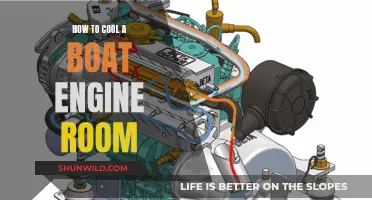

If you notice fuel coming out of your boat's exhaust, there could be a few reasons for this. It could be due to a faulty injector tip, a leaking power valve, a stuck cylinder, or a problem with the engine temperature control. Additionally, it could be caused by a blockage in the seawater pump or a cracked cylinder head or head gasket. It is important to address this issue as it could lead to environmental concerns and potential safety hazards.

What You'll Learn

A cracked cylinder head or head gasket

A cracked cylinder head or a blown head gasket can be a serious issue and may require costly repairs. In the case of a boat engine, these issues can lead to fuel or oil leaking into the water through the exhaust, causing a sheen on the water's surface. This can be a significant environmental concern and should be addressed promptly.

Symptoms of a Cracked Cylinder Head or Blown Head Gasket

- White exhaust smoke: Thick white smoke, especially during startup or acceleration, indicates that coolant is likely burning in the combustion chamber. This occurs when a crack forms or the head gasket fails, allowing coolant to mix with fuel and air. This smoke often has a sweet smell and may be accompanied by a rough-running engine and reduced power.

- Engine overheating: A compromised cooling system due to a cracked cylinder head or blown head gasket can result in coolant escape or the entry of combustion gases into cooling passages, leading to air pockets that hinder proper cooling. Your temperature gauge may creep up during highway driving or idling in traffic. Topping off the coolant provides temporary relief, but the problem persists as the system cannot maintain pressure.

- Unexplained coolant loss: If you notice an empty coolant reservoir without any visible leaks underneath your boat, it indicates a potential issue. The cooling system is pressurised and sealed, so coolant disappearance suggests an alternative escape route, such as burning in the combustion chamber or escaping through a crack when the engine is hot and under pressure.

- Oil-coolant mixture: A light brown or milky colour in the oil indicates that coolant has mixed with engine oil, often referred to as "milkshake oil." This occurs when the barrier between the cooling and lubrication systems fails, resulting in a mixture that cannot effectively lubricate the engine's moving parts. Continued operation can lead to additional damage.

- Poor engine performance: A rough-running engine, misfires, and lack of power can be attributed to coolant contamination in the combustion chamber, disrupting the air-fuel mixture required for proper combustion. Combustion gases can escape through the damaged area, reducing power output and engine performance, particularly when the engine is cold or during acceleration.

Causes of a Cracked Cylinder Head or Blown Head Gasket

Engine overheating is the primary cause of head gasket failure and cracked cylinder heads. When the engine overheats, metal parts expand beyond the gasket's capacity, leading to warping and seal breakage. Other factors include age-related deterioration, improper installation during previous repairs, or the use of incorrect coolant, which can erode the gasket material.

Repair Options and Costs

Repairing a cracked cylinder head or replacing a blown head gasket can be labour-intensive and expensive. For a head gasket replacement, costs can range from $1,500 to $3,000, depending on the vehicle model and local labour rates. In contrast, repairing a cracked cylinder head may require replacing the entire engine, with costs ranging from $4,000 to $7,000 or more.

Diagnosis and Prevention

To definitively diagnose a cracked cylinder head or blown head gasket, the engine must be disassembled for inspection. However, there are some preliminary steps you can take:

- Check for external coolant leaks, especially around the head gasket area.

- Examine the engine oil and coolant for signs of mixing, such as a milky or light brown colour.

- Perform a compression test to reveal pressure leakage between cylinders.

- Conduct a cooling system pressure test to identify potential external leaks.

- Utilise special dyes or gas analysers to detect combustion gases in the cooling system.

To prevent head gasket failure and cylinder head cracking, ensure your cooling system is well-maintained and functioning correctly. Check for leaks, ensure the radiator is working efficiently, and maintain the correct coolant level. Additionally, keep the fan in good condition and ensure it has a shroud to increase efficiency.

Salon Makeover: Wood-Look Vinyl for Boats

You may want to see also

Blocked seawater pump

A blocked seawater pump can cause fuel to leak out of your boat's exhaust. This issue can be caused by a blockage in the seawater pump, which in turn leads to insufficient seawater circulation and heat exchanger obstruction. This can result in engine temperature control issues and, ultimately, fuel leaking out of the exhaust.

