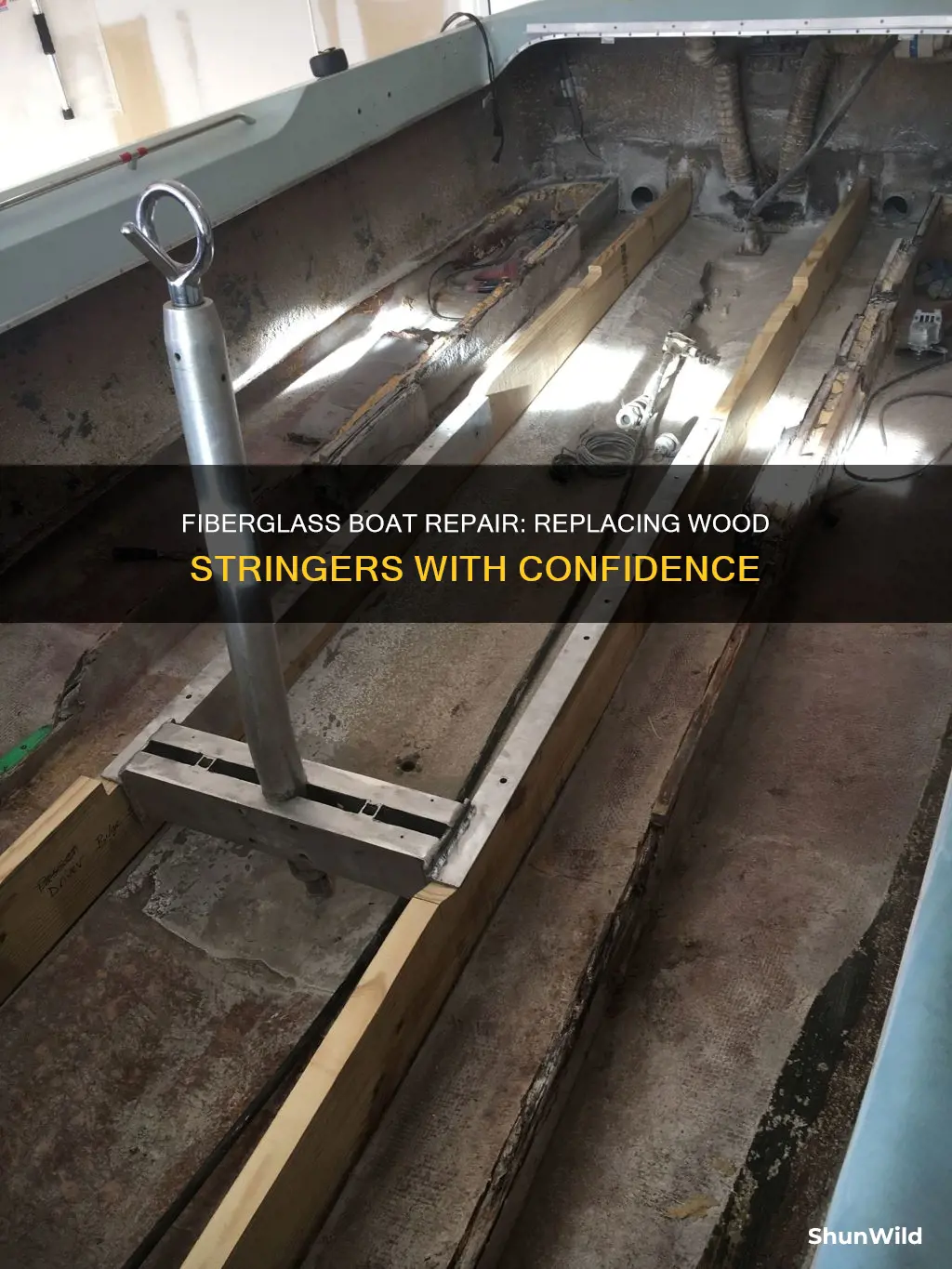

Replacing wood stringers in a fiberglass boat is a crucial maintenance task to ensure the vessel's structural integrity and longevity. Over time, wood stringers can deteriorate due to exposure to water, UV rays, and marine environments, leading to potential safety hazards. This guide will provide a step-by-step process for replacing these stringers, offering valuable insights for boat owners and enthusiasts. By following these instructions, you can restore the boat's strength and appearance, ensuring a safe and enjoyable boating experience.

