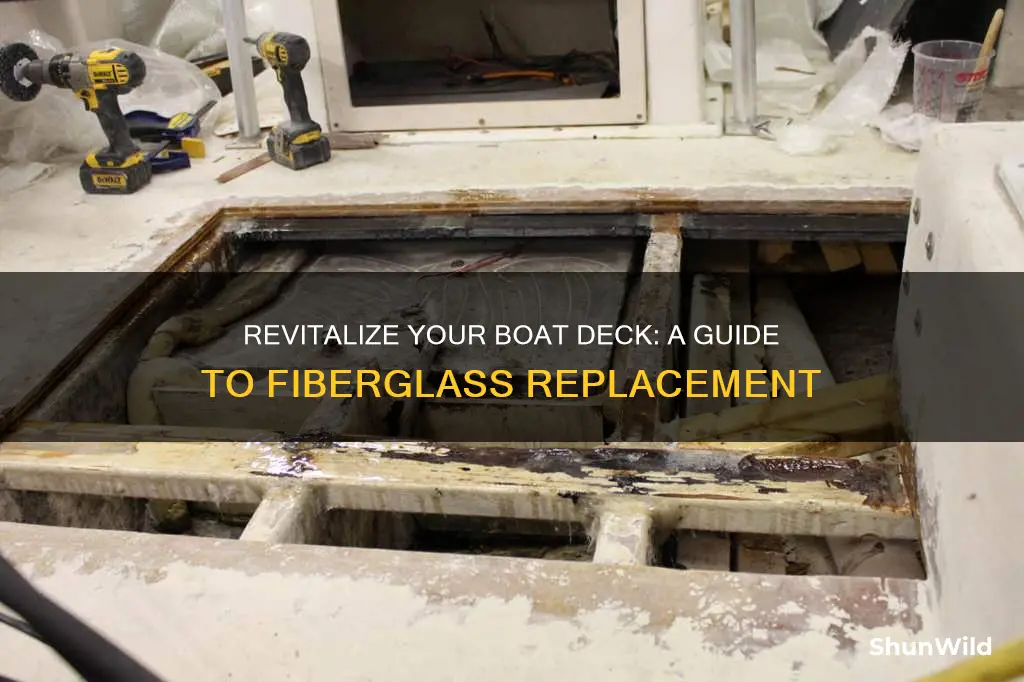

Replacing a boat deck made of fiberglass can be a challenging but rewarding project for any boat owner. The process involves several steps, including removing the old deck, preparing the surface, and installing a new fiberglass layer. This guide will provide a comprehensive overview of the steps involved, from assessing the damage to the deck to choosing the right materials and techniques for a successful replacement. Whether you're dealing with a cracked, worn-out, or damaged deck, this guide will offer practical tips and insights to help you navigate the process with confidence.

What You'll Learn

- Fiberglass Repair Tools: Essential tools for cutting, shaping, and bonding fiberglass

- Surface Preparation: Clean and sand the deck for optimal bonding

- Fiberglass Patching: Apply a fiberglass patch and resin to repair damage

- Bonding Techniques: Learn proper bonding methods for a strong repair

- Finishing Touches: Sand, fair, and paint for a smooth, professional finish

Fiberglass Repair Tools: Essential tools for cutting, shaping, and bonding fiberglass

When it comes to replacing a boat deck made of fiberglass, having the right tools is crucial for a successful repair. Here's an overview of the essential tools you'll need for cutting, shaping, and bonding fiberglass:

Cutting Tools:

- Fiberglass Cutter: A sharp and durable cutter specifically designed for fiberglass is essential. Look for a tool with a fine, sharp blade that can easily cut through the material without causing damage. These cutters often have a comfortable grip and a locking mechanism for easy handling.

- Utility Knife: A standard utility knife with a sharp, replaceable blade is a versatile tool for cutting fiberglass. It can be used for precise cuts and is handy for making initial incisions or cutting around existing hardware. Ensure you have a sharp blade to get clean cuts.

