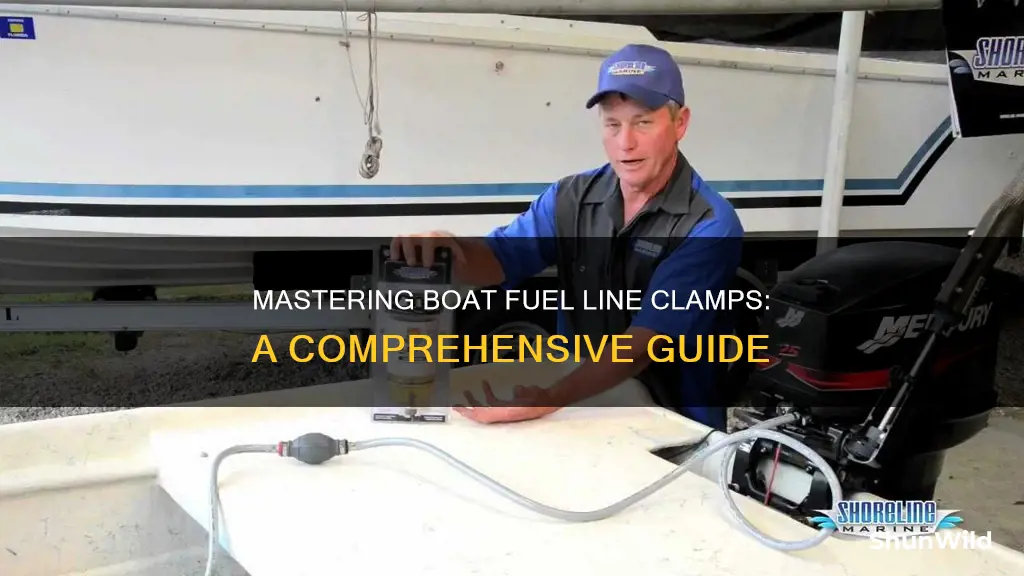

Working with boat fuel line clamps requires careful attention to detail and adherence to safety protocols. Before beginning any maintenance or repairs, it's crucial to understand the specific type of clamp you're dealing with, as different designs may have unique installation methods. Typically, fuel line clamps are used to secure fuel lines to various components of a boat's engine, ensuring a tight and leak-free connection. When working with these clamps, it's essential to use the right tools, such as a fuel line cutter and a fuel line crimper, to ensure a proper fit. Additionally, always wear protective gear, including gloves and safety goggles, to prevent injury from sharp edges or fuel spills. Properly tightened clamps are vital to maintaining the integrity of the fuel system, so take the time to follow manufacturer guidelines and best practices to ensure a secure and reliable connection.

What You'll Learn

- Clamp Selection: Choose the right clamp size and material for your fuel line

- Preparation: Clean and prepare the fuel line before clamping

- Installation Technique: Use a torque wrench for proper tightening

- Leak Testing: Inspect for leaks after clamping

- Maintenance: Regularly check and tighten clamps to prevent issues

Clamp Selection: Choose the right clamp size and material for your fuel line

When it comes to working with boat fuel lines, selecting the appropriate clamp size and material is crucial for a secure and reliable connection. The right clamp ensures that the fuel line remains tightly sealed, preventing any potential leaks or damage. Here's a guide to help you choose the ideal clamp for your boat's fuel line:

Size Matters: The first step is to determine the correct clamp size. Fuel lines come in various diameters, and it's essential to match the clamp's inner diameter to the fuel line's size. Measure the fuel line carefully to find its diameter, ensuring you get the closest match. Clamps that are too small may not provide a tight seal, while overly large clamps can be bulky and less effective. A precise fit is key to maintaining the integrity of the fuel system.

Material Considerations: Clamp materials play a significant role in their performance and durability. Common materials include stainless steel, brass, and plastic. Stainless steel is highly recommended for marine applications due to its corrosion resistance and strength. It can withstand the harsh marine environment and provides excellent longevity. Brass clamps are also a good choice, offering a balance between strength and flexibility. For lighter-duty applications or where weight is a concern, plastic clamps can be used, but ensure they are UV-resistant to handle outdoor exposure.

