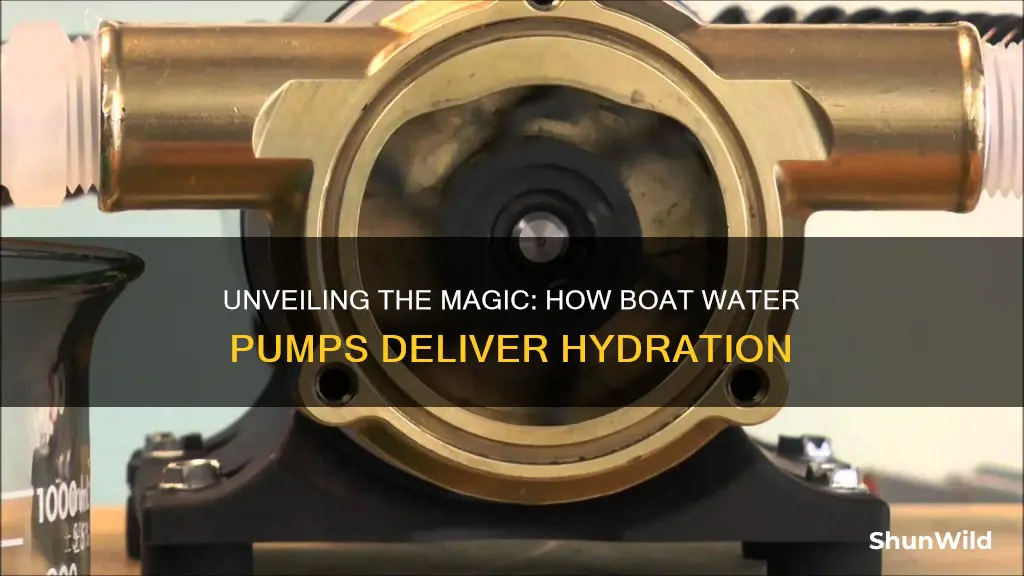

A boat water pump is a crucial component for any vessel, ensuring a reliable supply of fresh water for various purposes. These pumps are designed to move water from one location to another, often from the sea or a reservoir to the boat's freshwater system. Understanding the mechanics of these pumps is essential for boat owners and operators to maintain their vessels effectively. The pump's operation involves a series of intricate processes, including the use of an electric or manual motor to create suction, which draws water into the pump and then expels it through a series of valves and pipes. This process is vital for ensuring a continuous supply of water for drinking, cooking, and other essential onboard functions.

What You'll Learn

- Engine Power: The pump operates via engine power, converting mechanical energy into water flow

- Intake and Pressure: Water is drawn into the pump, creating pressure to force it out

- Impeller Rotation: The impeller's rotation generates centrifugal force, propelling water forward

- Pressure Relief: A pressure relief valve prevents excessive pressure buildup, ensuring safe operation

- Water Discharge: The pump expels water through an outlet, providing the desired water flow rate

Engine Power: The pump operates via engine power, converting mechanical energy into water flow

A boat water pump is a crucial component for any vessel, ensuring a reliable supply of fresh water for drinking, cooking, and sanitation. These pumps are typically driven by engine power, which is a fundamental aspect of their functionality. When an engine is started, it generates mechanical energy, which is then harnessed to drive the pump. This process is a key element in understanding how these pumps work.

The engine power system is designed to convert the raw mechanical energy produced by the engine into a controlled and directed flow of water. This conversion is achieved through a series of intricate components. Firstly, the engine's output shaft is connected to a pump drive shaft, often via a belt or a direct drive mechanism. As the engine rotates, it imparts its mechanical energy to the drive shaft, which then rotates the pump's impeller.

The impeller is a critical part of the pump, consisting of a series of blades or vanes. These blades are designed to create a vortex of water as the impeller rotates. This vortex generates a pressure differential, with higher pressure at the impeller's center and lower pressure at the outer edge. The pressure differential is what drives the water flow, forcing it through the pump and out into the boat's water system.

The pump's design ensures that water is drawn into the pump's intake, located at the lowest point, due to the pressure differential. This intake is often connected to a suction hose or a series of suction cups that create a seal with the water surface. As the impeller rotates, it pulls water into the pump, where it is then pressurized and pushed through the pump's outlet, which is connected to the boat's water lines or storage tanks.

In summary, the engine power system in a boat water pump is a sophisticated mechanism that transforms mechanical energy into a controlled water flow. This process involves the engine's rotation, which drives the pump's impeller, creating a pressure differential that forces water through the pump and into the boat's water distribution system. This efficient design ensures a steady supply of fresh water, making it an essential feature for any boating experience.

