A boat's hot foot is a clever device that utilizes the principle of heat transfer to propel the vessel forward. It operates by converting the heat generated by the engine into mechanical energy, which is then transferred to the propeller. This innovative system allows for efficient power transmission, ensuring that the boat's engine power is effectively utilized to move through the water. The hot foot mechanism is a fascinating example of how marine engineering can harness and utilize energy sources to enhance boat performance.

What You'll Learn

- Engine Power: Boat's hot foot uses engine power to propel the vessel

- Thrust: The system generates thrust by expelling water backward

- Propeller: Propeller design is crucial for efficient hot foot operation

- Fuel Efficiency: Optimizing fuel efficiency is key to hot foot's performance

- Safety: Hot foot systems require careful maintenance to ensure safe operation

Engine Power: Boat's hot foot uses engine power to propel the vessel

The 'hot foot' technique in boating is an innovative method that utilizes engine power to enhance propulsion and improve overall performance. This technique involves a clever arrangement of the engine and propeller, allowing for a more efficient and powerful drive. By optimizing the engine's power, hot foot enables boats to accelerate quickly and maintain higher speeds, especially in challenging conditions.

At its core, the hot foot system relies on the engine's ability to generate force and transmit it to the propeller. When the engine is engaged, it produces rotational energy, which is then transferred to the propeller via a driveshaft. The propeller, designed with specific blades and angles, converts this rotational force into thrust, pushing the boat forward. The key to the hot foot's success is the precise alignment and synchronization of the engine, propeller, and transmission, ensuring optimal power transfer.

One of the advantages of this system is its ability to provide a rapid response to the operator's commands. When the throttle is opened, the engine's power is instantly directed to the propeller, resulting in a quick acceleration. This is particularly beneficial for boats in competitive racing or those requiring sudden bursts of speed. The hot foot technique allows for a more dynamic and responsive driving experience, giving the boat a competitive edge.

Furthermore, the hot foot design often incorporates a variable pitch propeller, which can adjust its blade angle during operation. This feature enables the propeller to optimize its performance at different speeds and loads. By altering the pitch, the propeller can efficiently convert engine power into thrust, ensuring maximum efficiency across various boating scenarios. This adaptability is crucial for maintaining performance in changing water conditions and loads.

In summary, the hot foot technique in boating harnesses the power of the engine to create a highly effective propulsion system. By carefully managing the engine's force and its transmission to the propeller, boats can achieve superior acceleration and speed. This method is a testament to the ingenuity of marine engineering, providing boaters with a powerful and responsive driving experience.

Salvaging a Flooded Boat Engine: Steps to Take

You may want to see also

Thrust: The system generates thrust by expelling water backward

The 'hot foot' system is an innovative propulsion method used in certain boats, particularly those designed for speed and maneuverability. This system operates on a principle similar to that of a jet engine, but instead of burning fuel, it utilizes the force of expelled water to create forward motion. Here's a detailed explanation of how it works:

Thrust is the primary force that propels the boat forward. In the hot foot system, this thrust is generated by expelling water in a highly efficient and directed manner. The boat's engine drives a pump, which forces water into a high-pressure reservoir. This reservoir is designed to store the water temporarily, building up pressure within the system. When the operator initiates the thrust, the water is released from the reservoir through a narrow nozzle, often located near the stern of the boat.

The key to the hot foot system's efficiency lies in the design of the nozzle. It is carefully crafted to control the flow and direction of the water jet. This nozzle acts as a throttle, allowing the operator to regulate the amount of water expelled and, consequently, the force of the thrust. By adjusting the nozzle's opening, the boat's driver can control its speed and acceleration, providing a responsive and customizable propulsion system.

As the high-pressure water exits the nozzle, it creates a powerful force in the opposite direction, pushing the boat forward. This forward motion is a result of Newton's third law of motion, where the boat exerts an equal and opposite force on the expelled water. The design and placement of the nozzle ensure that the water is expelled at a precise angle, optimizing the thrust and minimizing any unnecessary drag.

The hot foot system offers several advantages over traditional propeller-based propulsion. It provides better control and responsiveness, especially at lower speeds, as the operator can fine-tune the thrust. Additionally, this system can be more efficient in terms of fuel consumption, as it doesn't require the same amount of energy to create forward motion compared to traditional engines. This makes it an attractive option for boats that require frequent starts and stops or those operating in shallow waters where propellers might be less effective.

The Mystery of Niagara Falls' Famous Boat's Name

You may want to see also

Propeller: Propeller design is crucial for efficient hot foot operation

The propeller is a critical component in the hot foot system of a boat, and its design significantly impacts the efficiency and performance of the entire setup. Propeller design involves several key factors that contribute to the overall functionality and effectiveness of the hot foot mechanism. Firstly, the propeller's blade shape and angle play a vital role in generating thrust. The blades are typically designed with a specific angle of attack, which determines the lift and drag forces acting on the propeller. A well-designed propeller with an optimal angle of attack will produce the necessary thrust to propel the boat forward while minimizing energy loss.

