When it comes to installing a boat engine, one crucial aspect is understanding where the engine plug should be positioned. This component, often referred to as the exhaust or plug, plays a vital role in directing engine exhaust away from the boat and ensuring optimal performance. The placement of the engine plug is essential for maintaining the boat's efficiency, safety, and overall functionality. In this discussion, we will explore the various considerations and techniques involved in determining the ideal location for the engine plug, ensuring a smooth and efficient boating experience.

| Characteristics | Values |

|---|---|

| Location | The boat engine plug, also known as the engine mount or engine bracket, is typically attached to the engine block and secured to the hull or frame of the boat. It provides a stable and secure mounting point for the engine. |

| Purpose | The plug serves to anchor the engine, ensuring it is firmly in place and reducing vibration and movement during operation. It also helps to distribute the engine's weight evenly, preventing excessive stress on the boat's structure. |

| Design | Engine plugs can vary in design depending on the boat model and engine type. They often feature a sturdy metal construction with a threaded or bolted connection to the engine and a flat or curved surface to attach to the boat's frame. |

| Installation | Installation involves attaching the engine plug to the engine block using appropriate fasteners, then securing it to the boat's hull or frame using additional hardware. This process requires precise alignment and tightening to ensure a secure fit. |

| Maintenance | Regular inspection and tightening of the engine plug's fasteners are essential to maintain a secure installation. Over time, corrosion or wear may require replacement or repair. |

What You'll Learn

- Engine Placement: Identify the correct location for the engine plug on your boat

- Engine Mounting: Understand how to securely mount the engine to the boat

- Plug Access: Ensure easy access to the plug for maintenance and repairs

- Wiring Connections: Learn the wiring process for connecting the engine to the boat's electrical system

- Fuel System: Familiarize yourself with the fuel system and its connection to the engine plug

Engine Placement: Identify the correct location for the engine plug on your boat

The engine plug, also known as the exhaust outlet, is a critical component of a boat's engine system. Its primary function is to safely release exhaust gases from the engine to the atmosphere. Proper placement of the engine plug is essential for efficient engine performance, safety, and compliance with marine regulations. Here's a guide to help you identify the correct location for the engine plug on your boat:

Understanding Engine Placement:

The engine plug is typically located at the rear of the boat, near the stern. This position allows for the natural flow of exhaust gases out of the boat's hull. When the engine is running, the exhaust gases are directed through the exhaust manifold, which routes them to the engine plug. It is crucial to ensure that the engine plug is not obstructed by any boat components or structures.

Checking the Engine Manual:

The best starting point for determining the engine plug's location is the boat's engine manual. This manual, often provided by the manufacturer, contains detailed diagrams and specifications for your specific engine model. Look for illustrations that show the exhaust system, including the engine plug's position. The manual will also provide instructions on how to access and inspect the engine plug.

Inspecting the Engine Compartment:

