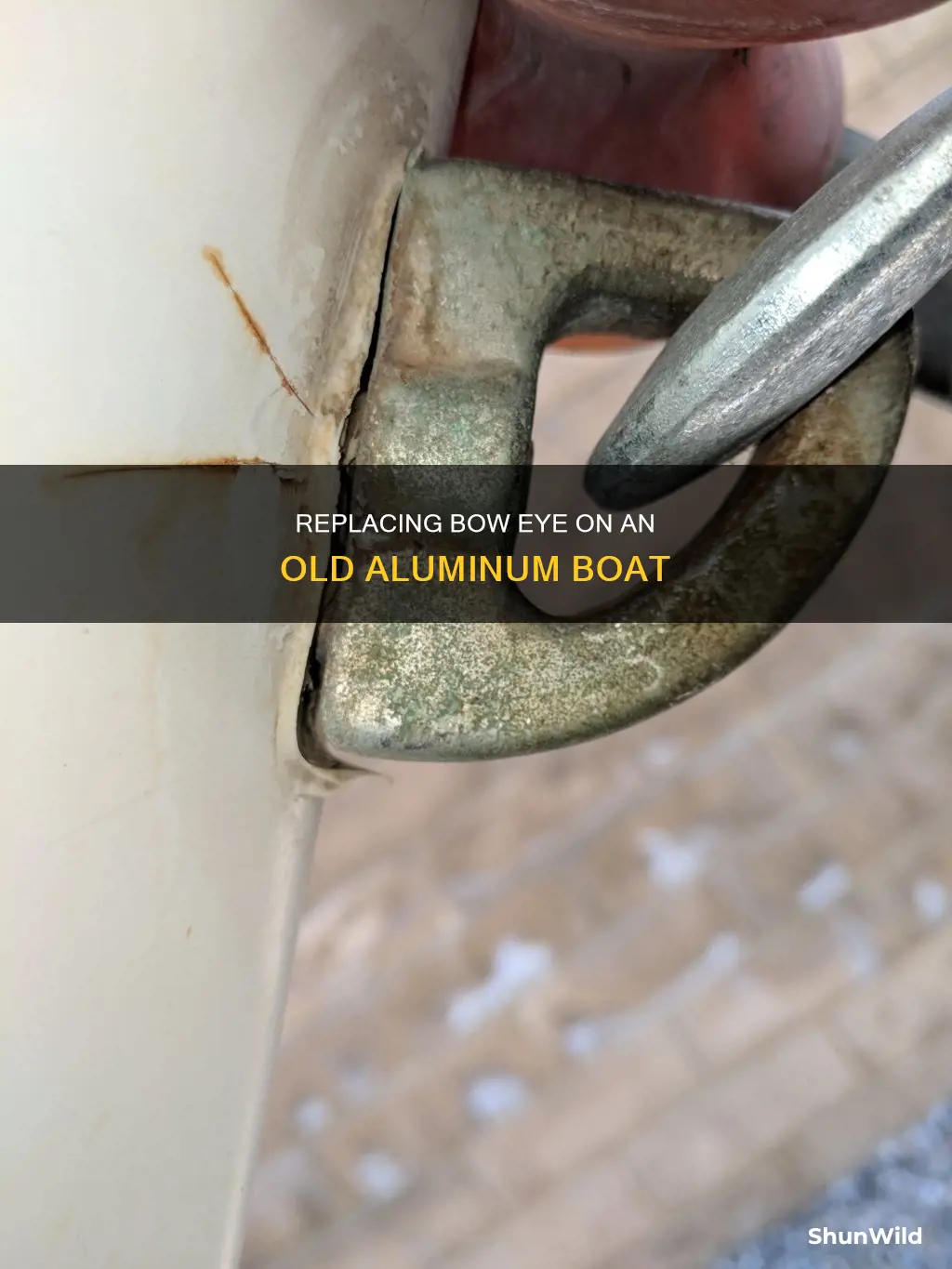

The bow eye on a boat is a small hook responsible for bearing a lot of weight when towing. It is important to regularly inspect the bow eye for any loosening or movement, as the continuous strain can slowly cause it to pull out of the hull. If you notice any issues, it is important to repair or replace the bow eye immediately. The process of replacing a bow eye involves removing the old eye, examining the fitting for any corrosion or damage, and installing a new eye. When installing a new bow eye, it is recommended to use a backup plate for added security.