- Glass Cutter: This tool is specifically designed for cutting glass fiber and can provide a clean, precise cut. It typically has a diamond-coated blade that glides smoothly over the fiberglass surface, leaving a smooth edge.

Shaping and Forming Tools:

- Fiberglass File: A set of files, including both coarse and fine options, is essential for shaping and smoothing fiberglass. Files help remove excess material and create a smooth surface for bonding. Use the coarse file to remove larger amounts of material and then switch to the finer file for detailed work.

- Sandpaper: In addition to files, various grades of sandpaper are necessary for smoothing and refining the fiberglass surface. Start with a coarser grit and gradually move to finer grits for a polished finish.

- Heat Gun or Blowtorch: For more complex repairs, a heat gun or blowtorch can be used to shape and mold fiberglass. Applying heat allows the material to become more pliable, making it easier to form and conform to the desired shape.

Bonding and Adhesion Tools:

- Fiberglass Resin and Catalyst: The primary materials for bonding fiberglass are resin and catalyst. Choose a high-quality resin system suitable for marine applications. Follow the manufacturer's instructions for mixing and applying the resin.

- Stir Sticks and Mixing Containers: You'll need containers and sticks specifically designed for mixing resin and catalyst. These tools ensure accurate measurements and proper mixing to achieve optimal bonding.

- Bonding Tools: Various bonding tools can assist in the application process. This includes brushes for spreading resin, rollers for even coating, and gloves to protect your hands during the bonding process.

Having these tools readily available will make the fiberglass repair process more manageable and efficient. Remember to always follow safety guidelines when working with fiberglass and other chemicals, and ensure proper ventilation in your workspace.

Relocating Boat Batteries: A Step-by-Step Guide for Center Consoles

You may want to see also

Surface Preparation: Clean and sand the deck for optimal bonding

Before you begin the process of replacing a boat deck with fiberglass, proper surface preparation is crucial to ensure a successful and long-lasting repair. The first step in this process is thorough cleaning, which will remove any dirt, grime, or old materials that could interfere with the bonding of the new fiberglass. Start by using a stiff-bristled brush or a power washer to scrub the entire deck surface, paying extra attention to areas where old fiberglass or paint might have flaked or peeled off. This initial cleaning step is essential to create a clean and smooth base for the new material.

Once the deck is thoroughly cleaned, it's time to focus on surface preparation through sanding. This process helps to create a rough texture on the surface, providing an ideal environment for the fiberglass to adhere to. Use a high-grit sandpaper, such as 120-grit or higher, to gently sand the entire deck area. Work in small sections, applying even pressure to ensure a consistent finish. The goal is to remove any remaining smooth or shiny spots that might hinder the bonding process. After sanding, use a shop vac or a damp cloth to remove all the dust and debris, ensuring a clean and ready surface.

The key to a successful bond is a rough, textured surface that the fiberglass can grip onto. This is why sanding is a critical step in the preparation process. It's important to be thorough and consistent in your sanding to avoid any areas of smooth surface that might cause issues with adhesion. Once the sanding is complete, inspect the deck to ensure it is free of any debris and that the surface is evenly textured. This preparation will significantly contribute to the overall success and longevity of your fiberglass repair.

Remember, the goal of surface preparation is to create a surface that is clean, rough, and ready for the new fiberglass material. This process might seem tedious, but it is a vital step that will ensure your boat deck repair is secure and long-lasting. By taking the time to properly clean and sand the deck, you are setting the foundation for a successful fiberglass installation.

Christian Grey's Luxurious Boat: A Lavish Escape

You may want to see also

Fiberglass Patching: Apply a fiberglass patch and resin to repair damage

When it comes to repairing damage to your boat's fiberglass deck, a patch job can be a cost-effective and efficient solution. Here's a step-by-step guide to help you through the process:

Step 1: Assessment and Preparation

Start by thoroughly inspecting the damaged area. Carefully examine the extent of the damage, ensuring you understand the size and shape of the affected area. Clean the surface around the damage, removing any dirt, debris, or loose fibers. This step is crucial to ensure proper adhesion of the patch.

