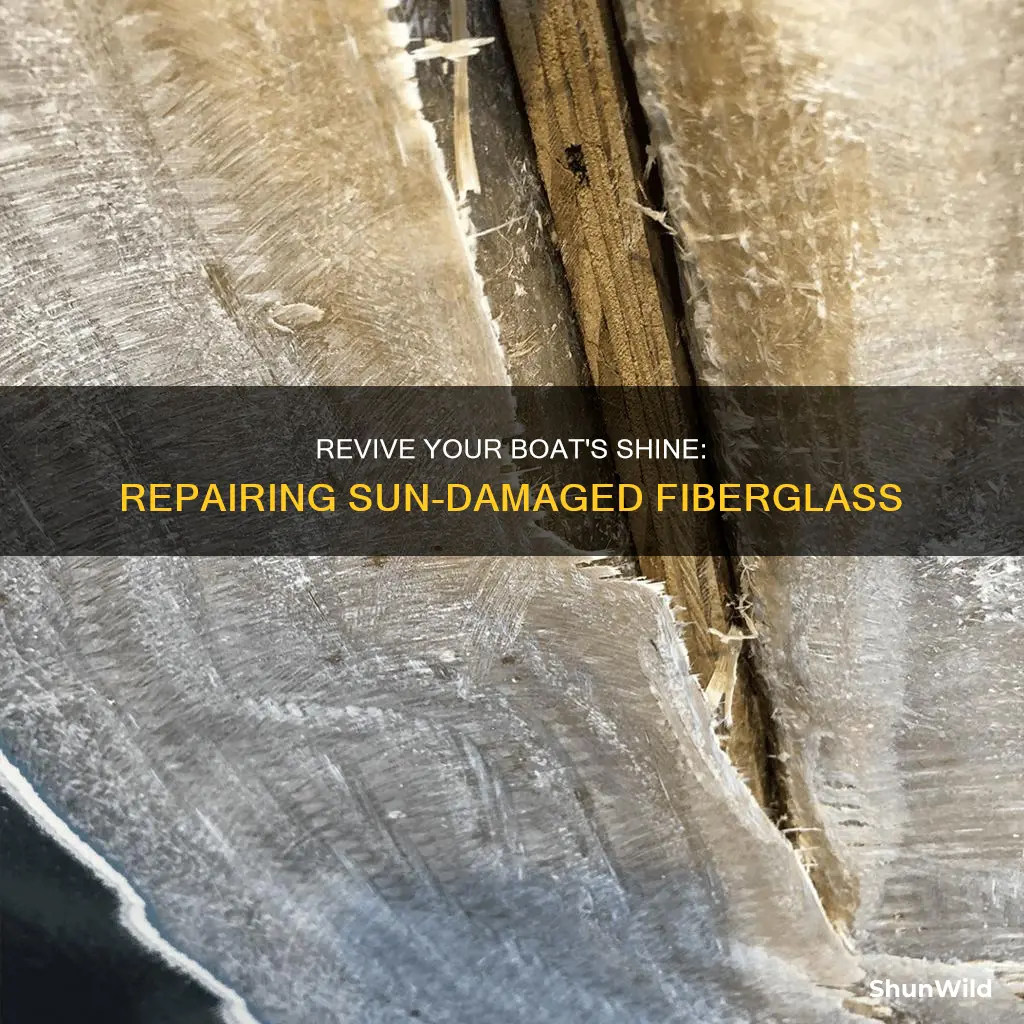

Repairing sun-damaged fiberglass boats requires careful attention to detail and the right materials. The process begins with a thorough inspection to assess the extent of the damage, which may include fading, chalking, or even cracking of the gelcoat. Once the damage is identified, the repair process can commence. This involves cleaning the affected area, applying a specialized fiberglass repair kit, and carefully blending the new material to match the existing surface. Proper preparation and the use of appropriate products are crucial to ensure a seamless and long-lasting repair.