How to replace bow eye on boat 1988 aluminum

| Characteristics | Values |

|---|---|

| Materials | Aluminum, Stainless Steel, Wood, Epoxy, Fiberglass, Silicon, Steel |

| Tools | Dremel tool, Grinder, Drill, Welder, Torch, Pencil Flame, Wire Wheel, Die, Map Torch |

| Brands | Academy, iboats, Alumacraft, Permatex, BoatLIFE, Seachoice |

| Websites | iboats.com, tinboats.net, boatlife.com |

What You'll Learn

Inspecting the bow eye for damage

Step 1: Understand the Function and Importance of the Bow Eye

The bow eye is a crucial component on your boat, providing a sturdy connection point for towing, anchoring, and securing your vessel. It is typically made of metal or plastic and is attached to the front end, or bow, of the boat. By regularly inspecting and maintaining the bow eye, you can ensure its functionality and prevent potential issues.

Step 2: Know the Common Issues and Problems

The bow eye is subjected to significant weight and force during towing and anchoring. Over time, this continuous strain can cause the bow eye to slowly loosen and, in some cases, pull out of the hull. Other common issues include corrosion, especially in saltwater conditions, and loose fittings due to constant vibrations while navigating rough waters. By being aware of these common problems, you can pay close attention to specific areas during your inspection.

Step 3: Conduct a Thorough Inspection

Begin your inspection by checking for any visible signs of damage or loosening. Look for rust, corrosion, or loose fittings around the bow eye. Pay attention to the attachment points on the hull and inspect for any cracks, stress marks, or signs of weakening in the material. If your boat has eye bolts, remove the nuts and examine the stem of the bolts for any damage. Remember that your boat may have multiple bolts, so inspect each one carefully.

Step 4: Address Any Identified Issues

If you notice any damage or wear during your inspection, it is important to address it promptly. Depending on the severity of the issue, you may need to replace the bow eye or its components. For example, if you notice corrosion, apply anti-corrosion agents and consider replacing the affected parts with marine-grade stainless steel hardware. If you find loose fittings, use the appropriate tools and techniques to tighten them securely.

Step 5: Preventative Maintenance

In addition to inspecting for damage, it is essential to maintain and care for your bow eye regularly. After each use, clean the bow eye with freshwater to remove any saltwater residue and prevent corrosion. Apply a rust inhibitor or lubricant to protect the fitting from the harsh marine environment. You can also use a marine-grade polish or wax to provide an extra layer of protection against UV rays and saltwater, helping to prolong the life of the bow eye.

Remember, regular inspection and maintenance of your 1988 aluminum boat's bow eye are crucial for ensuring the safety and integrity of your vessel during towing and anchoring activities. By following these steps and staying vigilant, you can identify and address any issues promptly, maintaining the optimal condition of your boat's bow eye.

Stingray Boats: Smooth Sailing or Rough Waters?

You may want to see also

Removing the old bow eye

To remove the old bow eye from your 1988 aluminum boat, you will need to determine how the bow eye is attached to the boat. This will guide the tools and methods you will need to use.

Bolted Bow Eye

If the bow eye is bolted to the boat, you will need to gather the appropriate tools, including wrenches or sockets to remove the nuts and bolts.

Begin by locating the bolts and nuts that secure the bow eye in place. Depending on the design of your boat, there may be multiple bolts, so ensure you identify all of them. Once located, use the appropriate tool to remove the nuts from the bolts. If the nuts are rusted or difficult to remove, you may need to apply a penetrating oil or lubricant to help loosen them.

After removing the nuts, you may need to cut or grind through the bolts to separate the bow eye from the boat. This can be done with a grinder, Dremel tool, or a hacksaw. Once the bolts are cut, you can remove the old bow eye.

Welded Bow Eye

If the bow eye is welded to the boat, you will need to use a different approach. In this case, you will need to use a chisel and hammer to break the welds that hold the bow eye in place. Place the chisel at the point where the bow eye meets the boat and use the hammer to strike the chisel, applying force to break the weld. You may need to strike the chisel multiple times until the weld breaks. Once the welds are broken, you can remove the old bow eye.

