Fiberglass is a popular choice for boat flooring for several reasons. Firstly, it is lightweight and durable, making it easy to install and long-lasting. The material is also resistant to water and moisture, which is crucial for boat interiors as they are often exposed to the elements. Additionally, fiberglass can be easily shaped and molded to fit various boat designs and layouts, providing a seamless and aesthetically pleasing finish. Its strength and flexibility make it an ideal material for creating a sturdy yet comfortable and safe walking surface on boats, ensuring a smooth and secure ride for passengers.

What You'll Learn

- Durability: Fiberglass provides a strong, impact-resistant layer over boat flooring, enhancing durability and protecting the underlying structure

- Water Resistance: It acts as a barrier, preventing water absorption and ensuring the boat's interior remains dry and comfortable

- Aesthetic Appeal: The smooth, sleek surface of fiberglass offers a visually appealing finish, enhancing the boat's overall appearance

- Easy Maintenance: Cleaning and maintaining a fiberglass-covered floor is straightforward, requiring minimal effort and specialized cleaning products

- Sound Insulation: Fiberglass can reduce noise and vibrations, creating a quieter and more comfortable environment for passengers

Durability: Fiberglass provides a strong, impact-resistant layer over boat flooring, enhancing durability and protecting the underlying structure

Fiberglass is an excellent choice for boat flooring for several reasons, particularly when it comes to durability. One of the primary benefits of using fiberglass in this application is its exceptional strength and impact resistance. When applied over boat flooring, fiberglass creates a robust and protective layer that significantly enhances the overall durability of the vessel.

The underlying structure of a boat, including the floor, is subjected to various stresses and impacts during its lifetime. From accidental bumps and collisions to the constant wear and tear of daily use, the boat's floor takes a beating. Fiberglass, when properly installed, provides a formidable barrier that safeguards the underlying materials from these potential damages. It acts as a protective shield, absorbing and distributing the force of impacts, thus preventing scratches, dents, and structural damage to the floor and the boat's frame.

This impact-resistant property is especially crucial in areas where the boat floor is more susceptible to damage, such as the bow, stern, and sides. These regions often bear the brunt of waves, wind, and accidental contact with obstacles. By covering the flooring with fiberglass, boat owners can ensure that these vulnerable areas are well-protected, maintaining the structural integrity of the vessel over time.

Furthermore, fiberglass is known for its ability to withstand the harsh marine environment. It is resistant to corrosion, UV radiation, and the general wear and tear associated with saltwater exposure. This resistance ensures that the boat flooring remains in excellent condition, even after prolonged use in marine settings. The durability offered by fiberglass allows boat owners to maintain a safe and comfortable environment, free from the risks of structural damage or floor deterioration.

In summary, the use of fiberglass over boat flooring is a practical and effective method to enhance durability. Its strength and impact resistance provide a protective layer, safeguarding the underlying structure from potential damage. This application ensures that boat owners can enjoy their vessels for years to come, confident in the knowledge that their boat's flooring is well-protected against the rigors of marine life.

Boat Insurance: When a Captain is a Requirement

You may want to see also

Water Resistance: It acts as a barrier, preventing water absorption and ensuring the boat's interior remains dry and comfortable

Fiberglass is an essential component in boat construction, especially when it comes to the flooring. Its primary purpose is to provide an effective barrier against water absorption, ensuring that the interior of the boat remains dry and comfortable for passengers and crew. This is a critical aspect of boat design, as boats are inherently exposed to water and moisture, and without proper protection, the interior can quickly become damp and unpleasant.

