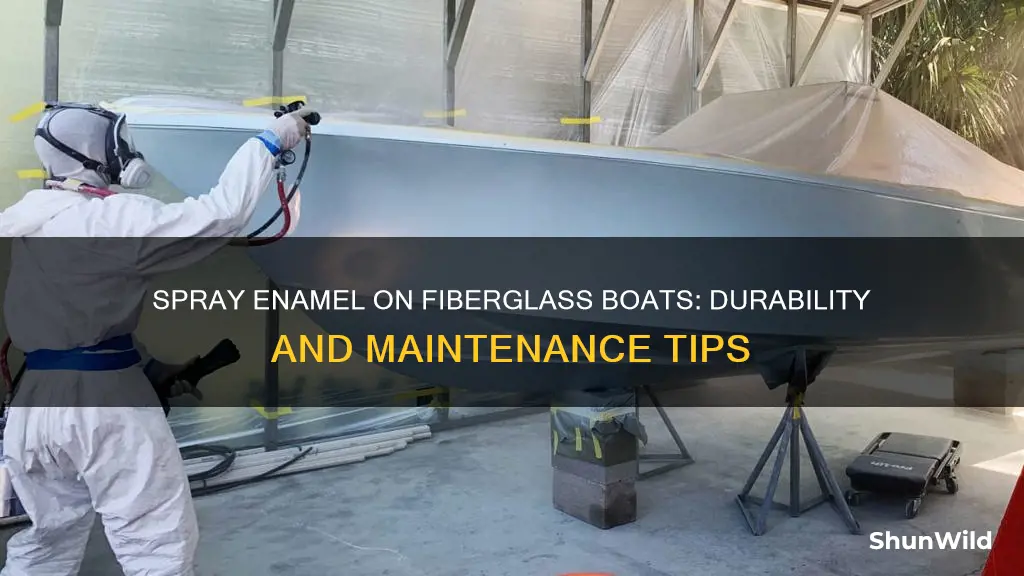

Spray painting a fiberglass boat with enamel paint is a popular choice for those looking to give their vessel a fresh coat of color. However, many enthusiasts wonder if the paint will adhere to the boat's surface and remain intact over time. This paragraph aims to explore the feasibility of using spray enamel on fiberglass boats, considering the unique properties of both materials and the potential challenges and benefits of this painting technique.

| Characteristics | Values |

|---|---|

| Adhesion | Spray enamel can adhere to fiberglass, but the bond may not be as strong as with metal or wood. |

| Durability | It offers good durability and resistance to wear and tear, making it suitable for outdoor use. |

| Color Options | A wide range of colors are available, allowing for customization and personalization. |

| Application | The process involves spraying the enamel directly onto the fiberglass surface, ensuring an even and smooth finish. |

| Weather Resistance | Enamel is known for its ability to withstand various weather conditions, including UV rays and moisture. |

| Maintenance | Regular maintenance is required to keep the enamel in good condition, including touch-ups for any chips or scratches. |

| Cost | Compared to other painting methods, spray enamel can be more expensive due to the specialized equipment and materials needed. |

| Environmental Impact | Some spray enamels may contain volatile organic compounds (VOCs), so it's important to choose low-VOC or water-based options for a more environmentally friendly approach. |

What You'll Learn

- Durability: Enamel spray paint is durable and resistant to chipping and peeling on fiberglass boats

- Adhesion: The paint adheres well to the smooth surface of fiberglass, ensuring a long-lasting finish

- Weather Resistance: Enamel is resistant to UV rays and weather conditions, making it ideal for outdoor use

- Color Options: A wide range of colors is available, allowing for customization and a professional look

- Application Technique: Proper preparation and application techniques are crucial for a successful and long-lasting result

Durability: Enamel spray paint is durable and resistant to chipping and peeling on fiberglass boats

Enamel spray paint is renowned for its exceptional durability, making it an ideal choice for enhancing the appearance and protection of fiberglass boats. This type of paint is specifically formulated to adhere strongly to various surfaces, including the smooth and often challenging texture of fiberglass. When applied correctly, it forms a robust and long-lasting finish that can withstand the rigors of marine environments.

The durability of enamel spray paint lies in its chemical composition. It is designed to be highly resistant to the elements, including UV radiation, which is a common issue for outdoor surfaces. This resistance ensures that the paint remains vibrant and intact for an extended period, even when exposed to sunlight and harsh weather conditions. The paint's formulation also includes additives that enhance its flexibility, allowing it to withstand minor impacts and vibrations without cracking or peeling.

On fiberglass boats, where the surface can be prone to moisture and temperature fluctuations, enamel spray paint excels. It creates a protective barrier that safeguards the boat's finish from the corrosive effects of salt water, preventing rust and corrosion. This is particularly important for maintaining the structural integrity of the boat, as well as its aesthetic appeal. The paint's durability also means it can handle the constant movement and vibrations associated with boating, ensuring a long-lasting and reliable finish.