Wood Block Attachment

In some cases, the bow eye may be attached to a wood block inside the boat. If this is the case, you will need to access the wood block to remove it. Try using a wood chisel or an oscillating tool to split the wood block, allowing you to move the bow eye forward and cut through the bolt.

Riveted Bow Eye

If the bow eye is riveted to the boat, you have a few options for removal. You can use a rivet gun to remove the rivets, or you can drill out the rivets with a drill and an appropriate bit. If the rivets are difficult to remove, you may need to use a combination of these methods.

Once you have determined the attachment method and gathered the necessary tools, you can proceed with removing the old bow eye from your 1988 aluminum boat. Remember to work carefully and wear appropriate safety gear, including eye protection and gloves, to protect yourself during the removal process.

Repairing Reinell 192M Stringers: A Comprehensive Guide

You may want to see also

Preparing the area for a new bow eye

To prepare the area for a new bow eye on your 1988 aluminum boat, you'll need to follow these steps:

Remove the Old Bow Eye:

First, you'll need to address the old bow eye. If it's welded, consider taking it to a local welder or radiator shop to have it removed professionally. If it's bolted, try to loosen and remove the bolts. If they're rusted or stubborn, use a penetrating oil like PB Blaster or Kroil, and let it soak for a few hours before attempting to loosen them again. You can also apply heat with a small torch to help break the corrosion. If all else fails, you may need to cut the bolts.

Clean and Inspect the Area:

Once the old bow eye is removed, clean the area thoroughly. Inspect the hull for any signs of damage, corrosion, or weakness. If there is significant corrosion or damage, you may need to repair and reinforce the hull before installing the new bow eye.

Prepare the Surface:

If the hull is in good condition, you can prepare the surface for the new bow eye. Sand the area behind the stem to create a fresh surface for the new installation. Clean the sanded area with a solvent to remove any residue or contaminants.

Install a Backing Plate:

To reinforce the hull and provide a strong base for the new bow eye, consider installing a backing plate. Cut a block of hardwood or machine a chunk of aluminum to fit snugly inside the boat, directly behind the bow eye. This will help distribute the force and prevent the bow eye from tearing through the hull.

Drill Holes:

Drill holes through the hull and the backing plate for the new bow eye. Ensure the holes are aligned and large enough to accommodate the bolts of the new bow eye. You may also need to drill smaller holes for locating dowels or to accommodate the shape of the new bow eye.

Now that the area is prepared, you can move on to installing the new bow eye. Remember to follow the specific instructions provided with your chosen bow eye product and always use high-quality fasteners and hardware suitable for marine environments.

Sailing Boat: A Noun and So Much More

You may want to see also

Installing a new bow eye

Step 1: Assess the Damage

Before installing a new bow eye, it is important to understand why the previous one failed. Inspect the area for any signs of corrosion or damage. If the previous bow eye was pulled out of the hull, you may need to reinforce the surrounding area to prevent this from happening again.

Step 2: Gather the Right Tools and Materials

To install a new bow eye, you will need the following tools and materials:

- A new bow eye that fits your boat

- Stainless steel bolts and nuts

- A drill

- A backing block made of hardwood or aluminium

- Marine-grade sealant or epoxy

- Sandpaper

- Solvent

- Woven fiberglass cloth (optional)

Step 3: Prepare the Surface

If the previous bow eye left behind any residue or damage, it is important to prepare the surface before installing the new one. Use a wood chisel or oscillating tool to remove any remnants of the old bow eye. Sand the area to create a smooth surface, and clean it with a solvent to ensure that the new bow eye will adhere properly.

Step 4: Install the New Bow Eye

Drill holes in the hull that align with the new bow eye. The number and placement of the holes will depend on the design of the bow eye. Insert the bolts through the holes and secure them with nuts on the inside. Use a backing block to distribute the force and prevent the bow eye from tearing through. Apply marine-grade sealant or epoxy around the bow eye to create a watertight seal.

