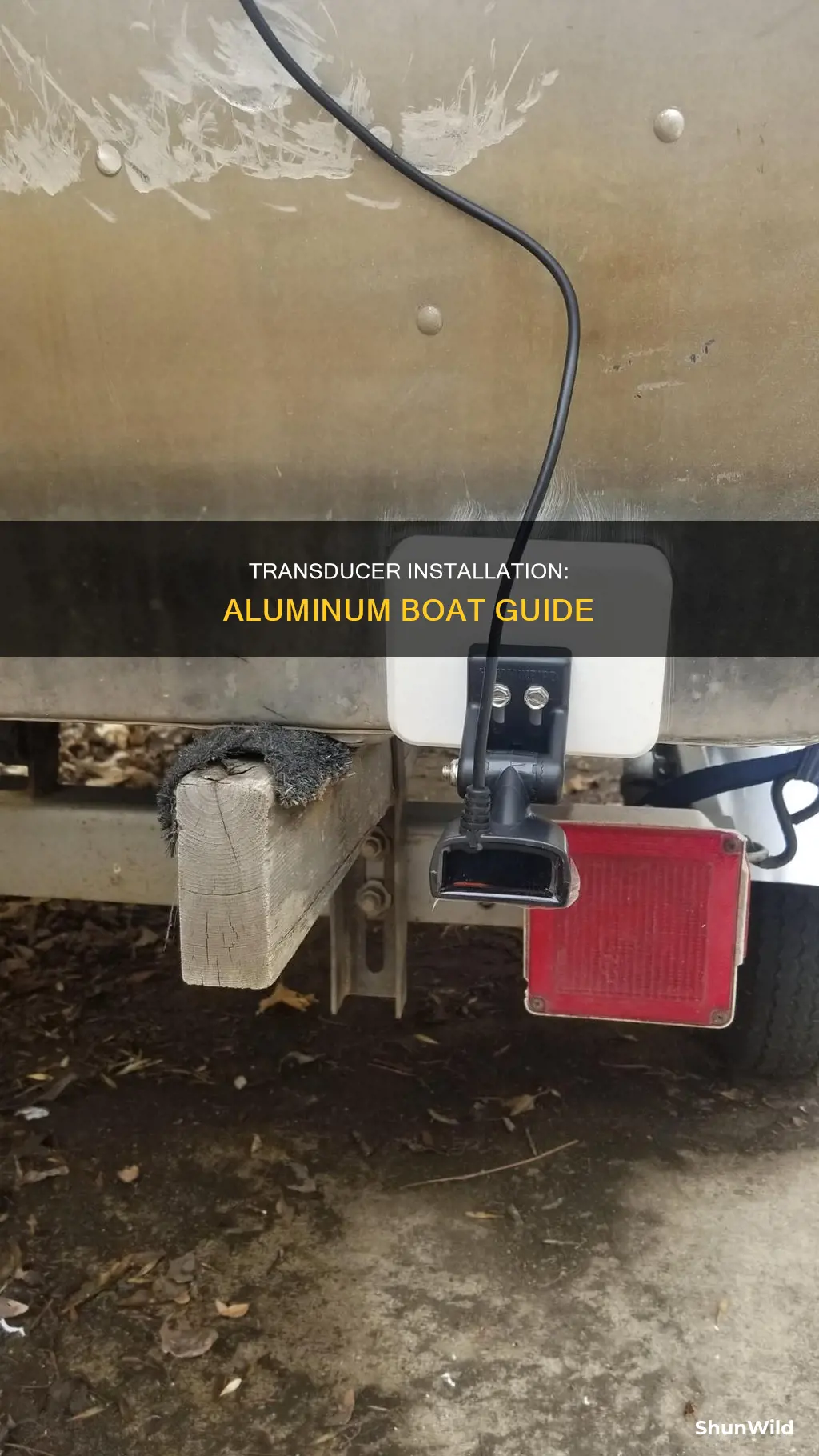

Installing a transducer on an aluminium boat can be done in several ways. Some people choose to drill holes and mount the transducer directly on the transom, while others prefer to use a mounting plate or block to avoid drilling multiple holes. The type of sealant or adhesive used is also a consideration, with options including silicone, epoxy, and marine glue. It's important to prepare the surfaces properly to ensure a strong bond, especially when bonding aluminium with HDPE. When deciding on a mounting location, it's crucial to avoid interference from the boat's trailer, ribs, or engine, and to periodically clean the transducer to maintain sensitivity.