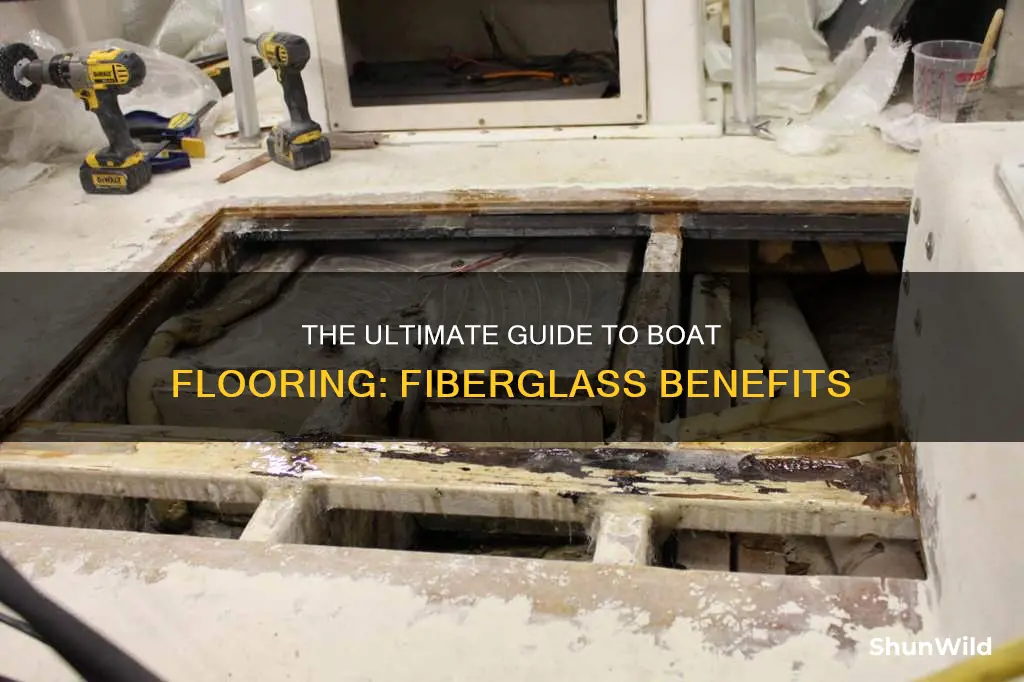

The process of installing fiberglass over boat flooring is a meticulous one. It involves carefully laying the fiberglass material over the existing floor structure, ensuring that every inch is covered. This layer acts as a protective shield, preventing water from seeping through any gaps or imperfections in the boat's hull. The fiberglass is typically applied in multiple layers, creating a strong and durable barrier that can withstand the constant exposure to water and the harsh marine environment.

One of the key advantages of using fiberglass for this purpose is its ability to provide a seamless and smooth surface. This is crucial for maintaining a comfortable and safe interior environment. A smooth surface reduces the risk of passengers slipping and falling, especially in wet conditions. Additionally, a well-installed fiberglass floor ensures that the boat's interior has a clean and professional appearance, enhancing the overall user experience.

Furthermore, fiberglass is an excellent choice for boat flooring because it is highly resistant to water absorption. Unlike some other materials, fiberglass does not absorb water easily, which means that even if water finds its way into the boat, it will not penetrate the interior. This is particularly important in areas where water intrusion can cause significant damage, such as beneath the floorboards or in compartments that are not easily accessible for drying.

In summary, the use of fiberglass over boat flooring is a critical design feature that ensures the boat's interior remains dry and comfortable. Its water-resistant properties act as a protective barrier, preventing water absorption and potential damage to the boat's interior. Proper installation and multiple layers of fiberglass create a robust and seamless surface, contributing to a safe and pleasant boating experience. This simple yet effective solution is a testament to the ingenuity of boat builders and their commitment to providing a reliable and enjoyable marine environment.

Can Boat Paint Be Used on Ceramic Tubs?

You may want to see also

Aesthetic Appeal: The smooth, sleek surface of fiberglass offers a visually appealing finish, enhancing the boat's overall appearance

The decision to cover boat flooring with fiberglass is primarily driven by its aesthetic benefits, which significantly contribute to the overall visual appeal of the vessel. Fiberglass, known for its smooth and sleek surface, provides a refined and polished look that is highly desirable in the marine industry. This material offers a seamless and continuous finish, eliminating the need for visible seams or joints, which can detract from the boat's sleek design. The smooth texture of fiberglass creates a uniform and elegant appearance, making the boat's interior feel more luxurious and well-crafted.

