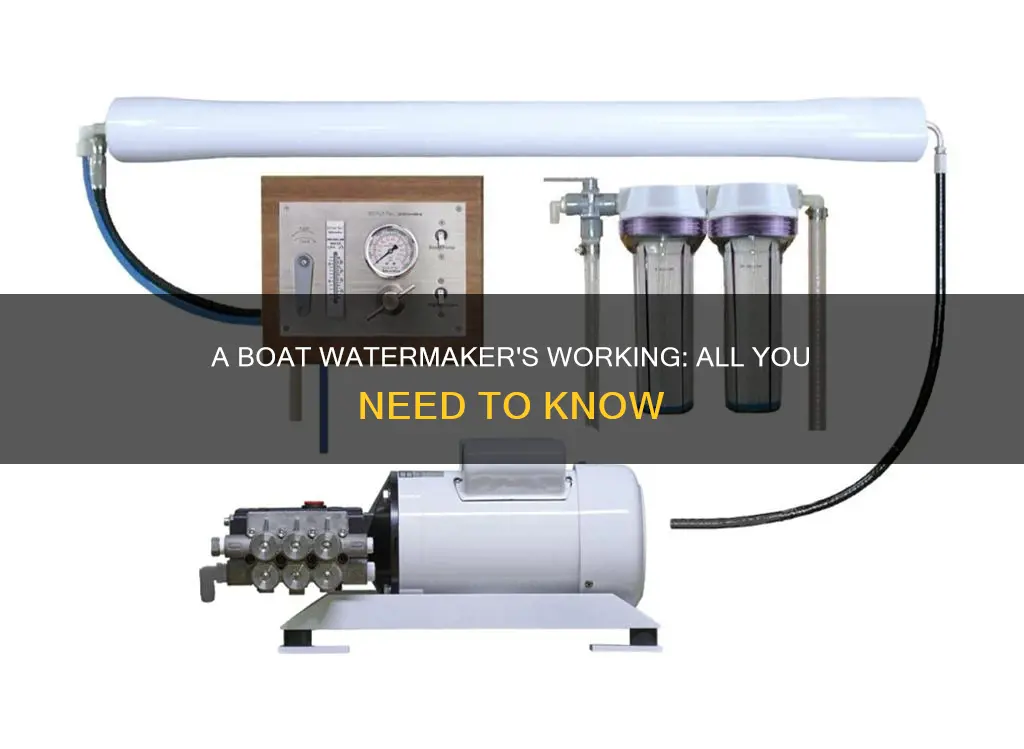

Marine watermakers are devices that convert seawater into safe, fresh drinking water. They are used by seafarers to ensure a constant supply of potable water while at sea. Watermakers are also referred to as desalinators and are particularly useful for long-distance ocean cruisers. They can be expensive to acquire and maintain, but they reduce the need for large water tanks.

| Characteristics | Values |

|---|---|

| What is it? | A device used to obtain potable water by reverse osmosis of seawater |

| Other names | Desalinators, atmospheric water generators |

| How does it work? | Exploits the principle of "reverse osmosis": a high-pressure pump forces seawater through a membrane that allows water but not salt to pass |

| How much water does it make? | 2 to 150 litres per hour of operation (0.53 to 41 gallons) depending on the model |

| How is it powered? | Electricity from the battery bank, an engine, an AC generator or hand operated |

| How much space does it require? | Relatively little space |

What You'll Learn

- Watermakers use reverse osmosis to convert seawater into drinking water

- Watermakers are expensive to acquire and maintain

- Watermakers are portable and can be converted to manual operation in an emergency

- Watermakers can be powered by electricity, an engine, an AC generator or hand operation

- Watermakers are used by long-distance ocean cruisers

Watermakers use reverse osmosis to convert seawater into drinking water

The heart of any marine watermaker is a process called reverse osmosis. Reverse osmosis is the principle where we reverse natural osmotic pressure to separate the saline content from seawater, thereby producing fresh and drinkable water. Popular brands of yacht watermakers typically make from 2 to 150 litres per hour of operation (0.53 to 41 gallons) depending on the model. There are strong opinions among small boat cruisers about the usefulness of these devices. The arguments may be summarised as: A watermaker uses only a small amount of fuel to generate a large amount of water, eliminating the need for large, heavy water tanks. The user is independent of shore-based water supplies, which is especially important in remote areas. They provide safe water when shore-based water is of uncertain quality. Some designs are portable and can be converted to manual operation in an emergency.

