Understanding the wiring connected to your boat's throttle is crucial for safe and efficient operation. The throttle, which controls the speed of your boat's engine, is a critical component that relies on precise electrical signals to function. When you press the throttle pedal or button, an electrical current is sent through the wires to the throttle body, which then adjusts the engine's speed accordingly. Identifying the correct wires and their connections is essential for troubleshooting issues like erratic acceleration, stalling, or a non-responsive throttle. This knowledge can help you diagnose and resolve problems, ensuring your boat's engine runs smoothly and reliably.

What You'll Learn

- Wire Colors and Functions: Identify wire colors and their respective functions in throttle control

- Throttle Cable Routing: Understand the path of throttle cables from the wheel to the engine

- Throttle Sensor Types: Learn about different throttle sensors and their impact on performance

- Throttle Cable Adjustment: Guide on adjusting throttle cables for optimal throttle response

- Common Issues and Fixes: Diagnose and resolve common throttle wire-related problems in boats

Wire Colors and Functions: Identify wire colors and their respective functions in throttle control

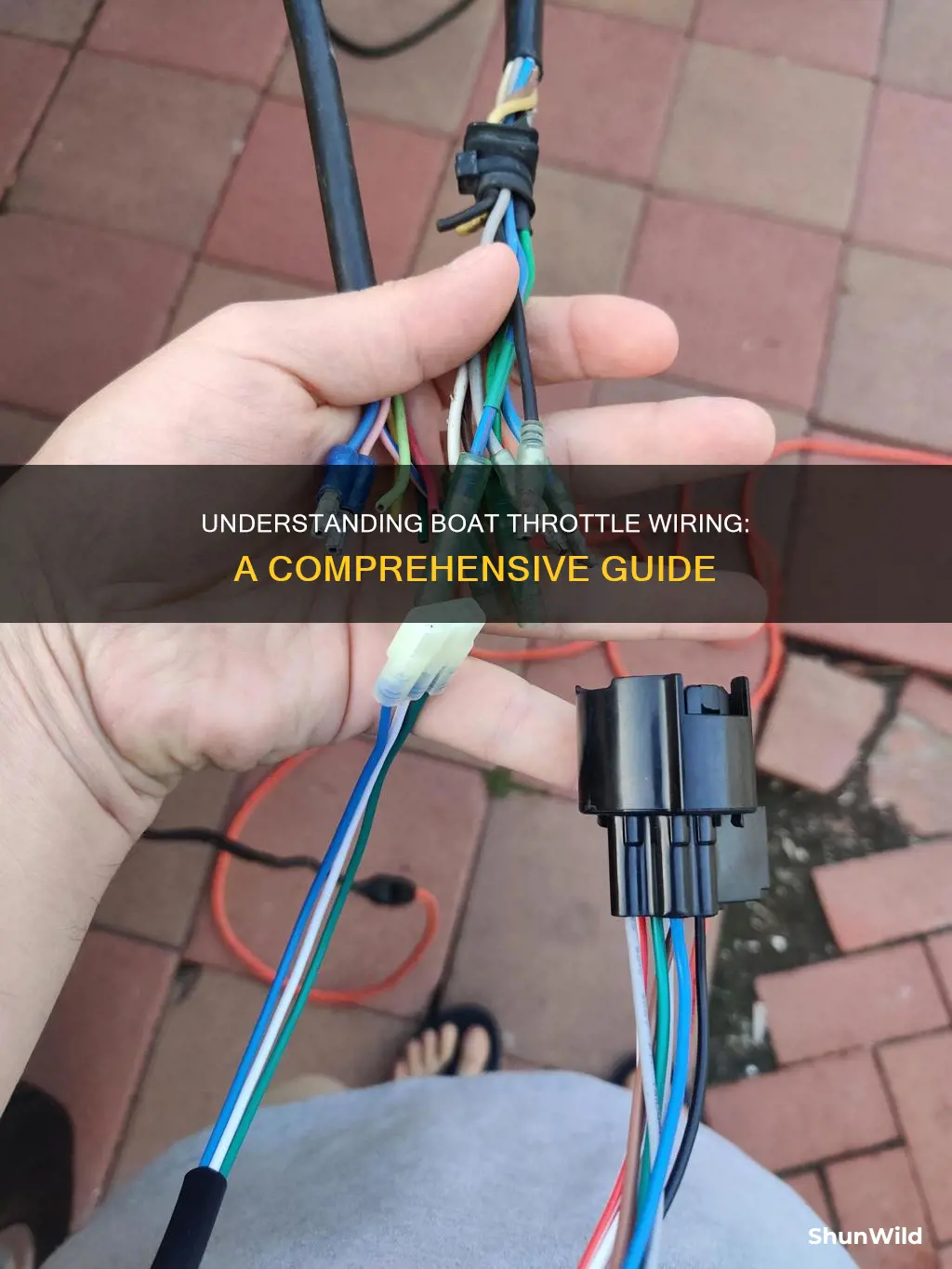

When it comes to understanding the wiring in your boat's throttle system, identifying the wire colors and their respective functions is crucial for any boat owner or enthusiast. Throttle control is a critical component of your vessel's performance and safety, and the correct wiring ensures smooth operation. Here's a detailed breakdown of the common wire colors and their roles in throttle control:

Black Wire: This wire is typically the ground or earth wire. It is used to provide a reference point for electrical circuits and is often connected to the engine block or a sturdy metal part of the boat's structure. The black wire ensures that any electrical current flowing through the throttle system has a safe path to return to the battery or power source, preventing electrical issues and potential hazards.

White Wire: The white wire is often associated with the throttle position sensor. This sensor is responsible for communicating the throttle's position to the engine control unit (ECU). When the throttle is moved, the white wire carries the signal to the ECU, allowing the engine to respond accordingly. For example, when you press the throttle, the white wire sends a signal indicating the desired power output, and the engine adjusts its speed accordingly.

Brown Wire: In many throttle systems, the brown wire is connected to the throttle actuator or motor. This wire carries the power supply to the actuator, which is responsible for physically moving the throttle valve or lever. When you press the throttle pedal or lever, the brown wire sends power to the actuator, causing it to move and open the throttle, allowing more air into the engine.

Green Wire: The green wire is often used for the ignition or start signal. When you turn the key or press the start button, this wire sends an electrical signal to the throttle system, instructing it to prepare for engine operation. It ensures that the throttle is in the correct position for starting, and it may also be connected to the fuel pump to activate it during the starting process.