| Characteristics | Values |

|---|---|

| Mounting method | Drilling holes, using a mounting plate, gluing, or epoxy |

| Materials | Metal, plastic, nylon, PVC, HDPE, wood, epoxy, silicone, screws, bolts, washers, caulking, sealant |

| Considerations | Electrolysis, air bubbles, vibration, water seepage, speed, side imaging, sensitivity |

What You'll Learn

Drilling holes and using screws and sealant

Drilling holes in your boat is not always recommended, but it is possible to do so without causing damage. If you are set on this method, there are a few things to keep in mind. Firstly, you will need to use the right type of screw and sealant to ensure a strong and secure hold that won't leak. It is also important to prepare the surface properly before drilling.

When it comes to choosing screws, stainless steel is a good option as it is strong and resistant to corrosion. You will also want to use a sealant that is specifically designed for marine use, such as silicone or epoxy. It is important to follow the instructions on the sealant packaging carefully to ensure a proper seal.

Before drilling, clean the area where the transducer will be mounted to remove any dirt, grease, or oxidation. This will help ensure a strong bond between the sealant and the boat. It is also recommended to roughen the surface of the drilling area with sandpaper to further enhance the bond.

When you are ready to drill, mark the holes carefully to ensure they are in the correct position. Take your time and use a drill bit that is the appropriate size for the screws you are using. Drill slowly and carefully to avoid damaging the boat.

Once the holes are drilled, insert the screws and tighten them securely. Apply a generous amount of sealant around the screws and the perimeter of the transducer to create a watertight seal. Follow the instructions on the sealant for the appropriate curing time.

Finally, test your setup in the water to ensure that it is secure and functioning properly. Enjoy your new transducer!

Boat Engine Controls: Universal Standard or Customized?

You may want to see also

Using a mounting plate

To use this method, you will need to purchase or create a mounting plate. Commercially available options include screw-on Starboard plates and stick-on plates, or you can make your own out of Starboard or expanded PVC. A transducer mounting plate is typically a small, inexpensive piece of polyethylene plastic or a similar durable, synthetic material.

Once you have your mounting plate, you will need to drill two small holes in your boat's transom. It is important to measure the length of your screws and mark the necessary depth on your drill bit to avoid drilling too deep. After drilling the holes, you can fasten the mounting plate to the hull using the screws and a marine silicone adhesive to seal the holes and keep the plate in place.

With the mounting plate installed, you can now mount your transducer to the plate. This method provides the flexibility to adjust or move your transducer as needed without drilling additional holes in your hull. If you plan to use multiple transducers or upgrade to a new unit in the future, the mounting plate makes it easy to accommodate these changes without modifying your boat.

Bass Boat Speed: How Fast Can They Go?

You may want to see also

Using epoxy glue

When installing a transducer on an aluminium boat, there are several options available to you. If you want to avoid drilling holes in your boat, you can use epoxy glue to attach the transducer to the hull. This method is suitable for fiberglass boats and possibly aluminium boats, though it is not recommended by the manufacturers.

To install a transducer on an aluminium boat using epoxy glue, follow these steps:

- Choose an accessible area on the hull below the waterline. Ensure there are no air bubbles in the fiberglass or aluminium, and sand the area thoroughly to expose any air bubbles and create a rough surface for the epoxy to adhere to.

- Use an orbital sander with coarse sandpaper to prepare the surface.

- Create a dam around the area using plumber's putty to keep the epoxy in place.

- Weight or brace the transducer overnight until the epoxy sets.

- Turn up the sensitivity on your graph to compensate for sound waves travelling through the hull.

You can also use epoxy glue to attach a plastic transducer plate to your aluminium boat. This method provides a more secure attachment than screws alone and allows for future adjustments without drilling additional holes in the boat. Here are some tips for using epoxy glue with a transducer plate:

- Use a two-part epoxy or 3M 5200, a long-term flexible adhesive.

- Jig or tape the plate in place for the 7-day cure time.

- Drill holes in the plate and use screws for added security.

- Create a "mechanical bond" by milling slots in the back of the plate with a keyway cutter or dovetail bit in a router. This gives the epoxy something to grip onto and strengthens the attachment.

- Sand and clean the surface of the aluminium boat to ensure the epoxy adheres properly.

