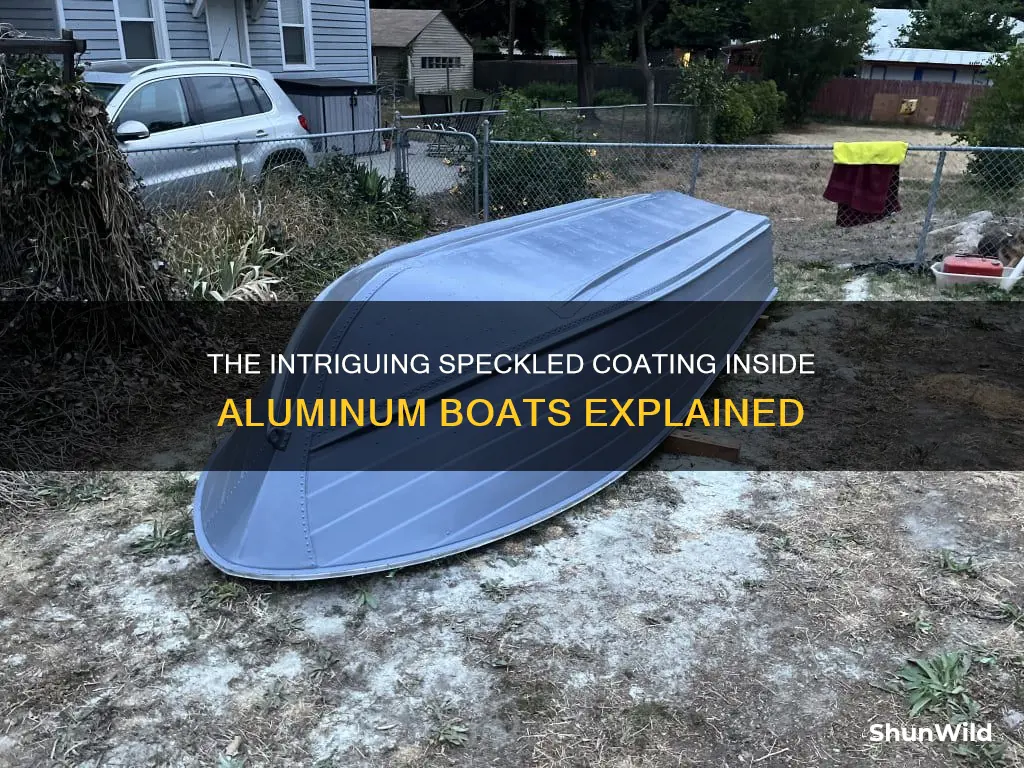

Aluminum boats are often coated with epoxy barrier paint to prevent corrosion and provide a superior adhesion for antifouling and other paints. This type of coating is designed to protect the boat from the elements and improve its performance. The speckled coating inside an aluminum boat is likely a textured coating, which can be touched up with spray cans of Zolotone or powder coating.

What You'll Learn

The speckled coating is likely to be Zolotone

The speckled coating inside an aluminium boat is likely to be Zolotone. Zolotone is a type of epoxy coating that is applied to aluminium boats to provide a textured, speckled finish. It is often used as a touch-up solution for areas where the original coating has worn away or been scraped off.

Zolotone can be purchased from industrial paint supply stores and is available in spray cans, making it convenient for small touch-up jobs. It is important to note that the newer Zolotone formulations are different from the original version, as they are epoxy-based and offer improved wear resistance.

When applying Zolotone or any other coating to an aluminium boat, proper surface preparation is critical. The aluminium surface must be clean, bright, and free of oxidation and contaminants. Etching the surface is also recommended to ensure better adhesion of the coating.

In addition to Zolotone, there are other coating options available for aluminium boats, such as epoxy barrier coats and clear coats. Epoxy barrier coats, like the TotalBoat Aluminum Boat Barrier Coat, provide corrosion protection and can be used above and below the waterline. Clear coats, such as Alumetron, can be applied over paint or raw aluminium to provide additional protection and enhance the finish.

It is always recommended to follow the manufacturer's instructions and guidelines when applying any type of coating to an aluminium boat to ensure optimal results and longevity.

Exploring Mackinac Island: Boat Trip from Mackinaw City

You may want to see also

Zolotone is an epoxy-type coating

To apply Zolotone, you will need to use a special spray gun with low pressure (50 psi max). The surface should be cleaned, degreased, and scuffed with a Scotch-Brite pad or something similar to give the coating something to stick to. Several passes may be needed to ensure full coverage, as the coating spits and spatters out of the gun.

