Oxidation is a common issue for boats, especially those that are often exposed to water. It is a form of corrosion that occurs when a substance attempts to move into a stable state, causing it to lose electrons when it reacts with oxygen. This process can cause boats to lose their shine and appear dull, especially below the waterline. While oxidation on an aluminium boat is not typically structurally damaging, it can be unsightly and challenging to fix.

What You'll Learn

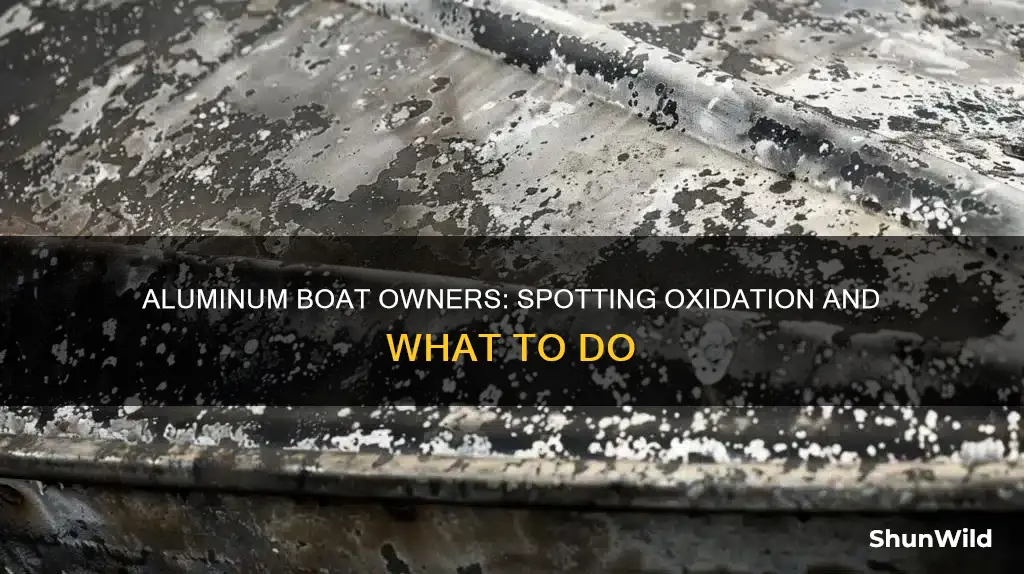

How to identify oxidation on an aluminium boat

Aluminium boats are susceptible to oxidation, which occurs when the metal reacts with oxygen molecules in the water. This process results in a chalky substance appearing on the surface of the boat, giving it a dull appearance. While oxidation on an aluminium boat is not typically structurally damaging, it can be unsightly and is something that boat owners may want to identify and address.

- Look for a chalky substance: Oxidation on aluminium often manifests as a chalky substance that coats the surface of the boat. This substance can be white, grey, or black and is usually dull in appearance.

- Check for a loss of shine: One of the most noticeable effects of oxidation is the loss of shine on the boat's exterior. If your aluminium boat appears dull, especially below the waterline, it may be due to oxidation.

- Inspect for pitting, flaking, or spalling: In some cases, aggressive and unchecked oxidation can lead to pitting, flaking, or spalling of the aluminium surface. This typically occurs when the oxidation process continues due to cracks or impurities in the metal.

- Examine for discolouration: Oxidation can cause discolouration on aluminium, turning it a metallic brown or green colour.

- Feel for a rough texture: Oxidation can give the aluminium surface a rough, chalky texture.

If you suspect your aluminium boat may be oxidised, there are products available specifically designed to remove oxidation and restore the metal's appearance. However, it is important to exercise caution when using these products, as some contain hydrofluoric acid, which can be dangerous if not handled properly. Regular cleaning and maintenance of your boat can also help reduce the effects of oxidation.

The Luxury Yacht 'Bad Company' and Its Owner

You may want to see also

How to clean oxidation from an aluminium boat

Aluminium boats are great because they are highly resistant to rust and are suitable for both salt and freshwater. However, oxidation is a common issue for aluminium boats. Oxidation occurs when a substance naturally attempts to move into a stable state, and in the process, it loses electrons when it reacts with oxygen. This process speeds up when the aluminium surface is exposed to water, and even faster when it is saltwater.