Unmooring a Boat: A Step-by-Step Guide to Getting Started

You may want to see also

Using a plastic or HDPE block

To use this method, you will need to purchase or fabricate a plastic or HDPE mounting block. The block should be thick enough to provide adequate support for the transducer, typically around 3/4" to 1". You can find these blocks at marine supply stores or online.

Once you have your block, you will need to decide how to attach it to your boat. There are several options, including:

- Epoxy: You can use a strong epoxy adhesive to glue the block to the transom of your boat. Make sure to sand and clean both the block and the boat surface to ensure a strong bond. Some people also recommend using a flame treatment on the HDPE block for better adhesion.

- Screws: You can drill holes through the block and the transom and use stainless steel screws to secure the block in place. It is recommended to use silicone or marine sealant around the screws to prevent leakage.

- Tape: Some pre-made mounting blocks, such as the Stern Pad, use 3M VHB tape to attach to the boat. This method is designed to be waterproof and does not require drilling holes.

After attaching the block, you can then mount your transducer to the block using screws or epoxy, following the instructions provided with your transducer.

When installing the transducer, make sure to follow the manufacturer's guidelines for placement and spacing. It is generally recommended to mount the transducer at least one foot away from the engine's lower unit and to avoid mounting directly behind the ribs or through-hull fittings.

Additionally, remember to periodically clean the transducer with soap and water to remove any oil or dirt build-up, as this can reduce its sensitivity and affect its operation.

Boat Shoes and Socks: A Fashion Faux Pas

You may want to see also

Using a nylon plate

When installing a transducer on an aluminium boat, it is recommended to use a plastic transducer mount to avoid potential electrolysis problems. One way to do this is by using a nylon plate.

To install a transducer on an aluminium boat using a nylon plate, follow these steps:

- Purchase or cut a nylon plate to the appropriate size. The plate should be large enough to accommodate the transducer mount and provide a stable base.

- Mount the nylon plate to the transom of the boat. You can do this by drilling holes through the nylon plate and the transom, then securing it with nuts, bolts, and rubber-coated washers. Alternatively, you can use an adhesive like marine epoxy or marine-grade 2-part epoxy to glue the nylon plate to the transom without drilling holes.

- Seal the mounting holes to prevent leakage. This is an important step to ensure that water does not enter the boat through the mounting holes. Use a silicone sealant or marine-grade caulking to seal the holes.

- Screw the transducer mount to the nylon plate. Make sure the transducer is secure and tightly fastened to the plate.

- Connect the transducer wires to your fish finder or depth finder unit, following the manufacturer's instructions.

When installing the nylon plate and transducer, it is important to consider the placement. On aluminium boats, it is recommended to mount the transducer between two ribs, and at least one foot away from the engine's lower unit to prevent air bubbles from interfering with the propeller. Additionally, periodically wash the bottom of the transducer with soap and water to remove any oil or dirt build-up, as this can reduce the transducer's sensitivity.

By following these steps and considerations, you can successfully install a transducer on an aluminium boat using a nylon plate, ensuring a secure and functional setup.

The Boys in the Boat: Practicing on Lake Washington

You may want to see also

Frequently asked questions

There are several ways to install a transducer on an aluminium boat. One way is to use a transom mounting plate, which requires drilling only two holes and allows for future adjustments without drilling more holes. Another method is to drill holes and mount the transducer directly on the transom, using silicone or another product to seal the holes.

Yes, it is possible to install a transducer on an aluminium boat without drilling holes. One option is to use an adhesive such as marine epoxy or glue to attach a mounting board to the transom, and then screw the transducer into the board. Another method is to use a suction cup or a bracket that attaches above the waterline with clamps or bolts.

When sealing the holes, it is recommended to use silicone or marine-grade epoxy to prevent leakage. It is also important to ensure that the mounting area is clean and free of any oxidation. Additionally, consider using washers and nuts to secure the transducer in place.

It is recommended to mount the transducer at least one foot away from the engine's lower unit to prevent air bubbles from interfering with the propeller. On aluminium boats, mounting the transducer between two ribs typically works best. It is also important to avoid mounting directly behind the ribs or through-hull fittings.

Yes, it is important to periodically wash the bottom of the transducer with soap and water to remove any oil film or growth that may collect. Oil and dirt can reduce the transducer's sensitivity and even prevent its operation.