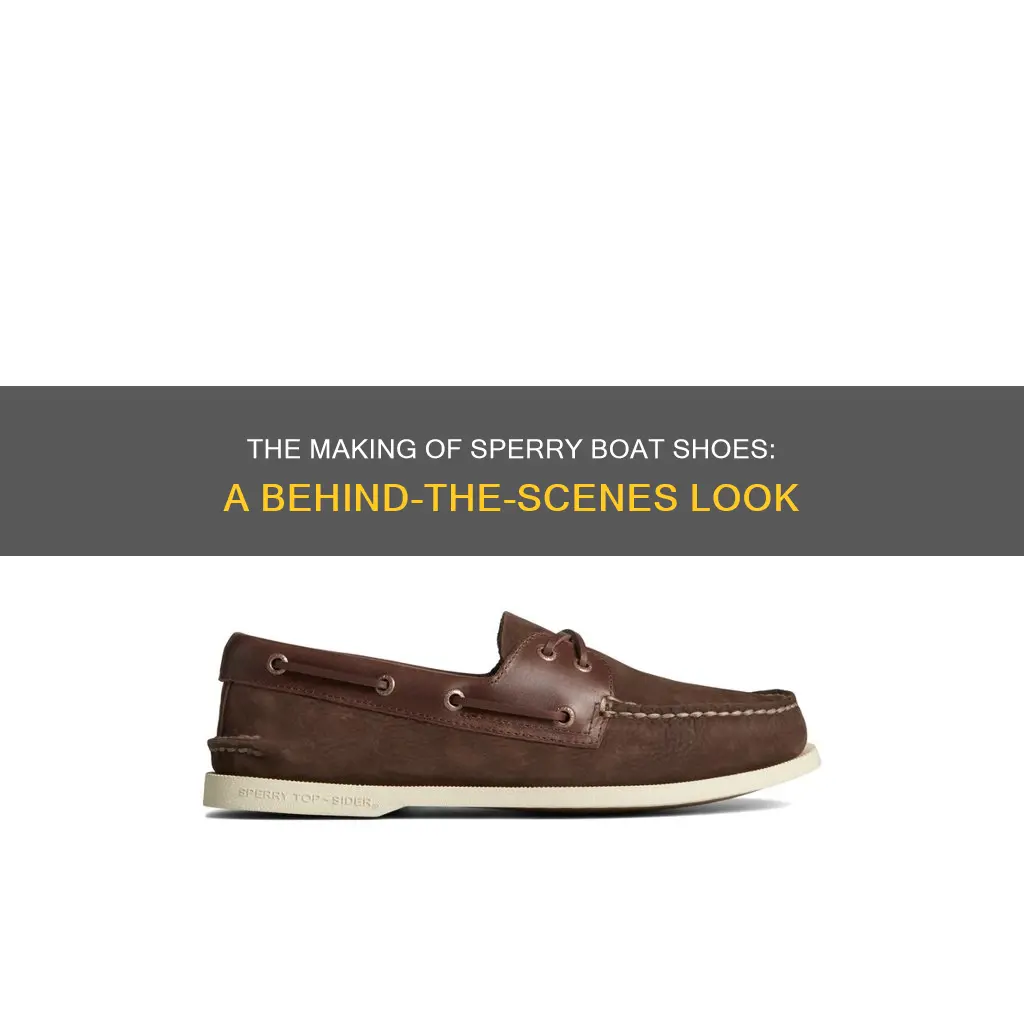

Sperry boat shoes are an iconic American brand of boat shoe, first designed in 1935 by Paul A. Sperry. The shoes were originally intended for sailors and those who work on boats, but they have since become popular with a wider audience, including celebrities. While Sperry is an American brand, most of its iconic Top-Sider boat shoes are made in Vietnam, Indonesia, and China. However, Sperry has also released a “Made in Maine” product line, handcrafted in Maine, USA, using U.S.-sourced leather and the finest materials.

| Characteristics | Values |

|---|---|

| Country of origin | United States |

| Current owner | Authentic Brands Group |

| Licensee for North America operations | Aldo Group |

| Where they are made | Vietnam, Indonesia, China |

| Where they used to be made | Maine, USA |

What You'll Learn

- Sperry boat shoes are designed in the USA but mostly made in Vietnam, Indonesia, and China

- Sperry is an American brand, founded by Paul Sperry, who designed the first-ever boat shoe in 1935

- Sperry boat shoes are made by artisans in factories, using leather and other materials sourced from the USA

- Sperry boat shoes are hand-stitched and sewn, requiring the special skills of artisans

- Sperry launched a 'Made in Maine' product line in 2012, but it seems to have been discontinued

Sperry boat shoes are designed in the USA but mostly made in Vietnam, Indonesia, and China

Sperry boat shoes are an iconic American shoe brand. The first-ever boat shoe was designed in 1935 by Paul Sperry, an avid sailor. The inspiration for these shoes came when he slipped off the deck of his boat and fell overboard. The Sperry "Top-Sider" boat shoe introduced in 1935 featured a canvas upper, herringbone siping, and a white outsole. The Commonwealth Shoe and Leather Co. later partnered with Sperry on a design using specially tanned water-resistant leather, which became the classic Sperry "boat shoe".