Oxidation will take away the shine from your boat's exterior, leaving it looking dull, especially below the waterline. Luckily, there are steps you can take to reduce and remove oxidation.

Firstly, it is important to clean your boat regularly. This will help reduce oxidation and prevent it from ruining the appearance of your boat. When cleaning your boat, it is best to do so on a day that is not too hot, as direct sunlight can cause the aluminium to become too hot to touch. Place the boat in a shady spot and give it an initial wash with soap and water to remove any loose dirt and debris.

Next, apply an aluminium boat cleaning solution. Most aluminium boat cleaning products are concentrates that must be diluted with water before application. Soak a scrubbing brush in the solution and scrub the aluminium surfaces, paying extra attention to any areas that didn't come clean during the initial wash.

Finally, buff the aluminium to restore its shine. You can do this by hand or with a buffing machine. If using a buffing cloth or pad, apply the aluminium polish and press it into the boat's surface, buffing in a circular pattern. If using a buffing machine, apply the polish to the pad while it is in motion, then press the pad into the aluminium and slowly move from side to side.

Some specific products that can be used include Star Brite Alum Cleaner and Restorer, 3M Alum Cleaner, and Star Brite Instant Hull Cleaner.

Boating Accident Report Requirements: When to File

You may want to see also

How to prevent oxidation on an aluminium boat

Aluminium boats are popular because they are extremely light yet durable, increasing their speed on the water and ability to be transported via trailer. Although they are corrosion-resistant, they are not entirely corrosion-proof, especially if a low-grade aluminium is used.

Oxidation is a form of corrosion that occurs when a substance naturally attempts to move into a stable state. As the substance changes, its characteristics also change. A substance loses electrons when it reacts with oxygen.

Aluminium boats are particularly susceptible to galvanic corrosion, which is more prevalent in saltwater. This is when a metal in an electrically conductive solution (such as saltwater) gives up atoms to a dissimilar metal in the same solution. When a metal loses atoms, it begins to fall apart or corrode.

- Regularly clean the entire boat, inside and out.

- Only use paint and coatings designed for use with aluminium.

- Always rinse the boat with freshwater after use, especially if it has been in saltwater.

- Do not exceed 1,300 millivolts of impressed voltage when protecting the aluminium.

- Repair cracks and scratches that expose the bare aluminium, as soon as possible.

- Do not use an automotive battery charger on the boat.

- Use sacrificial zinc anodes. As long as the anode is electrically connected to the aluminium part, either by direct contact or by wire, it stuffs the aluminium with excess electrons so it loses those rather than the aluminium giving up its own electrons.

- Use a copper-free, aluminium-compatible bottom paint for your aluminium boat.

- Avoid using any lubricant made with graphite.

- Employ an isolation transformer whenever the boat is connected to AC shore power.

- Use a floating boat lift to keep your boat out of the water when not in use.

Jump-Starting a Boat: A Step-by-Step Guide

You may want to see also

Types of oxidation that can occur on an aluminium boat

Aluminium boats are susceptible to oxidation, a form of corrosion that occurs when a substance attempts to move into a stable state by reacting with oxygen. This process causes the boat to lose its shine, leaving it with a dull appearance, especially below the waterline. While oxidation alone may not be structurally damaging, it can be unsightly and indicate the presence of other forms of corrosion that could be detrimental to the boat.

There are three types of oxidation that can occur on an aluminium boat:

Galvanic Corrosion

Galvanic corrosion occurs when two dissimilar metals come into contact with each other while immersed in an electrolyte, such as saltwater or impure water. The presence of saltwater facilitates the corrosion of metals by acting as an electrolyte. In galvanic corrosion, one metal becomes the anode (the less noble metal) and corrodes faster, while the other becomes the cathode and corrodes slower. This creates a galvanic response that can result in pitting, flaking, and spalling of the aluminium hull.