What You'll Learn

- Identify Sun Damage: Inspect boat for fading, cracks, or chalking

- Clean and Prepare: Wash boat, remove old finish, and sand surface

- Choose Repair Method: Decide between filling, bonding, or re-painting

- Apply New Finish: Use marine-grade paint or gelcoat for long-lasting protection

- Finish with Care: Polish and protect with UV-resistant sealant

Identify Sun Damage: Inspect boat for fading, cracks, or chalking

When it comes to repairing a sun-damaged fiberglass boat, the first step is crucial: identifying the extent of the damage. This process involves a thorough visual inspection to ensure you understand the problem areas. Start by carefully examining the entire surface of the boat, paying close attention to the gelcoat, which is the clear outer layer of the fiberglass. Look for signs of fading, which often appears as a dull or muted color compared to the surrounding areas. Fading can be an early indicator of UV damage, and it may be accompanied by a loss of shine or gloss.

Next, inspect the surface for any cracks or hairline fractures. These can be caused by the expansion and contraction of the gelcoat due to temperature changes and UV exposure. Cracks can vary in size and may be visible to the naked eye or require a closer look. Over time, these cracks can grow and lead to more significant structural issues if left unattended.

Chalking is another common issue associated with sun damage. It occurs when the gelcoat loses its bonding strength with the fiberglass, causing it to become powdery and white. This is often a result of prolonged UV exposure and can lead to further deterioration if not addressed. Chalking may be more noticeable in areas with less paint or protective coating, as the gelcoat's integrity is compromised.

During your inspection, take note of any patterns or areas where the damage is more prevalent. For example, the upper deck and sides of the boat are more exposed to direct sunlight, making them more susceptible to fading, cracks, and chalking. Understanding the distribution of damage will help you plan the repair process more effectively.

Remember, early detection is key to successful repair. By thoroughly inspecting your boat for these signs of sun damage, you can take the necessary steps to restore its appearance and structural integrity. This initial assessment will guide your decision on whether to perform the repairs yourself or seek professional assistance.

Putting Wheels on Your Jon Boat: A Step-by-Step Guide

You may want to see also

Clean and Prepare: Wash boat, remove old finish, and sand surface

Before you begin the repair process, it's crucial to thoroughly clean and prepare the damaged fiberglass boat. This step ensures that any old finish or contaminants are removed, providing a clean slate for the repair. Here's a detailed guide on how to clean and prepare your boat:

Washing the Boat: Start by giving your boat a thorough wash. Use a mild detergent or a specialized marine cleaner to remove dirt, grime, and any loose debris. Pay extra attention to the damaged areas, ensuring you clean them thoroughly. Rinse the boat thoroughly with water to remove any soap residue. This initial cleaning step is essential to ensure that no dirt or contaminants interfere with the repair process.

Removing the Old Finish: Sun damage can often cause the boat's finish to become dull, faded, or even cracked. To address this, you'll need to remove the old finish. Use a non-abrasive cleaner or a specialized paint remover designed for marine applications. Follow the manufacturer's instructions carefully, as some products may require specific application techniques. Gently scrub the damaged areas to lift off the old finish, being cautious not to scratch the underlying fiberglass. Rinse the boat again to remove any residue.

Sanding the Surface: Once the old finish is removed, it's time to smooth out the fiberglass surface. Use fine-grit sandpaper (800-1200 grit) to gently sand the damaged areas. Work in small sections, following the direction of the fiberglass weave. This process helps to remove any rough patches and prepares the surface for the new repair material. Ensure you wear protective gear, including gloves and a dust mask, to avoid inhaling any fiberglass dust. After sanding, wipe away any dust with a damp cloth and allow the surface to dry completely.

By following these steps, you'll create a clean and smooth canvas for your fiberglass boat repair. This preparation process is vital to ensure the success of the repair, as it allows for better adhesion of the new materials and promotes a seamless finish. Remember to take your time and be meticulous in your approach to achieve the best results.

Docking a Boat: Understanding the Right Way

You may want to see also

Choose Repair Method: Decide between filling, bonding, or re-painting

When it comes to repairing sun-damaged fiberglass boats, the choice of repair method depends on the extent of the damage and the specific needs of your vessel. Here's a breakdown of the options:

Filling: This method is ideal for minor to moderate damage, such as small holes, cracks, or surface imperfections. Filling involves using a specialized fiberglass repair compound or filler material that is applied to the damaged area. The key advantage is its ability to restore structural integrity and smoothen the surface. You'll need to carefully prepare the damaged area by cleaning and etching it, ensuring a strong bond for the filler. After applying the filler, sand it down to create a smooth surface, then prime and paint over it to match the boat's finish. This process requires patience and attention to detail, but it can effectively camouflage the repair.