One of the key advantages of using enamel spray paint on fiberglass is its ability to resist chipping and peeling. The paint's hard, glossy finish provides excellent protection against minor scratches and impacts, ensuring that the boat's appearance remains intact. Unlike some other types of paint, enamel does not lift or peel off easily, making it a reliable choice for long-term use. This durability is especially beneficial for boat owners who want a low-maintenance solution that can withstand the demands of regular use.

In summary, enamel spray paint is an excellent option for those seeking a durable and long-lasting finish for their fiberglass boats. Its resistance to chipping, peeling, and the elements makes it a reliable choice, ensuring that the boat's appearance and structural integrity remain intact for years to come. With proper application and care, this type of paint can provide a beautiful and protective coating, enhancing the overall value and appeal of the vessel.

How Jet Drives Propel Boats Forward

You may want to see also

Adhesion: The paint adheres well to the smooth surface of fiberglass, ensuring a long-lasting finish

The process of painting a fiberglass boat with spray enamel requires careful consideration of the material's unique properties to ensure a successful and long-lasting finish. One of the critical factors is adhesion, which refers to the bond between the paint and the surface it is applied to. In the case of fiberglass, achieving strong adhesion is essential to guarantee the paint's durability and resistance to wear and tear.

Fiberglass, a composite material, has a smooth and non-porous surface, which can be challenging for paint to adhere to. The key to successful adhesion lies in preparing the fiberglass surface properly. Before applying the spray enamel, it is crucial to clean the boat's surface thoroughly. This process involves removing any dirt, grease, or old paint residue. A simple yet effective method is to use a mild detergent mixed with water and a soft brush to scrub the surface gently. This step ensures that the paint has a clean and smooth base to adhere to.

Additionally, sanding the fiberglass surface can significantly improve adhesion. Lightly sanding the boat's exterior with fine-grit sandpaper will create a slightly textured surface, providing more surface area for the paint to grip. This technique is particularly useful for filling in any small imperfections or scratches, ensuring a smooth and even finish. After sanding, it is essential to wipe away any dust and debris to create a clean, dry surface before painting.

Spray enamel, known for its durability, forms a strong bond with the fiberglass material due to its chemical composition. The paint's formulation includes additives that enhance adhesion, allowing it to penetrate the surface and create a secure bond. When applied correctly, the spray enamel will create a seamless and long-lasting finish, protecting the fiberglass boat from the elements and maintaining its appearance over time.

In summary, achieving excellent adhesion when painting a fiberglass boat with spray enamel involves proper surface preparation. Cleaning and sanding the fiberglass ensure a smooth and textured surface, respectively, providing an ideal base for the paint to adhere. The use of high-quality spray enamel with enhanced adhesion properties further contributes to a durable and long-lasting finish, making it an excellent choice for boat owners seeking to refresh their fiberglass vessel.

Choosing the Right Boat Battery: A Comprehensive Guide

You may want to see also

Weather Resistance: Enamel is resistant to UV rays and weather conditions, making it ideal for outdoor use

Enamel paint is renowned for its exceptional weather resistance, making it an excellent choice for outdoor applications, including those involving fiberglass boats. One of the key advantages of enamel is its ability to withstand the harsh elements of nature, ensuring that your boat remains protected and aesthetically pleasing over time.

The weather resistance of enamel can be attributed to its chemical composition. Enamel paint is typically a two-part system, consisting of a resin and a hardener. When mixed, these components create a durable, cross-linked polymer network. This network forms a tough, protective layer on the surface, providing excellent resistance to UV rays, which are a major contributor to paint degradation. UV rays can cause paint to fade, crack, and become brittle, but enamel's resistance to these rays ensures that the paint remains intact and vibrant.

In addition to UV resistance, enamel also excels in withstanding various weather conditions. It is highly resistant to fading, chalking, and color change, even in the face of intense sunlight and temperature fluctuations. This is particularly important for fiberglass boats, as they are often exposed to the elements, including rain, snow, and wind. Enamel's weather resistance ensures that the paint remains intact, preventing the formation of cracks or chips that could compromise the boat's structural integrity.

The durability of enamel paint is further enhanced by its ability to form a smooth, even finish. This smooth surface acts as a protective barrier, reducing the impact of environmental factors on the underlying fiberglass. It also allows for easy cleaning, ensuring that dirt and grime do not accumulate and further damage the paint.

Furthermore, enamel's weather resistance contributes to its long-lasting nature. It can maintain its integrity for extended periods, even in harsh marine environments. This makes it an excellent choice for boat owners who want a paint solution that requires minimal maintenance and can withstand the test of time. With proper preparation and application, enamel can provide a beautiful, weather-resistant finish for your fiberglass boat, ensuring it remains in top condition for years to come.

Understanding the Inner Workings: How a Boat Shifter Functions

You may want to see also

Color Options: A wide range of colors is available, allowing for customization and a professional look

Spray enamel is an excellent choice for painting fiberglass boats, offering a durable and long-lasting finish. When it comes to color options, the possibilities are indeed vast, catering to both customization and a polished appearance. The wide array of colors available ensures that boat owners can achieve their desired aesthetic while also maintaining a professional and sleek look.

