When it comes to securing carpets to the interior of a fiberglass boat, many enthusiasts turn to Liquid Nails as a reliable bonding solution. This paragraph explores the effectiveness of Liquid Nails in adhering carpet to the smooth surface of a fiberglass boat, considering factors such as the material's strength, flexibility, and resistance to water and UV exposure. It also highlights the importance of proper surface preparation and the use of appropriate adhesives to ensure a long-lasting and secure bond.

| Characteristics | Values |

|---|---|

| Adhesion Strength | Liquid Nails can provide strong bonding, but the specific strength may vary depending on the application and surface preparation. |

| Flexibility | It offers some flexibility, allowing for minor movement and accommodating slight shifts in the boat's structure. |

| Water Resistance | The product is designed to be waterproof, making it suitable for marine environments. |

| Application Ease | Easy to apply and can be used with various tools for a precise bond. |

| Drying Time | Typically dries quickly, allowing for faster project completion. |

| Compatibility | Can be used on a variety of surfaces, including carpet and fiberglass. |

| Temperature Tolerance | Suitable for a wide range of temperatures, making it versatile for different weather conditions. |

| Cleanliness | Requires a clean surface for optimal bonding, so surface preparation is essential. |

| Longevity | With proper application and care, the bond can last for an extended period. |

| Availability | Widely available in hardware stores and online retailers. |

What You'll Learn

- Adhesive Strength: Liquid Nails' bond between carpet and fiberglass in boats

- Surface Preparation: Cleaning and priming for optimal bonding

- Environmental Factors: Impact of temperature and humidity on adhesion

- Durability: Long-term performance of the bond under stress

- Application Techniques: Methods for best results

Adhesive Strength: Liquid Nails' bond between carpet and fiberglass in boats

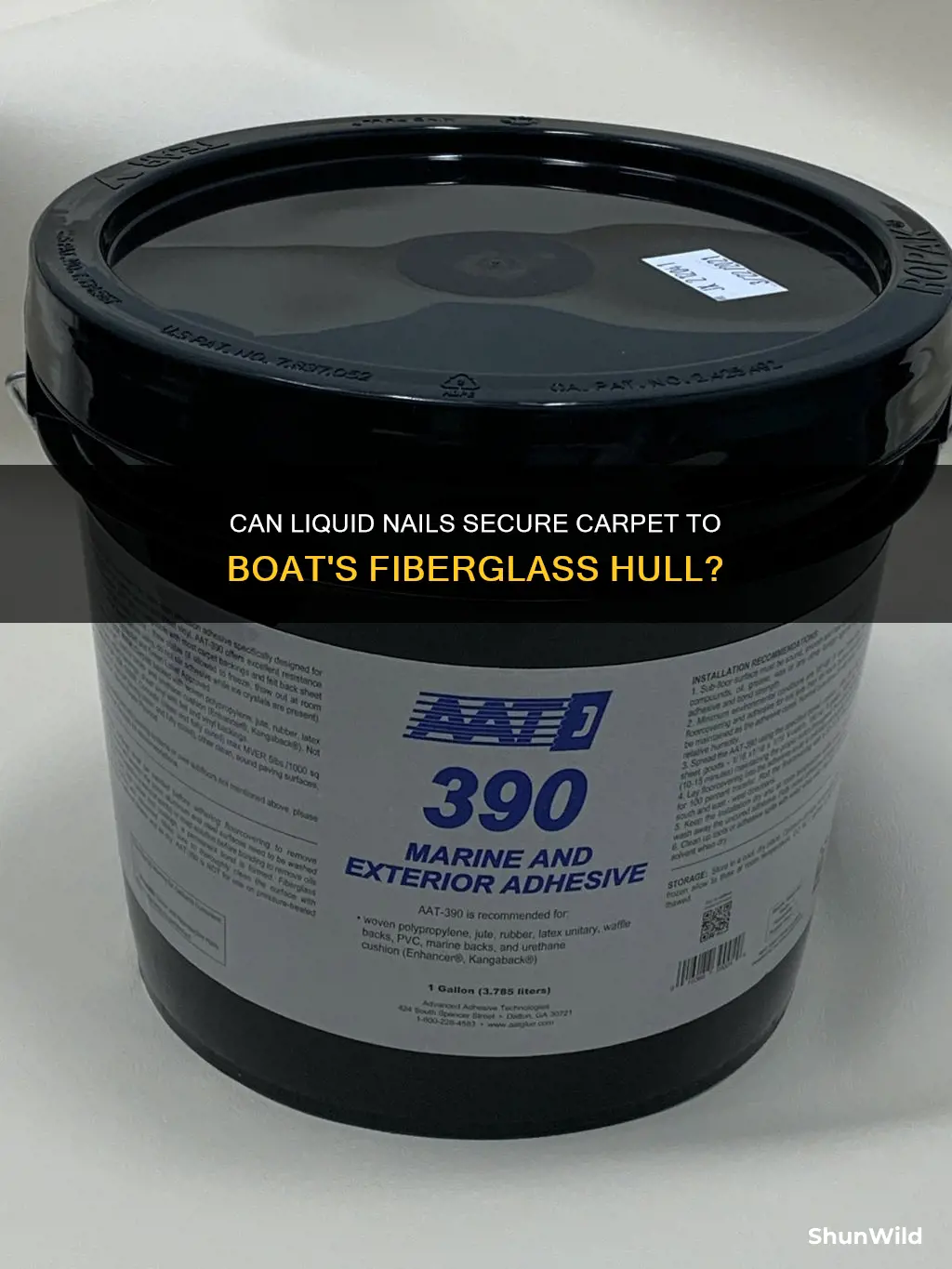

When it comes to bonding carpet to a fiberglass boat, the choice of adhesive is crucial for a secure and long-lasting installation. Liquid Nails, a popular adhesive brand, offers a range of products that can effectively bond carpet to fiberglass surfaces. The adhesive strength of Liquid Nails is a key factor in ensuring a reliable bond, especially in the challenging environment of a boat.

