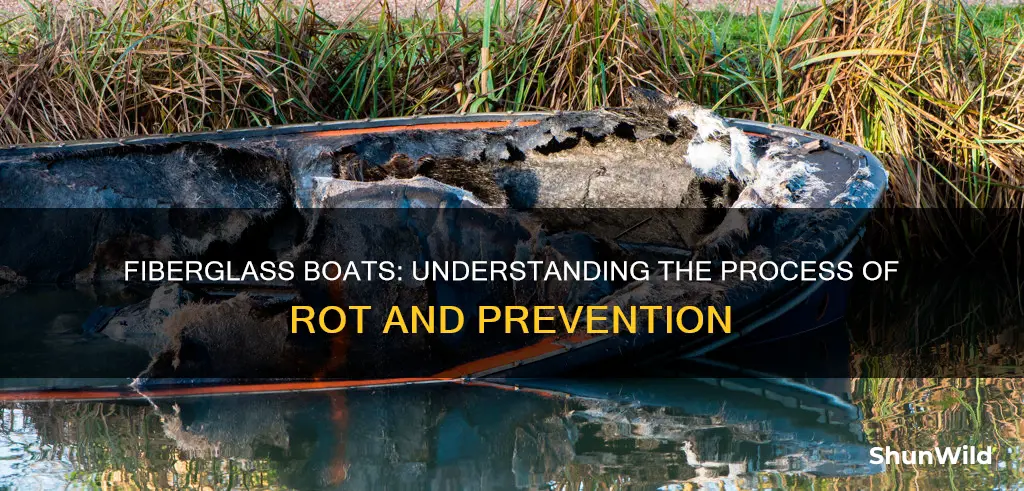

Fiberglass boats, known for their durability and lightweight design, are a popular choice for recreational boating. However, despite their initial robust appearance, these boats can be susceptible to a common issue: rot. This phenomenon occurs when the boat's fiberglass hull, which is often reinforced with a core material like balsa wood or foam, absorbs moisture from the environment. Over time, this moisture can lead to the degradation of the core material, causing it to weaken and eventually rot. The process is often accelerated by exposure to sunlight, saltwater, and other environmental factors, making proper maintenance and regular inspections crucial to prevent and address this issue. Understanding the causes and effects of rot in fiberglass boats is essential for boat owners to ensure the longevity and safety of their vessels.

What You'll Learn

- Fiberglass Degradation: UV rays, moisture, and chemicals accelerate boat material breakdown

- Wood-Fiberglass Bond: Weak bonds between wood and fiberglass lead to structural decay

- Corrosion: Metal fasteners and hardware in fiberglass boats can corrode, causing structural damage

- Gelcoat Erosion: UV exposure and pollutants damage the gelcoat, leading to a loss of shine and protection

- Interior Decay: Moisture intrusion and poor maintenance cause interior materials to deteriorate and rot

Fiberglass Degradation: UV rays, moisture, and chemicals accelerate boat material breakdown

The degradation of fiberglass in boats is a complex process influenced by various environmental factors, primarily UV rays, moisture, and chemicals. These elements accelerate the breakdown of the boat's material, leading to structural deterioration over time.

UV Rays: The sun's ultraviolet (UV) radiation is a significant contributor to fiberglass degradation. UV rays can cause a chemical reaction in the fiberglass, breaking down the polymer chains that hold the material together. This process, known as photo-oxidation, results in a loss of strength and flexibility. Over time, the boat's structure becomes more susceptible to damage, as the fiberglass becomes brittle and more prone to cracking and chipping.

Moisture: Water is a critical factor in the deterioration of fiberglass. When a boat is exposed to moisture, especially in the form of condensation or seawater, the water can seep into the fiberglass matrix. This moisture absorption leads to a process called hydrolysis, where the water reacts with the fiberglass's resin, causing it to weaken and degrade. The presence of moisture can also promote the growth of mold and mildew, further accelerating the breakdown of the material.