Orange or Yellow Wire: These colors are sometimes used for additional sensors or control modules. For instance, an orange wire might be connected to a temperature sensor that monitors the engine's intake air temperature. This information is crucial for the ECU to adjust fuel injection and engine performance accordingly.

Understanding the wire colors and their functions is essential for troubleshooting throttle-related issues. If you encounter any problems with your boat's throttle, identifying the correct wires and their connections can help you pinpoint the cause and make the necessary repairs or adjustments. Always refer to your boat's manual or consult a professional if you're unsure about any wiring connections.

Easy Aluminum Boat Repair: No Welding Required

You may want to see also

Throttle Cable Routing: Understand the path of throttle cables from the wheel to the engine

The throttle cables in a boat are an essential component of the engine's operation, allowing the operator to control the engine's speed and power output. Understanding the routing of these cables is crucial for maintenance, troubleshooting, and ensuring the boat's performance. When you turn the throttle wheel, the cables transmit this action to the engine, enabling the driver to accelerate or decelerate the vessel.

The path of the throttle cable begins at the throttle wheel, typically located on the boat's steering console or dashboard. This wheel is connected to the throttle body or carburetor via a series of cables and pulleys. The throttle wheel often has a mechanical linkage that moves in response to the operator's input, translating the rotational motion into linear movement. This linear motion is then transferred through the cable system.

In most boats, the throttle cable runs from the throttle wheel through a series of protective sleeves or conduits to reach the engine compartment. These sleeves are designed to protect the cables from damage caused by sharp edges, vibrations, or exposure to the elements. The routing of the cables is carefully planned to ensure they do not interfere with other components, such as the steering mechanism, fuel lines, or electrical wiring.

Upon entering the engine compartment, the throttle cable connects to the throttle body or carburetor. Here, the cable's end is equipped with a throttle cable anchor or adjustment point. This anchor secures the cable and allows for fine-tuning of the throttle's sensitivity and response. The throttle body is responsible for controlling the engine's air-fuel mixture and is a critical component in the engine's performance.

Proper routing of the throttle cable is essential to maintain optimal engine performance and ensure the boat's responsiveness. Any damage or interference with the cable can result in erratic throttle response, reduced engine power, or even engine stall. Regular inspection and maintenance of the throttle cable system are recommended to identify and address any issues promptly. Understanding the routing and components of the throttle cable system empowers boat owners and operators to take better care of their vessels and enhance their overall boating experience.