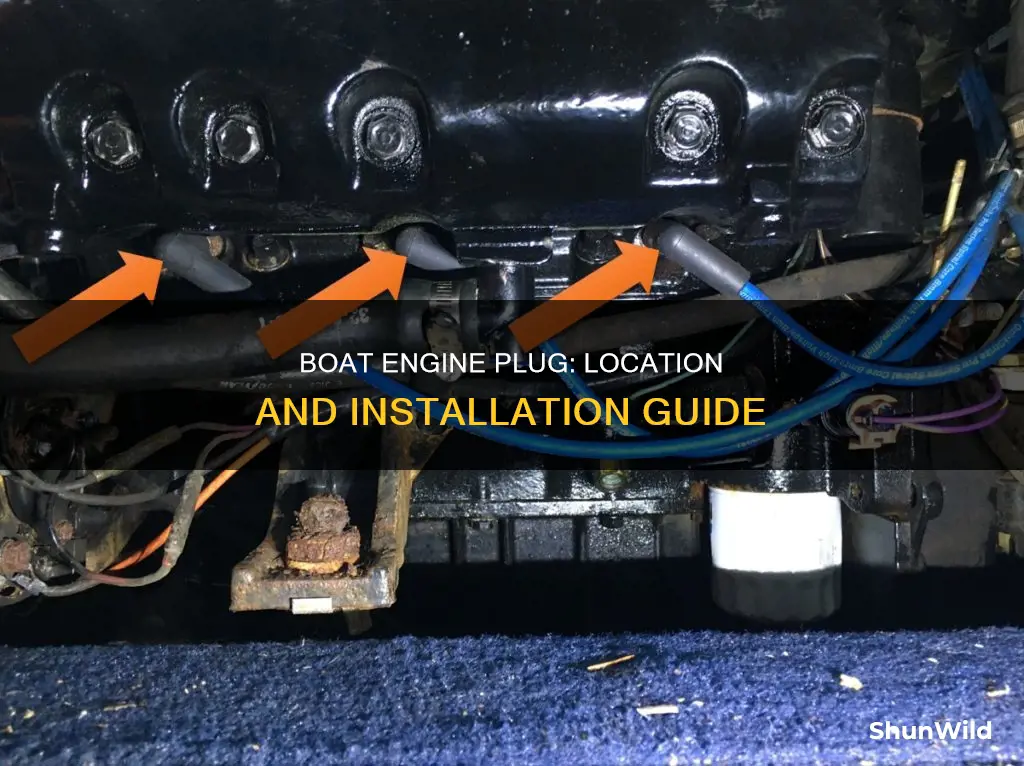

If you don't have access to the engine manual, physically inspect the engine compartment. Locate the exhaust manifold, which is usually a metal pipe or assembly connected to the engine's cylinders. Follow the exhaust manifold's path until you reach the engine plug. It is often a cylindrical or conical-shaped component with a small opening at the bottom. Ensure that the plug is securely attached and not damaged.

Considering Engine Type and Design:

Different boat engine types and designs may vary in engine plug placement. Inboard engines, where the engine is mounted inside the boat's hull, typically have the engine plug located near the stern. Outboard engines, on the other hand, may have the plug positioned at the bottom of the engine mount, allowing for easier access during maintenance. Understanding the specific design of your boat's engine will help you identify the correct location.

Regular Maintenance and Inspection:

Regularly inspecting the engine plug is essential for maintaining your boat's performance and safety. Over time, the plug may become clogged with carbon deposits or debris, requiring cleaning or replacement. Check for any signs of damage, corrosion, or blockages that could affect exhaust flow. Proper maintenance ensures that the engine plug functions optimally, preventing potential issues related to engine performance and emissions.

Firming Up Your Boat: Fixing Soft Spots in Center Consoles

You may want to see also

Engine Mounting: Understand how to securely mount the engine to the boat

Engine mounting is a critical aspect of boat construction, ensuring the engine is securely and safely installed to withstand the rigors of marine environments. The process involves several steps to guarantee optimal performance and longevity of the engine and the boat itself. Here's a comprehensive guide to understanding and executing engine mounting:

Preparation and Planning: Before beginning the mounting process, it's essential to have a well-thought-out plan. Start by studying the manufacturer's guidelines for your specific engine model. These instructions will provide detailed specifications regarding the engine's dimensions, weight, and recommended mounting points. Understanding these details is crucial to ensure the engine is mounted correctly and securely. Additionally, consider the boat's design and available space. The engine must fit within the allocated area, allowing for proper ventilation and access for maintenance.

Choosing the Right Mounting Points: Engine mounting involves attaching the engine to the boat's structure using specialized brackets, frames, or plates. The chosen mounting points should be strategically placed to distribute the engine's weight evenly and provide stability. Typically, engines are mounted in the center or towards the rear of the boat for better balance. It's important to consider the boat's center of gravity and ensure that the engine's weight is not concentrated in a single area, which could lead to structural issues.

Engine Brackets and Frames: These components play a vital role in securing the engine to the boat. Engine brackets are typically made of sturdy materials like aluminum or stainless steel to withstand corrosion and provide excellent strength. They are designed to fit the engine's mounting holes and should be tightened securely to prevent any movement. Frames, on the other hand, are larger structures that provide additional support, especially for larger engines. They are often custom-made to fit the specific engine and boat dimensions.