Step 5: Reinforce the Area (Optional)

If you are concerned about the strength of the bow eye installation, you can reinforce the area by adding layers of woven fiberglass cloth and epoxy. Flatten the shape of the fiberglass near the bolt hole and drill through the layers to reinstall the bow eye. This will provide additional strength and support.

Step 6: Final Checks

Once the new bow eye is installed, inspect it thoroughly to ensure that it is secure and properly aligned. Test the strength of the installation by applying force to the bow eye and checking for any movement or loosening.

By following these steps, you can confidently install a new bow eye on your 1988 aluminum boat, ensuring a strong and durable connection for towing.

Laughlin Boat Launching: Best Places to Know

You may want to see also

Maintenance and repair tips

The bow eye on a boat is a small but critical component that requires regular inspection and maintenance to ensure the safety and security of the boat when towing it in and out of the water. Here are some maintenance and repair tips for the 1988 aluminum boat owner:

- Regularly inspect the bow eye for any signs of loosening or movement. Over time, the continuous strain of towing can cause the bow eye to slowly pull out of the hull, so it is important to catch this early on.

- If you notice any issues with the bow eye, such as corrosion or damage, it is important to address them immediately. Do not continue towing the boat until the situation is handled.

- When repairing or replacing the bow eye, start by identifying the stem of the eye bolts and removing the nuts that hold them in place. Keep in mind that there may be multiple bolts, so repeat this step for each one.

- Once the nuts are removed, examine the eye fitting for any signs of corrosion or damage. If there is any doubt about its integrity, it is better to replace the bow eye altogether.

- To repair the area around the stem, sand the area behind it to create a fresh surface. Then, clean it with a solvent and add layers of woven fiberglass cloth and epoxy, following the product instructions.

- While the fiberglass is still soft, flatten its shape near the hole for the bolt. This will ensure a secure fit for the new boat eye.

- When installing a new boat eye, drill through the layers of fiberglass and use a backup plate for added strength and security.

- If the bow eye is welded to the hull, consider seeking professional help or consulting a welding expert. A local radiator shop may be able to repair it for a reasonable price.

- When replacing the bow eye, consider upgrading to a stainless steel through-bolt design, especially if the original broke. Stainless steel provides added strength and is less susceptible to corrosion.

- To prevent water from becoming trapped and acidifying, use a bedding material between the eye and the hull. This will also help to keep the boat eye secure.

- If you are unable to tighten or loosen the bolt on the inside of the bow eye, try using a lubricant like PB Blaster or Kroil and letting it soak for a few hours. You can also use a torch with a pencil flame to heat up the nut and bolt to free them.

- When drilling holes for the new bow eye, consider adding a V-shaped block on the inside to prevent the eye from tearing through. This can be made from hardwood or aluminum.

- Always use stainless steel bolts and nuts when installing a new bow eye, and consider using a nylock nut for added security.

Exploring the Watery Distance Between Alaska and Hawaii

You may want to see also

Frequently asked questions

It's important to inspect your bow eye regularly for any signs of loosening or movement. One of the most common issues is the bow eye slowly pulling out of the hull due to continuous strain. If you spot any such problems, it's best to replace the bow eye immediately to avoid further damage.

Here are the general steps, which may vary depending on your boat's specific design:

- Identify the stem of the eye bolts and remove the nuts holding them in place.

- Examine the eye fitting for any corrosion or damage.

- If needed, replace the bow eye with a suitable alternative, such as a stainless steel through-bolt design.

- Repair the area around the stem by sanding, cleaning with a solvent, and adding layers of woven fiberglass cloth and epoxy.

- Flatten the shape of the fiberglass near the bolt hole.

- Drill through the added layers and install a new boat eye, preferably with a backup plate for extra security.

When replacing the bow eye on an older boat like your 1988 model, it's essential to consider the specific design and construction. Consult a professional or a boat repair forum to ensure you're using the correct replacement parts and procedures for your boat's make and model. Additionally, consider the following:

- If the bow eye is welded on, you may need to consult a welder to repair or replace it.

- If the bolt is rusted or difficult to remove, try using a lubricant like PB Blaster or Kroil, and then attempt to turn the bolt again.

- To ensure a secure fit, you may need to add a larger backing block or V-block of wood on the inside of the hull.