The controls in this temperature regulation system are designed to respond to the sensor data. One of the primary controls is the coolant flow rate, which is regulated by a pump. The pump's speed can be adjusted to control the volume of coolant flowing through the engine. By increasing the flow rate, the system can quickly dissipate heat, thus maintaining a stable engine temperature. Conversely, reducing the flow rate can help conserve coolant, which is especially important when the boat is stationary or during periods of low engine activity.

In addition to the pump, the system may also include a thermostat, which acts as a valve to control the coolant flow. When the engine is cold, the thermostat is closed, allowing the engine to heat up quickly. As the engine warms up, the thermostat opens, allowing coolant to flow and maintain the desired temperature. This mechanism ensures that the engine doesn't overheat when it's cold and doesn't waste coolant when it's already at operating temperature.

Advanced temperature regulation systems may also incorporate feedback loops and microcontrollers to fine-tune the engine's performance. These systems can automatically adjust the coolant flow, fan speed, and other parameters based on the engine's load and operating conditions. By continuously monitoring and adjusting these factors, the system can ensure that the engine remains within safe temperature limits, even during extended periods of operation. This level of control is crucial for maintaining the longevity and reliability of the boat's engine.

How to Check for Liens on a New Jersey Boat Title

You may want to see also

Frequently asked questions

The freshwater cooling system on a boat is designed to maintain the engine's optimal operating temperature by circulating freshwater through a series of passages or jackets around the engine block. When the engine is running, the coolant absorbs heat from the engine components, and as it circulates, it passes through a heat exchanger or radiator, where the heat is transferred to the surrounding freshwater. This process helps regulate the engine's temperature, preventing overheating during extended periods of use.

The primary purpose is to ensure the engine operates within a safe temperature range, preventing damage from excessive heat. Freshwater cooling is essential for boats, especially those used for extended cruising or in warmer climates, as it provides a more efficient and reliable cooling method compared to air cooling, which can be less effective in humid environments.

Regular maintenance is crucial to ensure the system's longevity and optimal performance. It is recommended to check the coolant level and condition monthly and top it up if necessary. Additionally, annual coolant flush and replacement are advised to prevent the buildup of contaminants. Regularly inspecting the radiator for blockages or damage and ensuring proper airflow around the engine are also essential maintenance tasks.

Freshwater is specifically recommended and designed for the cooling system. Saltwater contains minerals and salts that can corrode engine components over time, leading to potential damage. Freshwater, being free of these corrosive elements, helps protect the engine and ensures the cooling system's efficiency. Using saltwater in the cooling system can void the manufacturer's warranty and may result in costly repairs.