The pitch of the propeller is another essential design consideration. Propeller pitch refers to the distance a propeller would travel in one revolution if it were moving in a straight line. A higher pitch means the propeller can move water more efficiently, resulting in better acceleration and higher top speeds. However, a higher pitch also increases the propeller's resistance to water, which can affect the boat's fuel efficiency. Finding the right balance between thrust and efficiency is crucial for optimal hot foot operation.

Additionally, the number of blades on the propeller can impact performance. Multi-bladed propellers are often preferred for hot foot systems due to their ability to provide more even thrust distribution. This even distribution helps reduce vibrations and noise, making the hot foot operation smoother and quieter. The number of blades also influences the propeller's weight and size, which can affect the boat's overall performance and handling.

Propeller design also involves considerations such as material selection and surface treatment. Modern propellers often utilize lightweight materials like composite alloys to reduce the boat's overall weight and improve fuel efficiency. The surface of the propeller may also be treated with specialized coatings to reduce friction and corrosion, ensuring a longer lifespan and optimal performance.

In summary, propeller design is a complex yet crucial aspect of hot foot operation. Engineers and designers must carefully consider various factors, including blade shape, angle, pitch, blade count, material, and surface treatment, to create a propeller that maximizes thrust, efficiency, and overall boat performance. A well-designed propeller will contribute to a smoother, faster, and more reliable hot foot system.

Boat Sails: Valuable Assets or Costly Liabilities?

You may want to see also

Fuel Efficiency: Optimizing fuel efficiency is key to hot foot's performance

Optimizing fuel efficiency is a critical aspect of enhancing the performance of a hydrofoil boat, commonly known as a "hot foot." This technology involves lifting the boat's hull out of the water using underwater wings or foils, allowing it to glide over the surface with reduced drag and increased speed. To maximize the benefits of this system, several strategies can be employed to optimize fuel efficiency.

One key factor is the design and configuration of the hydrofoil system itself. Engineers can adjust the angle and shape of the foils to optimize lift and reduce drag. By carefully selecting the foil design, boat manufacturers can ensure that the hydrofoil system generates the necessary lift to lift the hull while minimizing the energy required to do so. This includes optimizing the foil's camber, chord length, and angle of attack to achieve the desired lift-to-drag ratio.

Weight management is another crucial element in fuel efficiency. Hot foot boats typically require a lightweight design to ensure that the hydrofoil system can efficiently lift the vessel. This involves using lightweight materials for the hull, deck, and other components. By reducing the overall weight, the boat's engine can propel it more efficiently, resulting in improved fuel economy. Additionally, minimizing the weight of onboard equipment and passengers can further enhance fuel efficiency.

Engine optimization plays a significant role as well. The engine should be tuned to provide the necessary power to drive the hydrofoil system while maintaining efficiency. This includes selecting an engine with the right horsepower-to-weight ratio and ensuring it operates within its optimal power band. Proper engine management systems can also contribute to fuel efficiency by optimizing fuel injection and combustion processes. Regular maintenance and tuning of the engine can help identify and rectify any issues that may impact performance and fuel consumption.

Furthermore, the boat's hull design and hydrodynamics are essential considerations. A streamlined hull shape reduces drag, allowing the boat to cut through the water more efficiently. This includes optimizing the hull's shape, chines, and chines to reduce wave-making resistance. Additionally, incorporating features like underwater keels or rudders can further enhance stability and reduce drag, contributing to overall fuel efficiency.

In summary, optimizing fuel efficiency in hot foot boats involves a comprehensive approach, including meticulous foil design, lightweight construction, engine optimization, and advanced hull hydrodynamics. By implementing these strategies, boat manufacturers can create high-performance vessels that offer exceptional speed and fuel economy, making them an attractive choice for those seeking efficient and thrilling watercraft.

