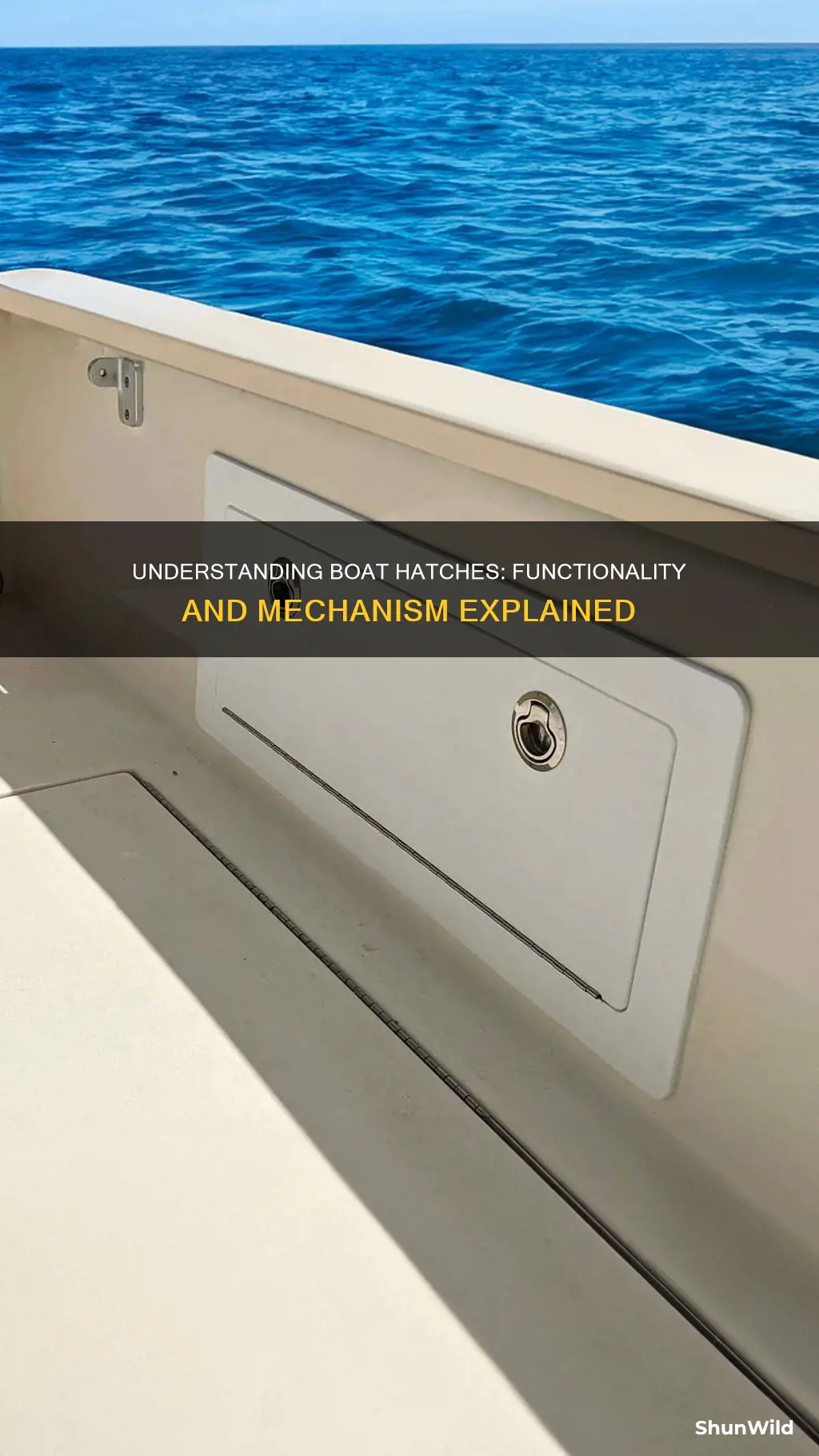

Boat hatches are doors that allow access to the storage, cargo or additional living space within a boat. They are designed to withstand foot traffic and come in a variety of materials, shapes and sizes. Hatches can also be used for ventilation, as windows and as escape routes in the event of a disaster.

| Characteristics | Values |

|---|---|

| Purpose | Access to storage, cargo or additional living space within a boat |

| Material | Plastic, Starboard, Acrylic |

| Functionality | Must be waterproof, must support the weight of people and objects placed on it, must weather the elements |

| Hinge assembly | Utilises one long piano hatch or multiple smaller piano hatches |

| Latch | Compression latches are common, requiring you to both lift and twist to open the deck |

| Ventilation | Allows breeze into ventilated cabins |

| Escape | Escape hatches allow for an easy escape from the cabin |

What You'll Learn

- Boat hatches are doors that allow access to items and spaces below the deck

- They can be used as escape hatches in the event of a disaster

- Hatches can be made from plastic, starboard or acrylic

- They are susceptible to weather damage and need replacing when crumbling, leaking or rotting

- Different types of latches are used for different hatches

Boat hatches are doors that allow access to items and spaces below the deck

Boat hatches are constructed from a variety of materials, including plastic, starboard, and acrylic. Plastic and starboard are extremely strong, but don't allow light into cabin areas and don't have the same shine as acrylic. Acrylic is not as strong but works well for windows and portholes, and can be polished to a gloss finish.