Electrolysis

Electrolysis is caused by the presence of potential current (AC or DC) between two different objects, often due to stray electrical current travelling through the water. It is an invisible force that can chew away at the boat's structure, causing corrosion. Electrolysis is particularly concerning for moored boats, as it can be influenced by the electrical systems of neighbouring vessels and the marina's electrical services. A well-maintained bonding system that meets ABYC standards can help protect against electrolysis.

Crevice Corrosion

Crevice corrosion occurs when moisture (electrolyte) is trapped in a crack, crevice, or any space that can trap and stagnate moisture. This type of corrosion can occur when contaminated water is trapped against the aluminium, such as under paint edges that were not properly prepped. It can also happen when there are crevices or joints in the boat's structure that collect and trap water. Crevice corrosion can cause extensive pitting and thinning of the aluminium hull, leading to significant repairs.

To summarise, the three types of oxidation that can occur on an aluminium boat are galvanic corrosion, electrolysis, and crevice corrosion. These processes can be controlled and largely prevented with proper understanding, safeguards, and regular maintenance.

Mastering the Art of Driving a Boat Sideways

You may want to see also

How to remove oxidation from an aluminium boat with home remedies

Oxidation on an aluminium boat will leave a chalky, dull substance on the exterior, particularly below the waterline. If you want to restore your boat's shine, there are several home remedies you can try to remove the oxidation. Here are some detailed instructions on how to do this:

Clean your boat regularly:

This is the simplest way to prevent oxidation. Make it a habit to clean the entire exterior and interior of your boat often. This will help reduce the build-up of oxidation and maintain the appearance of your boat.

Use anti-fouling paint:

Painting the bottom of your aluminium boat with anti-fouling paint can help protect it against oxidation and growth. This creates a barrier that prevents corrosion.

Try home remedies:

You can mix white vinegar and lemon juice in a 5-gallon container of warm water. This solution is highly acidic and will help remove oxidation. Alternatively, you can use a product like Simple Green, which is also effective in removing oxidation.

Use a scrub pad:

Spray an aluminium cleaner and restorer, such as Star Brite, onto the affected areas. Lightly scrub with a scrub pad and then hose off. This method is effective in removing oxidation and restoring the shine to your boat.

Buff and wax:

If you have a fiberglass boat, oxidation can often be removed by buffing the surface to get rid of the chalky substance. Follow this by waxing your boat to protect it against corrosion.

Commercial aluminium cleaners:

There are various commercial aluminium cleaners available that can help remove oxidation. For example, 3M Alum Cleaner, Zep-A-Lume, JJV's aluminium cleaner, or Slimey Grimey's Blazin product. Always wear rubber gloves when using these products and test them on a small area first to ensure they don't damage your boat's finish.

Polishing compounds:

You can use polishing compounds, such as Mothers aluminium polish or Woody Wax Ultra Gloss, to remove oxidation and restore shine. These products may require more elbow grease but can provide good results.

Abrasive pads and balls:

You can use abrasive pads, such as Scotch-Brite pads, or abrasive balls attached to a drill to remove oxidation. Start with a medium grit and progress to finer grits to achieve the desired result. Be careful not to damage the surface of your boat.

Barletta's Metal Jacket tube protectant:

If you own a Barletta boat, you can use their Metal Jacket tube protectant, which is a form of ceramic coating. This product is thicker and more durable than other coatings and helps protect against oxidation.

Remember to always test any new product on a small, inconspicuous area first to ensure it doesn't damage your boat's finish. Additionally, always follow the manufacturer's instructions and take the necessary safety precautions when using any cleaning or polishing products.

Traveling Bukavu-Goma: A Boat Trip Adventure

You may want to see also

Frequently asked questions

Oxidation on an aluminum boat will leave a chalky, dull substance on the exterior, taking away the shine from the boat.

Oxidation is the process that occurs when a substance naturally attempts to move into a stable state. As the substance changes, the characteristics also change with it. A substance loses electrons when it reacts with oxygen.

To reduce the effects of oxidation, regularly clean your boat. You can also paint the bottom of the boat with anti-fouling paint to act as a barrier against corrosion.