The color range for spray enamel on fiberglass boats is extensive, typically covering a spectrum of vibrant hues. From classic white and shades of gray to bold reds, blues, and greens, the options are limitless. This variety allows boat owners to choose a color that complements their personal style or the overall design of the vessel. Whether you prefer a traditional, understated look or a bold, eye-catching statement, the color selection process can be tailored to individual preferences.

Customization is a key advantage of this painting method. With numerous color choices, boat owners can create a unique and personalized design. For instance, you might opt for a custom color that matches your boat's interior or exterior trim, ensuring a cohesive and well-integrated appearance. Alternatively, you can go for a contrasting color scheme to make a bold statement on the water. The flexibility in color selection empowers boat owners to express their creativity and make their vessel truly stand out.

In addition to the aesthetic appeal, the color options for spray enamel on fiberglass boats contribute to a professional finish. A wide range of colors ensures that the final result is not only visually appealing but also aligns with industry standards and expectations. This is particularly important for boats used in commercial settings or those that are frequently exposed to harsh marine environments. By choosing from a comprehensive color palette, boat owners can ensure that their vessel appears well-maintained, attractive, and in line with professional standards.

Furthermore, the availability of various colors allows for easy maintenance and touch-ups. Over time, the boat's surface may show signs of wear, and touch-ups can be seamlessly integrated into the existing paint job. With a wide color range, matching the existing paint becomes more accessible, ensuring that the boat retains its professional appearance even after years of use. This aspect of customization and longevity is a significant advantage of using spray enamel for fiberglass boat painting.

Moored or Docked: What's the Difference for Boats?

You may want to see also

Application Technique: Proper preparation and application techniques are crucial for a successful and long-lasting result

When it comes to applying spray enamel to a fiberglass boat, proper preparation and technique are essential to ensure a durable and aesthetically pleasing finish. The process requires attention to detail and a systematic approach to achieve the best results. Here's a guide on how to tackle this project:

Surface Preparation: Begin by thoroughly cleaning the fiberglass surface. Remove any dirt, grime, or old paint using a mild detergent and a soft brush. Rinse the boat and allow it to dry completely. Inspect the surface for any imperfections, such as scratches, chips, or small holes. Fill these areas with a suitable fiberglass repair compound or putty, ensuring it is smooth and level. Sand the entire surface gently with fine-grit sandpaper to create a uniform texture, which will provide better adhesion for the enamel.

Priming: Priming is a critical step that cannot be overlooked. Apply a suitable marine primer to the prepared surface. This step helps to seal the fiberglass and provides a base for the enamel to adhere to. Follow the manufacturer's instructions for application, ensuring an even and thin coat. Allow the primer to dry completely according to the manufacturer's guidelines.

Application: Now it's time to spray the enamel. Use a high-quality spray gun and a fine-mist setting to achieve an even and smooth finish. Start in a well-ventilated area or outdoors, ensuring proper ventilation during the application process. Hold the spray gun at a consistent distance from the surface, typically around 6-8 inches, to avoid overspray and ensure an even coat. Apply multiple thin coats, allowing sufficient drying time between each layer. This technique ensures a smooth and professional-looking finish.

Edge and Detail Work: When spraying near edges, trim, or intricate details, use a small brush or a detailer's pad to carefully apply the enamel. This allows for precise control and ensures that these areas are not missed. Take your time with this step to achieve a flawless result.

Drying and Curing: After the final coat is applied, allow the enamel to dry completely. The drying time may vary depending on the product and environmental factors. Once dry, the enamel will have a glossy appearance. To cure the enamel and enhance its durability, apply a clear coat or sealant specifically designed for marine use. This final step will protect the enamel and provide a long-lasting finish.

Lightning Strikes: Boats and the Perils of Nature

You may want to see also

Frequently asked questions

Yes, spray paint can be used on fiberglass boats, but it requires proper preparation and the right products. Fiberglass is a porous material, so it's essential to clean and sand the surface to create a smooth, non-porous base for the paint to adhere. Use a mild detergent and water to clean the boat, then lightly sand the area to roughen the surface.

For fiberglass, opt for marine-grade spray paint specifically designed for outdoor use and resistant to UV rays and water. These paints often have a longer shelf life and provide better colorfastness. Look for brands that offer a wide range of colors and finishes suitable for marine environments.

It's generally not recommended to spray paint directly onto the gelcoat (the clear outer layer of the fiberglass) as it can damage the gelcoat's protective properties. Instead, focus on painting the exposed fiberglass areas and consider using a gelcoat paint or a specialized marine paint for the gelcoat section to maintain its integrity.

Proper preparation and application techniques are crucial to ensure the paint's longevity. Follow the manufacturer's instructions for the chosen paint, ensuring you apply thin, even coats. Allow sufficient drying time between coats. Additionally, use a primer designed for marine applications to create a strong bond between the paint and the fiberglass.

Yes, roll-on or brush-on paints are excellent alternatives. These paints often provide more control and precision, allowing for a smoother finish. You can also consider using marine-grade vinyl wraps or decals, which offer a wide range of design options and can be easily applied to fiberglass surfaces without the need for painting.