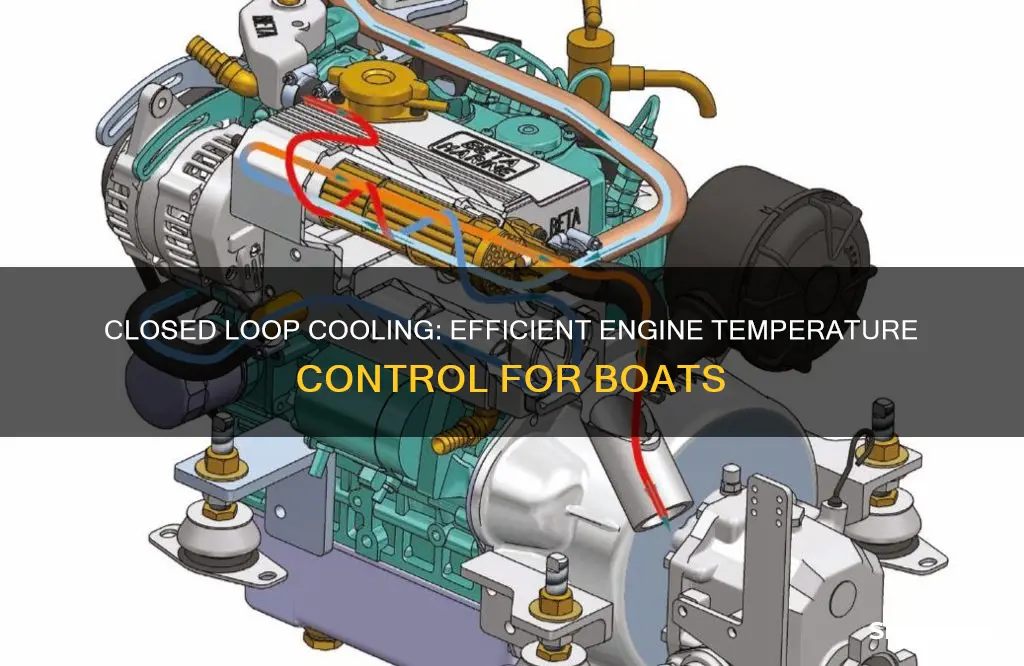

Closed-loop cooling systems are an essential component in marine engineering, particularly for boats, as they provide efficient temperature regulation. This innovative technology is designed to maintain optimal engine and machinery temperatures, ensuring the vessel's performance and longevity. The closed-loop cooling system works by circulating a coolant through a network of pipes, absorbing heat from the engine and transferring it to a cooling unit, often a radiator or a heat exchanger. This process prevents overheating and allows the engine to operate at its peak efficiency, even in demanding conditions. By continuously monitoring and controlling the temperature, this system offers a reliable and sustainable solution for boat cooling, enhancing overall performance and safety.

What You'll Learn

- Engine Cooling: Closed-loop systems use a radiator and coolant to regulate engine temperature

- Heat Exchange: Coolant absorbs heat from the engine and releases it to the environment

- Coolant Circulation: A pump circulates coolant through the engine and radiator

- Temperature Control: Sensors monitor temperature, and the system adjusts accordingly

- Efficiency and Safety: Efficient cooling prevents overheating, ensuring optimal boat performance

Engine Cooling: Closed-loop systems use a radiator and coolant to regulate engine temperature

A closed-loop cooling system is an essential component of any boat's engine, ensuring optimal performance and longevity. This system is designed to maintain the engine's temperature within a safe operating range, preventing overheating and potential damage. Here's a detailed explanation of how it works:

In a closed-loop cooling system, the engine's heat is transferred through a network of passages and components, primarily using a coolant. The coolant is a special liquid specifically formulated to absorb and carry heat away from the engine block. When the engine is running, the coolant circulates through the engine block, absorbing heat from various components like the cylinder head, pistons, and valves. This process is facilitated by a water pump, which circulates the coolant at a consistent pressure, ensuring efficient heat exchange.

As the coolant picks up heat, it flows through a series of passages and channels, eventually reaching the radiator. The radiator is a crucial component, often located near the front of the boat, where it provides ample surface area for cooling. Coolant passes through the radiator, where it is exposed to the surrounding air, allowing the heat to be dissipated. The radiator's design includes fins and a large surface area to maximize heat transfer, ensuring the coolant remains at an optimal temperature.

After passing through the radiator, the cooled coolant returns to the engine block, completing the closed loop. This continuous cycle ensures that the engine's temperature is regulated, preventing overheating during extended periods of operation. The system's design also includes a thermostat, which controls the flow of coolant, allowing for efficient temperature regulation.

