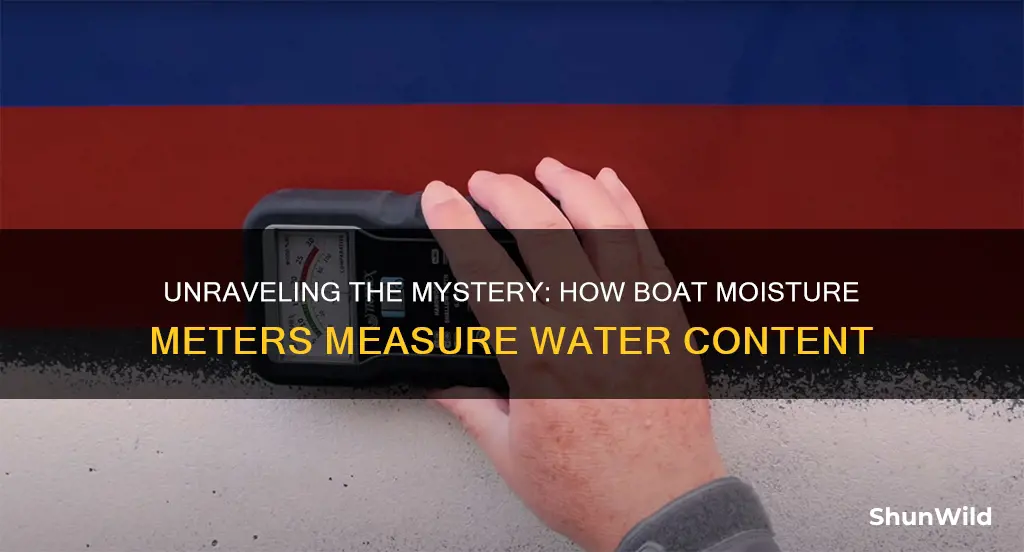

Boat moisture meters are essential tools for boaters and marine enthusiasts to ensure the safety and longevity of their vessels. These devices measure the moisture content in various materials, such as wood, upholstery, and electronics, which can help prevent water damage and mold growth. Understanding how these meters work is crucial for anyone looking to maintain a boat's interior and ensure a dry and safe environment. This paragraph will delve into the mechanics of boat moisture meters, explaining how they detect and quantify moisture levels, and why this knowledge is vital for boat owners.

What You'll Learn

- Principle: Boat moisture meters measure humidity by sensing changes in electrical conductivity or temperature

- Sensors: These devices use sensors like capacitive or resistive elements to detect moisture levels

- Calibration: Regular calibration ensures accurate readings by adjusting sensor responses

- Data Interpretation: Moisture meters interpret sensor data to provide humidity percentages or other relevant metrics

- Applications: They are used in marine environments to monitor boat interiors and ensure safety

Principle: Boat moisture meters measure humidity by sensing changes in electrical conductivity or temperature

Boat moisture meters are essential tools for marine enthusiasts and professionals, ensuring the comfort and safety of their vessels. These devices measure the humidity or moisture content in the air, providing valuable insights into the environment inside a boat. The principle behind these meters is a fascinating application of physics and engineering, utilizing two primary methods: electrical conductivity and temperature sensing.

The electrical conductivity method is based on the principle that moisture in the air is a conductor of electricity. When a boat's interior becomes humid, the water vapor in the air increases the electrical conductivity of the surrounding environment. Moisture meters designed for this purpose use a small electrical current to measure this conductivity. The meter contains two electrodes that are placed in the air, and the current is applied between them. As the humidity rises, the electrical resistance decreases, allowing for a more accurate measurement of moisture levels. This method is particularly useful for boats with enclosed spaces, where humidity can quickly become a concern.

On the other hand, temperature sensing meters operate on the idea that the presence of moisture in the air affects the temperature of a given space. When water vapor is introduced, it absorbs heat from the surrounding environment, leading to a slight decrease in temperature. These meters typically consist of a temperature sensor and a humidity sensor. The temperature sensor measures the ambient temperature, and the humidity sensor detects the moisture content. By analyzing the temperature changes, the meter can calculate the relative humidity. This technique is often employed in larger boats or those with more complex ventilation systems, where temperature variations can provide a more comprehensive understanding of the air's moisture content.

Both methods offer unique advantages and are chosen based on the specific requirements of the boat and its environment. Electrical conductivity meters are ideal for quick measurements and are often more affordable, making them a popular choice for general-purpose applications. Temperature sensing meters, while more complex, provide highly accurate results and are preferred in critical situations where precision is essential. Understanding these principles allows boat owners and operators to make informed decisions when selecting the appropriate moisture meter for their needs.

