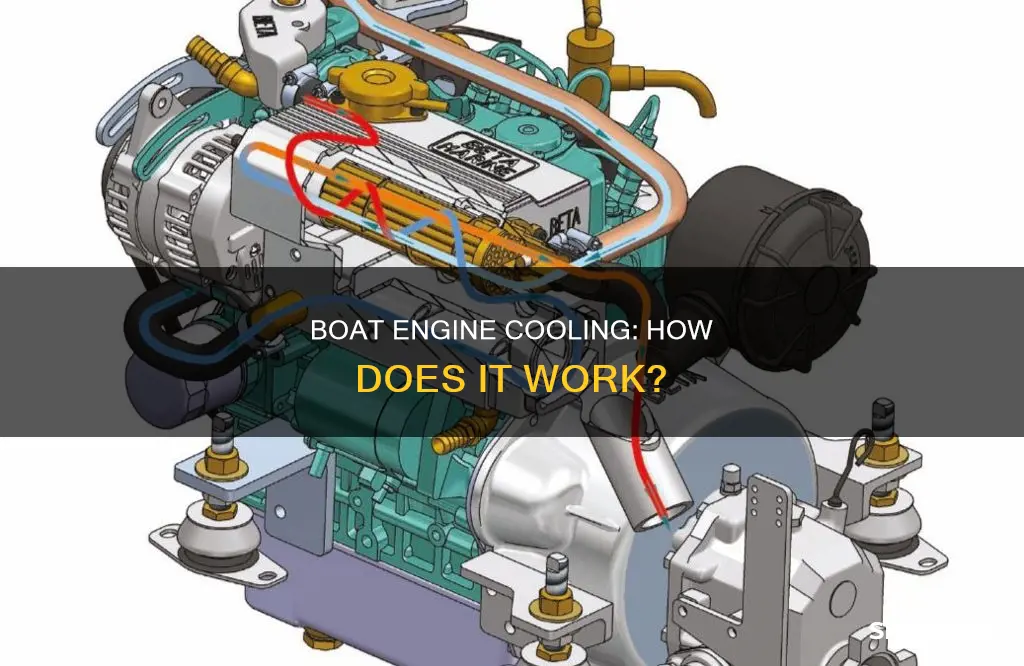

Marine engines are usually cooled using a closed-circuit cooling system, which is similar to a car radiator. This system is called keel cooling. In keel cooling, the engine coolant circulates through a keel cooler, which is mounted externally on the hull below the waterline. The coolant is then cooled by the seawater before it returns to the engine. This process keeps the engine from overheating.

| Characteristics | Values |

|---|---|

| Type of Engine Coolant | Freshwater (coolant) |

| Engine Coolant Temperature | 170-180 degrees |

| Heat Exchanger | Coils filled with freshwater surrounded by raw water |

| Raw Water | Seawater |

| Raw Water Pump | Rubber impeller |

| Freshwater Pump | Metal impeller |

| Filter | Sea strainer |

| Cooling System | Keel cooling |

| Keel Cooling Type | Closed circuit cooling system |

| Keel Cooler Location | Mounted externally on the hull below the waterline |

Wet exhaust systems

The water injected into the exhaust gas stream should be diffused through a series of holes that are about five-sixteenths of an inch in diameter. The number of holes depends on the water flow rate. This allows the water to surround the exhaust gases, cooling them evenly and avoiding hot spots that could lead to hose or tube failures.

It is important that the flow of water from the point of injection until it exits the vessel is on a continuous downward slope. The angle of the elbow itself is critical: 15 degrees from horizontal is the minimum, with others specifying 25 degrees. A vertical angle is best. If the angle is too shallow, there is a risk of water backing up into the elbow and into the engine, as well as localized overheating and possible failure of the hose or tube.

Alabama Boating: Age Requirements for Operating Vessels

You may want to see also

Dry exhaust systems

The design and installation of a dry exhaust system are critical. Un-cooled exhaust piping expands, so flexible "bellows" are necessary. These bellows are typically made from 321 stainless steel, which has proven reliable in demanding, high-hour commercial applications. The system must be carefully spaced and supported under the deck, with proper insulating blankets or covers used. Support brackets must be designed to allow minimal heat transfer to adjoining surfaces.

