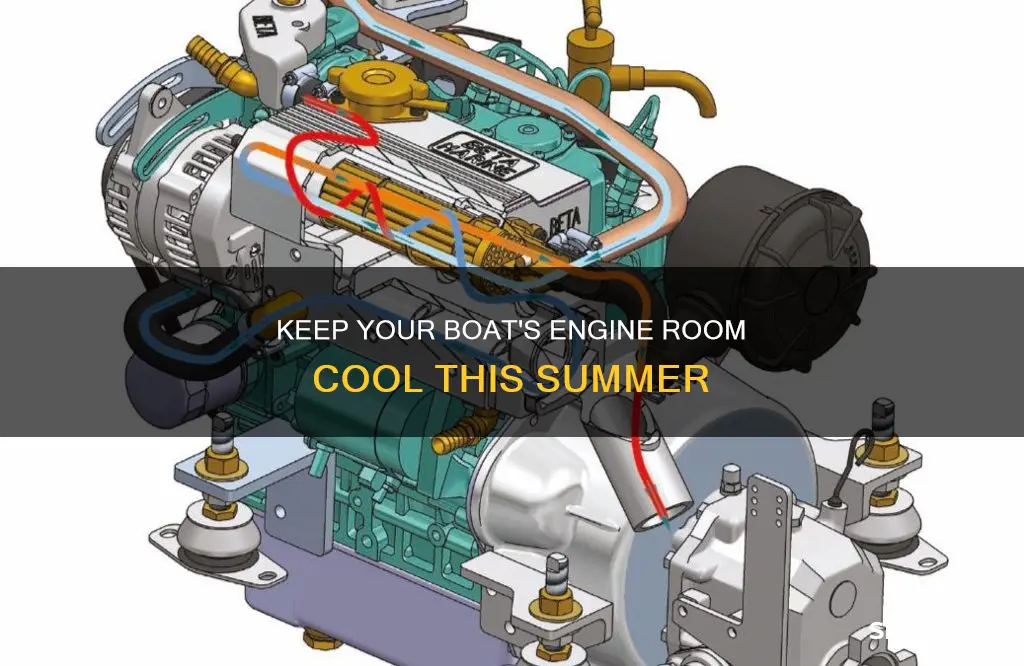

Keeping a boat's engine room cool is important, as high temperatures can cause wear and deterioration to accelerate. In this article, we will discuss ways to cool a boat engine room, including improving airflow and ventilation, and maintaining engine components. We will also cover safety considerations such as fire suppression systems and bilge ventilation. By following these tips, boat owners can ensure their engine room remains at a safe and optimal temperature.

| Characteristics | Values |

|---|---|

| Engine room temperature | Should be maintained at no higher than 10°C above the ambient temperature. |

| Air density | The cooler the air, the denser it is, which offers better operating conditions. |

| Fuel efficiency | Greater fuel efficiency is achieved when the engine room temperature is in a good operational range. |

| Heat sources | The engine is the biggest source of heat, but there may also be a generator and other gadgets. |

| Airflow | Airflow should be assessed to ensure it is free and clear, allowing air to circulate efficiently. |

| Air vents | The positioning of air vents is critical to their success. Correct placement of air in and air out grilles will ensure the air is turning over and not just recirculating hot air. |

| Engine requirements | Engine manufacturers calculate how much air their models need and the vent sizing necessary to provide it. |

| Ventilation | Passive ventilation systems rely on the engines, which are powerful air pumps, to create enough suction to pull air in from both the intake and exhaust vents. Powered ventilation systems use blowers to increase airflow. |

| Engine room pressure | The air pressure within the engine room should be neutral to slightly negative. |

| Air intake and outlet | Air intakes should be located outside the normal spray range, or they should incorporate air/mist separators. Outlets should be located high and as far opposite the intake as practical. |

| Airflow requirements | CFM = (55.0 * BTU/m)/ DeltaT, where CFM is cubic feet per minute of airflow, BTU/m is British Thermal Units per minute, and Delta-t is the temperature difference between the outside air temperature and the temperature in the engine room. |

