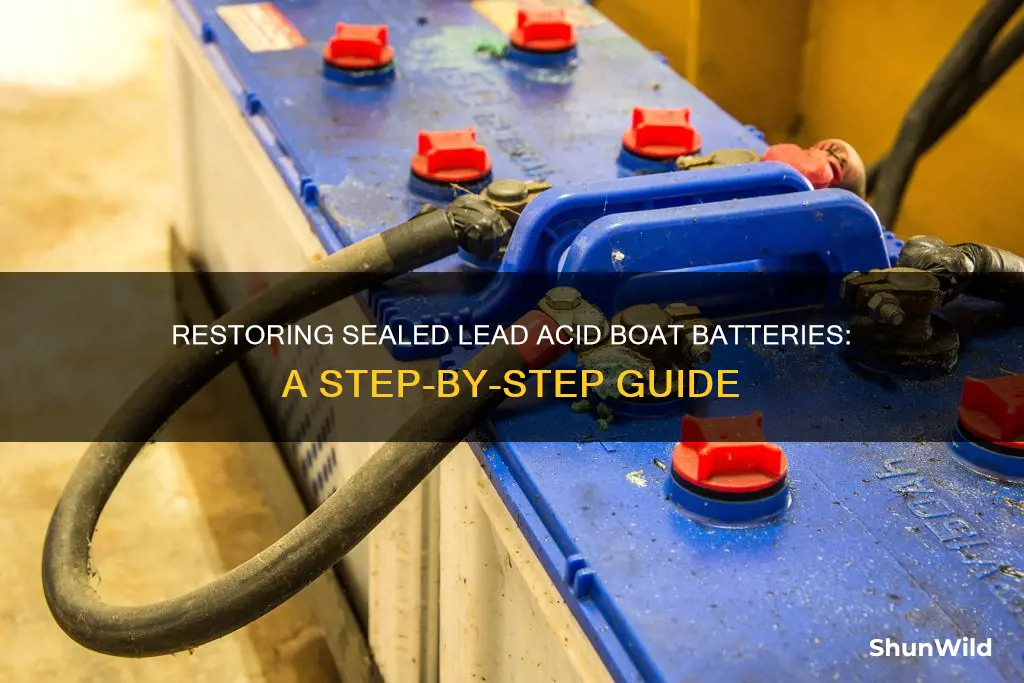

Sealed lead acid batteries are a cost-effective power source for boats, but they can be prone to losing their charge due to an accumulation of lead sulphate crystals on their internal plates. This can be avoided by ensuring the battery is fully recharged immediately after a discharge cycle. However, if the battery has been left to deplete entirely, it may be possible to revive it by creating a solution of magnesium sulphate and distilled water, draining the battery acid, and filling the battery with the solution. The battery can then be charged, and the process repeated until the battery is restored to around 70-80% of its original capacity.

| Characteristics | Values |

|---|---|

| Battery Voltage Before Charging | Should be above 11.8v (30%) |

| Battery Voltage After Charging | Should be above 12v |

| Battery Voltage After Charging | Should be above 12v |

| Battery Voltage After Charging | Should be above 12v |

| Battery Type | Sealed Lead Acid (SLA) |

| Battery Age | Less than 5 years for 99% recovery, 50-75% recovery after 5 years |

| Battery Contents | Sulphuric Acid, Distilled Water, Lead |

| Required Supplies | Multimeter, Adjustable PSU or Taper Charger, Distilled Water, Rubber Gloves, Screwdriver, Flashlight, Super Glue, Paper Towel, Syringe , <co: 2,3>DC Power Supply, Sharped Pointed Tool, Wires or Clips, Clean Workplace |

What You'll Learn

Inspect the cells for white fabric

Inspecting the cells for white fabric is a crucial step in restoring a sealed lead acid battery. This process will help determine the battery's condition and the likelihood of successful revival. Here's a detailed guide on inspecting the cells for white fabric:

Step 1: Prepare the Battery

Before inspecting the cells, ensure you have the necessary safety equipment, such as rubber gloves and eye protection. Place the battery on a clean, well-ventilated work area and cover the surrounding areas with paper towels to catch any spills.

Step 2: Open the Battery

Use a screwdriver to carefully remove the lid of the battery. This step may vary depending on the type of sealed lead acid battery you are working on. Some batteries may have hidden caps that need to be removed. Always refer to the specific instructions for your battery model.

Step 3: Inspect the Cells

With the battery open, it's time to inspect the cells. Look inside each cell and observe the condition of the fabric within. What you see will indicate the battery's health and guide the next steps in the restoration process.

