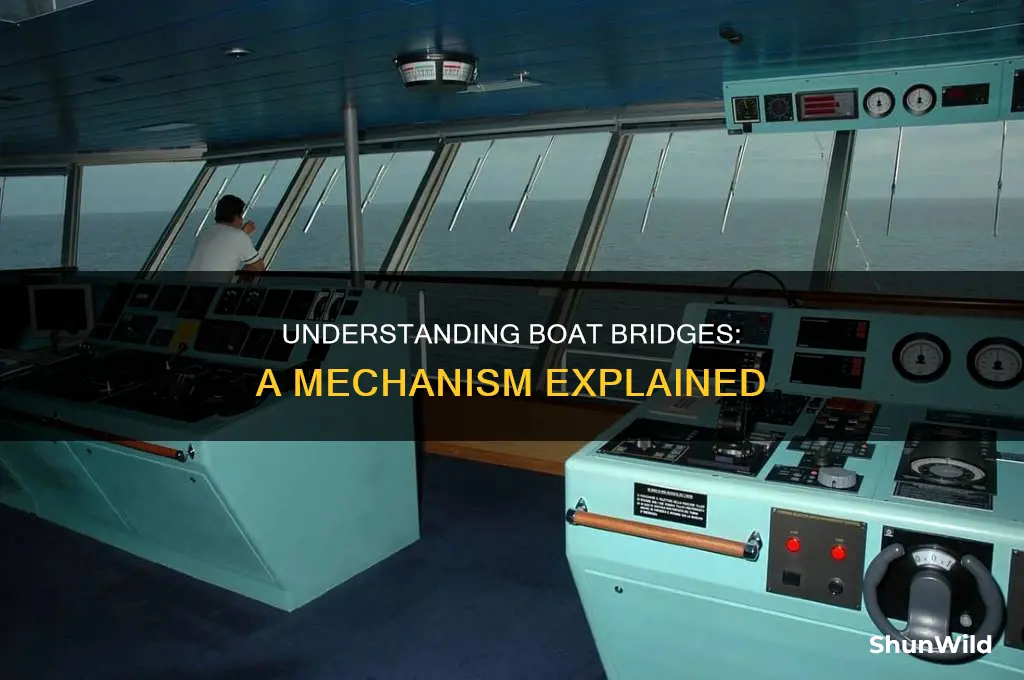

A boat bridge can refer to two different things. Firstly, it can mean a floating bridge, which is a type of bridge that floats on water and supports a continuous deck for pedestrian and vehicle travel. These bridges are typically temporary and used in wartime or civil emergencies, but there are also permanent floating bridges in civilian use. The other meaning of boat bridge is the command centre of a ship, also known as the bridge or wheelhouse. This is where the ship is commanded and controlled, and it is usually located above the weather deck to provide an unobstructed view.

| Characteristics | Values |

|---|---|

| Other Names | Pontoon Bridge, Floating Bridge |

| Use | Military, Civilian |

| Construction | Wood, Metal, Rubber, Concrete, Asphalt, Modular Metal |

| Buoyancy | Limited by the buoyancy of the supports |

| Permanence | Temporary, Permanent |

| Purpose | Pedestrian, Vehicle Travel |

What You'll Learn

Buoyancy and Load Distribution

Understanding the concept of buoyancy is crucial to grasping how floating bridges work. Picture a boat floating on a lake; it remains afloat because it displaces an amount of water equal to its own weight. Similarly, floating bridges, or pontoon bridges, rely on each pontoon or floating dock acting as a giant buoy, supporting the bridge deck above the water's surface.

The real challenge lies in load distribution. The bridge must support not only its own weight but also the weight of vehicles, pedestrians, and sometimes even light rail systems. This is achieved through careful load distribution, ensuring that the total weight across the pontoons maintains the structure's buoyancy.

For example, the Lake Washington bridge in Seattle consists of multiple pontoons tied together, each supporting a segment of the roadway. This modular design allows for load distribution, keeping the bridge stable and flexible, able to adapt to shifts without compromising its integrity.

The buoyancy of the pontoons is limited, which restricts the maximum load they can carry. Civil engineers must consider Archimedes' principle when designing pontoon bridges: each pontoon can support a load equal to the mass of the water it displaces. This includes the weight of the bridge and the pontoon itself. If the maximum load capacity of a bridge section is exceeded, one or more pontoons may become submerged.