The unique composition of Liquid Nails allows it to create a strong, flexible bond between various materials, including carpet and fiberglass. This is particularly important in boat construction, where the materials used are often lightweight, durable, and prone to movement. Liquid Nails' ability to adhere to these materials provides a secure foundation for carpet installation, ensuring it remains firmly in place despite the dynamic nature of a boat's environment.

One of the advantages of using Liquid Nails for this application is its versatility. It can be used in both indoor and outdoor settings, making it suitable for a wide range of boat applications. The adhesive can be applied in various ways, including as a bead, a spray, or a spread, allowing for customization based on the specific bonding requirements. This versatility ensures that Liquid Nails can accommodate different carpet thicknesses and textures, providing a consistent and strong bond.

In terms of performance, Liquid Nails has proven its effectiveness in bonding carpet to fiberglass. Its strong adhesive properties create a secure bond that can withstand the rigors of boat use, including exposure to water, UV rays, and temperature fluctuations. This level of durability is essential for ensuring the carpet remains intact and functional over the long term, enhancing the overall appearance and comfort of the boat's interior.

Additionally, Liquid Nails offers a user-friendly application process. The adhesive can be easily applied with a caulking gun or a spray bottle, making it accessible to both professionals and DIY enthusiasts. This simplicity in application contributes to a successful bond, as proper adhesion is achieved with minimal effort. Overall, Liquid Nails provides an effective and reliable solution for bonding carpet to fiberglass in boats, offering strength, versatility, and ease of use.

Striper Boats: Worth the Hype?

You may want to see also

Surface Preparation: Cleaning and priming for optimal bonding

When preparing the surface for bonding carpet to a fiberglass boat, thorough cleaning and priming are essential steps to ensure a strong and durable bond. The process begins with a meticulous cleaning to remove any dirt, grime, or old adhesive residue that could interfere with the bonding process. Start by using a mild detergent or a specialized boat cleaner to wash the fiberglass surface. Rinse thoroughly with water to eliminate any soap residue, as this can also affect the bonding strength. For carpeted areas, it's crucial to vacuum and remove any loose fibers or debris that might hinder the adhesion.