Bonding: Bonding is a more advanced technique suitable for larger, more complex repairs. It involves bonding two or more pieces of fiberglass together to restore structural integrity. This method is often used for repairing large gashes, replacing damaged sections, or reinforcing weak areas. Bonding requires precise skill and the use of specialized adhesives and resins. You'll need to carefully cut and shape the replacement or repair piece to fit seamlessly, then apply the adhesive and carefully lay up the fiberglass cloth. This process can be time-consuming and may require professional expertise, but it ensures a strong and durable repair.

Re-painting: While not a structural repair, re-painting can enhance the appearance of a sun-damaged fiberglass boat. This method is best for cosmetic improvements, covering up minor damage and fading. Re-painting involves removing the old paint, cleaning the surface, and applying a new coat or two of marine-grade paint. It's important to choose a paint specifically designed for marine environments, as it needs to withstand the elements. This process can refresh the boat's appearance and protect the underlying fiberglass from further UV damage. However, it's essential to note that re-painting alone won't address structural issues, so it's often combined with other repair methods.

Deciding between filling, bonding, or re-painting depends on the severity of the damage and your desired outcome. For minor cosmetic issues, re-painting might be sufficient. Moderate damage could benefit from filling, while more extensive structural repairs may require bonding. It's crucial to assess the damage thoroughly and consider seeking professional advice to ensure the best repair method is chosen for your fiberglass boat.

Small Boat, Big Decision: Choosing the Right Anchor

You may want to see also

Apply New Finish: Use marine-grade paint or gelcoat for long-lasting protection

When it comes to restoring a sun-damaged fiberglass boat, one of the most crucial steps is applying a new finish that provides long-lasting protection. Marine-grade paint and gelcoat are specifically designed for the harsh marine environment and can significantly enhance the boat's appearance and durability. Here's a detailed guide on how to achieve this:

Prepare the Surface: Before applying any new finish, thorough preparation is essential. Start by thoroughly cleaning the damaged area of the fiberglass. Use a mild detergent and a soft brush to remove any dirt, grime, or old paint residue. Rinse the surface with freshwater to ensure a clean slate. Next, inspect the fiberglass for any remaining damage. Fill any small holes or cracks with a suitable fiberglass repair compound, following the manufacturer's instructions for application and curing times. Once the repairs are complete, sand the entire surface smooth using fine-grit sandpaper. This step ensures that the new paint or gelcoat adheres properly and creates a seamless finish.

Choose the Right Marine-Grade Finish: Marine-grade paint and gelcoat come in various colors and finishes, so select one that closely matches the original color of your boat. Consider the type of finish you desire; marine-grade paint offers a smooth, glossy appearance, while gelcoat provides a more textured, non-slip surface, which is beneficial for safety. Always opt for products specifically formulated for fiberglass, as they are designed to adhere well to the material.

Application Process: Start by applying a suitable primer to the prepared surface. This step ensures better adhesion and provides a base for the final finish. Follow the primer manufacturer's instructions for application and drying times. Once the primer is dry, carefully apply the marine-grade paint or gelcoat using a brush, roller, or spray gun. Ensure an even coat and follow the recommended thickness guidelines to achieve the desired finish. Allow sufficient drying time between coats, as per the product instructions. Typically, multiple thin coats are preferable to a single thick layer to ensure a smooth and durable finish.

Curing and Maintenance: After the final coat is applied, allow ample time for the finish to cure. This process may take several days, depending on the product and environmental conditions. During this time, avoid exposing the boat to harsh sunlight or extreme temperatures. Once cured, your boat will have a refreshed appearance and increased protection against the elements. Regular maintenance, including cleaning and occasional re-application of marine-grade paint or gelcoat, will ensure the longevity of the repair and keep your boat looking its best.

By following these steps and using marine-grade finishes, you can effectively repair sun-damaged fiberglass and extend the life of your boat. This process not only restores the boat's aesthetics but also provides essential protection against further sun damage and marine wear.