Transferring Boat Titles: Mississippi's Process Simplified

You may want to see also

Throttle Sensor Types: Learn about different throttle sensors and their impact on performance

The wires connected to your boat's throttle are an essential component of its engine management system, and understanding the different throttle sensors can greatly impact your vessel's performance and overall experience. Throttle sensors play a crucial role in monitoring and controlling the engine's speed, ensuring smooth operation and efficient power delivery. Here's an overview of some common throttle sensor types and their significance:

- Throttle Position Sensors (TPS): These sensors are commonly found in both marine and automotive applications. The TPS measures the angle of the throttle pedal or valve, providing real-time data to the engine control unit (ECU). By monitoring the throttle's position, the ECU can precisely control the engine's speed and power output. This sensor is vital for maintaining optimal performance, especially during acceleration, as it allows for quick and accurate adjustments. When the TPS fails, it can result in poor engine response, erratic idling, and reduced power, making it a critical component for smooth operation.

- Mass Airflow (MAF) Sensors: In some boats, especially those with larger engines, a MAF sensor is used in conjunction with the throttle position sensor. The MAF sensor measures the amount of air entering the engine, which is crucial for calculating the air-fuel mixture. This sensor provides data to the ECU, allowing for precise fuel injection and combustion control. By ensuring the correct air-fuel ratio, the engine can operate efficiently and produce optimal power. A malfunctioning MAF sensor may lead to poor performance, reduced fuel efficiency, and even engine misfires.

- Throttle Actuators: These sensors are responsible for translating the driver's input from the throttle pedal into mechanical movement, which then controls the engine's throttle valve. Throttle actuators are commonly used in electronic throttle control (ETC) systems, where they provide precise control over the engine's speed. By using stepper motors or solenoids, these sensors ensure smooth and responsive throttle operation. Modern boats often feature ETC systems, which offer improved performance, better fuel efficiency, and enhanced safety by preventing sudden throttle responses.

- Wide-Open Throttle (WOT) Sensors: In certain high-performance boats, a WOT sensor is employed to detect when the throttle is fully open. This sensor triggers specific engine functions, such as rev-matching or boost control, during aggressive driving conditions. By identifying WOT, the sensor enables the engine to perform at its maximum potential, providing a thrilling driving experience. However, it's important to note that WOT sensors are more common in racing or high-performance boats and may not be standard equipment on all vessels.

Understanding the different throttle sensor types and their functions is essential for maintaining and optimizing your boat's performance. Each sensor contributes to the overall efficiency and responsiveness of the engine, ensuring a smooth and enjoyable boating experience. Regular maintenance and timely replacement of these sensors can prevent performance issues and ensure your boat's throttle system operates at its best.

Olympic Sailing Boat Categories: Exploring the Diverse Classes

You may want to see also

Throttle Cable Adjustment: Guide on adjusting throttle cables for optimal throttle response

When it comes to optimizing your boat's throttle response, one crucial aspect is the adjustment of throttle cables. These cables play a vital role in transmitting the driver's input to the throttle mechanism, and proper calibration can significantly enhance your boating experience. Here's a comprehensive guide to help you master the art of throttle cable adjustment:

Understanding the Components: Before making any adjustments, it's essential to familiarize yourself with the throttle cable system. Typically, a throttle cable consists of a cable housing, a cable itself, and various fittings. The cable runs from the throttle pedal or lever to the throttle body or carburetor, where it controls the opening and closing of the throttle. Understanding the layout and components will make the adjustment process more accessible.

Identifying the Issue: Throttle cable issues can manifest in various ways. You might notice a delayed response when applying pressure to the throttle pedal, a sticky or unresponsive throttle, or uneven idling. These problems often arise from cable wear, improper tension, or misalignment. Identifying the specific issue will guide your adjustment strategy.

Adjusting Cable Tension: The key to a responsive throttle is finding the right tension in the cable. Start by ensuring the cable is securely attached to both the throttle pedal and the throttle body. Loosen the cable clamp or adjustment nut to release tension, then gently pull the cable to check for any slack. Adjust the tension by tightening the clamp or nut, ensuring the cable remains flexible. Aim for a slight resistance when pulling the cable, indicating optimal tension.