Installation Process: Mounting the engine involves several steps. First, position the engine in the desired location, ensuring it aligns with the mounting points. Then, secure the engine using the appropriate brackets or frames, tightening the fasteners to the recommended torque specifications. It's crucial to check for any play or movement in the engine after installation. If there's any wiggle room, additional support or adjustments might be needed. Properly sealing the engine's mounting points with marine-grade gaskets or tape is essential to prevent water intrusion and corrosion.

Testing and Final Adjustments: After the engine is mounted, it's essential to test its stability and performance. Start the engine and check for any unusual noises or vibrations. Ensure that all fasteners are tight and secure. Make any necessary adjustments to the engine's position or the mounting system to optimize stability. Regularly inspecting the engine mountings and making minor adjustments over time can help maintain a secure and efficient setup.

By following these steps and paying close attention to detail, you can ensure that your boat's engine is securely mounted, providing reliable performance and a long-lasting relationship between the engine and the vessel. Remember, proper engine mounting is a key factor in the overall safety and functionality of your boat.

Troubleshooting: Why Your Boat Thruster Suddenly Stops Working

You may want to see also

Plug Access: Ensure easy access to the plug for maintenance and repairs

When it comes to boat engine maintenance, ensuring easy access to the plug is crucial for efficient repairs and regular upkeep. The boat engine plug, often referred to as the fuel or electrical plug, is a critical component that connects the engine to various systems on the vessel. Proper placement and accessibility of this plug are essential to prevent potential issues and ensure the boat's performance.

The location of the plug can vary depending on the boat's make and model, but it is typically positioned in a way that allows for convenient access during routine checks and repairs. It is usually mounted on the engine block or near the engine compartment, providing easy reach for technicians and boat owners. This strategic placement ensures that the plug is not obstructed by other components, making it readily accessible for maintenance tasks.

To ensure optimal access, it is recommended to follow these guidelines. Firstly, inspect the boat's engine bay regularly to identify the specific location of the plug. Look for any obstructions or modifications that might hinder access. If the plug is located in a hard-to-reach area, consider modifying the engine bay layout to provide better accessibility. This could involve adjusting the positioning of other components or adding a small access panel to provide a clear view and reach for the plug.

Secondly, when performing maintenance or repairs, ensure that the engine is properly secured and cooled before attempting to access the plug. This is essential for safety and to prevent any accidental damage to the engine or surrounding components. By taking the time to properly prepare the engine, you can minimize the risk of injury and ensure a smooth maintenance process.

Lastly, always refer to the boat's owner's manual or consult with a qualified marine technician to understand the specific requirements for your vessel. They can provide detailed instructions on the proper maintenance procedures, including access points and any unique considerations for your boat's engine plug. Following these guidelines will help ensure that your boat's engine plug remains accessible, allowing for efficient maintenance and minimizing potential downtime.

Understanding Porpoising in Bass Tracker Boats

You may want to see also

Wiring Connections: Learn the wiring process for connecting the engine to the boat's electrical system

When it comes to wiring the engine to your boat's electrical system, it's crucial to understand the process and ensure proper connections to avoid any issues. Here's a step-by-step guide to help you navigate the wiring connections:

Preparation and Safety: Before you begin, ensure you have the necessary tools and equipment, including wire connectors, heat shrink sleeves, and a multimeter for testing. Safety should always be a priority, so wear protective gear, and make sure the boat is securely anchored or on land.

Engine Wiring Diagram: Obtain a wiring diagram specific to your boat engine model. This diagram will provide a visual representation of the electrical connections, making it easier to understand the wiring process. Identify the engine's power terminals, which are typically located near the engine control unit (ECU) or the starter motor. These terminals will be connected to the boat's electrical system.

Connecting the Engine to the Boat's Electrical System: Start by locating the engine's power terminals and the corresponding wires in your boat's electrical system. The engine's wires will usually be thicker and more robust compared to the boat's wiring. Connect the positive terminal (often red) of the engine to the positive terminal of the boat's battery. Ensure a secure connection using the appropriate wire connectors. Then, connect the negative terminal (often black) of the engine to the negative terminal of the battery, again using the recommended connectors.

