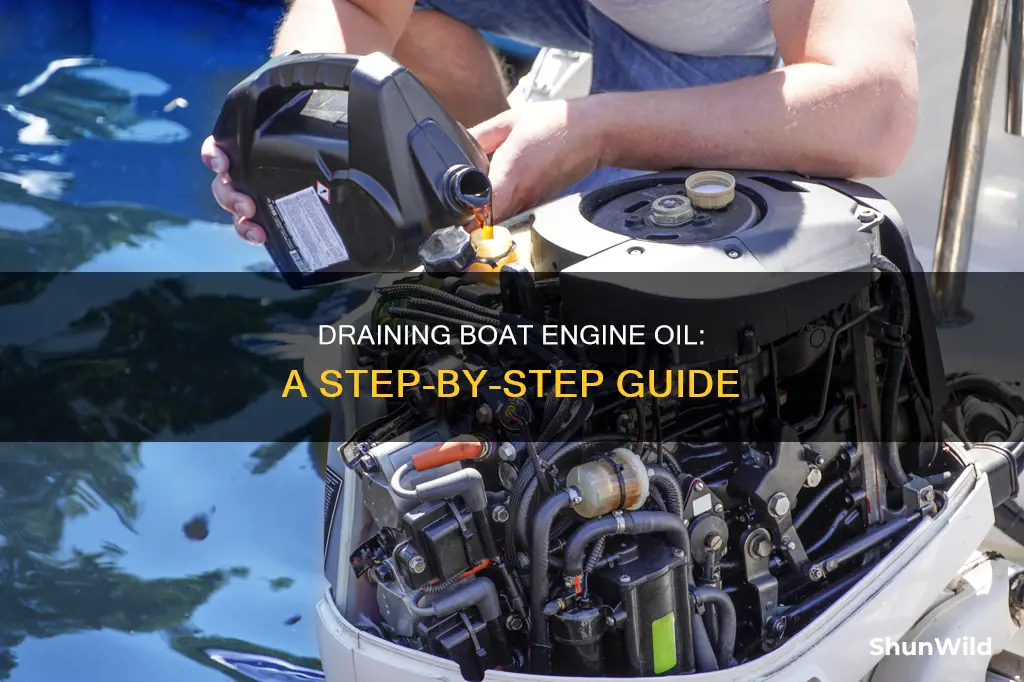

Changing your boat's engine oil is an important part of boat ownership. Regular oil changes can extend the life of your boat engine by thousands of hours and ward off breakdowns. Engine manufacturers recommend changing your engine oil after every 100 hours of use or annually, at a minimum. However, changing the oil in a boat engine can be a difficult and messy job. Unlike car engines, boat engines often have inaccessible or non-existent oil drain plugs, and there is usually inadequate space beneath the engine for a container to catch the draining oil. This article will provide a step-by-step guide on how to drain your boat's engine oil, offering tips and tricks to make the process as smooth as possible.

What You'll Learn

Warm the engine

Warming up your boat engine before draining the oil is a crucial step in the oil-changing process. This is because warm oil is thinner and less viscous, making it easier to drain. By ensuring the engine is fully warmed up, you can achieve a more efficient, complete, and smoother drainage process. This is especially important if you are manually sucking the oil out through the dipstick tube, as warm oil will flow more readily through the tube. Additionally, heating the oil helps to suspend any contaminants within it, ensuring that they are removed along with the old oil. This is essential for maintaining the health of your engine.

There are a few methods to warm up your boat engine. One way is to run the engine for a few minutes, allowing the oil to reach normal operating temperatures. This can be done on the water or while the boat is lifted out of the water. If you are warming the engine while it is lifted, it is important to run water through the engine to prevent certain parts from getting too warm. Another method is to use an electric pump to warm the oil. This option can be more expensive but reduces the task to simply flipping a switch.