While Sperry is an American brand, most of its iconic Top-Sider boat shoes are made in Vietnam, Indonesia, and China. This is likely due to the cheaper labour and materials available overseas. In 2012, Sperry did launch a "Made in Maine" product line, but this was a small product line and has since been discontinued.

The "Made in Maine" collection was handcrafted by artisans in Maine, using U.S.-sourced leather and the finest materials. Sperry celebrated over seventy-five years of heritage as the Authentic Original and an icon of American style. The shoes featured a 360° lacing system with rust-proof eyelets for a secure fit and a 100% premium leather footbed with an embossed Made in Maine signature logo.

The process of making Sperry boat shoes involves cutting leather on a machine into different pieces that will make up the main parts of the shoe. Each piece of leather is inspected, and sometimes discarded if not up to Sperry's standards. Holes are punched into the leather, eyelets are added, and rawhide leather laces are intertwined. The upper pieces of the shoe are then stitched together by a sewing machine and soaked in water to make the leather more pliable.

The pieces are then pulled over a last (the shoe form) and held in place with shoe tacks. The top and bottom pieces are hand-stitched together using an awl to punch the holes and two needles to fasten the threads. The shoe is then dried for about 24 hours as it continues to take the shape of a shoe. Once the drying process is complete, the leather midsole and rubber outsole are attached, and the edges are trimmed and smoothed. Finally, the last is removed from the shoe, and the leather sock liner is glued in.

Sailing Upwind: Understanding the Art of Wind Navigation

You may want to see also

Sperry is an American brand, founded by Paul Sperry, who designed the first-ever boat shoe in 1935

Sperry is an American brand, founded by Paul Sperry, who designed the first boat shoe in 1935. An avid sailor, Sperry's inspiration for the boat shoe came when he slipped off the deck of his boat and fell overboard. He wanted to create a non-slip shoe for boating. While experimenting, he noticed his cocker spaniel's ability to run down an icy hill without slipping. He examined the dog's paws and saw traction-enhancing grooves, which he mimicked by cutting a pattern of them into a natural rubber sole—a process known as siping. The first Sperry Top-Sider boat shoe featured a canvas upper, herringbone siping, and a white outsole to prevent the shoe from leaving scuff marks on a boat's deck.

The Commonwealth Shoe and Leather Co. later partnered with Sperry on a design using specially tanned water-resistant leather, which became the classic Sperry "boat shoe". Sperry's shoes remained a niche product for boaters until 1939 when the US Navy negotiated the right to manufacture the shoe for its sailors at the United States Naval Academy. As a result of this increased production, Sperry sold the brand to the US Rubber Co. in 1940.

In 2012, Sperry made a marketing push to bring back American manufacturing for their most popular boat shoes and launched a "Made in Maine" product line. However, this product line was only a small portion of their overall production and has since been discontinued. Today, most Sperry shoes are made in Vietnam, Indonesia, and China.

The "Made in Maine" collection of footwear is hand-stitched by artisans in Maine, using U.S.-sourced leather and the finest materials. Sperry celebrates over seventy-five years of heritage as the Authentic Original and an icon of American style. The shoes are known for their soft leather, white stitching, and laces that weave around the shoe's opening. Each shoe is handcrafted with a commitment to quality and attention to detail.

Mounting Back-to-Back Boat Seats: A Step-by-Step Guide

You may want to see also

Sperry boat shoes are made by artisans in factories, using leather and other materials sourced from the USA

Sperry boat shoes are crafted by skilled artisans in factories, combining traditional techniques with modern processes. The iconic footwear is renowned for its soft leather, distinctive white stitching, and unique lacing system. While most Sperry shoes are produced outside the USA, the company has a small product line, the "Made in Maine" collection, which stays true to its American roots.

The "Made in Maine" range is handcrafted by artisans in Maine, honouring the brand's heritage. These artisans bring their special skills to the intricate process of creating each shoe. The process begins with carefully selecting and cutting premium leather sourced from the USA. Each piece of leather is meticulously inspected to ensure it meets the stringent standards set by Sperry.