When it comes to boat flooring, the visual impact is crucial, as it sets the tone for the entire vessel's aesthetics. A well-finished fiberglass surface can transform a basic boat interior into a stylish and inviting space. The material's ability to mimic the look of wood or other high-end materials, while also providing durability and water resistance, makes it an excellent choice for those seeking a premium appearance. This is especially important in the marine market, where boat owners often strive for a unique and personalized look to stand out from the competition.

The installation process of fiberglass flooring is designed to be seamless, ensuring that the final finish is free from any visible imperfections. This is achieved through a meticulous application process, where the fiberglass is carefully laid and shaped to fit the boat's contours perfectly. The result is a smooth, continuous surface that aligns with the boat's overall design, creating a cohesive and aesthetically pleasing interior. This level of craftsmanship is often a key selling point for boat manufacturers and owners alike.

Furthermore, the color and finish options available with fiberglass allow for a wide range of customization. From solid colors to intricate patterns and even custom designs, the material can be tailored to match the owner's preferences and the boat's overall theme. This level of customization ensures that the boat's interior can be made to look exactly as the owner envisioned, further enhancing the aesthetic appeal.

In summary, the use of fiberglass over boat flooring is a strategic choice that significantly enhances the vessel's visual appeal. Its smooth surface, seamless installation, and customization options contribute to a luxurious and well-designed interior. By providing a refined and polished look, fiberglass ensures that the boat not only performs well but also stands out for its exceptional aesthetics. This combination of functionality and beauty is a strong motivator for boat owners and manufacturers to invest in high-quality fiberglass flooring.

Camouflage Your Fiberglass Boat: Tips for a Natural Look

You may want to see also

Easy Maintenance: Cleaning and maintaining a fiberglass-covered floor is straightforward, requiring minimal effort and specialized cleaning products

The use of fiberglass as a covering material for boat flooring offers a multitude of benefits, and one of the most appealing aspects is its ease of maintenance. Unlike traditional wooden or carpeted floors, a fiberglass-covered floor is incredibly low-maintenance and requires minimal effort to keep it clean and in good condition. This is particularly advantageous for boat owners who want to spend less time on upkeep and more time enjoying their vessel.

The surface of a fiberglass floor is smooth and non-porous, which means it naturally resists stains and water absorption. This inherent characteristic makes it highly resistant to the accumulation of dirt, grime, and other contaminants that can be easily removed with a simple cleaning routine. Regular maintenance involves using a mild detergent or a specialized boat cleaner, ensuring that the floor remains spotless and free from any unsightly marks.

One of the key advantages of this maintenance-friendly design is the ability to quickly address any spills or stains. In the event of an accident or a messy situation, the fiberglass floor can be cleaned with just a few simple steps. A quick wipe-down with a damp cloth and a suitable cleaner will effectively remove any residue, ensuring that the floor looks as good as new. This ease of cleaning is especially beneficial for boats that are frequently used in marine environments, where spills and splashes are common occurrences.

Furthermore, the non-slip nature of fiberglass flooring adds an extra layer of safety and convenience. The textured surface provides excellent traction, reducing the risk of slips and falls, which is crucial on a moving boat. This feature, combined with the easy-to-clean surface, ensures that the boat remains a safe and comfortable space for passengers and crew.

In summary, the decision to cover boat flooring with fiberglass is not only aesthetically pleasing but also highly practical. The material's non-porous nature and smooth surface make it incredibly easy to maintain, requiring only basic cleaning products and minimal effort. This level of simplicity in maintenance is a significant advantage for boat owners, allowing them to focus on the joy of boating without the hassle of frequent and time-consuming floor care.