It is worth noting that the temperature of the oil affects its viscosity. All oils become thinner to some extent as they are warmed up. For example, 10W-40 oil will have a viscosity of less than 40 when it is very hot. This decrease in viscosity is why hot oil flows more easily and can be beneficial when trying to drain it from your engine.

When warming up your boat engine, it is important to ensure that the boat is securely parked with the brakes applied to prevent any unexpected movement. Additionally, while warming up the engine, you should also prepare your workspace by gathering the proper tools and placing an oil catch pan underneath the engine to prevent spills.

By taking the time to warm up your boat engine before draining the oil, you can ensure a more efficient and complete oil change, which will help extend the life of your engine.

The Boat to the Underworld: Charon's Ferry Duty

You may want to see also

Use an oil extractor

An oil extractor pump is a convenient way to drain the oil from your boat engine. It is designed to suction oil through a small opening and drain it into a container. There are two types of oil extractor pumps: manual and electric. The manual pump requires continuous pumping by hand, but it is a great option if you don't have access to a power source. On the other hand, electric pumps are more convenient but require a bit of extra care. They cannot pump water or other non-lubricating liquids as the components often require lubrication from the oil being pumped.

When using an oil extractor pump, follow these steps:

- Ensure your boat engine has had a chance to cool down before using the extractor, especially if you've been out on the water. It's recommended to wait for about 15 minutes after turning off the engine.

- Remove the oil dipstick and insert the extractor tube into the dipstick pipe until it reaches the bottom of the oil pan.

- For manual pumps, continuously pump the device to keep the oil flow moving. Electric pumps will take care of this process for you.

- As you pump, you may find that you extract less oil the deeper the tube goes. Try moving the suction tube up from the bottom until you start sucking oil more effectively.

- Once the oil is drained, remove the extractor tube and securely close the oil fill port.

- Dispose of the extracted oil responsibly. Take it to a recycling facility or your local marina, which likely has a disposal or recycling program.

Using an oil extractor pump offers several benefits:

- It eliminates the need to raise your boat or crawl underneath it to remove the oil, making the process cleaner and more convenient.

- Oil extractor pumps are generally affordable, with some options available for under $20.

- They can be used on various vehicles, including boats, cars, trucks, tractors, and heavy machinery.

- The process is relatively quick and can be completed in a matter of minutes, especially if the oil is warm.

- There is less risk of spillage compared to traditional draining methods.

However, there are also a few drawbacks to consider:

- It may not remove all the oil from the engine, especially if the tube cannot reach the very bottom of the oil pan.

- The process can be noisy, especially with electric pumps.

- Manual pumps require physical effort to operate, and electric pumps need a power source.

- Extracting oil can be slower than traditional draining, especially if the engine is cold.

Boat Registration Numbers: Placement Guide for Washington State

You may want to see also

Place catch pans and oil-absorbent pads beneath the engine

Before you begin the process of draining your boat's engine oil, it is important to take precautions to ensure that the used oil is properly contained and does not spill. Placing catch pans and oil-absorbent pads beneath the engine is a crucial step in this process. This will help to catch any accidental spills or leaks during the oil-changing procedure.

To start, you will need to gather the necessary materials. Obtain a suitable catch pan or container that can hold all the used oil. A foil roasting pan from the supermarket can be a good option, but be sure to check its capacity with water first to ensure it can hold all the oil. You can also use an old can or a plastic container. If you use a foil pan, place a piece of thin plywood underneath to keep the bottom rigid and prevent buckling when it's full of oil. Spread an oil-absorbent cloth or pad beneath the pan to catch any splashes or spills that may occur.

Additionally, you may want to consider using a double-bag system if you're draining the oil into a plastic bag. Band the mouth of the bag to a tin can with both ends removed, such as a pineapple can, to collect the oil. This is especially useful in restricted spaces. To further prevent leaks, you can use two heavy-duty bags, one inside the other, as hot oil tends to seep through some plastics.

