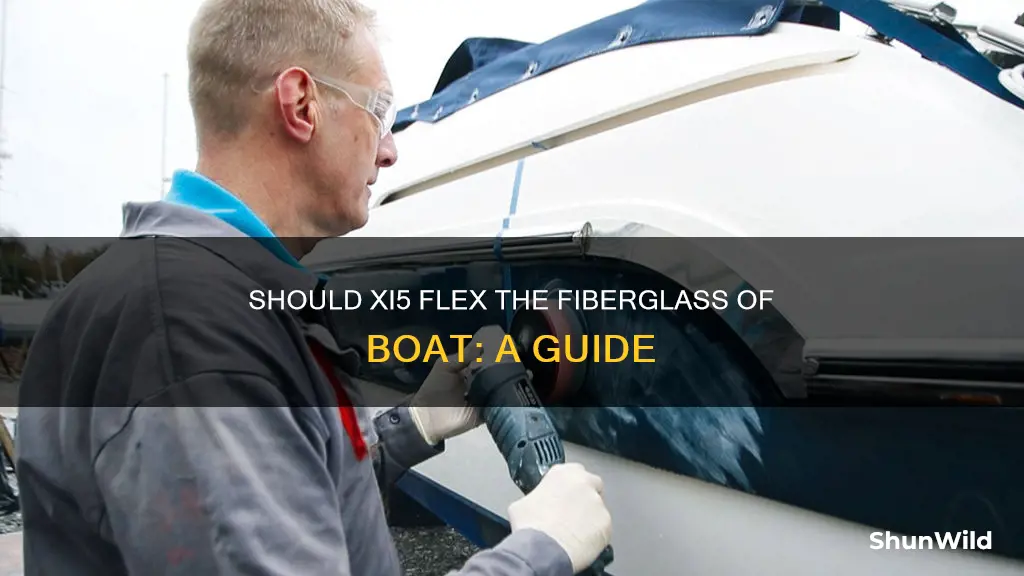

Should Xi5 Flex the Fiberglass of a Boat? This question delves into the delicate balance between customization and preservation of a vessel's structural integrity. Flexing the fiberglass, a common practice in boat maintenance, can enhance performance and aesthetics but requires careful consideration to avoid compromising the boat's structural integrity. The decision hinges on factors such as the boat's age, condition, and intended use, as well as the expertise of the individual performing the task.

What You'll Learn

- Fiberglass Reinforcement: Enhancing boat structure with flexible fiberglass for improved strength and durability

- Flexibility Benefits: Flexing fiberglass reduces stress, enhances boat performance, and increases comfort during navigation

- Material Selection: Choosing the right fiberglass type for optimal flexibility and boat customization

- Installation Techniques: Proper techniques ensure fiberglass flexibility without compromising boat integrity

- Maintenance and Care: Regular maintenance keeps fiberglass flexible, preventing damage and ensuring long-term boat performance

Fiberglass Reinforcement: Enhancing boat structure with flexible fiberglass for improved strength and durability

The reinforcement of fiberglass in boat construction is a technique that has revolutionized the marine industry, offering a unique blend of flexibility and strength to enhance boat structure. This innovative approach involves the strategic integration of flexible fiberglass materials into the boat's framework, providing a range of benefits that contribute to improved performance and longevity.

Fiberglass, known for its exceptional strength-to-weight ratio, becomes a powerful tool when utilized for reinforcement. Its flexibility allows it to conform to the natural curves and contours of the boat's hull, ensuring a seamless and robust structure. This is particularly crucial in areas where traditional rigid materials might fail to provide the necessary support, such as in the intricate curves of the boat's sides and deck. By incorporating flexible fiberglass, boat builders can create a more resilient and durable vessel.

The process of fiberglass reinforcement involves carefully laying and bonding the flexible fiberglass cloth or mats onto specific areas of the boat's structure. This can include the hull, deck, and even the interior compartments. The fiberglass is applied in layers, often with a resin system, to create a composite material that is both strong and lightweight. This technique is especially valuable in boat repairs, where damaged areas can be reinforced to restore structural integrity without replacing large sections.