What You'll Learn

- Preparation: Gather tools and materials, ensuring a safe and organized workspace

- Remove Old Stringers: Carefully take out the old wood stringers, being mindful of fiberglass integrity

- Repair Fiberglass: Inspect and repair any damage, using appropriate resins and fillers

- Install New Stringers: Securely fasten new wood stringers with marine-grade hardware

- Finish and Test: Sand, paint, and test the boat to ensure structural integrity and aesthetics

Preparation: Gather tools and materials, ensuring a safe and organized workspace

Before you begin the process of replacing wood stringers in a fiberglass boat, it's crucial to prepare your workspace and gather the necessary tools and materials. This step ensures a safe and efficient working environment, making the repair process smoother and more effective.

Gathering Tools and Materials:

- Start by collecting all the required tools and supplies. You'll need a variety of equipment, including a utility knife, a pair of gloves, safety goggles, and a respirator mask to protect your respiratory system when working with fiberglass. Additionally, ensure you have a set of screwdrivers, a hammer, and a set of replacement stringers made of a suitable material, such as marine-grade plywood or composite materials.

- Prepare the replacement stringers by ensuring they are the correct size and shape to fit the existing frame. Consider the boat's design and the specific requirements of the damaged area.

- Gather cleaning supplies like a mild detergent, a soft-bristled brush, and a clean cloth. These will be essential for preparing the fiberglass surface before installation.

- For the adhesive, choose a marine-grade epoxy or a specialized bonding agent suitable for fiberglass. Ensure you have enough to cover the entire length of the stringers.

- Safety equipment is paramount. Wear protective clothing, including long sleeves, pants, and closed-toe shoes, to minimize the risk of injury.

Workspace Preparation:

Designate a well-ventilated area for the repair work. If possible, choose an outdoor space or a garage with good airflow. Cover the ground with a drop cloth or old newspapers to catch any debris and protect the surrounding area.

- Ensure easy access to the boat's interior and exterior where the stringers are located. Remove any obstacles or trip hazards to create a safe and organized workspace.

- Consider using a workbench or a sturdy table to place the boat on, providing a stable base for your repairs.

- If the boat is in a confined space, use appropriate lighting to ensure you have good visibility during the repair process.

By thoroughly preparing your workspace and gathering the necessary tools and materials, you'll be well-equipped to tackle the replacement of wood stringers in your fiberglass boat, ensuring a successful and safe repair.

Repairing Your Zodiac Inflatable: A Step-by-Step Guide

You may want to see also

Remove Old Stringers: Carefully take out the old wood stringers, being mindful of fiberglass integrity

When replacing wood stringers in a fiberglass boat, the process requires careful consideration to ensure the structural integrity of the boat is maintained. The first step is to remove the old stringers, a task that demands precision and attention to detail. Begin by inspecting the boat to identify the specific stringers that need replacement. These stringers are typically found along the length of the boat's hull, providing structural support.

Carefully access the stringers by removing any panels or access points that might conceal them. This step may involve taking off interior trim or accessing the hull from below. Once the stringers are visible, use the appropriate tools to carefully pry them out. It is crucial to work gently to avoid damaging the surrounding fiberglass. Consider using a flathead screwdriver or a specialized tool designed for prying out fiberglass-encased wood. Take your time and be methodical to ensure you don't compromise the boat's structure.

As you remove the stringers, be vigilant about preserving the fiberglass. Fiberglass is a lightweight, strong material that provides structural rigidity to the boat. When prying out the stringers, ensure that you don't create any cracks or damage to the fiberglass surface. Work carefully around the stringers, and if necessary, use a small chisel to carefully remove any remaining wood without affecting the fiberglass.

During this process, it's essential to have a clear understanding of the boat's layout and the role of each stringer. Some stringers might be critical to the boat's stability, so plan the removal process accordingly. Consider marking or documenting the positions of the removed stringers to ensure accurate replacement. This documentation will be invaluable when it's time to install the new stringers.

Remember, the goal is to replace the wood stringers while preserving the boat's original fiberglass structure. Take your time, work methodically, and seek guidance if needed to ensure a successful and safe repair.