Grounding Connections: Proper grounding is essential for a reliable electrical system. Identify the engine's ground terminal, which is typically a bare copper wire. Connect this wire to a suitable ground point on the boat's hull or frame. Use a ground strap or a dedicated ground wire to ensure a solid connection.

Testing and Verification: After completing the wiring connections, it's crucial to test the system. Use a multimeter to check for continuity between the engine's power terminals and the corresponding boat wiring. Ensure that all connections are secure and free of corrosion. Verify that the engine starts when you engage the starter motor and that the electrical accessories function as expected.

Remember, wiring can be complex, and it's always recommended to consult a professional marine electrician or mechanic if you're unsure. They can provide expert guidance and ensure your boat's electrical system is safe and reliable.

Repairing Spider Web Cracks in Your Boat's Gelcoat

You may want to see also

Fuel System: Familiarize yourself with the fuel system and its connection to the engine plug

The fuel system is a critical component of any boat's engine, and understanding its intricacies is essential for any boat owner or enthusiast. When it comes to the engine plug, or the fuel intake, it is crucial to know its location and function within the fuel system. The engine plug is typically a small opening or port on the engine block, designed to allow fuel to enter the engine. This plug is an essential part of the fuel injection or carburetor system, depending on the boat's engine type.

In the context of the fuel system, the engine plug is connected to the fuel lines or hoses that carry the fuel from the fuel tank to the engine. These fuel lines are carefully routed to ensure a steady and controlled supply of fuel to the engine. The plug's position is strategically chosen to allow for efficient fuel delivery while minimizing the risk of contamination or fuel spillage. It is often located in a position that provides easy access for maintenance and fueling, ensuring convenience for boat operators.

Familiarizing yourself with the fuel system's layout will help you understand the path of the fuel from the tank to the engine. The system typically includes a fuel pump, which is responsible for creating the necessary pressure to move the fuel through the lines. The pump is usually located near the engine or in the fuel tank, depending on the boat's design. From the pump, fuel is directed to the engine plug, where it enters the combustion chamber, ready to be ignited.

It is important to note that the specific design and placement of the fuel system can vary between different boat models and engine types. Some boats may have a more complex fuel system with additional components, such as fuel filters, fuel pressure regulators, or electronic fuel injection systems. Understanding these variations will enable you to properly maintain and troubleshoot the fuel system, ensuring optimal performance and longevity of your boat's engine.

By taking the time to study the fuel system and its connection to the engine plug, you can become more confident in your boat's maintenance and operation. This knowledge will allow you to identify potential issues, such as clogged fuel lines or faulty pumps, and take appropriate action to keep your boat's engine running smoothly. Remember, a well-maintained fuel system is crucial for the overall performance and reliability of your boat's powerplant.

Baking Bread Aboard Old Sailboats: What's the Story?

You may want to see also

Frequently asked questions

The engine plug, also known as the fuel line plug or intake fitting, is typically found on the side or bottom of the boat engine. It is a small opening or port where the fuel line connects to the engine's carburetor or fuel injection system. This plug is crucial for ensuring the engine receives the correct fuel-air mixture for optimal performance.

Attaching the engine plug involves a few steps. First, locate the fuel line and ensure it is clean and free of any debris. Then, insert the fuel line into the engine plug, making sure it is aligned correctly. Tighten the plug securely using the appropriate tool, being careful not to overtighten to avoid damage. Finally, check for any leaks around the connection and ensure the engine is running smoothly before taking it out on the water.

If you notice that the engine plug is loose, it's essential to address the issue promptly. Start by disconnecting the fuel line and inspecting the plug for any signs of damage or wear. If the plug is damaged, it may need to be replaced. Ensure you have the necessary tools and spare parts before attempting any repairs. When reinstalling, follow the same procedure as described in the previous answer, tightening the plug securely and checking for leaks. Regular maintenance and inspections can help prevent such issues and ensure your boat's engine runs efficiently.