Fixing a Stiff Stearing: Boat Handling Simplified

You may want to see also

Anchorage Techniques

Anchoring a floating bridge is akin to anchoring a ship in stormy seas. It requires precision, foresight, and a deep understanding of the forces at play. The pontoons are anchored to the lakebed using massive cables or rods, designed to hold the bridge in place while allowing a degree of movement to accommodate water level variations and currents.

The stability of a floating bridge depends significantly on its anchorage system. Advanced engineering techniques are employed to secure these massive structures against the forces of nature. Anchors, often massive concrete blocks or anchors drilled into the lakebed, are connected to the pontoons through steel cables or rods. This system allows the bridge to resist lateral movements due to wind or currents while providing enough flexibility to adjust to changing water levels.

Concrete pontoons are indispensable to the construction of continuous pontoon bridges. They are designed to resist water ingress and the damaging effects of aquatic organisms. Their resilience is further enhanced by incorporating air cells, increasing buoyancy and forming a reliable foundation for the bridge deck.

The connection of the bridge to the shore requires the design of approaches that are not too steep, protect the bank from erosion, and provide for the bridge's movement during (tidal) changes in water level.

The choice of anchoring technique depends on various factors, including the type of seabed, weather conditions, and the size of the vessel. Here are some common anchoring techniques:

- Bow Anchoring: This is the most common form of anchoring, with the anchor deployed from the bow of the boat. It is typically used because the bow is designed to cut through waves and is the most seaworthy end of the boat.

- Stern Anchoring: This technique is used when the stern of the boat needs to face the shore, usually in calm conditions with a beach shoreline.

- Bahamian Moor: This technique uses two anchors set in opposite directions, useful in narrow channels where the tide changes direction.

- Two Anchors Off The Bow: In heavy weather or rocky bottoms, setting two anchors off the bow provides extra security.

- Mediterranean Mooring: Common in crowded Mediterranean harbors, this method involves dropping the anchor and then backing toward the dock or quay.

When anchoring a floating bridge, it is important to select the right type of anchor suitable for the specific conditions. Here are some factors to consider:

- Boat Size: Larger boats require anchors with greater holding power.

- Bottom Conditions: Different anchors perform best in specific seabed types. For example, a fluke anchor is ideal for sandy or muddy bottoms, while a plow anchor can handle various conditions, including rock, sand, and mud.

- Weather and Sea Conditions: If sailing in areas with rough weather and high winds, a more robust anchor is needed.

- Storage Space: Some anchors require more storage space than others, so consider the size of your vessel.

- Budget: The cost of the anchor and its rode should be considered, although it shouldn't be the deciding factor.

Who Steers the Ship: Navy Boat Operators

You may want to see also

Key Materials

Boat lifts are made up of four main components: a bunk or cradle, a framework or structure, a winch system, and cables or straps.

The bunk or cradle supports the boat's hull and holds it securely. These can be fixed or adjustable. The framework or structure contributes to the overall stability of the lift, holding the cradles or bunks in place. The winch system consists of a winch, a spool, and a cable or strap, which work together to raise and lower the boat. Finally, the cables or straps connect the boat to the lift and are designed to withstand the boat's weight.

Boat lifts can be manual or motorized, with hydraulic and electric systems being the most common. Hydraulic boat lifts utilize battery power, allowing the boat to be raised and lowered with the push of a button or the use of a remote. Electric screw drives, on the other hand, feature an electric motor connected to a screw-like mechanism that rotates to raise or lower the lift.

Boat lifts are typically made from aluminum, galvanized steel, or polyethylene. Aluminum is sturdy and lightweight, while polyethylene is known for its durability and resistance to corrosion.

Boat lifts can also be categorized into several types, including cantilever boat lifts, hydraulic boat lifts, freestanding boat lifts, floating boat lifts, bottom-standing lifts, shore-mounted lifts, piling mount lifts, and vertical boat lifts. The choice of lift depends on factors such as boat type, size, and the water conditions where the lift will be installed.

Finding a Missing Boat: Strategies for Success

You may want to see also

Design and Construction

A boat lift is a machine that transports boats between two different water elevations. They are an alternative to canal locks and can be vertically moving, like the Anderton boat lift in England, rotational, like the Falkirk Wheel in Scotland, or operate on an inclined plane, like the Ronquières inclined plane in Belgium.