This closed-loop cooling system is highly effective due to its ability to maintain a consistent temperature, even under varying load conditions. It provides several advantages, including improved engine reliability, reduced risk of engine failure, and enhanced performance. By using a radiator and coolant, this system ensures that the engine operates within safe temperature limits, contributing to the overall efficiency and longevity of the boat's powerplant.

The Boat Name of America's Founding Father, George Washington

You may want to see also

Heat Exchange: Coolant absorbs heat from the engine and releases it to the environment

In the context of boat cooling systems, heat exchange is a critical process that ensures the engine operates at an optimal temperature. This is achieved through a closed-loop cooling system, which is a highly efficient and reliable method of maintaining engine temperature. The core principle of this system is the use of a coolant, typically a mixture of water and antifreeze, which acts as a medium to absorb and transfer heat.

The process begins with the coolant entering the engine's cooling system, where it comes into direct contact with the engine block and cylinder head. The engine's high operating temperatures cause the coolant to absorb heat from these components. This absorption is a result of the coolant's ability to transfer thermal energy, which is a fundamental property of all fluids. As the coolant absorbs heat, its temperature rises, and it becomes a carrier of thermal energy.

Once the coolant has absorbed a significant amount of heat, it is directed to the radiator, which is a crucial component in the heat exchange process. The radiator is designed to provide a large surface area for heat dissipation, allowing the coolant to release the absorbed heat to the surrounding environment. This release is facilitated by the flow of air through the radiator, which acts as a natural cooling agent. As the coolant passes through the radiator, it loses its thermal energy to the air, thereby cooling down.

The cooled coolant is then recirculated back to the engine, completing the closed loop. This continuous cycle ensures that the engine maintains a stable temperature, even under varying operating conditions. The effectiveness of this system lies in its ability to continuously transfer heat, preventing the engine from overheating and ensuring optimal performance.

In summary, the heat exchange process in a closed-loop cooling system for boats involves the coolant's role as a heat absorber and transporter. By absorbing heat from the engine and releasing it to the environment through the radiator, the system maintains the engine's temperature within safe limits, contributing to the overall efficiency and longevity of the vessel's powerplant. This method of cooling is a testament to the ingenuity of marine engineering, providing a reliable and efficient solution for engine temperature management.

Exploring Italy's Distance from Africa by Boat

You may want to see also

Coolant Circulation: A pump circulates coolant through the engine and radiator

In the intricate system of closed-loop cooling on boats, the circulation of coolant is a critical component that ensures optimal engine performance and longevity. At the heart of this process is a pump, a vital device that facilitates the continuous movement of coolant throughout the engine and radiator system. This pump is designed to maintain a steady flow, preventing any stagnation and ensuring efficient heat dissipation.

The pump's role is to create a pressure that propels the coolant through the engine's intricate network of passages and channels. These passages are strategically designed to maximize surface area, allowing for efficient heat exchange between the coolant and the engine components. As the coolant circulates, it absorbs heat from various engine parts, including the cylinder head, block, and other critical areas. This heat absorption is a natural consequence of the coolant's thermal conductivity, which is specifically chosen for its ability to efficiently transfer heat.

Once the coolant has absorbed heat, it continues its journey through the radiator, a vital component in the cooling system. The radiator is designed to dissipate the heat absorbed by the coolant into the surrounding environment, thus cooling the engine. This process is facilitated by the radiator's intricate network of fins and tubes, which provide a large surface area for heat transfer. As the coolant passes through the radiator, it releases the accumulated heat, maintaining a stable engine temperature.

The pump's operation is a delicate balance of pressure and flow rate. It must ensure that the coolant circulates at an optimal speed to prevent overheating while also maintaining sufficient pressure to overcome any potential engine blockages. This balance is crucial, as it directly impacts the engine's performance and longevity. Modern boats often employ sophisticated pump systems that can be adjusted or controlled to optimize cooling performance based on various factors, such as engine load and environmental conditions.

In summary, the pump's role in coolant circulation is pivotal in the closed-loop cooling system of boats. It ensures that the coolant effectively absorbs and dissipates heat, maintaining optimal engine temperatures. This intricate process, combined with the strategic design of engine passages and radiators, contributes to the overall reliability and efficiency of marine engines. Understanding and maintaining this system is essential for boat owners to ensure their vessels operate at peak performance while navigating the waters.

Gelcoat Restoration: Reviving Your Bass Boat's Shine

You may want to see also

Temperature Control: Sensors monitor temperature, and the system adjusts accordingly

In the context of boat cooling systems, temperature control is a critical aspect of maintaining optimal performance and comfort. Closed-loop cooling systems employ a network of sensors and automated controls to precisely manage the temperature within the engine compartment and other critical areas. These sensors play a vital role in this process by continuously monitoring various parameters, ensuring the system operates efficiently and effectively.