Zolotone is typically applied in a three-coat process: a primer, a solid coat of Zolotone, and a final coat of Zolotone applied at low pressure with an internal mix tip. It is important to note that Zolotone should not be applied over any 1-part finish. The surface should be wiped down with a degreaser, sanded, and cleaned again.

Zolotone can be purchased from most automotive paint stores or jobbers.

Raising Boat Seats: Easy Adjustments for Better Comfort and Control

You may want to see also

You can buy Zolotone in spray cans

The speckled coating inside an aluminium boat is likely an epoxy primer. This type of primer provides exceptional corrosion protection on aluminium boats, pontoons, and underwater metals. It is applied after the surface has been etched and prepared, and it serves as a base for the paint to adhere to.

You can buy Zolatone in spray cans, and it is a unique product that offers excellent hiding ability for stains and scuff resistance. It can be applied to almost any substrate, which makes it a popular choice for many commercial painting projects. Zolatone is commonly used for boat interiors, truck beds, and automotive compartments. It is known for its flecked texture and appearance and is considered one of the most durable finishes available.

When applying Zolatone, it is important to mix the colours by hand agitation rather than using a mechanical or pneumatically operated agitator. The surface also requires a white primer before applying Zolatone. Additionally, Zolatone is typically not thinned and is sprayed in a way that creates a slightly splattered finish.

Zolatone is often applied using an internal mix 2100 spray gun by Binks, which uses a paint pressure pot that is ASME-rated. This setup allows for high fluid and air pressures, ensuring a good spray. A compressor is also necessary, with a capacity of at least 7 CFM but preferably 20 CFM for ideal results.

The process of spraying Zolatone is unique. The first coat is applied lightly and held further back from the surface than typical coatings, at about 12 inches. This initial coat has smaller particles and serves as a base for adhesion. The second coat is thicker and is applied at an even greater distance from the surface, about 2 feet. It is important to wait for the first coat to dry before applying the second one. For the final coat, less air pressure is used compared to the initial coat to avoid breaking the paint particles.

Hudson Yang's Departure from Fresh Off the Boat?

You may want to see also

You can also mix powder with methylethylketone to dab or brush on

The speckled coating inside an aluminium boat is likely to be a powder coating. This is a type of coating that is easy to clean and provides corrosion protection.

If the powder coating is damaged, it can be touched up by mixing powder with methylethylketone (MEK) to dab or brush onto the affected area. MEK is a highly volatile and toxic substance, so it should be handled with care. It is also flammable, so should not be heated or exposed to flames.

To repair a powder coating with MEK, first, scuff and clean the area to be treated. Then, mix a small amount of powder with MEK to create a paste with a similar consistency to model paint. Apply this paste to the affected area with a brush or spreader. Once cured, any lumps can be sanded down and the area can be waxed or sealed with a very low-viscosity powder/MEK mix.

MEK is a strong chemical that will cause the powder to chemically bond with the original coating. This method is not as durable as a full powder coating, but it is a good option for repairing small dings and scratches without needing to strip and re-coat the entire area.

Repairing a Boat Skeg: A Step-by-Step Guide to Fix Yours

You may want to see also

For a speckled coating, you can also dab on multiple colours

The speckled coating inside an aluminium boat is likely to be a powder coating. Powder coating is an efficient finishing process that can produce results that standard paint cannot achieve. To create a speckled finish, you can dab on multiple colours by blending the individual colours directly. This will give you a unique speckled finish that is different from what you would get by mixing liquid paints.

There are several ways to create a speckled finish with multiple colours. One way is to physically blend two or more powder colours to create a speckled finish. For example, you can mix orange, medium brown and dark brown to simulate a rust patina. You can also mix a light teal green with black to create a weathered copper look.

Another technique is to apply dry powder in one colour onto part of your target and then cover the rest of it with another colour. This will create a gradient effect at the intersection of the two colours. You can also try spraying multiple dry layers of light and dark brown powders and then 'combing' the finish to simulate a wood grain effect.

If you want to add some shine to your speckled finish, you can mix in metallic or pearlescent pigments. The simplest technique is to blend an already-made powder coating with a metallic pigment. You can use aluminium, bronze or stainless steel pigments to create fascinating effects.

For a truly unique finish, you can add holographic effects by incorporating microscopic flakes that possess a prismatic effect. These flakes are rather expensive but will produce a rainbow of colours as you change your viewing angle. Keep in mind that multi-colour powder coating can be challenging and may require a lot of time and experience to get right.

Connecting Power to Fishfinders: Stratos Bass Boat Guide

You may want to see also

Frequently asked questions

The speckled coating inside an aluminum boat could be Zolatone, an epoxy-type coating that is wear-resistant.

You can buy spray cans of Zolatone to touch up the interior coating of your aluminum boat.

Another option for coating the inside of an aluminum boat is to use a powder coat.