What You'll Learn

- Ensure adequate ventilation by adding engine room fans to increase air movement

- Assess your air paths to ensure they are free and clear for efficient air circulation

- Position intake and outlet air vents correctly to ensure air is turning over and not recirculating hot air

- Get a qualified assessment to ensure your engine room is operating within the correct temperature range

- Install exhaust blowers to create negative pressure and draw in cool air through the passive intake vents

Ensure adequate ventilation by adding engine room fans to increase air movement

Ensuring adequate ventilation is crucial to keeping your boat's engine room cool and maintaining the longevity of its equipment. Adding engine room fans is a great way to increase air movement and create directional airflow towards equipment and hotspots. Here are some detailed steps to help you ensure adequate ventilation by adding engine room fans:

Choose the Right Fans

Select fans that are powerful enough to provide sufficient airflow for your engine room. Consider the size of your engine room and any restrictions that may impact airflow, such as ducting or hoses. Calculate the required airflow using formulas that account for heat, airflow, and temperature difference. Pick fans that can move enough air within the constraints of your engine room.

Position the Fans Strategically

Place the fans in locations that maximize their effectiveness. Install intake fans lower in the engine room, directing cool air towards the keel and under the engine sump. Position exhaust fans higher up, where hot air naturally accumulates, and as far as possible from the intake ducting. Ensure the fans are pulling in fresh air and expelling it overboard.

Install Multiple Fans

Consider installing multiple fans to improve airflow further. You can place additional fans in the center of the engine room to enhance circulation. Just ensure that the intake fans are slightly less powerful than the exhaust fans to maintain negative pressure and draw cool air through the engine room effectively.

Wire the Fans Correctly

Wire the fans to start when the engines do and to stay on for a while after shutdown. This will help cool the engine room faster. Use a time-delay relay, such as the Blue Sea ATD Automatic Timer Disconnect, for this purpose. Also, ensure the fans are wired to shut down immediately if the automatic fire-extinguishing system is triggered to prevent feeding oxygen to any potential fires.

Maintain the Fans Regularly

Regular maintenance of your fans is essential to keep them in good working condition. Clean the fans regularly to remove any dust or debris that may accumulate. Lubricate fan motors according to the manufacturer's instructions to prevent wear and tear and reduce the likelihood of breakdowns.

Paddling Solo: Four-Person Boat Challenge

You may want to see also

Assess your air paths to ensure they are free and clear for efficient air circulation

Keeping a boat's engine room cool is very important. When things get too hot, wear and deterioration accelerate, including wear on any people who need to spend time in there. Spending any length of time in a 130-degree space is not just uncomfortable, it's dangerous.

To cool the engine room, you need to ensure there is efficient air circulation. Air is very lazy, and just having appropriately-sized in and out vents won't necessarily get the best results. You need to ensure your air paths are free and clear, which will allow the air to circulate efficiently.

- Check for any blockages or restrictions in the air paths. This includes the ducts, hoses, and vents. Make sure there is nothing obstructing the airflow, such as debris, dust, or grease.

- Ensure the ducts and hoses are the appropriate size for the amount of air you need to move. Too narrow ducts or hoses can restrict airflow and create back pressure, reducing the overall efficiency of the cooling system.

- Check for any leaks or damage in the ducts, hoses, or vents. Leaks can allow hot air to escape and reduce the overall effectiveness of the cooling system.

- Ensure the positioning of intake and outlet air vents is correct. The vents should be placed to ensure that the air is turning over and not just recirculating hot air. The path of the air over the equipment is crucial to ensuring that the ambient air is regularly changed.

- Consider the placement of fans. Fans can be used to increase air movement and create directional airflow. Ensure they are positioned correctly to maximise their effectiveness.

- Consult a specialist. A qualified engine technician or marine airflow specialist can assess your engine room and provide recommendations to improve airflow and cooling.

By following these tips, you can help ensure that your boat's engine room remains cool and efficient, creating a more pleasant and safer environment for both the engines and any people who may need to work in that space.