Clamp Type: There are different types of fuel line clamps available, such as the 'V' clamp, 'C' clamp, and quick-release clamps. 'V' clamps are simple and effective, featuring a V-shaped design that grips the fuel line. 'C' clamps provide a more secure hold with their C-shaped design, ideal for thicker fuel lines. Quick-release clamps offer convenience, allowing for easy installation and removal without tools. Choose the type that best suits your boat's fuel line configuration and your personal preference for ease of use.

Testing and Adjustment: Once you've selected the appropriate clamp size and material, it's essential to test the fit. Tighten the clamp securely, ensuring it doesn't slip or loosen over time. Check for any signs of fuel line movement or play. If necessary, make small adjustments to the clamp position to optimize the seal. Remember, a well-fitted clamp should provide a snug and secure connection without causing any damage to the fuel line.

By carefully considering the size, material, and type of clamp, you can ensure a professional-grade installation for your boat's fuel lines. This attention to detail will contribute to a safer and more efficient marine experience.

Affixing Registration Stickers to Your Boat's Side in Wisconsin

You may want to see also

Preparation: Clean and prepare the fuel line before clamping

Before you begin clamping the fuel line, it's crucial to ensure that the process is done correctly and safely. The first step in this process is thorough preparation, which involves cleaning and preparing the fuel line. This step is often overlooked but is essential to ensure a secure and reliable connection.

Start by removing the fuel line from the boat's fuel system. This might require disconnecting some components, so have the necessary tools ready. Once the line is removed, it's time to clean. Use a mild detergent or soap solution to wash the fuel line. This step helps to remove any dirt, grime, or old fuel residue that could interfere with the clamping process. Rinse the line thoroughly to ensure no residue remains.

After cleaning, inspect the fuel line for any signs of damage or wear. Look for cracks, punctures, or any other visible issues. If you find any, it's best to replace the line before proceeding with clamping. This is because any existing damage could worsen during the clamping process or lead to leaks.

For a more thorough preparation, consider using a fuel line conditioner. This product can help to clean and protect the fuel line, ensuring it's in optimal condition for clamping. Apply the conditioner according to the manufacturer's instructions, and allow it to dry before proceeding.

Once the fuel line is clean, dry, and in good condition, you're ready to move on to the clamping process. This step requires precision and care to ensure a secure and leak-free connection.

Reinforcing Your Aluminum Boat Hull: Strategies for Strengthening

You may want to see also

Installation Technique: Use a torque wrench for proper tightening

When working with boat fuel line clamps, ensuring proper installation is crucial to guarantee a secure and reliable fuel system. One essential technique to achieve this is by using a torque wrench for precise tightening. This tool is indispensable for maintaining the integrity of your fuel lines and preventing potential leaks or damage.

The process begins with selecting the appropriate torque wrench for the job. Different fuel line clamps may require specific torque values, so it's essential to consult the manufacturer's guidelines or technical specifications. Using the right torque wrench ensures that you apply the correct amount of force during installation.

Once you have the torque wrench, locate the clamp and position it around the fuel line. Ensure that the clamp is aligned correctly and securely positioned over the fuel line. Then, begin tightening the clamp using the torque wrench. Apply a steady and controlled force, following the recommended torque value. It's important to maintain a consistent and even pressure to avoid over-tightening or under-tightening.

As you tighten the clamp, you should feel a resistance or resistance, indicating that the clamp is engaging with the fuel line. Continue turning the wrench until you reach the specified torque value. At this point, the clamp should be securely fastened, providing a tight seal around the fuel line. Over-tightening can lead to damage, so be cautious and precise during this step.

After achieving the correct torque, double-check the installation. Ensure that the clamp is firmly in place and there are no visible signs of distortion or damage to the fuel line. Properly tightened clamps will create a secure connection, preventing fuel leaks and ensuring the safety and efficiency of your boat's fuel system. Remember, using a torque wrench is a critical step in the installation process, ensuring a professional and reliable outcome.

Who is the Owner of the Hilarium Yacht?

You may want to see also

Leak Testing: Inspect for leaks after clamping

After clamping the fuel lines to your boat's engine, it's crucial to perform a thorough leak test to ensure the system's integrity and prevent any potential issues. This step is often overlooked, but it's an essential part of the process to guarantee a safe and efficient fuel supply. Here's a detailed guide on how to inspect for leaks:

Start by turning on the fuel pump and allowing it to run for a few minutes. This action will create pressure in the system, simulating real-world conditions. During this time, carefully observe the clamps and connections for any signs of leakage. Pay close attention to the areas where the fuel lines are clamped, as these points can be prone to leaks due to the stress and movement they endure. Look for any wet spots or stains around the clamps, as these could indicate a potential issue.