To address this problem, you should first confirm that your boat's seawater pump is indeed blocked. Check for any signs of obstruction or blockage in the pump and its associated components. If you find any blockages, you will need to clear them to restore the normal flow of seawater. This may involve cleaning or replacing affected parts.

Additionally, it is important to inspect the heat exchanger for any signs of obstruction or damage. If the heat exchanger is compromised, it may need to be repaired or replaced.

In some cases, a blocked seawater pump may be a symptom of a larger issue, such as a faulty engine temperature control system or a malfunctioning cooling system. Therefore, it is crucial to thoroughly diagnose and address any underlying problems to prevent recurrence.

If you are unsure about the cause of the blockage or how to resolve it, it is recommended to consult a qualified marine mechanic. They can provide expert advice and guidance tailored to your specific boat and engine configuration.

Life Vest Essentials: Boat Safety and Requirements

You may want to see also

Insufficient seawater circulation

Seawater is used as a cooling medium in the machinery systems of boats, directly cooling the heat exchangers. Seawater cooling systems are an essential component of boats as they help to prevent machinery malfunction and breakdown by reducing or carrying away excess heat energy.

However, issues with seawater circulation can lead to fuel or oil leaks in the water coming from the exhaust system. Insufficient seawater circulation can be caused by a blockage in the seawater pump or heat exchangers. This can be due to the build-up of mud, algae, barnacles, or other debris in the seawater cooling system, which restricts the flow of seawater through the system.

To resolve this issue, it is important to regularly clean and maintain the seawater cooling system. This includes cleaning or replacing filters, strainers, and the seawater pump if necessary. It is also recommended to perform a "bucket test" to check the water flow rate and ensure it is sufficient for the proper functioning of the system.

In addition, it is important to monitor the engine temperature and watch for any signs of coolant leakage. A sudden increase in engine temperature or the presence of coolant in the exhaust water may indicate a more serious issue, such as a cracked cylinder head or a faulty head gasket.

By addressing these issues and maintaining the seawater cooling system, boat owners can help prevent fuel or oil leaks in the water exhaust and ensure the efficient and safe operation of their vessels.

Exploring Philippines' Best Sail Boat Harbors and Anchorages

You may want to see also

Poorly adjusted exhaust valves

To address this problem, it is recommended to "kit" the cylinders to improve compression. Adjusting the exhaust valves properly is crucial for effective cylinder sealing. Additionally, ensuring that the engine block heaters are functioning properly can help prevent the issue.

The Common Denominator: Our Shared Human Experience

You may want to see also

Faulty injector

A faulty injector can cause fuel to leak out of your boat's exhaust. Injectors are responsible for spraying fuel into the engine's combustion chamber, but if they are dirty, clogged, or damaged, they may not function properly. This can result in an insufficient amount of fuel being delivered to the engine, leading to unusual vibrations and a rough idling engine. In some cases, a faulty injector may also cause a fuel leak, which is dangerous as the exposed fuel could catch fire.

If you suspect that your boat's exhaust is emitting fuel due to a faulty injector, it is important to take immediate action. Start by checking for common signs of a faulty injector, such as unusual vibrations, rough idling, and a strong fuel smell. You may also notice black smoke in your exhaust fumes, indicating the presence of unburned fuel.

To diagnose a faulty injector, you can start by checking your engine light. If it is blinking or illuminated, it could indicate an issue with the fuel injector. However, as this light can also indicate other problems, it is recommended to take your boat to a mechanic for a proper diagnosis. They may use tools such as an OBD2 code reader to scan for error codes and identify the specific issue.

Once the faulty injector is identified, you have a few options for repair. Some people choose to clean the injectors, but this may only provide a temporary solution, as the problem often recurs within a year. A more durable solution is to replace the faulty injector with a new one. The cost of injector replacement typically ranges from $100 to $500, including parts and labour.

To prevent future issues with your boat's injectors, regular maintenance is key. It is recommended to have your injectors cleaned annually or bi-annually, either by a professional or using fuel additives. By keeping your injectors clean and well-maintained, you can help ensure they function optimally and extend their lifespan.

Exploring Italy: Venice to Rome by Boat

You may want to see also

Frequently asked questions

This could be due to a number of reasons, including a bad injector tip, a faulty MAP sensor, a leaking power valve, a stuck cylinder, or a faulty head gasket.

If you're getting a sheen on the water, it could be due to a bad injector tip.

Other potential causes include a faulty MAP sensor, a leaking power valve, a stuck cylinder, or a faulty head gasket.

It is recommended to consult a professional mechanic or a boating forum for specific advice and guidance.