Chemicals: Various chemicals can accelerate the degradation of fiberglass. These include pollutants in the air, such as acids and salts, which can be present in industrial areas or coastal regions. When these chemicals come into contact with the boat's surface, they can react with the fiberglass, leading to a process known as chemical weathering. This weathering can cause the fiberglass to become discolored, brittle, and more susceptible to structural failure. Additionally, certain cleaning agents and maintenance products used on boats can also contribute to the degradation of the material if not used properly.

Understanding these factors is crucial for boat owners and maintenance personnel. By implementing proper maintenance routines, including regular cleaning, painting, and the use of protective coatings, boat owners can slow down the degradation process and extend the lifespan of their fiberglass vessels. Additionally, storing boats in shaded areas and using UV-resistant materials can help mitigate the effects of UV radiation.

Protecting Your Boat Investment: Wrapping Vinyl Boat Seats

You may want to see also

Wood-Fiberglass Bond: Weak bonds between wood and fiberglass lead to structural decay

The bond between wood and fiberglass is a critical aspect of boat construction, and its strength is often overlooked. When a fiberglass boat is built, the composite material is typically used as a shell or hull, and wood is often incorporated as a core or structural component. This combination is chosen for its lightweight and strength, but the interface between these two materials can be problematic. The weak bond between wood and fiberglass is a primary reason why fiberglass boats can deteriorate over time, leading to structural issues and, in some cases, complete failure.

The weakness of the bond can be attributed to several factors. Firstly, the chemical nature of the materials themselves plays a role. Fiberglass, composed of woven glass fibers and a resin matrix, is inherently non-porous and does not readily accept wood's natural oils and cellulosic structure. This incompatibility can lead to poor adhesion, especially if the wood is not properly treated or if the surface is not prepared correctly before bonding. Secondly, the manufacturing process and techniques used can significantly impact the bond's strength. If the fiberglass is not applied evenly or if the wood core is not properly saturated with the resin, voids and weak spots can form, making the bond more susceptible to failure.

Over time, the weak bond between wood and fiberglass can lead to a range of structural problems. One common issue is delamination, where the layers of the composite material separate due to the bond's inability to withstand the stresses of the boat's environment. This can cause the fiberglass shell to crack, delaminate, or even separate from the wood core, leading to structural weakness. In some cases, the wood core may rot or deteriorate, especially if it is exposed to moisture, as wood is naturally susceptible to water damage. The presence of water can accelerate the decay process, leading to further structural degradation.

To prevent these issues, it is essential to ensure that the bond between wood and fiberglass is strong and durable. Proper preparation of the wood surface, including sanding and the use of specialized adhesives, can improve adhesion. Additionally, using a wood core that is compatible with the resin system and ensuring adequate curing time can enhance the bond's strength. Regular maintenance and inspections are also crucial, as they can help identify weak bonds or areas of deterioration early on, allowing for timely repairs and preventing further damage.

In summary, the weak bond between wood and fiberglass is a significant factor in the deterioration of fiberglass boats. Understanding the causes of this bond's weakness and implementing appropriate measures to strengthen it can help ensure the longevity and structural integrity of the vessel. By addressing the bond's quality during construction and through regular maintenance, boat owners can mitigate the risks associated with structural decay and enjoy a safer and more reliable marine experience.

The Boat Show's Allure: Unraveling the Mystery of the Crowds

You may want to see also

Corrosion: Metal fasteners and hardware in fiberglass boats can corrode, causing structural damage

The deterioration of a fiberglass boat is a complex process, and one of the primary factors contributing to its degradation is corrosion, especially when metal fasteners and hardware are involved. Fiberglass, a composite material made from reinforced plastic, is known for its strength and durability, but it is not immune to the effects of corrosion. Metal components, such as fasteners, anchors, and hardware, are often used to join and reinforce the structure of a boat, providing essential support and stability. However, these metal parts can be susceptible to corrosion when exposed to certain environments.