Step 2: Gather Materials

For this repair, you'll need a few essential items. First, acquire a suitable fiberglass patch kit, which typically includes a fiberglass cloth or mat, resin, and hardener. Choose a patch that matches the existing fiberglass in color and texture as closely as possible. Additionally, you'll need a non-woven glass cloth (also known as a 'sanding pad') for smoothing and a small brush for applying the resin.

Step 3: Prepare the Resin and Hardener

Follow the instructions on your chosen resin and hardener carefully. Typically, you'll mix the two in a specific ratio to create a strong bonding agent. Stir the mixture thoroughly to ensure a consistent consistency, avoiding any lumps. Allow the resin to sit for a short period, as this can help it become more workable.

Step 4: Apply the Patch and Resin

Lay the fiberglass patch over the damaged area, ensuring it covers the entire affected zone. Use the brush to gently spread a thin layer of the mixed resin over the patch and the surrounding area. This initial layer, known as a 'gel coat,' provides a smooth surface for the patch to adhere to. Allow the gel coat to set for a short time, following the resin's instructions.

Step 5: Secure and Smooth the Patch

Once the gel coat has set, carefully lay the non-woven glass cloth over the patch, ensuring it is taut and smooth. Use a rolling pin or a similar tool to apply firm pressure and adhere the cloth to the resin. This step creates a strong bond between the patch and the existing fiberglass. Smooth out any wrinkles or bubbles using the back of the brush or a putty knife.

Step 6: Allow for Curing

After securing the patch, leave it undisturbed for the recommended curing time, which can vary depending on the products used. During this time, avoid any pressure or impact on the repaired area. Once cured, the patch should feel firm and integrated with the surrounding fiberglass.

Remember, this process requires patience and attention to detail. Take your time to ensure a clean and effective repair. With proper application and curing, your fiberglass boat deck can be restored to its original strength and appearance.

Sealing an Aluminum Boat: Tips for Success

You may want to see also

Bonding Techniques: Learn proper bonding methods for a strong repair

When it comes to repairing or replacing a boat deck made of fiberglass, understanding the proper bonding techniques is crucial for a strong and durable repair. Bonding is the process of joining two materials together, ensuring they work as a single unit. Here's a detailed guide on how to achieve a robust bond for your fiberglass boat deck repair:

Surface Preparation: Before bonding, the surfaces to be joined must be clean, smooth, and free from contaminants. Start by thoroughly cleaning the existing fiberglass surface. Remove any dirt, grease, or old bonding agents using a mild detergent or acetone. Rinse the area and allow it to dry completely. For a seamless repair, ensure the surface is slightly roughened using fine-grit sandpaper. This creates a mechanical bond and improves the adhesion of the new material.

Choosing the Right Bonding Agent: Select an appropriate bonding agent or adhesive specifically designed for fiberglass repairs. There are various options available, including epoxy resins, urethanes, and specialized marine adhesives. Epoxy resins are commonly used due to their strong bonding properties and ability to fill gaps. When choosing an adhesive, consider the type of fiberglass, the environmental conditions, and the load-bearing requirements of the repair. Always follow the manufacturer's instructions for application.

Application Technique: Proper application is key to a successful bond. Start by mixing the bonding agent according to the manufacturer's guidelines. Apply a thin layer of the adhesive to the prepared surface, ensuring complete coverage. For larger repairs, consider using a fabric or mesh to reinforce the bond and provide structural integrity. Press the new fiberglass layer onto the adhesive, ensuring good contact. Use a roller or a heavy object to apply pressure and remove any air bubbles. Allow the adhesive to cure according to the manufacturer's instructions, which may involve multiple layers and curing times.