While dry exhaust systems are less common than wet exhaust systems, they have certain advantages. They do not require water cooling, which simplifies the process of dissipating heat. They also allow for the use of lighter-weight materials due to the absence of cooling water.

Anchoring an AV Drive Boat: Step-by-Step Guide

You may want to see also

Keel cooling

The keel cooler is a critical component of the keel cooling system. It is mounted below the waterline on the hull's exterior, ensuring that the coolant circulates through it, dissipating heat before it returns to the engine. This design optimises the cooling system's performance by maximising the heat exchange between the coolant and seawater. Keel coolers are engineered with features such as baffles and other flow disruptions to enhance heat transfer and improve cooling efficiency.

One of the key advantages of keel cooling is the elimination of the seawater circuit. Unlike traditional open-circuit cooling systems, keel cooling does not require seawater to enter the hull, increasing safety and efficiency. This closed-circuit design also reduces maintenance requirements by removing the need for internal heat exchangers, untreated water pumps, filters, and seawater piping. Additionally, it prevents sediment, algae, and sand accumulation, protecting the system from saltwater corrosion.

Disassembling the H100 RC Boat: A Step-by-Step Guide

You may want to see also

Heat exchangers

Most marine inboard engines are fresh-water-cooled. A captive amount of freshwater (coolant) is continually circulated through a heat exchanger, which maintains the engine at a temperature set by the thermostat. This is usually between 170 and 180 degrees Fahrenheit.

Marine engines, unlike car engines, do not have a radiator, as there is no airflow available to cool the engine. Instead, they utilise the relatively cool seawater, also known as raw water. The raw water is pumped from the sea to a heat exchanger tube, where coils filled with freshwater (coolant) are surrounded by flowing raw water (seawater). As the cold raw water flows through the heat exchanger, it cools the hot freshwater that is keeping the engine from overheating.

The raw water passes through the heat exchanger only once before being expelled back into the sea, while the freshwater continues to recirculate. As the raw water exits the heat exchanger, it will mix with the exhaust gases and pump out the back of the boat.

The raw water system has a dedicated pump with a rubber impeller, and a filter installed between the through-hull and the pump, known as the sea strainer. This filter is necessary because the raw water sometimes carries debris like kelp, eelgrass, plastic bags, or even small fish. The sea strainer is usually made of clear glass or plastic so that it can be checked without opening the filter.

A skipper should always check that the boat is "pumping water" when starting the engine and while the engine is running. It is best to inspect the flow while standing on the dock, as it can be hard to see from the cockpit.

Replacing Anti-Siphon Valve on Your Boat: A Step-by-Step Guide

You may want to see also

Raw water cooling

While raw water cooling systems are simpler and do not require a heat exchanger, they have significant drawbacks. The water flowing through the engine can cause scale buildup and corrosion inside the engine's water jacket, which can ultimately destroy the engine. This is especially true if the boat is operating in salt water, as salt water tends to build up corrosive scale when the engine operates above 140°F. In extreme cases, the scale buildup can block cooling passages. For this reason, most raw-water-cooled engines operate at a lower temperature than those with a closed system.

Overall, while raw water cooling systems are simpler and less expensive, they can cause significant engine damage due to scale buildup and corrosion.

Boat Launches in Georgia: Free or Fee?

You may want to see also

Frequently asked questions

Keel cooling is a closed-circuit cooling system externally mounted on the hull of a boat, below the waterline. It is similar to a car radiator, where the engine coolant circulates through the keel cooler, dissipating heat before returning to the engine.

The keel cooler is in constant contact with seawater, allowing efficient heat transfer between the coolant and seawater.

Keel cooling eliminates the need for internal heat exchangers, untreated water pumps, filters, and seawater piping, reducing maintenance. It also prevents sediment, algae, and sand accumulation, protecting the system from saltwater corrosion.

A dry exhaust system is an alternative to the standard wet exhaust system, where seawater mixes with exhaust gases. It eliminates this mixture, allowing the exhaust line to be completely independent, reducing the risk of water entering the engine.

Most marine inboard engines use fresh water cooling, where a captive amount of freshwater (coolant) is continually circulated through a heat exchanger. The seawater, or "raw water", is pumped through a separate circuit, cooling the fresh water through a heat exchanger.