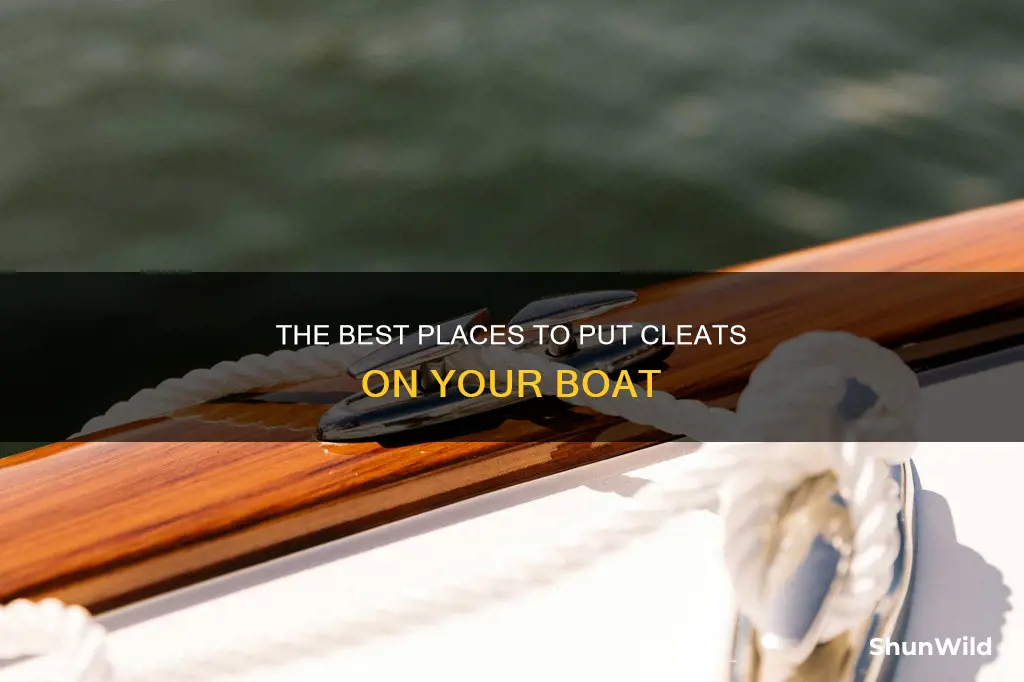

Boat cleats are essential for tying up your boat securely. The number of cleats you can install depends on the size of your boat, but as a minimum, you should have three per side: stern, amidships (for spring lines), and bow. When deciding where to put cleats on your boat, it's important to consider the purpose of the cleat and the load it will need to bear. For example, a small wooden cleat may be aesthetically pleasing, but it will only be suitable for hanging a fender from, whereas a sturdy steel cleat with a backing plate would be more appropriate for main bow or stern dock lines.

What You'll Learn

Stern cleats

When considering where to place stern cleats on your boat, it's important to follow some basic guidelines. Firstly, cleats should be placed at regular intervals along the port and starboard sides of your boat. As a minimum, you should have three cleats per side: one at the stern, one amidships (for spring lines), and one at the bow. However, it's always better to have more cleats, as they provide additional security and versatility when docking your boat.

The size of the cleat you choose depends on the size of the line you use, and the size of the line depends on the size of your boat. A good rule of thumb is that the cleat length from tip to tip should be 1" for every 1/16" of line diameter. For example, if your boat is 40' in length, you would need 1/2" dock lines, which means your cleats need to be at least 8" long.

When installing stern cleats, it's important to use the proper hardware and techniques to ensure a secure mounting. This may include using backing plates, through bolts, washers, and nuts. It's also crucial to consider the material of the cleats, choosing ones that are strong enough for the job, such as stainless steel, which is both sturdy and aesthetically pleasing.

By following these guidelines and best practices, you can ensure that your stern cleats are properly placed and installed, providing a safe and secure mooring experience for your boat.

The Time Bandit Boat's Fate and Final Journey

You may want to see also

Amidships cleats

When choosing amidships cleats, consider the material and size. The material depends on the purpose of the cleat. For example, a small wooden cleat may look nice and be suitable for hanging a fender, while a sturdy steel cleat with a backing plate would be more appropriate for main bow or stern dock lines. The size of the cleat depends on the size of the line and the boat. As a general rule, the cleat length from tip to tip should be 1" for every 1/16" of line diameter, and dock lines should be 1/8" in diameter for every 9 feet of boat length. For a 40-foot boat, you would need 1/2" dock lines and 8" long cleats.

When installing amidships cleats, it is important to use backing plates, stainless hardware, locking nuts, washers, and bedding compound or marine caulk. If your deck is cored, you should also seal the exposed wood after drilling holes.

Exploring Vice City: Mastering Boat Driving

You may want to see also

Bow cleats

Placement and Installation:

- The placement of bow cleats is crucial. Ideally, they should be installed as close to the bow and the centreline as possible. This positioning ensures that your boat faces directly into wind and wave action when anchored.

- When installing bow cleats, always use backing plates, stainless hardware, locking nuts, washers, and bedding compound or marine caulk. If your boat has a cored deck, consider sealing the exposed wood after drilling to prevent water intrusion.

- The size of the cleat you need depends on the size of the boat and the diameter of the dock lines. As a rule of thumb, the cleat length from tip to tip should be 1" for every 1/16" of line diameter. For example, a 40' boat would require 1/2" dock lines and 8" long cleats.

- Consider installing additional cleats along the port and starboard sides of your boat. At a minimum, you should have three cleats per side: one at the stern, one amidships (for spring lines), and one at the bow. More cleats provide more mooring options.