Exploring Paxos: A Short Boat Ride from Corfu

You may want to see also

Sound Insulation: Fiberglass can reduce noise and vibrations, creating a quieter and more comfortable environment for passengers

Fiberglass, when applied as an overlay to boat flooring, offers a significant advantage in terms of sound insulation, which is a crucial aspect of boat design and comfort. The primary reason for its use in this context is to minimize noise and vibrations, ensuring a smoother and more pleasant journey for passengers.

Boats, especially those in open waters, are exposed to various sources of noise and vibrations. The engine, propeller, and even the movement of the vessel itself can generate significant sound and vibration. These factors can contribute to an uncomfortable and potentially tiring experience for those on board. By installing fiberglass over the flooring, boat manufacturers can effectively dampen these sounds and vibrations. Fiberglass is an excellent material for sound insulation due to its ability to absorb and block sound waves. It acts as a barrier, preventing the transmission of noise from the lower deck to the upper areas of the boat, where passengers are typically seated. This is particularly important in recreational boats, where creating a peaceful and relaxing atmosphere is essential for a positive user experience.

The process of sound insulation with fiberglass involves a careful and precise application. The fiberglass is typically laid over the existing flooring, ensuring complete coverage. This layer acts as a sound-absorbing barrier, trapping and dampening the vibrations before they can travel upwards. The material's structure and composition are designed to absorb and dissipate sound energy, reducing the overall noise levels within the boat. This is especially beneficial in areas where passengers gather, such as the salon or dining areas, where a quiet and serene ambiance is desired.

Furthermore, the use of fiberglass for sound insulation contributes to the overall structural integrity of the boat. It provides additional support and strength to the flooring, making it more robust and durable. This is particularly important in marine environments, where boats are exposed to various weather conditions and potential impacts. The added layer of fiberglass can enhance the boat's ability to withstand these external factors while maintaining a comfortable interior.

In summary, fiberglass, when applied to boat flooring, serves as an effective sound insulation solution. Its ability to reduce noise and vibrations significantly improves the overall comfort and enjoyment of the vessel. By creating a quieter environment, boat manufacturers can ensure that passengers have a more pleasant and relaxing experience, even during long journeys or in challenging marine conditions. This simple yet impactful feature is a testament to the thoughtful design considerations that go into modern boat construction.

Blue Wave Boats: Are They Worth the Hype?

You may want to see also

Frequently asked questions

Fiberglass is a popular choice for boat flooring because it offers several advantages. Firstly, it is lightweight, making it easier to handle and install. Secondly, it is durable and resistant to water, which is crucial for boat applications as it helps prevent water damage and ensures the boat's structural integrity. Fiberglass also provides a smooth and non-slip surface, enhancing safety and comfort for passengers.

By using fiberglass as a flooring material, boats benefit from its excellent structural properties. Fiberglass is known for its strength and rigidity, allowing it to distribute weight evenly and provide a sturdy base. This is particularly important in high-performance boats, where stability and responsiveness are key. The material's ability to withstand impact and resist deformation ensures a longer lifespan for the boat and its components.

The installation process typically involves several steps. First, the existing boat flooring is prepared by cleaning and smoothing the surface. Then, a layer of fiberglass cloth or mat is laid over the prepared area, followed by a resin or epoxy adhesive. This process is repeated to create multiple layers, building up strength and durability. Finally, the fiberglass is cured, resulting in a solid and seamless flooring system.

Yes, regular maintenance is essential to keep the fiberglass flooring in good condition. Cleaning the surface with mild soap and water is recommended to remove dirt and grime. It's also important to inspect the flooring periodically for any signs of damage, such as cracks or delamination. Repairing any issues promptly will help maintain the boat's overall performance and appearance.

Fiberglass offers several benefits over traditional boat flooring materials like wood or carpet. It is more resistant to rot and decay, ensuring a longer-lasting flooring solution. Fiberglass is also easier to repair compared to other materials, as it can be patched and reinforced without replacing large sections. Additionally, its lightweight nature reduces the overall weight of the boat, potentially improving fuel efficiency and handling.