Reinforcement and Finishing: To enhance the bond's strength, consider adding mechanical fasteners like screws or bolts, but be cautious not to damage the existing fiberglass. After the adhesive has cured, sand the repair area to create a smooth surface. Ensure the finish matches the surrounding fiberglass using the appropriate sanding tools and techniques. Finally, apply a suitable topcoat or gelcoat to protect the repair and restore the boat's appearance.

Mastering these bonding techniques will enable you to create a robust and long-lasting repair for your boat deck. Remember, proper preparation and the use of the right materials are essential for a successful fiberglass repair.

Replacing Rear Main Seal: 352 Windsor Boat Engine Guide

You may want to see also

Finishing Touches: Sand, fair, and paint for a smooth, professional finish

When it comes to replacing a boat deck made of fiberglass, the finishing touches are crucial to achieving a smooth and professional appearance. Here's a step-by-step guide to ensure your boat deck looks flawless:

Sand and Smoothen: After the fiberglass replacement is complete, it's essential to sand the surface to create a smooth finish. Start with a coarse-grit sandpaper (around 40-60 grit) to remove any excess resin or imperfections. Work in small sections, gently sanding the surface to avoid damaging the new fiberglass. Gradually move to finer grits (80-120 grit) for a smoother texture. Pay attention to edges and corners, ensuring a consistent finish. Remember to wipe away any dust or debris regularly to maintain a clean work area.

Fairing and Filling: Once you've sanded the entire surface, it's time to fair the deck. Use a high-quality marine filler or putty to fill any remaining gaps, holes, or imperfections. Follow the manufacturer's instructions for application and drying times. After the filler has cured, sand it again with a finer grit to ensure a seamless transition between the filler and the surrounding fiberglass. This step is crucial for a professional-looking finish.

Final Sanding and Preparation: Before painting, give the surface one last thorough sanding. Use a very fine-grit sandpaper (320-400 grit) to create a smooth and slightly textured surface that will provide better adhesion for the paint. This final sanding step ensures the paint will adhere properly and create a long-lasting finish.

Painting and Finishing: With the surface prepared, you're now ready to paint. Choose a marine-grade paint suitable for fiberglass surfaces. Apply multiple thin coats, allowing sufficient drying time between each layer. This technique ensures a smooth and even finish. Consider adding a clear coat or varnish to protect the paint and enhance the appearance of your boat deck. Properly sealing the surface will also prevent any future issues with water damage or corrosion.

By following these finishing touches, you'll achieve a high-quality, professional-grade result for your boat deck's fiberglass replacement. Remember, attention to detail during this stage will contribute to the overall longevity and aesthetics of your boat's interior.

Attaching Boat Seats: Securing to an Aluminum Boat Floor

You may want to see also

Frequently asked questions

To replace a fiberglass boat deck, you will require a range of tools and materials. Essential items include a fiberglass repair kit, which typically includes a suitable resin, hardener, and a choice of fabrics or mats. You'll also need a fiberglass repair compound or filler to fill any holes or damage. Additionally, gather the necessary tools such as a fiberglass brush, a heat gun or hairdryer for resin application, a respirator for safety, and various sizes of fiberglass tape or mesh for reinforcement.

Proper preparation is key to a successful repair. Start by thoroughly cleaning the damaged area to remove any dirt, grime, or old resin. Use a sharp knife or a fiberglass scraper to carefully remove any loose or damaged fibers. If there are significant holes or damage, use the repair compound to fill and level the surface. Allow it to cure according to the manufacturer's instructions. Once prepared, you can begin the replacement process.

Begin by laying out the new fiberglass deck piece, ensuring it fits the boat's existing dimensions. Apply a thin layer of the mixed resin onto the prepared surface, followed by the chosen fabric or mat. Smooth out any bubbles or creases using a fiberglass brush. Build up the thickness gradually, following the resin manufacturer's guidelines. Once cured, inspect the work and reinforce any areas with additional layers or tape. Finally, sand the surface to a smooth finish and apply a suitable sealant to protect the new deck.