After cleaning, the surface needs to be roughened slightly to provide a better grip for the adhesive. This can be achieved by lightly sanding the fiberglass with fine-grit sandpaper. The goal is to create a subtle texture that will allow the Liquid Nail to penetrate and bond effectively. Ensure that the sanding is done evenly and gently to avoid damaging the surface. Once the sanding is complete, wipe away any dust with a clean cloth to create a smooth, prepared surface.

Priming the surface is the next critical step. A primer specifically designed for marine applications is ideal, as it will help the adhesive adhere better and provide additional protection against the marine environment. Apply the primer evenly to the prepared surface, following the manufacturer's instructions for drying times between coats. Allow sufficient time for each coat to dry before proceeding to the next step. Proper priming ensures that the adhesive has a clean, receptive surface to bond to, enhancing the overall strength and longevity of the carpet attachment.

It's important to note that the preparation process might vary slightly depending on the specific conditions and materials involved. Always refer to the product guidelines for the best results and safety precautions. By investing time in thorough surface preparation, you'll create an optimal environment for the Liquid Nail to effectively bond the carpet to the fiberglass boat, ensuring a secure and long-lasting installation.

Calculating Engine Horsepower: Unraveling the Mystery of 30-Foot Boats

You may want to see also

Environmental Factors: Impact of temperature and humidity on adhesion

The environmental conditions, particularly temperature and humidity, play a significant role in the adhesion of Liquid Nail to various surfaces, including carpet and fiberglass boats. Understanding these factors is crucial for ensuring a successful and long-lasting bond.

Temperature has a direct influence on the viscosity and flexibility of the adhesive. In general, Liquid Nail becomes more fluid and easier to apply at higher temperatures, allowing for better penetration into the substrate. When bonding carpet to a fiberglass boat, for instance, a moderate temperature range of around 68-77°F (20-25°C) is often recommended. This temperature range ensures that the adhesive remains in a workable state, allowing for proper application and initial bonding. However, it's important to note that extremely high temperatures can cause the adhesive to lose its tackiness over time, leading to potential failure. Conversely, low temperatures can make the adhesive too thick and difficult to apply, reducing its effectiveness.

Humidity, or the amount of water vapor in the air, also affects the adhesion process. High humidity levels can impact the curing process of the adhesive, potentially leading to weaker bonds. When working with Liquid Nail, it is advisable to maintain a low humidity environment, ideally below 60%. This helps prevent moisture-related issues that could interfere with the adhesion process. In contrast, very low humidity can cause the adhesive to dry too quickly, leaving no room for proper bonding. Therefore, finding the right balance in humidity levels is essential for optimal adhesion.

In the context of bonding carpet to a fiberglass boat, temperature and humidity control become even more critical. Fiberglass, being a composite material, can be sensitive to environmental changes. Extreme temperatures or high humidity can cause the material to expand or contract, potentially affecting the adhesion process. It is recommended to apply the adhesive when the boat is in a controlled environment, ensuring that both the surface and the adhesive are at the desired temperature and humidity levels.

To summarize, when using Liquid Nail to bond carpet to a fiberglass boat, it is essential to consider the environmental factors. Moderate temperatures and low humidity levels create an optimal environment for adhesion. By understanding and controlling these factors, you can ensure a strong and durable bond, maximizing the lifespan of your project. Always refer to the manufacturer's guidelines for specific recommendations regarding temperature and humidity ranges for your chosen adhesive.

Launching a Jon Boat: A Step-by-Step Guide

You may want to see also

Durability: Long-term performance of the bond under stress

When considering the long-term performance of a bond between carpet and fiberglass boat materials, it's crucial to evaluate the durability of the chosen adhesive. Liquid Nail, a popular choice for various bonding applications, can be an effective option for this specific task. However, the success of the bond depends on several factors, including the quality of the adhesive, surface preparation, and environmental conditions.

The durability of the bond is essential to ensure that the carpet remains securely attached to the boat's fiberglass structure over an extended period. Fiberglass, being a composite material, can be more challenging to bond compared to smooth surfaces like wood or metal. The texture and porosity of fiberglass can affect the adhesion of the adhesive, requiring careful preparation to ensure a strong bond. Liquid Nail, with its quick-drying formula, can provide a temporary bond, but for long-term performance, a more robust adhesive might be necessary.