Boathouse Mooring: Docking vs Anchoring for Beginners

You may want to see also

Intake and Pressure: Water is drawn into the pump, creating pressure to force it out

Water pumps are essential components in boats, ensuring a constant supply of fresh water for various purposes, such as drinking, cooking, and sanitation. The process begins with the intake mechanism, which is designed to draw water from the source, typically a lake, river, or the sea. This intake system is often located at the bottom of the vessel, featuring a strainer or filter to prevent debris and contaminants from entering the pump. As the boat moves through the water, the intake valve opens, allowing water to flow into the pump. This is achieved through a combination of a diaphragm or a piston, which is connected to a motor or an engine. When activated, the motor or engine drives the diaphragm or piston, creating a vacuum that pulls the water into the pump.

Once the water is inside the pump, it enters a sealed chamber where the magic happens. The pump's design utilizes a series of intricate passages and chambers to create pressure and move the water. This is where the concept of pressure comes into play. As the water is drawn into the pump, it creates a partial vacuum, which then generates pressure. This pressure is essential to force the water out of the pump and into the desired location, such as the boat's water tank or various fixtures. The pump's internal components, including impellers and turbines, are designed to accelerate the water and increase its pressure, ensuring efficient water distribution.

The pressure-creating mechanism is a critical aspect of the pump's functionality. It involves the use of a volute, a spiral-shaped chamber at the end of the pump. As the water flows through the volute, it accelerates due to the decreasing cross-sectional area, resulting in increased pressure. This pressure is then utilized to propel the water through the discharge pipe and out of the pump. The volute's design is crucial, as it helps to maintain a consistent flow rate and pressure, ensuring the water is delivered effectively.

In summary, the intake and pressure generation process in a boat water pump is a carefully engineered system. It starts with the intake valve drawing water into the pump, creating a vacuum that pulls the water in. Inside the pump, the water is subjected to a series of passages and chambers, where its pressure is increased. This pressure is then harnessed to force the water out through the discharge pipe, providing a continuous supply of fresh water to the boat's occupants. Understanding this process is key to appreciating the vital role these pumps play in maritime environments.

Repairing a Leaky Boat: A Comprehensive Guide

You may want to see also

Impeller Rotation: The impeller's rotation generates centrifugal force, propelling water forward

The impeller, a crucial component of a boat's water pump, plays a pivotal role in the pumping mechanism. When the impeller rotates, it creates a powerful force known as centrifugal force. This force is a direct result of the impeller's rapid spinning motion, which causes the water molecules to move outward in a circular path. As the impeller spins, it accelerates the water, pushing it away from the center of the impeller and in the direction of the pump's outlet.

The rotation of the impeller is a fundamental principle in fluid mechanics. As the impeller blades rotate, they create a series of pressure differentials within the pump casing. The impeller's blades, designed with a specific angle and shape, force the water to follow a curved path, creating a velocity gradient. This velocity gradient is essential as it increases the water's speed, allowing the pump to move a higher volume of water with each rotation.

Centrifugal force is a critical aspect of the pumping process. It is the force that pushes the water out of the pump and into the desired direction. This force is directly proportional to the impeller's rotational speed and the radius of the impeller's blades. Higher rotational speeds and larger impeller diameters result in greater centrifugal force, enabling the pump to move water more efficiently.

The design of the impeller is carefully engineered to optimize this process. Impeller blades are typically shaped with a slight curve, allowing water to flow smoothly over the blade's surface. This design minimizes turbulence and ensures that the water is directed in a straight line, reducing energy loss. The impeller's rotation speed is also carefully controlled to maintain the required flow rate and pressure.

In summary, the impeller's rotation is the driving force behind a boat's water pump. By generating centrifugal force, the impeller propels water forward, ensuring a steady supply of water for various onboard systems. Understanding the mechanics of impeller rotation is essential for optimizing pump performance and ensuring reliable water distribution on boats.

Deck Boats and Oceans: A Good Mix?

You may want to see also

Pressure Relief: A pressure relief valve prevents excessive pressure buildup, ensuring safe operation

A pressure relief valve is a critical component in the operation of a boat water pump, serving as a safety mechanism to prevent potential hazards associated with excessive pressure buildup. This valve is designed to automatically release pressure when it exceeds a predetermined threshold, ensuring the system operates within safe limits. The primary function of this valve is to safeguard the pump and the overall system from potential damage caused by overpressure, which could lead to system failure or even catastrophic events.

In the context of a boat water pump, pressure relief valves are commonly used in the circulation system, where they are strategically positioned to monitor and control the pressure of the water being pumped. The valve is typically connected to the pump's outlet, allowing it to sense the pressure of the water exiting the pump. When the pressure exceeds the set limit, the valve opens, providing a path for the excess water to be released, thereby preventing a dangerous pressure spike.

The design of the pressure relief valve is such that it remains closed under normal operating conditions, allowing the pump to function efficiently. However, when the pressure exceeds the threshold, the valve's internal mechanism activates, causing it to open and release the excess pressure. This process is often facilitated by a spring-loaded mechanism, which provides the necessary force to open the valve when the pressure exceeds the set point. The valve's opening is carefully calibrated to ensure that it releases pressure in a controlled manner, minimizing any potential disruption to the pump's operation.