Tracker Boats: Saltwater and Offshore Performance Reviewed

You may want to see also

Position intake and outlet air vents correctly to ensure air is turning over and not recirculating hot air

The positioning of your ventilation is critical to its success. Correct placement of both air in and air out grilles will ensure that the air is actually turning over and not just recirculating hot air. The path of the air over your equipment is also crucial in ensuring that the ambient air is regularly changed.

Ideally, fresh cool air is supplied low into the engine room (ER) either via ducts or the use of supply air fans discharging the air towards the keel and under the engine sump. Hot air should be exited out high and as far opposite the intake as is practical.

In a passive ventilation system, the engines, which are powerful air pumps, create enough suction to pull air in from both the intake and exhaust vents. If yours can't, and there's nothing obviously wrong (e.g. damaged ducting, clogged louvers or screens), your ventilation system needs help.

One way to test your boat and see if there's enough air getting to your motors is to check that your engines are getting enough air by running wide open for a few minutes, keeping an eye on the tach. If you have a genset, start it too. Give the engines time to inhale the air that's already in the engine room; sometimes, the revs start to fall as the air is used up. Then open the engine room hatch or door; if the revs go up, you need more airflow. If the suction from the gasping engines makes it hard to open the door, you really need more airflow.

Another way to test is to use thermometers. Mount one in the engine room and one someplace on deck, in the shade, to read the ambient outside temperature. Again, if you have a genset, start it. Now, after running the boat long enough and fast enough for things to get good and hot in the engine room, compare the thermometers: if the maximum engine room temp is more than 30 degrees higher than the ambient temp, or if it exceeds 120 degrees, you need more airflow.

If you find that you have airflow issues, you can either install bigger vents, or more of them, to maintain passive ventilation; or add exhaust and/or intake blowers to create a powered ventilation system.

Exhaust blowers increase airflow by creating negative pressure that draws in cool air through the passive intake vents, pulling it through the engine room and ejecting it, along with the heat it picked up along the way. For cooling, the exhaust fans should be mounted high in the engine room, where the hot air gathers naturally, and as far as possible from the intake ducting, which should introduce fresh air lower down in the space.

If you are installing intake blowers, they should be slightly less powerful than the exhaust blowers to maintain the negative pressure.

Unturned: Choosing the Best Boat for Your Needs

You may want to see also

Get a qualified assessment to ensure your engine room is operating within the correct temperature range

Getting a qualified assessment of your engine room is a crucial step in ensuring optimal performance and preventing potential issues. Here are some detailed instructions to help you get a qualified assessment and maintain the correct temperature range in your boat's engine room:

- Recognise the Importance: The engine room is a significant investment, housing critical equipment that manufacturers frequently monitor via constant data logging. A qualified assessment can help identify any potential issues and ensure your engine room operates within the correct temperature range.

- Find a Specialist: Engage the services of a specialist with experience in marine engine rooms. They can visit your site or conduct an assessment remotely through a brief interview and calculations.

- Provide Necessary Information: Be prepared to provide relevant information about your boat, such as engine specifications, existing ventilation system, and any issues you've noticed. This will help the specialist tailor their assessment to your specific needs.

- Conduct a Thorough Inspection: The specialist should conduct a comprehensive inspection of your engine room. This includes measuring temperatures at various points, assessing airflow and ventilation, and evaluating the condition of critical components like hoses, insulation, electrical systems, and more.

- Identify Problem Areas: Based on the inspection, the specialist can identify any areas of concern. This may include high engine room temperatures, inadequate ventilation, or deteriorating components susceptible to heat damage.

- Recommendations and Solutions: The specialist will provide recommendations to address any issues identified. This could involve adjustments to your ventilation system, adding or relocating fans, improving airflow paths, or addressing specific components that require maintenance or replacement.

- Implement Suggested Changes: Work with the specialist or a qualified technician to implement the suggested changes. This may involve repairs, upgrades, or modifications to your engine room setup.