Step 4: Identify White Fabric

Ideally, you should see white fabric that is dry within the cells. This white fabric indicates that the battery is in good condition and has not suffered from excessive sulfation. Sulfation is a common issue in lead-acid batteries, leading to reduced performance and capacity.

Step 5: Address Brown Fabric with White Lumps

If you observe brown fabric with white lumps, this is an indication of sulfation. The chances of successfully reviving a battery at this stage are slim. However, you may still attempt to rehydrate the cells and test the battery's performance.

Step 6: Rehydrate the Cells

Using a syringe, carefully fill each cell with distilled water, rainwater, or pure water (not tap water). Observe if the fabric is absorbing the water. This step is crucial, as sulfated batteries may have a reduced capacity to absorb water.

Step 7: Rest and Observe

After rehydrating the cells, slowly shake the battery gently and let it rest for about 10 minutes. This step will help distribute the water evenly and allow you to observe any signs of leakage or damage.

Inspecting the cells for white fabric is a vital diagnostic step in restoring a sealed lead acid battery. It helps identify the extent of sulfation and guides the revival process. Remember to prioritize safety and follow specific instructions for your battery model throughout the restoration process.

Diagnosing Boat Engine Overheating: What to Look For

You may want to see also

Remove the battery from the vehicle

Removing the battery from your boat is a simple task that can be completed in a few steps. Firstly, locate the battery in your boat. It is usually placed in an accessible location, such as under a seat or in a dedicated battery compartment. Once you have located the battery, disconnect the negative terminal first, followed by the positive terminal. Make sure you have the necessary tools, such as wrenches or socket sets, to loosen the terminal clamps. After disconnecting the terminals, carefully lift the battery out of its compartment. Be mindful of the weight of the battery and use gloves to protect your hands. Place the battery on a flat surface or a battery tray. Now you are ready to begin the restoration process.

Before you start working on the battery, it is important to take safety precautions. Lead-acid batteries contain sulphuric acid, which is highly corrosive and can cause serious injuries. Wear safety goggles and gloves to protect your eyes and hands. Ensure that you are working in a well-ventilated area to avoid inhaling harmful fumes. Cover your skin and avoid wearing loose clothing to minimise the risk of acid burns.

Now, let's move on to inspecting the battery. Check for any signs of damage, such as cracks or leaks. If the battery is damaged, it may not be safe to proceed with the restoration process. Examine the battery terminals for any signs of corrosion. Corrosion can affect the battery's performance and should be cleaned before proceeding. Use a wire brush or a corrosion cleaning solution to remove any corrosion buildup.

Once you have completed the safety checks and inspections, you can begin the restoration process. Refer to other sources or guides for detailed instructions on restoring a sealed lead-acid battery. Remember to follow safety precautions and work carefully throughout the process.

Protecting Your Boat: Best Sealants for Wooden Surfaces

You may want to see also

Use a syringe to drain each cell

To restore a sealed lead acid battery in a boat, you'll need to use a syringe to drain each cell. This is a crucial step in the restoration process, as it involves balancing the acid levels in each cell. Here's a detailed guide on how to do it:

Prepare Your Work Area:

Before you begin, make sure you have a clean and well-ventilated work area. Cover your work surface with paper towels to catch any spills. Put on safety goggles and gloves to protect yourself from the corrosive battery acid.

Gather Your Tools and Materials:

You will need the following items:

- A syringe

- A container to collect the drained acid

- A multimeter

- Distilled water

- Rubber gloves

- A screwdriver

- Paper towels

Locate the Battery Cells:

Find the battery cells, which are usually sealed with screw-in caps or a "`sealing' strip." If your battery has a sealing strip, use a flat screwdriver or a sharp craft knife to carefully pry or cut along the edges to remove it.

Remove the Caps:

Using a screwdriver, remove the caps from each individual cell. Some batteries have small rubber caps, while larger batteries usually have screw-in plugs. These plugs are typically not very tight and can be easily removed.

Drain the Acid:

Now, use the syringe to carefully drain each cell one by one. Drain each cell until they are around 50-60% full. If some cells are already lower than this, you can add some acid from the fuller cells to balance the levels. Be very careful when handling the acid, as it is highly corrosive. Place the drained acid in a glass or plastic container for safe disposal later.

Dispose of the Removed Acid Safely:

The acid you have removed contains heavy metals, mainly lead, and is extremely corrosive. Make sure to dispose of it in a safe and responsible manner. You can neutralize it by slowly adding it to a bucket of water while stirring. Then, add baking soda a little at a time until the bubbling reaction stops. This will neutralize the acid, and you can then pour it down the drain or dispose of it in a bare patch in your garden.