The Perfect Spot for Boat Numbers

You may want to see also

Repair Fiberglass: Inspect and repair any damage, using appropriate resins and fillers

When it comes to repairing a fiberglass boat, a thorough inspection is crucial to identify any existing damage and assess the extent of the repairs needed. Start by carefully examining the boat's structure, paying close attention to areas where stringers, which are structural components, are visible. Look for any signs of deterioration, such as cracks, delamination, or soft spots, as these could indicate underlying issues. It's important to note that wood stringers, if present, may need replacement if they have become compromised.

Once you've identified the damaged areas, it's time to gather the necessary materials and tools for the repair. For fiberglass repairs, you'll typically need a suitable resin system, which can vary depending on the specific type of fiberglass used in your boat. Choose a resin that is compatible with the existing material and ensure you have the appropriate hardener and catalyst. Additionally, select a filler material that can be used to fill in any voids or damaged areas. Common options include epoxy resins, polyester resins, or vinylester resins, each with its own advantages and applications.

The repair process begins with cleaning the damaged area to remove any dirt, grime, or old filler. Use a sharp blade or a scraper to carefully remove any loose or damaged material, ensuring you don't damage the surrounding fiberglass. Prepare the surface by roughening it slightly, creating a better bond for the new resin. Then, carefully apply the chosen resin, following the manufacturer's instructions for mixing and application. Use a brush or a spreader to ensure an even coat, and allow it to cure according to the resin's guidelines.

After the resin has cured, it's time to fill the repaired area. Mix the filler material according to the instructions, ensuring it is the correct consistency for your needs. Carefully apply the filler, using a putty knife or a similar tool to create a smooth surface. Allow the filler to cure, and once it's hard, sand it down to create a seamless finish. This step is crucial to ensure the structural integrity of the boat and to maintain its aesthetic appeal.

Finally, once the repairs are complete and all filler has been sanded down, you can further enhance the finish by applying a gelcoat or a topcoat. This will provide an additional layer of protection and improve the boat's overall appearance. Remember, when working with fiberglass and resins, it's essential to follow safety precautions, such as wearing protective gear and ensuring proper ventilation, to ensure a safe and successful repair process.

Proper Boat Launch Etiquette: Dos and Don'ts

You may want to see also

Install New Stringers: Securely fasten new wood stringers with marine-grade hardware

When replacing wood stringers in a fiberglass boat, ensuring a secure and durable installation is crucial to maintaining the vessel's structural integrity. Here's a step-by-step guide to installing new stringers with the appropriate hardware:

Step 1: Prepare the Boat and Stringers

Before beginning, ensure the boat is in a stable position, either on a lift or a dry dock. Carefully inspect the existing stringers and mark their positions. Remove any old stringers and clean the areas where they were attached. This preparation ensures accurate placement of the new stringers.

Step 2: Choose the Right Marine-Grade Hardware

For this task, you'll need marine-grade hardware specifically designed for boat applications. Opt for stainless steel or aluminum fasteners that are corrosion-resistant and suitable for saltwater environments. Common choices include stainless steel screws, bolts, and stainless steel or aluminum brackets. Ensure the hardware is appropriate for the thickness of the new stringers.

Step 3: Mark and Drill Holes

Carefully measure and mark the locations for the new stringers, ensuring they align with the original stringers' positions. Drill pilot holes at these marked spots. The holes should be slightly smaller in diameter than the fasteners to prevent them from splitting the wood. Take extra care when drilling near the fiberglass hull to avoid damage.

Step 4: Secure the Stringers

Now, it's time to fasten the new stringers. Start by placing the stringers in their respective positions and aligning them with the marked holes. Use the marine-grade hardware to secure the stringers to the boat's frame or existing stringers. Tighten the fasteners securely but be careful not to overtighten, as this can cause damage to the wood or fiberglass. Ensure the stringers are level and plumb for optimal support.

Step 5: Reinforce and Finish

Consider adding additional support by installing braces or cross-members between the new stringers to further enhance the boat's structural integrity. Once the stringers are securely fastened, you can fill the screw holes with marine-grade wood filler or epoxy to ensure a smooth and seamless appearance. Allow the filler to cure according to the manufacturer's instructions.