- Monitor and Maintain: After making any necessary changes, continue to monitor the engine room temperature and overall performance. Regular maintenance and periodic assessments will help ensure your engine room operates efficiently and within the correct temperature range.

By following these steps and working with qualified professionals, you can be confident that your boat's engine room is operating optimally and within the manufacturer's recommended temperature guidelines.

Fixing Navigation Lights: A Boat Owner's Guide to Repair

You may want to see also

Install exhaust blowers to create negative pressure and draw in cool air through the passive intake vents

Installing exhaust blowers is a great way to cool your boat's engine room. Here's a detailed guide on how to do it:

Understand the Importance of Engine Ventilation:

The engine room of your boat needs adequate ventilation to ensure the engine's performance and longevity. Proper ventilation supplies fresh air for combustion and helps maintain a cool temperature. Without enough ventilation, the engine can overheat, leading to reduced performance and even damage over time.

Assess Your Engine's Air Requirements:

Determine the amount of airflow your engine needs. This can be tricky, as it depends on the engine's efficiency, turbochargers, and electronic ignition-controlled systems. Yacht designer Dave Gerr offers a formula: CFM (cubic feet per minute) = 2.75 x Horsepower - 90. Alternatively, some experts suggest multiplying horsepower by 2.5.

Choose the Right Exhaust Blowers:

Select exhaust blowers that match your engine's airflow requirements. Exhaust blowers are typically mounted high in the engine room to draw out hot air. Make sure to choose heavy-duty blowers designed for continuous operation, such as centrifugal or "squirrel cage" blowers.

Install the Exhaust Blowers:

Position the exhaust blowers in the engine room, ensuring they are mounted high and away from the intake ducting. The blowers should be wired to start and stop automatically with the engine, with a time-delay relay to keep them running for about 15 minutes after engine shutdown to aid in cooling. Consider consulting a qualified marine electrician for installation.

Create Negative Pressure:

By creating negative pressure in the engine room, you can draw in cool air through the passive intake vents. To achieve this, ensure that the exhaust blowers are slightly more powerful than any intake blowers you have installed. This pressure differential will pull cool air in through the intake vents and push it out through the exhaust blowers, creating a continuous airflow.

Maintain Airflow and Prevent Obstructions:

Ensure that your intake and outlet vents are positioned correctly and free from obstructions. Proper placement of vents will ensure that air is circulated efficiently and not just recirculating hot air. Regularly check for any blockages, such as clogged louvers or screens, which can hinder airflow and affect cooling performance.

Consider Additional Measures:

While exhaust blowers are essential, you can also implement other strategies to enhance cooling. These may include adding engine room fans for targeted cooling, assessing and optimising air paths, and positioning intake and outlet vents to promote efficient airflow and prevent recirculation of hot air.

By following these steps, you can effectively cool your boat's engine room by installing exhaust blowers to create negative pressure and draw in cool air through the passive intake vents. Remember to consult a professional if you have any doubts or concerns during the installation process.

Assessing Seaworthiness: What Makes a Boat Safe?

You may want to see also

Frequently asked questions

There are a few indicators that your boat engine is overheating. The temperature gauge on your dashboard will go into the red, the engine may feel like it's losing power, the engine may not start again until it has cooled down, and there may be an unusually large amount of steam coming from the exhaust.

If you are far from a marina, you will need to cool the engine down before getting the boat to a mechanic. You can try the following:

- Check for blockages in the raw water strainer and "thru hulls".

- Check the coolant level.

- Lighten the boat's load by dumping ballast water or a beer cooler.

- Open the engine compartment to increase airflow.

- Run the blowers to remove hot air from the engine compartment.

To prevent your boat engine from overheating, you should perform regular maintenance on your cooling systems. This includes flushing the systems, checking hoses and fittings for leaks, tightening or replacing clamps, and replacing the impeller every 2-3 years.

To cool a boat engine room, you can increase airflow by adding engine room fans, assessing your air paths to ensure they are free and clear, and positioning your intake and outlet air vents correctly. You can also get a qualified assessment from a specialist who can advise on reducing operating costs and improving efficiency.