A well-constructed boat hatch must be waterproof, able to support the weight of people and objects placed on it, and able to weather the elements to the same degree as the rest of the deck. Boat hatches are more susceptible to weather damage than the rest of the deck because opening and closing them exposes them to salt water and grime.

The hinge assembly is the part of the hatch that the entire door pivots on. Most hatches use one long piano hatch or multiple smaller piano hatches. The latch is the last part of the hatch, and different hatches employ different styles of latches. Compression latches are common, requiring you to lift and twist to open the deck. Hatches that serve as windows and ventilation typically use large single-handle latches that twist to open the window.

Bennington Boat Cover: Tips for a Snug Fit

You may want to see also

They can be used as escape hatches in the event of a disaster

Boat hatches are doors that allow access to the storage, cargo or additional living space within a boat. They are designed to withstand foot traffic and come in different shapes and sizes. A well-constructed boat hatch must be waterproof and support the weight of people and objects placed on it.

Boat hatches can be used as escape hatches in the event of a disaster. Should a disaster happen aboard a boat, escape hatches allow for an easy escape from the cabin. They can also be used for ventilation and as windows. Escape hatches are also used to cover lockers used to store water skis, wakeboards and anchors.

Boat hatches are made from a variety of materials, including plastic, starboard and acrylic. Plastic and starboard are extremely strong but won't allow light into cabin areas, whereas acrylic is not as strong but works well for windows and portholes.

The hinge assembly is the part of the boat hatch that the entire door pivots on. Most hatches use one long piano hatch or multiple smaller piano hatches. The latch is the last part of the boat hatch and different hatches employ different styles of latches. Compression latches are common, requiring you to both lift and twist to open the deck. Hatches that serve as windows and ventilation typically use large single-handle latches that twist to open the window.

Getting Your Gas RC Boat Started: A Beginner's Guide

You may want to see also

Hatches can be made from plastic, starboard or acrylic

Boat hatches are doors that allow access to the storage, cargo or additional living space within a boat. They are designed to withstand foot traffic and come in a variety of shapes and sizes. They can be used for ventilation, as windows, or as escape hatches.

Hatches can be made from a variety of materials, including plastic, starboard, and acrylic. Plastic and starboard are extremely strong but do not allow light into cabin areas and do not have the same shine as acrylic. Acrylic is not as strong but is ideal for windows and portholes as it can be polished to a gloss finish.

Most hatches use a piano hinge assembly, with one long piano hatch or multiple smaller ones. They also employ different styles of latches, with compression latches being the most common. Single-handle latches are usually used for hatches that serve as windows and ventilation.

The Boat Name of America's Founding Father, George Washington

You may want to see also

They are susceptible to weather damage and need replacing when crumbling, leaking or rotting

Boat hatches are doors that allow access to items or spaces below a boat's deck. They are designed to withstand foot traffic and come in a variety of shapes and sizes, serving many purposes. For example, hatches can be used for ventilation, as windows, or as escape hatches.

A well-constructed boat hatch must be waterproof, able to support the weight of people and objects, and withstand the elements. However, due to their mechanical nature, opening and closing a boat hatch exposes it to saltwater and grime, making it more susceptible to weather damage than the rest of the deck. As a result, boat hatches need to be replaced when they show signs of crumbling, leaking, or rot.

There are several materials suitable for boat hatches, including plastic, starboard, and acrylic. Plastic and starboard are strong but do not allow light into cabin areas or have the same shine as acrylic. Acrylic, while not as strong, is ideal for windows and portholes and can be polished to a gloss finish.

The hinge assembly is an important component of a boat hatch, allowing the door to pivot. Most hatches use either one long piano hatch or multiple smaller piano hatches. The type of latch used also varies depending on the function of the hatch. For example, compression latches are common for deck hatches, while large single-handle latches are typically used for hatches that serve as windows and ventilation.

Repairing Riveted Aluminum Boats: A Comprehensive Guide

You may want to see also

Different types of latches are used for different hatches

Boat hatches are doors that allow access to the storage, cargo or additional living space within a boat. They are designed to withstand foot traffic and come in a variety of materials, shapes and sizes.

Plastic and Starboard can be used for hatches that need to be extremely strong, but these materials won't allow light into cabin areas and don't have the same shine as acrylic. Acrylic is not as strong but works great for windows and portholes, and can be polished to a beautiful gloss finish.

Finding a Boat on Exile Altis: Tips and Tricks

You may want to see also

Frequently asked questions

A boat hatch is a covering or portal that allows access to storage, cargo or additional living space within a boat from the boat deck.

Boat hatches can be made from a variety of materials, including plastic, starboard and acrylic. Plastic and starboard are extremely strong, but don't allow light into cabin areas and don't have the same shine as acrylic.

Boat hatches use a variety of different latches. Compression latches are common, requiring you to both lift and twist to open the deck. Hatches that serve as windows and ventilation typically use large single-handle latches that twist to open the window.

Boat hatches can serve many purposes. They are commonly used to allow access to the bilge, as the area below the main deck is known. They are also used as escape hatches, for ventilation and as windows.

A well-constructed boat hatch must be waterproof, must support the weight of people and objects placed on it, and must weather the elements to the same degree as the rest of the boat deck. A boat hatch is ready to be replaced when it shows signs of crumbling, leaking or rot.