Boat lifts are designed to move boats from the sea to a platform or dock and back into the water. They are made up of vertical supports or pilings, a platform where the boat is kept, a cradle, cables, pulleys, and a motor or winch system. The supports are anchored to the bottom of the water for stability, and the cables and pulley system help raise or lower the platforms. They can be operated manually or automatically.

There are several types of boat lifts, including:

- Freestanding boat lifts: These are mounted directly into the ground beside docks and underneath the water. They can be placed in the water or built on land and do not require other structures to function.

- Boathouse lifts: These are built into the boat or homeowner's docks and are a good option for those without the space for a freestanding lift.

- Piling mount boat lifts: These are mounted onto a dock piling, which is a large wooden post installed into the ground with concrete.

- Floating dock lifts: Boats can be driven onto these lifts on an inclined plane, keeping them out of the water without the need for a pulley system.

- Suspended boat lifts: These are suspended by cables or chains from a dock or structure above the water. They are used for boats in deep water or areas with varying water levels.

Pontoon bridges, also known as floating bridges, are another way to transport boats and can be used temporarily in wartime or civil emergencies, or permanently for civilian use. They are made up of shallow-draft boats or floats connected together to support a continuous deck for pedestrian and vehicle travel. The buoyancy of the supports limits the maximum load they can carry. Most pontoon bridges are designed for temporary use, but those across bodies of water with a constant water level can remain in place for longer.

Boat Cleaning Products: Best Options for Sparkling Results

You may want to see also

Maintenance

Boat bridges, or pontoon bridges, require regular maintenance to ensure their longevity and safety for users. Here are some key considerations for maintaining these unique structures:

Regular Inspections

It is crucial to conduct regular inspections of boat bridges to identify any potential issues. Inspections should include checking for structural integrity, such as cracks or corrosion, particularly in steel and concrete components. Given the dynamic nature of water bodies, it is essential to monitor the bridge's stability and ensure that mooring lines and anchors remain secure.

Preventative Measures

To mitigate damage from natural forces, such as wind and waves, preventative measures should be implemented. This includes regular maintenance of the bridge's exterior, such as repainting or applying protective coatings to steel components to prevent corrosion. Additionally, the buoyancy of the pontoons should be monitored to ensure they can adequately support the weight of the bridge and its load.

Traffic Management

As boat bridges have weight limitations, it is essential to manage the type and volume of traffic using the bridge. Regular assessments should be conducted to ensure that the bridge can safely accommodate the expected traffic, including both vehicular and pedestrian traffic. This may involve implementing weight restrictions or traffic management strategies to control the flow of vehicles.

Routine Cleaning and Repairs

Boat bridges are susceptible to the accumulation of debris, flotsam, and ice, which can impact their performance and safety. Therefore, routine cleaning and maintenance are necessary to remove any build-up and ensure the bridge's functionality. Repairs should be conducted promptly to address any damage, such as cracks or punctures in the pontoons, to prevent further deterioration.

Seasonal Adjustments

In locations with varying water levels or weather conditions, seasonal adjustments may be required. This could involve raising or lowering the bridge to accommodate changes in water levels or preparing the bridge for extreme weather events, such as storms or floods.

Long-Term Maintenance Planning

Given the specialised nature of boat bridges, it is essential to have a long-term maintenance plan in place. This should include scheduled major maintenance and upgrades, as well as a proactive approach to addressing potential issues. Regular condition assessments by qualified engineers can help identify areas requiring attention and ensure the bridge's longevity.

By implementing these maintenance strategies, operators of boat bridges can ensure the safety and functionality of these structures, providing reliable connections for users while minimising the risk of disruptions or accidents.

Hiding Numbers: Boat Owners' Privacy Protection from Registration Blur

You may want to see also

Frequently asked questions

A boat bridge, also known as a pontoon bridge, is a floating bridge that uses floats or shallow-draft boats to support a continuous deck for pedestrian and vehicle travel.

Boat bridges work based on the principle of buoyancy. Each pontoon or floating dock acts like a buoy, supporting the weight of the bridge and its load above the water's surface. The weight of the bridge and its load must be carefully distributed across the pontoons to maintain the structure's buoyancy.

Boat bridges are typically made of concrete pontoons, which are designed to resist water ingress and the damaging effects of aquatic organisms. The concrete pontoons are engineered with air cells to increase buoyancy and provide a reliable foundation for the bridge deck.

Boat bridges are used to span waterways and connect communities without hindering the flow of water beneath. They are often used as temporary solutions in wartime and civil emergencies but can also be permanent structures for long-term civilian use.