The Boys in the Boat: Bestselling Sensation

You may want to see also

Safety: Hot foot systems require careful maintenance to ensure safe operation

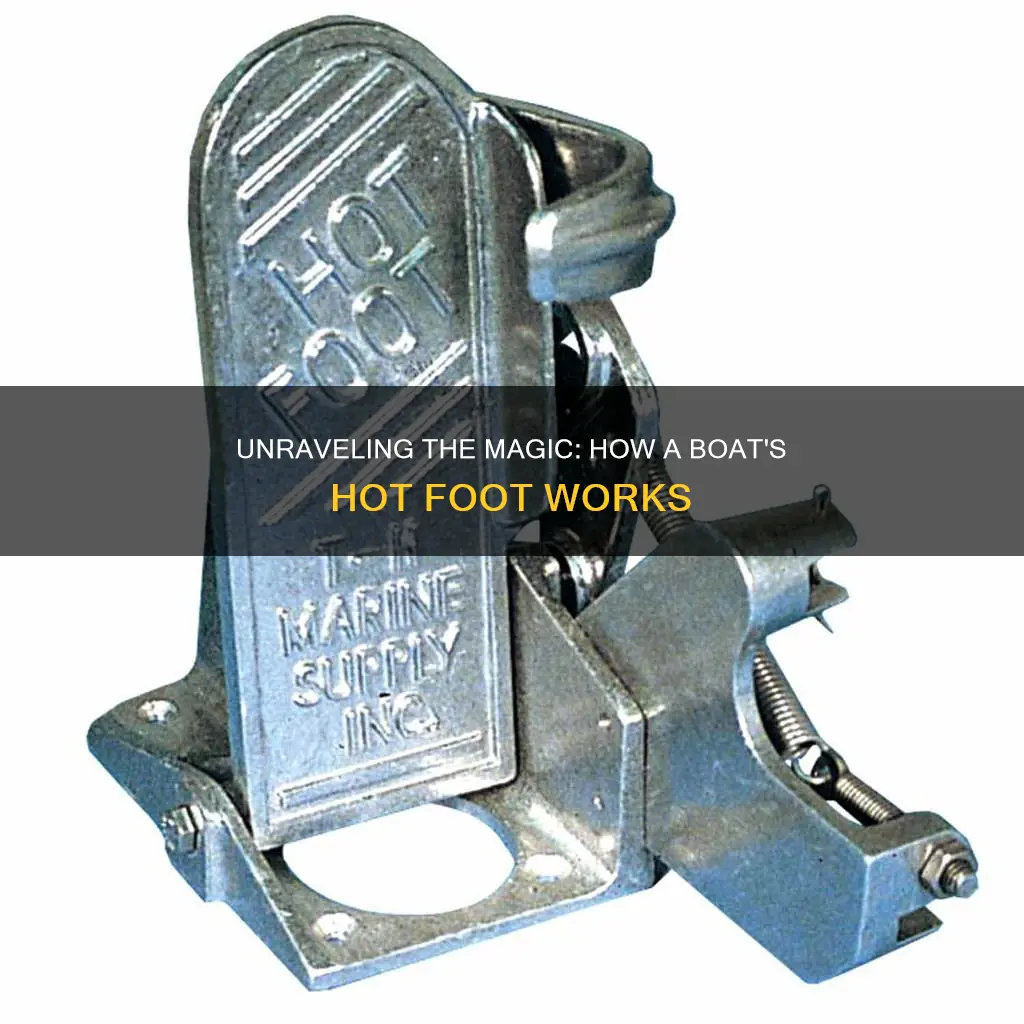

Hot foot systems, a popular method for propulsion in boats, particularly in smaller vessels, utilize a unique mechanism to generate thrust. This system involves a rotating shaft, often powered by an engine, that engages with a series of gears or cogs, known as the "hot foot." The hot foot is designed to rotate at a specific speed, creating a powerful and efficient drive. However, the very nature of this system, with its high-speed rotating parts, also presents potential safety hazards if not properly maintained.

Regular maintenance is crucial to ensure the safe operation of a hot foot system. One of the primary concerns is the risk of mechanical failure, which could lead to catastrophic consequences. Over time, the gears, bearings, and other moving parts can wear down, become misaligned, or even break. This wear and tear are often accelerated by the high-stress environment of the boat's engine compartment, where temperatures can be extreme and vibrations are common. To mitigate these risks, it is essential to perform routine inspections and replacements of worn-out parts.

A comprehensive maintenance schedule should include regular checks for any signs of damage, corrosion, or excessive wear. This involves examining the hot foot gears for any cracks or pitting, ensuring that the bearings are properly lubricated and free from debris, and checking the overall alignment of the system. Additionally, the engine's cooling system should be maintained to prevent overheating, as this can lead to premature failure of the hot foot components.

Another critical aspect of safety is the proper handling and disposal of waste products during maintenance. Hot foot systems generate a significant amount of heat, and this waste heat can be dangerous if not managed correctly. Maintenance personnel should be trained to handle and dispose of hot fluids and gases safely, using appropriate personal protective equipment (PPE) to prevent burns and other injuries.

Furthermore, operators and crew members should be educated about the potential risks associated with hot foot systems. This includes understanding the importance of not overloading the boat, as this can strain the propulsion system and lead to potential failure. Proper training can also help in identifying and addressing any issues promptly, ensuring that the system remains in optimal condition.

In summary, while hot foot systems offer an efficient and cost-effective propulsion solution for boats, their safe operation relies heavily on regular maintenance and a proactive approach to safety. By adhering to a strict maintenance schedule, addressing potential hazards, and educating crew members, the risks associated with these systems can be significantly reduced, ensuring a safer boating experience.

Aligning Your Boat's Drive Shaft: A Step-by-Step Guide

You may want to see also

Frequently asked questions

A hot foot is a term used in boating to describe a situation where the propeller is not properly aligned with the boat's drive shaft, causing excessive vibration and potential damage to the engine and drive train.

A hot foot happens when the propeller's hub, which connects it to the drive shaft, becomes misaligned due to various factors. This can be caused by improper installation, wear and tear, or impact damage. Over time, this misalignment can lead to increased friction and heat, hence the term "hot foot."

Common signs include unusual engine noises, vibrations felt in the boat's cabin, and potential damage to the propeller, drive shaft, or engine. If left unattended, a hot foot can result in costly repairs and engine failure. Regular maintenance and inspections are crucial to prevent this issue.