Corrosion occurs when metal reacts with substances in its surroundings, leading to the formation of rust or oxide. In the case of fiberglass boats, the corrosive process is often accelerated by the presence of salt water, which is a common element in marine environments. When metal fasteners are used to secure components together, they come into direct contact with the fiberglass and the surrounding moisture. Over time, the salt in the water can penetrate the fiberglass, leading to a chemical reaction with the metal, resulting in corrosion. This process weakens the metal, causing it to become brittle and potentially fail.

The impact of corrosion on a fiberglass boat's structure can be significant. As metal fasteners corrode, they may lose their ability to hold the boat's components together securely. This can lead to structural weaknesses, making the boat more susceptible to damage from waves, impacts, or even capsizing. In severe cases, corrosion can cause the boat's hull or deck to separate at the fastener points, compromising the overall integrity of the vessel. It is crucial for boat owners and enthusiasts to be aware of this issue, especially if they have older boats or those with frequent exposure to saltwater.

To prevent or mitigate corrosion, several measures can be taken. Regular maintenance and inspections are essential. Boat owners should check for any signs of corrosion, such as rust spots, discolored fasteners, or unusual wear on the boat's structure. Cleaning and lubricating metal fasteners periodically can also help reduce corrosion. Additionally, using corrosion-resistant fasteners, such as those made from stainless steel or specialized alloys, can significantly extend the lifespan of a fiberglass boat. Proper storage and maintenance practices, including keeping the boat dry and clean, can also minimize the risk of corrosion.

In summary, corrosion of metal fasteners and hardware is a critical aspect of understanding how a fiberglass boat ages and deteriorates. The presence of salt water and the chemical reaction between metal and fiberglass can lead to structural damage over time. By recognizing the signs of corrosion and implementing preventive measures, boat owners can ensure the longevity and safety of their fiberglass vessels. Regular maintenance and the use of appropriate materials can help preserve the boat's integrity and performance.

Boat Shoes: Timeless Fashion or Passing Trend?

You may want to see also

Gelcoat Erosion: UV exposure and pollutants damage the gelcoat, leading to a loss of shine and protection

The gelcoat, a protective layer applied to the surface of a fiberglass boat, is designed to shield the underlying fibers from environmental damage. However, over time, this protective layer can degrade, leading to a process known as gelcoat erosion. This erosion is primarily caused by two factors: UV exposure and pollutants.

UV exposure is a significant contributor to gelcoat degradation. The sun's ultraviolet rays can break down the chemical bonds in the gelcoat, leading to a loss of its protective properties. This UV damage is accelerated by the presence of pollutants, such as ozone and nitrogen oxides, which are common in urban and industrial areas. These pollutants increase the oxidative stress on the gelcoat, causing it to deteriorate more rapidly.

The effects of gelcoat erosion are visible in the form of a dull, faded appearance. The once-shiny surface of the boat begins to lose its luster, and the gelcoat may develop a chalky or hazy look. This not only affects the aesthetic appeal of the boat but also reduces its protection against the elements. Over time, the gelcoat's ability to shield the fiberglass from water, UV rays, and other environmental factors diminishes, leading to potential damage to the boat's structure.

To prevent or slow down gelcoat erosion, boat owners can take several measures. One effective method is to apply a gelcoat sealer or a specialized UV-resistant coating. These products can help protect the gelcoat from UV damage and pollutants. Regular cleaning and maintenance, including washing the boat with a mild detergent and water, can also help remove surface contaminants that contribute to gelcoat degradation. Additionally, storing the boat in a shaded or covered area can minimize direct UV exposure, thus preserving the gelcoat's integrity.

In summary, gelcoat erosion is a natural process accelerated by UV exposure and pollutants. Understanding these causes is essential for boat owners to take proactive measures in maintaining their fiberglass boats. By implementing protective measures and regular care, boat owners can ensure the longevity and appearance of their vessels.