Tying Up and Docking:

- When tying up to a cleat, use a cleat hitch. Start by wrapping the dock line around the farthest cleat horn and then the closest horn. Then, cross over the cleat and begin a figure-8 motion.

- After making the first cross, continue with the figure-8 motion and then make a half-hitch to secure the cleat.

- To avoid trip hazards and tangles, ensure that any remaining length of line is "flemished" neatly.

- When docking, avoid using only the bow cleat as it can pull the stern against a forward fender. Amidship cleats are ideal for spring lines and manoeuvring the boat around the dock.

- Consider using pop-up, pull-up, or flip-up cleats for convenience and to prevent tripping or placing a foot on them. These types of cleats can be retracted when not in use.

Choosing the Right Color for Your 14-Foot Rowboat

You may want to see also

Cleat materials

When choosing the material for your boat cleats, it is important to consider the purpose of the cleat. A small wooden cleat may be aesthetically pleasing as an accent, but it would likely only be suitable for hanging a fender from. A sturdy steel cleat with a backing plate, on the other hand, would be ideal for main bow or stern dock lines.

Boat cleats come in a variety of materials, including stainless steel, bronze, brass, zinc, aluminium, nylon, and various alloys. Stainless steel is a popular choice due to its strength and corrosion resistance, making it suitable for saltwater environments. Bronze, aluminium, and marinium (a magnesium-aluminium-titanium-beryllium alloy) also offer excellent tensile strength, with marinium providing a higher strength-to-weight ratio than aluminium.

For mooring, docking, and other applications that require the security of your boat, it is recommended to use stronger metals such as stainless steel, bronze, aluminium, or marinium. Zinc and nylon cleats are less expensive and suitable for small boat rigging, flags, and other low-load applications.

When selecting cleat materials, consider the following:

- Size: As a general guideline, it is recommended to have 1" of cleat length for every 1/16" of rope diameter.

- Strength: Choose cleats that can withstand the load they will be subjected to, especially in tough weather conditions.

- Corrosion resistance: In saltwater environments, opt for materials with excellent corrosion resistance, such as stainless steel.

- Design: Consider the design of the feet and ensure they have a large surface area relative to the size of the cleat. This is critical to the overall strength of the cleat assembly.

Boat Registration Numbers: Placement Guide for Washington State

You may want to see also

Cleat types

There are many different types of boat cleats, each with its own distinct advantages and disadvantages. The type of cleat you choose will depend on the purpose it will serve and the specific needs of your boat. Here are some of the most common types of boat cleats:

- Standard Fixed Cleats: These are the traditional, surface-mounted cleats that have been used on most powerboats for decades. They are inexpensive, require no cutouts or large holes for mounting, are completely waterproof, and have no moving parts that can fail. However, they can be toe-stubbers and tend to snag fishing lines, nets, and swimsuits.

- Pull-Up Cleats: These cleats can be manually pushed down into their bases when not in use and pulled up when needed. Most are surface-mounted, meaning the body of the cleat sits above the mounting surface. They are rounded and smooth to prevent snagging when not in use but still protrude more than flush-mounted cleats. Pull-up cleats require access to the back of the mounting surface for installation.

- Pop-Up Cleats: These are similar to pull-up cleats but have the added feature of a spring that pops the cleat up at the push of a button. Pop-up cleats are typically flush-mounted, resulting in a lower profile than surface-mounted cleats. They can be installed without access to the back of the mounting surface using special backing plates. However, they have more moving parts than pull-up cleats, can be noisy, and may occasionally stick, especially when sandy.

- Flush-Mount Cleats: These cleats are recessed into the mounting surface, resulting in an even lower profile than pop-up cleats. They are ideal for areas where people stand or walk, such as casting decks. However, they require relatively large cutouts in the mounting surface for installation.

- Folding Cleats: These cleats hinge down flat when not in use and are manually or spring-loaded to flip up when needed. When folded, they protrude about the same distance above the mounting surface as pull-up cleats. Folding cleats are fully waterproof and only require holes for fasteners, but they have larger footprints than pull-up or pop-up cleats and usually require access to the back of the mounting surface for installation.

- Horn Cleats: These are the basic, traditional cleats found on most boats and docks. They typically have two "horns" extending out from one or two fixed "legs" that are fastened to the deck or dock. Horn cleats can be made from a variety of materials, including wood, iron, brass, bronze, stainless steel, and more.

- S-Shape Cleats: These cleats have a unique design that prevents lines from slipping off, providing an additional layer of safety.

When choosing a cleat type, it's important to consider the material as well. Common materials include galvanized steel, nylon, and aluminum. Galvanized steel is cost-effective and corrosion-resistant, making it suitable for both fresh and saltwater setups. Nylon is lightweight, durable, and highly resistant to corrosion, making it ideal for small to medium-sized boats. Aluminum is lightweight, durable, and corrosion-resistant, making it a popular choice for freshwater environments.

Where to Buy the Pelican Bass Raider Boat

You may want to see also

Frequently asked questions

Place cleats at regular intervals along the port and starboard of your boat. At a minimum, use three per side: stern, amidships (for spring lines), and bow. The more cleats you can reasonably install, the better.

The absolute best way is to back plate them, assuming you have adequate access. If you can't use a backing plate, use through bolts, washers, and nylock nuts with the largest washers that will fit.

Do not use screws. Use stainless steel or bronze bolts, with stainless washers and nylock nuts. If possible, use a large piece of plywood as a backer to cover all the mounting holes.

Boat cleats are commonly made from wood, nylon, galvanized steel, stainless steel, and aluminum. Stainless steel offers superior corrosion resistance, durability, and longevity.

The size of the cleat you choose should correspond to the type of line you use to tie your boat up. The general rule of thumb is that the length of the cleat should be one inch for every sixteenth of an inch of line.