After the initial inspection, it's recommended to use a few simple techniques to further ensure the system's tightness. One method is to use a soapy water solution. Spray or brush the solution onto the clamps and connections, ensuring an even coverage. If a leak is present, you will notice bubbles forming around the affected area due to the soap's reaction with the fuel. This visual indicator will help you pinpoint any weak points in the clamping system.

Additionally, you can use a pressure gauge to test the fuel line's pressure. Connect the gauge to the fuel line and observe the reading. A properly clamped system should maintain stable pressure without any significant drops. If the pressure fluctuates or drops, it could be a sign of a leak, and you should investigate further.

Remember, taking the time to inspect for leaks is a critical step in maintaining your boat's performance and safety. It ensures that your fuel system operates efficiently and reliably, allowing you to focus on enjoying your time on the water without worrying about potential fuel-related issues. Always follow the manufacturer's guidelines for your specific boat model and fuel line system to ensure you perform the leak test correctly.

Choosing the Right Boat Battery: What Type to Pick?

You may want to see also

Maintenance: Regularly check and tighten clamps to prevent issues

Regular maintenance of your boat's fuel lines is crucial to ensure optimal performance and prevent potential issues. One critical aspect of this maintenance is checking and tightening the fuel line clamps. These clamps play a vital role in securing the fuel lines, preventing leaks, and maintaining the integrity of the fuel system. Here's a step-by-step guide on how to perform this task effectively:

Start by inspecting the fuel line clamps regularly, preferably during routine maintenance checks. Look for any signs of wear, damage, or corrosion. Over time, clamps can loosen due to vibration and movement, especially in the engine compartment where conditions can be harsh. Inspect the clamps for any visible signs of deterioration, such as cracks, bends, or excessive wear on the clamping surface. If you notice any issues, it's essential to address them promptly.

The next step is to tighten the clamps as needed. Use a wrench or a specialized tool designed for this purpose to ensure you apply the correct amount of force. Start by identifying the clamps that require tightening. These are typically located where the fuel lines connect to the engine, pumps, or other components. Apply firm pressure to the clamps, ensuring they are snug and secure. Remember, the goal is to create a tight seal without causing damage to the fuel lines or surrounding components.

When tightening the clamps, be cautious not to overtighten them, as this can lead to fuel line damage or even breakage. Use the appropriate tool to measure the clamp's tension accurately. If you're unsure about the correct tension, consult your boat's manual or seek guidance from a marine mechanic. Regularly checking and tightening the clamps will help maintain a secure connection, reducing the risk of fuel leaks and potential engine issues.

In addition to tightening, consider replacing worn-out or damaged clamps. Over time, even with regular maintenance, clamps may wear out and lose their effectiveness. If you notice any clamps that are no longer providing a secure hold, replace them with new ones. This proactive approach ensures that your fuel lines remain properly secured, promoting the overall reliability of your boat's fuel system.

By incorporating this maintenance task into your regular boat care routine, you can significantly contribute to the longevity and performance of your vessel's fuel system. Remember, proper maintenance is key to avoiding costly repairs and ensuring a safe and efficient boating experience.

Moss Landing Boat Ramp: Open or Closed?

You may want to see also

Frequently asked questions

Boat fuel line clamps are essential components used to secure and protect fuel lines on boats. They provide a secure and reliable connection, ensuring that the fuel lines remain in place and do not come loose during operation, which could lead to fuel leaks and potential hazards.

Installation is a straightforward process. First, ensure you have the correct size and type of clamp for your fuel line. Clean the fuel line and clamp to remove any dirt or debris. Slide the clamp over the fuel line, ensuring it is centered and fits snugly. Tighten the clamp using a wrench or spanner, being careful not to overtighten, as this can damage the fuel line. Repeat this process for each fuel line connection.

Yes, regular maintenance is important to ensure the longevity and effectiveness of the clamps. Check the clamps periodically for any signs of wear, corrosion, or damage. If you notice any issues, such as cracks or looseness, replace the clamps immediately. It's also a good practice to inspect the fuel lines and clamps after each boating session, especially if operating in harsh marine environments, to catch any potential problems early on.