A President's War Heroism: PT 109's Story

You may want to see also

Finish with Care: Polish and protect with UV-resistant sealant

After you've repaired the sun-damaged fiberglass on your boat, it's crucial to finish the job with care to ensure the longevity and aesthetics of the repair. The final steps will not only enhance the appearance but also provide essential protection against further UV damage. Here's a comprehensive guide to achieving a polished and protected finish:

Polishing for a Smooth Surface: Begin by thoroughly cleaning the repaired area. Remove any dust or debris using a soft cloth or a mild detergent solution. Once clean, apply a high-quality fiberglass polish specifically designed for marine use. This polish will help smooth out the surface, ensuring a seamless blend with the original fiberglass. Follow the manufacturer's instructions for application, typically involving a gentle rubbing motion to work the polish into the surface. Allow sufficient time for the polish to dry and then carefully buff it to a high shine. This step is essential for creating a visually appealing finish and preparing the surface for the next protective layer.

Choosing the Right UV-Resistant Sealant: Protecting your fiberglass boat from the sun's harmful rays is crucial, and the right sealant can provide long-lasting UV resistance. Select a marine-grade UV-resistant sealant that is specifically formulated for fiberglass. These sealants often contain additives that enhance their protective properties, such as titanium dioxide, which acts as a powerful UV blocker. When applying the sealant, ensure you follow the product's guidelines for optimal coverage. Typically, multiple thin coats are applied, allowing each layer to dry before adding the next. This process creates a robust barrier that not only seals the repair but also safeguards the fiberglass from future UV damage.

Application Technique: Start by cleaning the entire surface of the boat's hull and any other areas that will be sealed. Rinse the surface to remove any dirt or grime. Apply the UV-resistant sealant using a brush or a spray gun, ensuring an even and consistent coat. For best results, work in small sections, allowing each layer to dry before moving on. The drying time will vary depending on the product and environmental conditions, so be patient and allow adequate time for curing. After the sealant is fully cured, you'll have a durable shield against UV rays, ensuring your boat's finish remains intact and protected.

Final Touches and Maintenance: Once the sealant is applied and cured, inspect the entire boat for any remaining imperfections or areas that may require additional attention. Touch up any small spots as needed. Regular maintenance is key to preserving the boat's appearance and protection. Periodically clean the boat and reapply the UV-resistant sealant to maintain its effectiveness. This routine care will ensure your boat remains in top condition, showcasing a beautiful finish that withstands the test of time and the elements.

By following these steps, you'll not only repair the sun damage but also create a polished and protected finish, ensuring your fiberglass boat remains in excellent condition for years to come. Remember, proper preparation and the use of suitable products are key to achieving a successful and long-lasting repair.

Emery's Sexuality: Exploring Fresh Off the Boat Character

You may want to see also

Frequently asked questions

Sun damage to fiberglass can be a common issue, but there are effective ways to repair it. Start by cleaning the damaged area to remove any dirt or debris. Then, use a fiberglass repair kit, which typically includes a filler and a hardener. Fill the cracks or holes with the filler, ensuring it's level with the surface. After it dries, sand it down and apply a fiberglass repair compound to create a smooth finish. Finally, use a fiberglass primer and paint to match the original color.

Preparation is key to a successful repair. Begin by thoroughly cleaning the damaged area with a mild detergent and water solution. Rinse and dry the surface completely. If the damage is extensive, consider using a fiberglass repair tape to provide extra strength. Ensure the tape is properly adhered and trimmed to fit the shape of the damage. This step will help create a strong bond for the repair.

While some car fillers can be used for fiberglass, it's not ideal. Car fillers are typically not designed for the harsh marine environment and may not provide the necessary durability. Instead, opt for a specialized fiberglass repair kit, which is formulated to withstand the elements. These kits often include a filler, hardener, and sometimes a gelcoat to match the boat's finish.

Blending the repair with the original fiberglass is crucial for a seamless finish. After applying the filler, allow it to cure according to the kit instructions. Then, sand the repair area gently with fine-grit sandpaper to create a smooth surface. Follow up with a fiberglass repair compound to fill any remaining imperfections. Finally, use a high-quality fiberglass primer and paint to match the boat's color, ensuring a professional-looking result.

Preventative measures are essential to minimize future damage. Consider applying a marine-grade fiberglass gelcoat or a protective topcoat to the entire boat's surface, especially in areas prone to sun exposure. Regularly clean and maintain the boat to remove contaminants that may accelerate damage. Additionally, using a boat cover when not in use can provide an extra layer of protection against the sun's harmful rays.