The leather is then punched with holes, and eyelets are added to create a secure base for the laces. The laces themselves are made from rawhide leather, chosen for its pliability, allowing the laces to be intricately woven around the shoe's opening. This type of leather can be bent in different directions, providing both functionality and style.

Once the leather pieces are cut and prepared, the upper parts of the shoe are stitched together using a sewing machine. To make the leather more pliable, these pieces are soaked in water before being pulled over a last—the shoe form—and secured with shoe tacks. The artisans then hand-stitch the top and bottom pieces together, using an awl to punch holes and two needles to fasten the threads.

After being hand-sewn, the shoe is left to dry for approximately three hours. It remains on the last for another 24 hours to ensure it fully dries and takes on the recognisable shape of a Sperry boat shoe. The leather midsole is then attached using a specialised machine, and the pre-glued rubber outsole is heat-activated and affixed to the midsole.

The final steps include trimming the edges of the sole to achieve a smooth, rounded finish and removing the last from the shoe. The signature touch is the addition of a leather sock liner, glued into the bottom of the shoe, completing the iconic Sperry boat shoe.

Lacing Your Sperry Boat Shoes: A Step-by-Step Guide

You may want to see also

Sperry boat shoes are hand-stitched and sewn, requiring the special skills of artisans

The creation of each Sperry boat shoe begins with the selection and cutting of soft leather. The leather is cut into different pieces that will form the main parts of the shoe. Each piece is carefully inspected to ensure it meets the high standards of Sperry, and any leather that does not make the cut is discarded. This attention to detail and quality is a testament to the artisans' expertise.

After the leather pieces are cut, eyelets are added, and rawhide leather laces are intertwined. Rawhide is a pliable type of leather that can be bent in different directions, making it ideal for lacing around the shoe. The upper pieces of the shoe are then stitched together by a sewing machine. To make the leather more pliable, these stitched pieces are soaked in water.

The next step involves pulling the leather pieces over a last, the shoe form, and securing them with shoe tacks. This is where the artisans' skills truly come to life as they hand-stitch the top and bottom pieces together. Using an awl, the artisan punches holes and then fastens the threads using two needles. This meticulous process ensures the shoe's structural integrity and showcases the artisans' mastery of their craft.

Once the shoe is hand-sewn, it undergoes a drying process while still on the last. This step is crucial to remove excess moisture and allow the shoe to take shape. After drying, the leather midsole is attached with a specialised machine, and the rubber outsole is heat-activated and attached. The edges of the sole are then trimmed and smoothed to create an even and smooth finish.

The final steps include removing the last from the shoe and gluing in the leather sock liner. The result is a meticulously crafted Sperry boat shoe, renowned for its comfort, durability, and iconic style. The hand-stitching and sewing techniques employed by skilled artisans are integral to the shoe's construction, ensuring a secure fit and reflecting the brand's commitment to quality.

Boat Registration: AAA's Services and Your Vessel

You may want to see also

Sperry launched a 'Made in Maine' product line in 2012, but it seems to have been discontinued

Sperry boat shoes are an iconic American brand of boat shoe, designed in 1935 by Paul A. Sperry. The shoes were the first of their kind to be introduced to the boating and footwear markets. Sperry's shoes remained a niche product for boaters until 1939 when the US Navy negotiated the right to manufacture the shoe for its sailors at the United States Naval Academy.

In 2012, Sperry launched a "Made in Maine" product line, bringing back American manufacturing for their most popular boat shoes. However, it seems that this product line has since been discontinued. The "Made in Maine" collection was hand-stitched by artisans in Maine, using US-sourced leather and the finest materials. The collection celebrated over seventy-five years of heritage as the Authentic Original and an icon of American style.

Despite the discontinuation of the "Made in Maine" line, Sperry continues to be a popular and well-known brand for boat shoes. The company has expanded its operations and can be found in various stores across the United States.

While Sperry has discontinued its "Made in Maine" product line, the brand remains an iconic symbol of American style and craftsmanship, with a long history dating back to 1935.

Boat Shoes in the 50s: A Fashionable Decade?

You may want to see also

Frequently asked questions

Most Sperry boat shoes are made in Vietnam, Indonesia, and China. In 2012, Sperry launched a "Made in Maine" product line, but it seems like that product line has been discontinued.

No, most Sperry shoes are not made in the USA. However, Sperry is an American brand, and the company was founded by Paul Sperry, who designed the first-ever boat shoe in 1935.

Sperry boat shoes are made from leather, rubber, and canvas.