The importance of this safety feature cannot be overstated, especially in marine environments where water pumps are exposed to varying conditions. Without a pressure relief valve, the pump could be at risk of damage due to excessive pressure, leading to costly repairs or replacements. Moreover, the valve's role in preventing system failure contributes to the overall reliability and longevity of the boat's water circulation system.

In summary, pressure relief valves are essential components in boat water pumps, providing a critical layer of protection against potential hazards associated with overpressure. By ensuring safe operation, these valves contribute to the efficient and reliable functioning of the pump, making them a vital consideration in the design and maintenance of marine water circulation systems.

Best Boats for Diving: Safe and Fun Adventures

You may want to see also

Water Discharge: The pump expels water through an outlet, providing the desired water flow rate

A boat water pump is a crucial component for any vessel, ensuring a reliable supply of fresh water for various purposes, such as drinking, cooking, and sanitation. The primary function of this pump is to expel water through an outlet, providing the desired water flow rate, which is essential for the vessel's operations.

The process begins with the pump's impeller, a rotating component designed to create suction. When the pump is activated, the impeller spins, generating a low-pressure area in front of it and a high-pressure area behind. This pressure differential causes water to flow into the pump through an inlet. The impeller's design and rotation speed determine the volume and pressure of water drawn into the system.

As the water enters the pump, it is directed through a series of passages and chambers, where it is further pressurized. This pressurized water then exits the pump through an outlet, which is typically a nozzle or a pipe with a specific diameter. The outlet's design is critical in determining the water's flow rate and direction. A larger outlet diameter results in a higher flow rate, while a smaller one increases the pressure, allowing the pump to move water over longer distances.

The pump's efficiency is maximized when the water flow rate matches the vessel's requirements. This is achieved by adjusting the pump's speed or using a variable-speed drive, which allows for precise control over the water discharge. By modulating the pump's performance, operators can ensure that the water supply meets the demands of different onboard systems, such as sinks, showers, and toilets.

In summary, a boat water pump's primary role is to expel water through an outlet, providing the necessary flow rate for various onboard applications. The pump's design, including the impeller and outlet, plays a vital role in achieving the desired water discharge, ensuring a consistent and reliable water supply for the vessel's operations. Understanding these principles is essential for maintaining and optimizing the performance of boat water pumps.

Boat Fuel Basics: Understanding Gas Types for Marine Engines

You may want to see also

Frequently asked questions

A boat water pump is a device designed to move water from one location to another, typically from the sea or a lake into the boat's freshwater system. It operates by creating a partial vacuum, which pulls water into the pump through a suction process. This is achieved by rotating an impeller, a rotating blade-like component, inside a casing. As the impeller spins, it generates centrifugal force, pushing water outward and creating a low-pressure area at the center. This low pressure draws water into the pump, which then passes through a series of valves and pipes to the desired destination, such as the boat's freshwater tank or plumbing system.

There are several types of boat water pumps, each with its own unique design and purpose:

- Inboard Pump: This type of pump is typically installed inside the boat's engine compartment and is connected to the engine's raw water intake. It draws water from the sea and directs it to the engine's cooling system.

- Bilge Pump: Bilge pumps are designed to remove water that has accumulated in the boat's bilge, which is the lowest part of the hull. They are often used to prevent flooding and are usually electric-powered.

- Transom Pump: Transom pumps are mounted on the transom (back) of the boat and are commonly used for deck drainage or to pump water from the engine compartment.

- Foot Pump: A foot pump is a manual pump that requires the operator to push a pedal to create suction and pump water. It is often used for small-scale water transfer or as a backup in case of engine failure.

Proper maintenance is crucial to ensure the longevity and efficient operation of your boat water pump. Here are some maintenance tips:

- Regular Cleaning: Keep the pump and associated pipes clean to prevent the buildup of debris, algae, or mineral deposits. Use a soft brush or a cleaning solution recommended by the manufacturer.

- Check for Leaks: Inspect the pump and connections for any signs of leaks. Tighten fittings and replace worn-out gaskets or seals to prevent water loss.

- Inspect Impellers: Periodically remove the impeller and inspect it for wear or damage. Replace the impeller if it is worn out to maintain optimal performance.

- Test and Operate: Run the pump regularly to ensure it functions correctly. Test the pump's capacity and pressure to identify any issues.

Yes, boat water pumps can be versatile and used for various applications beyond their primary function of supplying freshwater. Here are a few alternative uses:

- Bilge Water Removal: As mentioned earlier, bilge pumps are excellent for removing water from the bilge, but they can also be used to pump out other liquids like fuel or oil in emergency situations.

- Deck Drainage: Transom pumps are commonly used for deck drainage, helping to keep the boat's deck dry and preventing water accumulation.

- Water Transfer: You can use a boat water pump to transfer water from one location to another, such as filling buckets or containers, especially when access to freshwater sources is limited.