Remember to wear protective gear and work in a well-ventilated area throughout the process. Working with lead-acid batteries can be dangerous if not done properly, so always prioritize your safety.

Coolant in Boat Engines: What You Need to Know

You may want to see also

Make a solution of magnesium sulphate and distilled water

To restore a sealed lead acid battery in a boat, you will need to revive it. This involves several steps, including measuring battery voltage, inspecting the cells, and testing the battery. One of the key steps is to "pump in some water" to the battery. While the source does not specify the type of water, distilled water is often used in such applications.

Now, to make a solution of magnesium sulphate and distilled water, you will need to follow these steps:

Firstly, it is important to understand that magnesium sulphate, also known as magnesium sulfate, is a chemical compound consisting of magnesium cations (Mg2+) and sulfate anions (SO2−4). It is usually found in the form of a hydrate, with the formula MgSO4·nH2O, where n can vary from 1 to 11. The most common form is the heptahydrate (n=7), known as Epsom salt, which is a household chemical with various uses.

To make the solution, follow these steps:

- Prepare the Magnesium Sulphate: Depending on your specific application, you may need to purchase or prepare magnesium sulphate in the desired form. The anhydrous form (without water) can be obtained by heating the heptahydrate to temperatures above 320 °C. For agricultural use, the monohydrate (n=1) form is commonly used.

- Measure the Ingredients: The amount of magnesium sulphate and distilled water required will depend on the concentration of the solution you need. A common concentration for magnesium sulphate solutions is around 4% to 8%, as indicated in medical applications.

- Mix the Ingredients: In a suitable container, add the measured amount of distilled water. Slowly add the magnesium sulphate to the water while stirring continuously. Continue stirring until all the magnesium sulphate has dissolved. You may need to adjust the amount of water or magnesium sulphate to achieve the desired concentration.

- Check the Solution: Use a tool such as a multimeter or a hydrometer to check the specific gravity or concentration of the solution. This step is important to ensure that you have achieved the desired concentration.

- Store the Solution: Label the container with the type of solution, concentration, and date. Store the solution in a cool, dry place, and ensure that it is out of the reach of children and pets.

By following these steps, you can make a solution of magnesium sulphate and distilled water. However, it is important to handle chemicals with care and take appropriate safety precautions, such as wearing protective gloves and goggles.

How to Retrieve a Lost Boat Title

You may want to see also

Recharge the battery

Now that you've removed the old acid and cleaned the plates, it's time to recharge your battery.

Firstly, you'll need to make sure that you have a battery charger. If you don't, you can jump-start your vehicle and then take it for a full hour or two drive to allow the battery to charge using the alternator.

If you do have a battery charger, connect it to the battery and let it complete the charging cycle. If the battery is heavily drained or damaged, you may need to leave it overnight with a trickle charger at a very low amperage.

If your battery is a valve-regulated lead-acid (VRLA) battery, it's important to leave the caps open while charging, as some gas will be released.

Once the battery is fully charged, you can remove the liquid and replace it with fresh sulphuric acid for better performance.

If you're using the Epsom salt method, you can leave the solution in the battery for a few weeks to assist with breaking down the lead sulphate crystals. However, for the best results, you should eventually remove the Epsom salt solution and replace it with fresh sulphuric acid.

After recharging, your reconditioned battery should last another six months to a year, and you can usually repeat this process about three to five times until it is no longer effective.

Marinette Boats: Performance and Quality Reviewed

You may want to see also

Frequently asked questions

The lead-acid battery is the oldest type of rechargeable battery, invented in 1859 by French physicist Gaston Planté. It has a low energy-to-weight ratio and a low energy-to-volume ratio, but its ability to supply high surge currents means that the cells have a relatively large power-to-weight ratio.

If your battery is completely dead, it's probably gone and you'll need to replace it. However, if there's still some charge left, you can try hooking it up to a smart battery charger to desulfate the lead plates and restore some performance.

You'll need a multimeter, an adjustable PSU or taper charger, distilled water or rainwater, rubber gloves, a screwdriver, a syringe, and safety goggles.

First, measure the battery voltage using a multimeter. If it's lower than 11.8v (30%), you'll need to revive it. Next, inspect the cells and remove any visible sulfation with paper towels. Fill each cell with water and let it sit for 10 minutes. Connect your multimeter to show how much the battery is drawing, and then connect your PSU or charger and let it sit for a day or two. Finally, test the battery by leaving it for an hour and hooking it up to a 12v bulb; the voltage shouldn't drop below 12v.

To extend the life of your sealed lead acid battery, it's important to give it attention, especially during the winter months. Don't let it sit idle for too long without operating or charging. Consider using a smart charger or trickle charger to maintain the battery when it's not in use.