Understanding Dual Battery Systems in Boats

You may want to see also

Interior Decay: Moisture intrusion and poor maintenance cause interior materials to deteriorate and rot

The interior of a fiberglass boat is susceptible to decay, especially when exposed to moisture and lacking proper maintenance. Over time, this can lead to significant structural damage and a compromised vessel. Moisture intrusion is a primary culprit in the deterioration process, as it creates an environment conducive to mold growth and material degradation. When water seeps into the boat's interior, whether through leaks, poor sealing, or inadequate drainage, it can quickly become trapped within the fiberglass structure. This trapped moisture then facilitates the growth of mold and mildew, which not only affects the aesthetics but also the structural integrity of the boat.

Fiberglass, while durable, is not immune to the effects of prolonged moisture exposure. The composite material used in boat construction can absorb and retain water, especially in areas with poor ventilation. As a result, the interior compartments, bilge areas, and even the hull itself may become damp and prone to corrosion. The presence of standing water or frequent moisture accumulation can lead to the degradation of the fiberglass matrix, causing it to become brittle and fragile. This is particularly concerning in the case of older boats or those that have experienced previous water damage, as the structural integrity of the boat may be compromised.

Poor maintenance exacerbates the issue of moisture intrusion. Regular upkeep, including cleaning and inspection, is essential to identify and address potential problems early on. Neglecting to clean and dry the interior after any water-related incidents can create a breeding ground for mold and bacteria. Additionally, failing to maintain the boat's sealing systems, such as gaskets and hatches, can lead to water seeping into previously dry areas. Over time, this recurring moisture exposure can cause the interior materials to rot, including the boat's interior lining, upholstery, and even the core of the fiberglass structure.

To prevent interior decay, boat owners should prioritize regular maintenance and inspections. This includes checking for any signs of water intrusion, such as discolored or warped materials, and addressing any issues promptly. Proper ventilation and drying techniques should be employed after any water-related incidents to minimize the risk of mold growth. Additionally, ensuring that all sealing systems are in good condition and functioning correctly will help maintain a dry interior environment. By taking proactive measures, boat owners can significantly extend the lifespan of their fiberglass vessel and avoid the costly repairs associated with interior decay.

Alumacraft Boat Company: Ownership and Leadership

You may want to see also

Frequently asked questions

Fiberglass boats, while durable, can still be susceptible to damage and deterioration over time. Rot in a fiberglass boat is primarily caused by water intrusion and the subsequent exposure to moisture and humidity. When water enters the boat's hull, it can lead to the degradation of the fiberglass composite material, especially if the water contains contaminants like salt or is left to dry out and re-moisten repeatedly. This process can weaken the boat's structure and compromise its integrity.

Water damage in a fiberglass boat may manifest in several ways. Look out for discolored or soft spots on the hull, deck, or interior panels. Check for any signs of mold or mildew growth, especially in enclosed areas. Inspect the boat's interior for warped or damaged wood, as water intrusion can lead to wood rot. Additionally, pay attention to any unusual noises or vibrations while operating the boat, which could indicate structural issues caused by water damage.

Preventing water damage is crucial for maintaining the longevity of your fiberglass boat. Ensure that all seams and openings are properly sealed to prevent water intrusion. Regularly inspect the boat for any signs of leaks or damage, especially after exposure to harsh weather conditions. Keep the boat dry and well-ventilated, and consider using desiccant packs to absorb moisture. Promptly address any water-related issues to minimize the risk of rot and structural damage.

While minor water damage can sometimes be addressed by boat owners, it is generally recommended to seek professional assistance for significant water-related issues. Repairing water damage in a fiberglass boat requires specialized knowledge and skills to ensure proper sealing and reinforcement of the composite material. Attempting DIY repairs without the necessary expertise may lead to further complications and potentially accelerate the rot process.

To maintain the health of your fiberglass boat and prevent rot, consider the following: regularly clean and rinse the boat to remove dirt and salt, especially after saltwater exposure; apply a protective coating or antifouling paint to the hull to minimize marine growth; keep the boat's interior dry by using bilge pumps and ventilation systems; and schedule regular inspections with marine professionals to identify and address any potential issues early on.