Boat Repair Experts in Acadiana: Who's the Best?

You may want to see also

Sensors: These devices use sensors like capacitive or resistive elements to detect moisture levels

Boat moisture meters are essential tools for boaters and marine enthusiasts, offering a means to monitor and manage the humidity levels within their vessels. These devices are particularly crucial for preventing mold growth, ensuring the longevity of materials, and maintaining a comfortable environment. At the heart of these moisture meters are sensors, which play a pivotal role in detecting and measuring moisture content.

Sensors in boat moisture meters typically employ two primary technologies: capacitive and resistive elements. Capacitive sensors operate based on the principle of capacitance, where two conductive plates are separated by a dielectric material. When moisture is present, it affects the dielectric, altering the capacitance. This change is then measured and converted into a readable moisture level. Capacitive sensors are known for their accuracy and ability to detect even small amounts of moisture.

Resistive sensors, on the other hand, work by measuring the resistance between two conductive materials. As moisture accumulates, it increases the conductivity between these materials, leading to a change in resistance. This change is then translated into a moisture reading. Resistive sensors are often more affordable and can provide quick responses, making them suitable for real-time monitoring.

The design of these sensors is crucial to their functionality. Capacitive sensors often consist of a pair of plates, one of which is permeable to moisture, allowing it to absorb water vapor. The other plate is typically non-permeable, ensuring that only the moisture in the air affects the measurement. Resistive sensors might feature a grid of conductive lines, with the moisture affecting the resistance between these lines.

In both cases, the sensors are connected to a display or indicator that translates the sensor readings into a moisture percentage or other relevant units. This allows users to quickly assess the moisture levels in their boats and take appropriate actions, such as dehumidifying or ventilating the space. Regular use of these moisture meters can help boaters maintain a healthy and safe environment, ensuring that their vessels remain in optimal condition.

Building a Paddle Boat: A Step-by-Step Guide

You may want to see also

Calibration: Regular calibration ensures accurate readings by adjusting sensor responses

Calibration is a critical process in ensuring the accuracy and reliability of boat moisture meters. It involves fine-tuning the device's sensors to provide precise moisture content readings. Regular calibration is essential because environmental factors and the natural degradation of sensors over time can affect the meter's performance. By calibrating the moisture meter, you can maintain its accuracy and ensure that the readings reflect the actual moisture levels in the boat's materials.

The calibration process typically involves a comparison between the moisture meter's readings and known, precise moisture content values. This is often done using calibration standards or reference materials with controlled moisture levels. For example, a calibration standard might be a piece of wood or fabric with a known moisture content, which is then measured by the boat moisture meter. By comparing the meter's reading to the known value, any discrepancies can be identified and adjusted.

During calibration, the sensor responses are adjusted to ensure they provide accurate measurements. This adjustment is made by altering the sensor's settings or parameters, such as sensitivity or response time. For instance, if the meter consistently reads higher moisture levels, the sensor's sensitivity might need to be reduced to account for any over-responsive behavior. Conversely, if readings are consistently lower, increasing sensitivity could be required. These adjustments are made carefully and precisely to avoid any further discrepancies.

It is recommended to calibrate boat moisture meters regularly, especially before and after extended periods of use or when there is a significant change in environmental conditions. Seasonal changes, for instance, can impact moisture levels, and thus, the meter's readings. By calibrating at these critical times, you can ensure that the device provides accurate and reliable data, which is crucial for proper boat maintenance and preservation.

In summary, regular calibration is a vital practice to maintain the accuracy of boat moisture meters. It involves adjusting sensor responses to match known moisture content values, ensuring that the device provides reliable and precise readings. By incorporating calibration into the maintenance routine, boat owners and professionals can effectively monitor and manage moisture levels, contributing to the overall health and longevity of the vessel.

Boat Trailers in Florida: Title Numbers and Registration

You may want to see also

Data Interpretation: Moisture meters interpret sensor data to provide humidity percentages or other relevant metrics

Moisture meters, also known as humidity meters, are essential tools for monitoring and managing the humidity levels in boats, especially those used for extended periods or in marine environments. These devices play a crucial role in ensuring the comfort and safety of passengers and crew, as well as the preservation of the boat's interior and exterior materials. The core functionality of a moisture meter lies in its ability to interpret sensor data and provide valuable insights into the humidity levels.