The sensors in a closed-loop cooling system are strategically placed to measure key environmental factors. Temperature sensors, for instance, are positioned at different points within the engine bay and coolant passages. These sensors detect the temperature of the coolant, which is a critical parameter in the cooling process. By monitoring the coolant temperature, the system can identify when the engine is running hot or cold and make the necessary adjustments.

When the temperature sensors detect a rise in coolant temperature, the system triggers a series of actions to cool down the engine. The primary mechanism is the activation of the cooling fans, which are strategically positioned to direct airflow over the engine block and radiator. These fans increase air circulation, promoting heat dissipation and reducing the engine's temperature. Additionally, the system may adjust the coolant flow rate, ensuring an optimal heat exchange between the engine and the coolant.

Conversely, if the temperature sensors detect a drop in coolant temperature, the system takes action to prevent overheating. In this scenario, the cooling fans may be slowed down or turned off to conserve energy and reduce the risk of coolant overheating. The system's intelligence lies in its ability to make these adjustments automatically, ensuring the engine operates within a safe temperature range at all times.

The beauty of this temperature control system is its ability to adapt to changing conditions. By continuously monitoring temperature, the system can quickly respond to any deviations from the desired range. This real-time feedback loop ensures that the engine remains within optimal temperature limits, enhancing its performance, longevity, and reliability. Effective temperature control is a cornerstone of closed-loop cooling systems, contributing to the overall efficiency and safety of boat engines.

The Basics of Revving Boat Engines While in Neutral

You may want to see also

Efficiency and Safety: Efficient cooling prevents overheating, ensuring optimal boat performance

Closed-loop cooling systems are a crucial component in ensuring the efficient and safe operation of boats, particularly those with powerful engines. These systems play a vital role in maintaining optimal performance by preventing overheating, which can lead to significant issues such as engine damage, reduced efficiency, and even catastrophic failures. The primary function of closed-loop cooling is to regulate the temperature of the engine by continuously circulating a coolant through a network of passages and heat exchangers.

In a closed-loop system, a coolant, typically a mixture of water and ethylene glycol, is pumped through the engine block, absorbing heat from the engine components. This heated coolant then passes through a radiator, where it dissipates excess heat into the surrounding air. The cooled coolant is then recirculated back to the engine, creating a continuous cycle. This process ensures that the engine operates at a stable temperature, preventing overheating during extended periods of use.

Efficiency is a key advantage of closed-loop cooling. By maintaining optimal engine temperatures, the system allows for improved power output and fuel efficiency. When an engine overheats, it can lead to a decrease in performance, as the components may not operate at their optimal capacity. Closed-loop cooling ensures that the engine remains within safe temperature limits, allowing for consistent and efficient operation. This is particularly important for boats, where engine performance directly impacts the overall speed and maneuverability of the vessel.

Safety is another critical aspect of closed-loop cooling. Overheating can cause severe damage to engine components, leading to costly repairs or even the need for a complete engine replacement. In extreme cases, overheating can result in engine failure, posing a significant risk to the boat and its occupants. Closed-loop cooling systems help prevent such catastrophic failures by maintaining a consistent and controlled temperature environment. This not only ensures the longevity of the engine but also enhances the overall safety of the boat, reducing the likelihood of unexpected breakdowns during cruises or voyages.

In summary, closed-loop cooling systems are essential for the efficient and safe operation of boats. By continuously circulating coolant and regulating engine temperature, these systems prevent overheating, maintain optimal performance, and ensure the longevity of the engine. The efficiency and safety benefits of closed-loop cooling make it a vital consideration for boat owners and operators, especially those with high-performance vessels that demand reliable and consistent cooling solutions.

Fresh Off the Boat: A Conclusion to the Huang Family's Story

You may want to see also

Frequently asked questions

Closed-loop cooling is a system designed to maintain the engine's optimal operating temperature by continuously circulating a coolant through the engine block and radiator. It works by absorbing heat from the engine and transferring it to the radiator, where it dissipates into the surrounding air. This process ensures the engine operates at a consistent and safe temperature, preventing overheating and potential damage.

The primary difference lies in the method of heat exchange. In a closed-loop system, the coolant is recycled and re-circulated through the engine, continuously removing heat. This system is more efficient as it doesn't require a large volume of coolant and can maintain a steady temperature even when the boat is stationary or moving at varying speeds. In contrast, an open system relies on a large coolant reservoir and may lose coolant if not properly sealed.

While some basic maintenance tasks can be performed by boat owners, it is generally recommended to have a professional mechanic handle the closed-loop cooling system. This includes checking the coolant level, inspecting for leaks, and ensuring the radiator is clean and free of debris. Regular maintenance helps prevent engine damage and extends the lifespan of the cooling system. It's also important to use the correct type of coolant and follow the manufacturer's guidelines for any necessary additives.