To enhance durability, it is recommended to use a high-quality epoxy-based adhesive specifically designed for marine applications. These adhesives offer excellent resistance to stress, UV radiation, and water, making them ideal for bonding in harsh marine environments. Proper surface preparation is key; the fiberglass surface should be clean, smooth, and free from any contaminants. Filling any voids or imperfections with a suitable filler material can improve bond strength and ensure a seamless attachment.

In addition to the adhesive choice, the application process plays a significant role in durability. Applying the adhesive in a thin, even layer ensures proper bonding and minimizes the risk of air bubbles, which can compromise the bond's integrity. Allowing sufficient curing time for the adhesive to set properly is essential, as rushing the process may result in a weaker bond.

For optimal long-term performance, regular inspections and maintenance are recommended. Check the bond periodically for any signs of detachment or wear, especially in areas exposed to friction or impact. Reapplying the adhesive or using a suitable sealant can help maintain the bond's strength and ensure the carpet remains securely attached to the fiberglass boat, even under stress.

Stern Balance: Weight Distribution for Better Boat Handling

You may want to see also

Application Techniques: Methods for best results

When it comes to securing carpet to a fiberglass boat, Liquid Nail can be a useful adhesive, but the application technique is crucial for achieving the best results. Here are some detailed methods to ensure a strong and durable bond:

Surface Preparation: Before applying Liquid Nail, ensure both the carpet and the fiberglass surface are clean and free from any debris or contaminants. Use a mild detergent and water solution to clean the areas, and then rinse and allow them to dry completely. This step is essential as any residue or moisture can affect the bond strength.

Application of Liquid Nail: Start by applying a thin and even layer of Liquid Nail to the back of the carpet. Use a small brush or a spreader to ensure a consistent application. Focus on the edges and any areas where the carpet might lift or move. For larger surfaces, multiple small applications are better than one large, thick layer, as this can lead to uneven bonding. Allow the first coat to dry slightly, but not completely, as you'll need to work quickly before it sets.

Positioning and Bonding: Once the initial coat is tacky, carefully position the carpet on the fiberglass boat. Ensure it is aligned correctly and smooth out any wrinkles or bubbles. You can use a heavy object or a rolling pin to gently press the carpet onto the surface, creating a firm bond. This step requires some patience and precision to avoid any air bubbles or misalignments.

Final Touches and Curing: After positioning the carpet, allow the Liquid Nail to cure fully according to the product's instructions. This process might take several hours or even overnight, depending on the product and the ambient temperature. During this time, avoid any pressure or stress on the bonded area. Once cured, the bond should be strong and long-lasting.

Remember, practice makes perfect when it comes to adhesive applications. Take your time, be precise, and don't rush the process to ensure a successful and durable bond between your carpet and fiberglass boat.

Mastering River Shoals: Trout Boat Techniques for Smooth Passage

You may want to see also

Frequently asked questions

Yes, Liquid Nails, specifically the marine-grade adhesive, can be an effective solution for bonding carpet to a fiberglass boat. It is designed to withstand the harsh marine environment and provides a strong, durable bond.

Before application, ensure both the carpet and fiberglass surfaces are clean, dry, and free of any debris. Sanding the carpet backing slightly can create a better bond. Allow the surfaces to cure properly before walking or placing pressure on the bonded area.

Liquid Nails marine adhesive offers excellent adhesion, flexibility, and resistance to water and chemicals. It can handle the expansion and contraction of the boat materials, ensuring a long-lasting bond. This method is often preferred over traditional sewing or gluing for a more discreet and permanent fix.

Yes, it's crucial to follow the manufacturer's instructions for application. Apply the adhesive in a thin, even layer, and ensure full contact between the surfaces. Press firmly and hold for the recommended time. Allow adequate curing time before using the boat to avoid any potential damage.

Absolutely! Liquid Nails has various marine-grade adhesives suitable for different boat interior applications, such as bonding foam, upholstery, or other materials. Always choose the appropriate product for your specific project to ensure optimal results.