When a moisture meter is used, it employs various sensors to measure the moisture content in the air or on surfaces. These sensors can be of different types, such as capacitive, thermal, or resistive sensors, each with its own unique mechanism for detecting moisture. For instance, capacitive sensors use a capacitor to measure the change in electrical capacitance caused by moisture absorption, while thermal sensors rely on the principle that moisture absorbs heat, leading to a temperature change. The data collected by these sensors is then processed by the meter's internal system.

The interpretation of sensor data is a critical aspect of moisture meters. The device analyzes the measured values and converts them into meaningful information, typically in the form of humidity percentages. This interpretation process involves complex algorithms and calculations to ensure accurate and reliable results. Moisture meters often display the humidity level on a digital screen, making it easy for users to read and understand the current conditions.

In addition to humidity percentages, some advanced moisture meters can provide other relevant metrics. These may include temperature readings, which are essential for understanding the environmental conditions affecting moisture levels. By combining humidity and temperature data, these meters offer a comprehensive view of the boat's internal climate. Furthermore, some models can also display trends over time, allowing users to identify patterns and potential issues related to moisture accumulation or depletion.

The interpretation of sensor data is a dynamic process, as moisture levels can fluctuate due to various factors such as weather changes, ventilation, and the boat's occupancy. Moisture meters are designed to provide real-time updates, ensuring that users can make informed decisions to maintain optimal humidity conditions. Regular monitoring and interpretation of this data can help prevent issues like mold growth, wood rot, and corrosion, which are common problems in marine environments.

Exploring Beaufort by Boat: How Far Can You Go?

You may want to see also

Applications: They are used in marine environments to monitor boat interiors and ensure safety

Boat moisture meters are essential tools for marine enthusiasts and professionals alike, offering a means to monitor and manage the humidity levels within boat interiors. These devices play a critical role in ensuring the safety and longevity of boats, particularly in environments where moisture can be a hidden threat.

In marine settings, boat moisture meters are used to detect and measure the moisture content in various materials found inside boats, such as wood, upholstery, and electronic components. Over time, excess moisture can lead to a range of issues, including mold growth, corrosion of metal parts, and damage to electrical systems. By regularly monitoring humidity levels, boat owners and operators can take proactive measures to prevent these problems.

One of the primary applications of boat moisture meters is to identify areas of high humidity that may indicate potential issues. For example, if a boat's cabin has a consistently high moisture level, it could be a sign of a leaking roof, poor ventilation, or condensation from engine exhaust. By pinpointing these areas, boat owners can take immediate action to address the problem, such as repairing leaks or improving ventilation systems.

Additionally, boat moisture meters are valuable for ensuring the safety of electronic equipment. Marine electronics are particularly susceptible to moisture damage due to their exposure to the elements. By regularly checking the humidity levels around these devices, boat owners can ensure they remain in optimal condition. This is especially important for navigation systems, communication equipment, and any other technology that relies on a dry environment to function correctly and reliably.

In summary, boat moisture meters are indispensable tools for maintaining the integrity and safety of marine environments. They provide a means to actively manage humidity levels, preventing potential issues and ensuring that boat interiors remain in optimal condition. By incorporating these devices into regular maintenance routines, boat owners can protect their investments and ensure a safe and comfortable experience on the water.

Mastering the Art of Driving a Cobalt Boat

You may want to see also

Frequently asked questions

A boat moisture meter is a device used to measure and detect the moisture content in various materials, especially in boat interiors and hulls. It operates by emitting a small electrical signal that travels through the material being tested. The meter then analyzes the signal's reflection or absorption, which is influenced by the moisture levels. This data is then converted into a readable moisture percentage, allowing users to identify areas of high moisture content.

Boat moisture meters are essential tools for identifying hidden water damage, especially in areas that are difficult to access or see. When water enters a boat, it can cause structural issues and promote mold growth, which may not be immediately visible. These meters can detect moisture levels below the surface, helping boat owners and maintenance teams pinpoint the source of the issue. By identifying damp areas, users can take prompt action to prevent further damage and potential safety hazards.

Yes, there are various types of moisture meters designed for different applications. Some common types include pin-type meters, which use two metal pins to measure moisture, and pin-less meters, which employ electromagnetic fields to detect moisture. Pin-less meters are often preferred for larger areas or non-conductive materials. Additionally, there are handheld and fixed-mount meters, each with its own advantages depending on the specific needs of the boat owner or maintenance team.

Regular maintenance is crucial to ensure the longevity and safety of a boat. It is recommended to use a boat moisture meter at least once a month, especially after any water-related incidents or during periods of high humidity. For boats stored outdoors, more frequent checks might be necessary. By incorporating moisture meter usage into a routine maintenance schedule, boat owners can proactively identify and address potential issues, ensuring a dry and healthy environment for the vessel and its occupants.