One of the key advantages of this reinforcement method is its ability to enhance the boat's overall strength and stiffness. The flexible fiberglass provides additional support, particularly in load-bearing areas, ensuring the boat can withstand various stresses and strains during operation. This is especially important for high-performance boats, where the combination of flexibility and strength allows for improved handling and reduced structural fatigue.

Furthermore, the use of flexible fiberglass in boat construction contributes to the vessel's long-term durability. The material's resistance to corrosion and its ability to withstand environmental factors make it an ideal choice for maintaining the boat's structural integrity over time. This is a critical aspect of boat ownership, as it ensures the vessel remains safe and reliable, even after years of use. By investing in fiberglass reinforcement, boat owners can enjoy a well-built, long-lasting vessel that provides an exceptional marine experience.

Understanding the Working of a Boat Jet Pump

You may want to see also

Flexibility Benefits: Flexing fiberglass reduces stress, enhances boat performance, and increases comfort during navigation

Flexibility in boat construction, particularly when it comes to the use of fiberglass, offers a multitude of advantages that contribute to an improved overall boating experience. One of the primary benefits is stress reduction. Fiberglass, when properly flexed, can absorb and distribute forces more effectively, minimizing the impact of waves and vibrations on the vessel. This is especially crucial in high-performance boats, where the structural integrity of the hull is paramount. By allowing the fiberglass to flex, designers can create a more resilient boat that can withstand the rigors of the water without compromising its structural integrity.

The performance of the boat is significantly enhanced by this flexibility. A boat with a flexible fiberglass hull can adjust to the water's contours, providing better handling and responsiveness. This is particularly advantageous during maneuvers, as the boat can adapt to the changing shape of the water, ensuring a smoother and more controlled ride. The flexibility also contributes to improved speed and acceleration, as the boat can cut through the water more efficiently, reducing drag and increasing overall performance.

In terms of comfort, the benefits of flexing fiberglass are equally impressive. The ability of the hull to flex and absorb vibrations means that passengers are less likely to feel the impact of waves and movements. This results in a smoother and more enjoyable journey, especially for those spending extended periods on the water. The reduced stress on the boat's structure also translates to a more comfortable ride, as the vessel can better adapt to the ever-changing conditions of the sea.

Furthermore, the flexibility of fiberglass allows for better sound insulation within the boat's interior. The material can act as a natural barrier, reducing the transmission of noise and vibrations, which is particularly beneficial for creating a peaceful and quiet environment inside the vessel. This feature is especially appreciated in luxury yachts and pleasure boats, where a serene atmosphere is a key selling point.

In summary, flexing fiberglass in boat construction is a strategic design choice that offers a range of advantages. From stress reduction and improved structural integrity to enhanced performance and increased comfort, the benefits are clear. By embracing flexibility, boat manufacturers can create vessels that not only perform exceptionally well but also provide a more enjoyable and safe experience for their passengers, making the most of the unique properties of fiberglass.

Boat Propeller Repair: What's the Cost?

You may want to see also

Material Selection: Choosing the right fiberglass type for optimal flexibility and boat customization

When it comes to boat construction, the choice of fiberglass is a critical decision that can significantly impact the vessel's performance, durability, and overall customization potential. The term "flexibility" in this context refers to the material's ability to bend and deform without breaking, which is essential for creating unique shapes and adapting to various boat designs. Here's an in-depth guide to understanding the different types of fiberglass and how to select the right one for your boat-building project.

Fiberglass, a composite material, is renowned for its versatility and strength. It is composed of glass fibers reinforced with a polymer matrix, offering a balance of rigidity and flexibility. The flexibility of fiberglass is primarily attributed to the glass fibers, which can be woven into various forms and shapes. The type of fiberglass chosen will depend on the desired characteristics of the boat, such as its intended use, size, and aesthetic appeal.