Remember, working on a boat's structure requires precision and attention to detail. Take your time, double-check measurements, and ensure that all fasteners are tight and secure. Properly installed stringers will provide the necessary support for the rest of the boat's components, ensuring a safe and reliable vessel.

Exploring Scotland and Ireland: A Boat Trip's Distance

You may want to see also

Finish and Test: Sand, paint, and test the boat to ensure structural integrity and aesthetics

After completing the replacement of the wood stringers, it's crucial to finish and test the boat to ensure its structural integrity and enhance its appearance. Here's a step-by-step guide to achieving this:

Sand and Smoothen: Begin by thoroughly sanding the entire boat's surface, paying close attention to the areas where the new stringers are installed. Use fine-grit sandpaper to create a smooth and even finish. This process helps to remove any roughness or imperfections left by the replacement process and ensures a seamless integration of the new stringers. Start with a lower grit (e.g., 120-grit) to remove any residual debris and then progress to higher grits (e.g., 220-grit) for a finer finish. Ensure that the sandpaper is damp to avoid scratching the fiberglass.

Prepare the Surface: Before painting, it's essential to clean the surface and remove any dust or debris. Use a tack cloth or a soft brush to wipe down the boat, ensuring a clean and dust-free environment for the paint. This step is crucial for the paint to adhere properly and provide a long-lasting finish.

Paint Application: Choose a high-quality marine-grade paint suitable for fiberglass surfaces. Apply multiple thin coats of paint, allowing sufficient drying time between each layer. This technique ensures a smooth and even finish. Start with a base coat to provide a solid color, and then add additional coats for depth and protection. Follow the manufacturer's instructions for the best results. Consider using a spray gun for an even and professional finish, especially in hard-to-reach areas.

Structural Testing: After the paint has cured, it's time to assess the boat's structural integrity. Perform a series of tests to ensure the boat is safe and sound. Start by applying pressure to various points along the stringers to check for any soft spots or areas of weakness. Use a stethoscope to listen for any unusual sounds, which could indicate potential issues. Additionally, inspect the boat for any visible cracks or deformations, especially around the stringer attachments.

Aesthetic Enhancements: To enhance the boat's appearance, consider adding trim or decorative elements. This could include stainless steel trim, custom graphics, or even a new coat of color. Ensure that any additional components are securely fastened and do not compromise the boat's structural integrity. Regular maintenance and inspections will also help preserve the boat's finish and overall aesthetics.

By following these steps, you can ensure that the replacement of wood stringers is not just a structural success but also a visually appealing one. Proper finishing and testing will contribute to the longevity and overall satisfaction of your fiberglass boat project.

Unraveling the Power: Tug Boats' Speeds and Their Mighty Role

You may want to see also

Frequently asked questions

Replacing wood stringers in a fiberglass boat typically involves a multi-step process. First, inspect the boat to identify the extent of the damage and the number of stringers that need replacement. Carefully remove the old stringers, ensuring you don't damage the surrounding fiberglass structure. Prepare the replacement stringers by cleaning and smoothing any rough surfaces. Then, apply a suitable bonding agent or epoxy to secure the new stringers in place. Finally, sand and fair the new stringers to match the existing contour, and carefully blend the repair into the boat's structure using appropriate fiberglass materials.

Achieving a strong bond between the new stringers and the fiberglass hull is crucial for a successful repair. Start by cleaning the surfaces of both the stringers and the hull to remove any dirt, grease, or old bonding materials. Ensure the surfaces are dry before applying a bonding agent or epoxy. Use a high-quality epoxy specifically designed for marine applications, and follow the manufacturer's instructions for application. Allow sufficient curing time for the epoxy to create a robust bond. Proper surface preparation and the use of appropriate bonding materials will contribute to a long-lasting repair.

Yes, there are specific tools and materials needed for replacing wood stringers in a fiberglass boat. Essential tools include a utility knife or a sharp blade for cutting and shaping, sandpaper or a sanding block for smoothing, and a respirator or dust mask for safety. You will also require a suitable epoxy or bonding agent designed for marine use, along with mixing cups and brushes for application. Fiberglass repair materials such as cloth, gelcoat, and primer may be needed to blend the repair into the existing structure. It is recommended to consult with a marine repair specialist or refer to the boat manufacturer's guidelines for the specific tools and materials required for your particular boat model.