Once you have your catch pans and oil-absorbent pads in place, you can proceed with the rest of the oil-changing process, knowing that you have added an extra layer of protection to keep accidental spills from reaching the bilge. Remember to always contain and dispose of waste oil properly, and keep a fresh oil-absorbent pad beneath the engine to aid in spotting leaks both after and between oil changes.

Federal Regulations: Drip Pans Beneath Boat Engines?

You may want to see also

Dispose of waste oil and fluids properly

Proper disposal of waste oil and fluids is crucial when changing your boat's engine oil. Here are some detailed instructions to ensure proper disposal:

Firstly, it is essential to collect all the used oil in a suitable container. Place an oil catch pan or a large container under the engine to catch the drained oil. Make sure the container is large enough to hold the quantity of oil your engine holds. You can also use an oil extraction pump to remove the oil through the dipstick tube. This method is often necessary for marine engines that don't have a drain plug or have an inaccessible one.

Once the oil has been drained, it's crucial to handle and store the waste oil properly. Used oil should be placed in a sealed container and labelled clearly as "waste oil". Store the waste oil separately from other fluids and absorbents to prevent contamination. Mixing different fluids can create a highly toxic mixture that is challenging to recycle.

Next, locate an authorized recycling centre or disposal facility. Many marinas have oil recycling or disposal programs, and some automotive parts stores also offer waste oil recycling. You can also contact the store where you purchased the oil and filter to inquire about their recycling policies. It is important to dispose of waste oil properly and not pour it down the sewer or into water bodies.

Finally, ensure you dispose of any other waste properly. This includes used oil filters, absorbent pads, and rags. Some recycling centres may accept these items, but if not, dispose of them as regular waste. Remember to handle all waste with caution, especially hot motor oil, as it can cause severe burns.

By following these instructions, you can help protect the environment and ensure that waste oil and fluids are disposed of or recycled properly.

Lake Conroe Boat Launching: Best Spots to Know

You may want to see also

Check for leaks

Once you've drained the old oil, changed the oil filter, and filled the crankcase with new oil, it's time to check for leaks.

Start the engine and let it run for about a minute. During this time, keep an eye out for any signs of oil leaks, especially around the oil pan and filter. If you notice any leaks, address them immediately to prevent further issues.

After stopping the engine, use the dipstick to check the oil level. The oil level should be between the high and low marks. If it's low, top it up with more oil.

It is important to deal with oil leaks as soon as they are detected. Small leaks can lead to consequential damage and will usually get bigger over time. They can also be a sign of other issues, such as a blown gasket or a cracked block. Additionally, oil leaks can create an unpleasant and potentially hazardous environment on the boat, with the risk of causing seasickness or masking the smell of a dangerous gas leak.

To make the leak detection process easier, consider installing a drip tray under the engine. This will not only capture any leaking fluids but also alert you to their presence. If your boat doesn't have a drip tray, you can easily retrofit one by gluing a piece of sheet aluminium across the front of the engine bearers to create a dam for the oil to collect in.

By regularly checking for leaks and addressing them promptly, you can maintain the engine's performance and longevity while also ensuring a more pleasant and safer boating experience.

Boat Ride at Blue Springs: Worth the Trip?

You may want to see also

Frequently asked questions

Engine manufacturers recommend changing the oil after every 100 hours of use or annually, at a minimum. For diesel engines, it is recommended to change the oil every 50 hours.

The process for draining boat engine oil depends on the type of engine. For inboard engines, an oil-evacuation system is typically required, using a manual or electric pump to transfer oil from the engine into a separate container. For four-stroke outboard engines, an oil extractor pump can be used via the dipstick hole, or the drain plug can be accessed directly.

After draining the oil, it is important to inspect the old oil for any signs of contamination or wear. The oil filter should also be changed, and a new oil filter installed. Finally, new oil can be added, and any leaks around the oil pan and filter should be addressed.