Fine-Tuning Throttle Response: After establishing the correct tension, it's time to fine-tune the throttle response. This step may require some trial and error. Gradually increase the tension on the cable while observing the throttle's behavior. Tighten the cable slightly, then test the throttle's sensitivity. You want to find a balance where the throttle responds promptly but doesn't feel overly stiff. Adjust the tension until you achieve a smooth and linear throttle movement.

Regular Maintenance: To ensure long-lasting performance, regular maintenance is crucial. Periodically inspect the throttle cables for any signs of wear, such as frayed housing or damaged fittings. Replace any worn-out components to maintain optimal throttle response. Additionally, keep the cable housing clean and free from debris to prevent interference with the cable's movement.

By following these steps, you can effectively adjust the throttle cables on your boat, resulting in a more responsive and enjoyable boating experience. Remember, proper maintenance and regular checks will contribute to the overall reliability of your vessel's throttle system.

Aluminum Boat Painting: Best Paints for Long-Lasting Protection

You may want to see also

Common Issues and Fixes: Diagnose and resolve common throttle wire-related problems in boats

When it comes to boat throttles, the wires connecting the throttle pedal to the engine are crucial for smooth operation. These wires can encounter various issues over time, leading to performance problems. Here's a breakdown of common throttle wire-related issues and how to address them:

Throttle Cable Slack or Damage:

- Issue: Worn-out or damaged throttle cables can cause the throttle to feel loose or unresponsive. You might notice the cable sagging or showing signs of fraying.

- Fix: Inspect the throttle cable for damage. If it's frayed, replace it with a new one. Ensure the cable is properly tensioned to prevent excessive play. Consider lubricating the cable (following manufacturer guidelines) to reduce friction and improve responsiveness.

Wire Connections Loose or Corroded:

- Issue: Loose connections between the throttle wire and the throttle body or engine can lead to erratic throttle response or complete loss of power. Corrosion on the wire or terminals can also disrupt the electrical signal.

- Fix: Carefully inspect all wire connections. Tighten any loose connections with a wrench. Clean any corrosion from the terminals using a wire brush or sandpaper. If corrosion is severe, consider replacing the affected wire segment.

Throttle Position Sensor Malfunction:

- Issue: The throttle position sensor (TPS) translates the throttle pedal's position to the engine's computer. A faulty TPS can result in inaccurate throttle control, leading to rough idling, stalling, or poor performance.

- Fix: Check the TPS for physical damage or debris. Clean the sensor's mounting surface and wiring harness. If the TPS is malfunctioning, replace it. This may require professional diagnosis and repair.

Electrical Issues:

- Issue: Wiring faults, such as short circuits or damaged insulation, can cause erratic throttle behavior. Water intrusion into the wiring harness can also lead to electrical problems.

- Fix: Carefully inspect the wiring harness for any signs of damage, such as cuts, burns, or moisture. Replace any damaged sections. Ensure all connections are secure and free of corrosion. If water damage is suspected, dry the affected areas and consider re-sealing the wiring harness.

Troubleshooting Tips:

- Check for Power: Use a multimeter to verify power at the throttle wire connections when the key is turned on.

- Test Throttle Response: Operate the throttle pedal through its range to identify any sticking points or delayed responses.

- Inspect for Physical Damage: Carefully examine the throttle wire, cable, and related components for any visible signs of wear, damage, or corrosion.

Remember, if you're unsure about any repairs, consult a qualified marine mechanic for assistance. Proper diagnosis and repair of throttle wire issues are essential for safe and efficient boat operation.

Get a Title for Your Homemade Boat in North Carolina

You may want to see also

Frequently asked questions

The wires connected to your boat throttle are part of the engine's electronic control system. They carry signals from the throttle pedal or lever to the engine's computer, which then sends commands to the fuel injectors and other components to control the engine's speed and power output.

If your boat's throttle response is inconsistent or slow, or if the engine doesn't respond to throttle inputs, it could indicate a problem with the throttle wiring. You can check for loose connections or damaged wires, especially where they connect to the throttle body or the engine control module.

Replacing throttle wires is a task that requires some mechanical knowledge and skill. It's generally recommended to have this work done by a qualified marine mechanic to ensure proper installation and avoid any potential issues with engine performance and safety.

Yes, some common problems include corrosion or damage to the wires, especially in areas prone to moisture or vibration. Corroded connections can lead to erratic throttle response, while damaged wires may cause the engine to stall or run poorly. Regular maintenance and inspections can help prevent these issues.