There are several types of fiberglass, each with unique properties:

- E-Glass: This is the most common and cost-effective type of fiberglass. E-Glass offers good strength and flexibility, making it ideal for a wide range of boat applications. It is known for its moderate stiffness and is often used in the construction of hulls and decks. E-Glass provides a balance between strength and weight, ensuring the boat remains lightweight yet sturdy.

- S-Glass: Short for "structural glass," S-Glass is a high-performance fiber known for its exceptional strength-to-weight ratio. It is stiffer than E-Glass, making it less flexible but more rigid. S-Glass is often used in critical load-bearing areas of the boat, such as the stringers and bulkheads, where added strength is required without compromising the overall structure's flexibility.

- W-Glass: This type of fiberglass is characterized by its high flexibility and is often used for creating curved or contoured shapes. W-Glass is less stiff than E-Glass, making it ideal for boat designs that require a more flexible and adaptable material. It is commonly used in the construction of boat sides and decks, allowing for smooth curves and unique design elements.

- AR-Glass: Advanced Reinforced (AR) Glass is a specialized type of fiberglass designed for high-performance applications. It offers excellent strength and stiffness while maintaining a good level of flexibility. AR-Glass is often used in racing boats or high-end recreational vessels, where a balance between strength and flexibility is crucial for optimal performance.

When selecting the right fiberglass type for your boat, consider the following factors:

- Boat Design: Different boat designs require specific levels of flexibility. For example, a fishing boat might benefit from the moderate flexibility of E-Glass, while a custom-built yacht may incorporate W-Glass for its ability to create smooth, curved surfaces.

- Load-Bearing Requirements: If your boat will carry heavy loads or experience significant stress, consider using S-Glass or AR-Glass in critical areas to ensure structural integrity.

- Cost and Availability: E-Glass is generally more affordable and widely available, making it a popular choice for most boat builders. S-Glass and AR-Glass may be more expensive but offer superior performance in specific applications.

- Longevity and Maintenance: Fiberglass types can vary in terms of UV resistance and chemical stability. Ensure the chosen material can withstand the environmental conditions it will be exposed to, especially if the boat will be used in saltwater or harsh weather conditions.

In summary, selecting the right fiberglass type is a crucial aspect of boat customization and construction. By understanding the properties of different fiberglass materials, boat builders can create vessels that are not only aesthetically pleasing but also highly functional and tailored to specific needs. The flexibility of fiberglass, when combined with its strength, allows for endless possibilities in boat design and customization.

Choosing the Right Battery Cable Size for Your Boat

You may want to see also

Installation Techniques: Proper techniques ensure fiberglass flexibility without compromising boat integrity

When it comes to boat construction, the use of fiberglass is a popular choice due to its strength, durability, and flexibility. However, the question arises: should you flex the fiberglass of a boat? The answer is a nuanced one, as it depends on the specific application and the desired outcome. Flexibility in fiberglass can be beneficial in certain scenarios, but it must be approached with caution to ensure the boat's structural integrity is not compromised.

Installation techniques play a crucial role in achieving the desired flexibility while maintaining the boat's overall strength. One method is to utilize pre-formed fiberglass bends, which are strategically placed along the boat's structure. These bends are carefully crafted to allow for a controlled amount of flexibility at specific points. By incorporating these bends, boat builders can create a more dynamic and adaptable structure, especially in areas prone to stress or movement, such as the hull-deck joint or the transom.

Another technique is the use of flexible core materials within the fiberglass construction. This involves inserting a lightweight, flexible core, such as foam or balsa wood, into the fiberglass layers. The core provides a degree of give without sacrificing the overall strength of the boat. This method is particularly useful in areas where the boat's design requires a certain level of flexibility, such as in the construction of the cabin floor or the interior panels.

Proper bonding and lamination techniques are also essential to ensure the fiberglass remains flexible yet sturdy. Using specialized adhesives and resins, boat builders can create a strong bond between the fiberglass layers, reinforcing the structure. Additionally, applying the correct amount of pressure and ensuring proper curing times are critical to achieving the desired flexibility without introducing weaknesses.