Most cruising boats are likely to fit a powered device that does the hard work for you and produces enough for all the boat’s fresh water needs. Broadly speaking, these fall into two main categories: those that produce the necessary pressure by using a traditional high-pressure pump, and those that use a dual piston Clark pump known as an energy recovery device (ERD).

Sailing to England: New York to England by Boat

You may want to see also

Watermakers are expensive to acquire and maintain

The process of reverse osmosis involves a high-pressure pump forcing seawater through a membrane that allows water but not salt to pass through. This can be achieved through a traditional high-pressure pump or a dual piston Clark pump, known as an energy recovery device (ERD). Depending on the design, watermakers can be powered by electricity from the battery bank, an engine, an AC generator or hand-operated.

Watermakers designed for small boats and yachts rely on the same technology, and popular brands typically make 2 to 150 litres per hour of operation. Some argue that watermakers are useful as they use only a small amount of fuel to generate a large amount of water, and they provide safe water when shore-based water is of uncertain quality. However, there are strong opinions among small boat cruisers about the usefulness of these devices. Some designs are portable and can be converted to manual operation in an emergency.

Inflatable Boat Registration: Alabama's Requirements and Exemptions

You may want to see also

Watermakers are portable and can be converted to manual operation in an emergency

Watermakers are devices that use reverse osmosis to obtain potable water from seawater. They are often referred to as "desalinators", and can be expensive to acquire and maintain. However, they are valuable because they reduce the need for large water tanks on long passages. Watermakers can be powered by electricity from a battery bank, an engine, an AC generator, or hand operation.

Some watermaker designs are portable and can be converted to manual operation in an emergency. These devices are typically handheld and manually powered. To use them, you immerse the inlet filter into a bucket of seawater and pump by hand to produce safe drinking water. This type of watermaker is often found in offshore liferaft kits and can provide enough water to keep someone alive.

Exploring Venice, Louisiana: Boat Ride Distance Revealed

You may want to see also

Watermakers can be powered by electricity, an engine, an AC generator or hand operation

Watermakers are devices used to obtain potable water by reverse osmosis of seawater. In boating and yachting circles, they are often referred to as 'desalinators'. They can be expensive to acquire and maintain, but they are valuable because they reduce the need for large water tanks for long passages.

Most cruising boats, however, are likely to fit a powered device that does the hard work for you and produces enough for all the boat’s fresh water needs. These fall into two main categories: those that produce the necessary pressure by using a traditional high-pressure pump, and those that use a dual-piston Clark pump known as an energy recovery device (ERD).

Saugatuck Duck Boat Rides: What Went Wrong?

You may want to see also

Watermakers are used by long-distance ocean cruisers

Watermakers use the principle of reverse osmosis to separate the saline content from seawater, producing fresh and drinkable water. This process involves using a high-pressure pump to force seawater through a membrane that allows water but not salt to pass through.

The amount of water produced by a watermaker depends on the model, with popular brands typically making between 2 and 150 litres per hour of operation. Watermakers can be powered by electricity from the battery bank, an engine, an AC generator, or hand operation. Some designs are portable and can be converted to manual operation in an emergency.

Watermakers can be expensive to acquire and maintain, but they are valuable for long-distance ocean cruisers as they provide a constant supply of potable water and eliminate the need for shore-based water supplies, which may be of uncertain quality or unavailable in remote areas.

Choosing the Right Boat for Pamlico Sound

You may want to see also

Frequently asked questions

A boat watermaker is a device used to obtain potable water by reverse osmosis of seawater.

Boat watermakers use a high-pressure pump to force seawater through a membrane that allows water but not salt to pass through. This process is known as reverse osmosis.

Boat watermakers reduce the need for large water tanks, which can be heavy and take up a lot of space. They also provide safe drinking water, which is especially important in remote areas where shore-based water supplies may not be available or of uncertain quality.

Popular brands of boat watermakers include Spectra and Katadyn Survivor.