In conclusion, while flexibility in fiberglass can be advantageous, it should be implemented with precision and care. By employing the right installation techniques, boat builders can achieve a balance between flexibility and structural integrity. This ensures that the boat remains adaptable to various conditions while maintaining its overall strength and longevity. It is a delicate process that requires expertise and attention to detail to get it right.

The Boat's Hull: Understanding Its Role and Importance

You may want to see also

Maintenance and Care: Regular maintenance keeps fiberglass flexible, preventing damage and ensuring long-term boat performance

Regular maintenance is crucial for preserving the integrity and performance of a boat's fiberglass components. Fiberglass, while durable, can be susceptible to damage over time, especially in the harsh marine environment. Proper care and maintenance are essential to ensure that the fiberglass remains flexible, strong, and capable of withstanding the rigors of boating.

One of the primary maintenance tasks is regular cleaning. Boat owners should keep the fiberglass surfaces clean and free from dirt, grime, and marine growth. Use a mild detergent or a specialized marine cleaner to wash the boat's exterior and interior fiberglass parts. Pay attention to areas around the waterline, as these spots are prone to algae and barnacle growth. Regular cleaning prevents the buildup of contaminants that can lead to degradation and brittleness of the fiberglass.

In addition to cleaning, regular inspections are vital. Check the boat's fiberglass for any signs of damage, such as cracks, chips, or delamination. These issues can often be caused by impact, UV radiation, or improper installation. Inspect the hull, deck, and any composite structures for any visible damage. If any issues are found, address them promptly. Minor repairs can be carried out by filling the damaged area with a suitable fiberglass repair compound and smoothing it out. For more extensive damage, it is advisable to consult a professional boat repair specialist.

Flexibility is a key characteristic of fiberglass, and this property can be maintained through the use of appropriate lubricants. After cleaning, apply a marine-grade fiberglass lubricant to the surfaces that require flexibility, such as hinges, tracks, and any moving parts. This helps to reduce friction and prevents the fiberglass from becoming stiff or brittle over time. Lubrication is especially important in areas where the boat's design incorporates flexibility, such as the bow and stern.

Finally, regular maintenance includes proper storage and protection. When not in use, store the boat in a dry, shaded area to minimize UV exposure and potential damage. Consider using a boat cover to provide an extra layer of protection. Additionally, ensure that the boat is properly drained and dried after each use to prevent the accumulation of water, which can lead to corrosion and damage to the fiberglass. By following these maintenance practices, boat owners can ensure that their fiberglass components remain flexible, durable, and capable of delivering optimal performance over an extended period.

Lake Lavon Boat Ramps: Open Launch Sites for Sailors

You may want to see also

Frequently asked questions

Flexing the fiberglass is a process used to enhance the structural integrity and flexibility of the boat's hull. It involves applying controlled pressure to the fiberglass material, allowing it to slightly deform and return to its original shape, which improves its ability to absorb impact and reduce stress concentration.

The frequency of flexing depends on various factors, including the boat's age, usage, and maintenance history. As a general guideline, it is recommended to flex the fiberglass at least once a year or after any significant repairs or modifications. Regular maintenance ensures the boat's structural health and longevity.

When performed correctly and with proper techniques, flexing the fiberglass should not cause any damage. However, improper or excessive flexing can lead to potential issues. It is crucial to follow manufacturer guidelines and consult with experienced professionals to ensure the process is carried out safely and effectively.

Yes, flexing fiberglass can provide several advantages. It helps to distribute stress evenly across the hull, reducing the risk of cracking or delamination. This process also improves the boat's ability to withstand impact, making it more durable and less prone to structural failures.

It is advisable to seek professional assistance from marine technicians or boat builders who have expertise in fiberglass flexing. They can provide guidance on the proper techniques, tools, and equipment required. Following their instructions and adhering to the manufacturer's recommendations will help ensure the best results and maintain the boat's integrity.